MegaControls NT50 Series User manual

Issue Date November 1, 2023

NT50 Series

RS-485 Modbus RTU Room Thermostats with LCD for Fan Coil Units

can support up to 32 NT50 Series

Modbus RTU devices. The BMGE

gateway spontaneously detects the

presence of slaves that go online in

its NET 1 and NET 2 networks.

The NT50 Series thermostats cover

a wide range of fan coil applications,

including 2 and 4-pipe fan coils and

direct connection to 3-speed fans.

Temperature sensing can be from a

built-in room sensor or a remote

sensor.

A fan-speed control touch key

allows control of a 3-speed fan. The

speed control key has 4 positions:

“Hi-Med-Low-Auto”. In the “Hi”,

“Med” or “low” position, the fan runs

continuously at the selected speed.

In the “Auto” mode, the fan speed is

temperature dependent and

controlled automatically at 2 K

differential increments from low to

high speed.

Mounting

The thermostats can be flush

mounted or secured to a standard

European 75 x 75 x 47 mm (strongly

recommended) electrical box. See

Fig. 2: Mounting Details. Two

mounting screws are included.

Ordering

To order, specify complete model

numbers.

www.megacontrols.com 1

Copyright © Mega Controls Limited

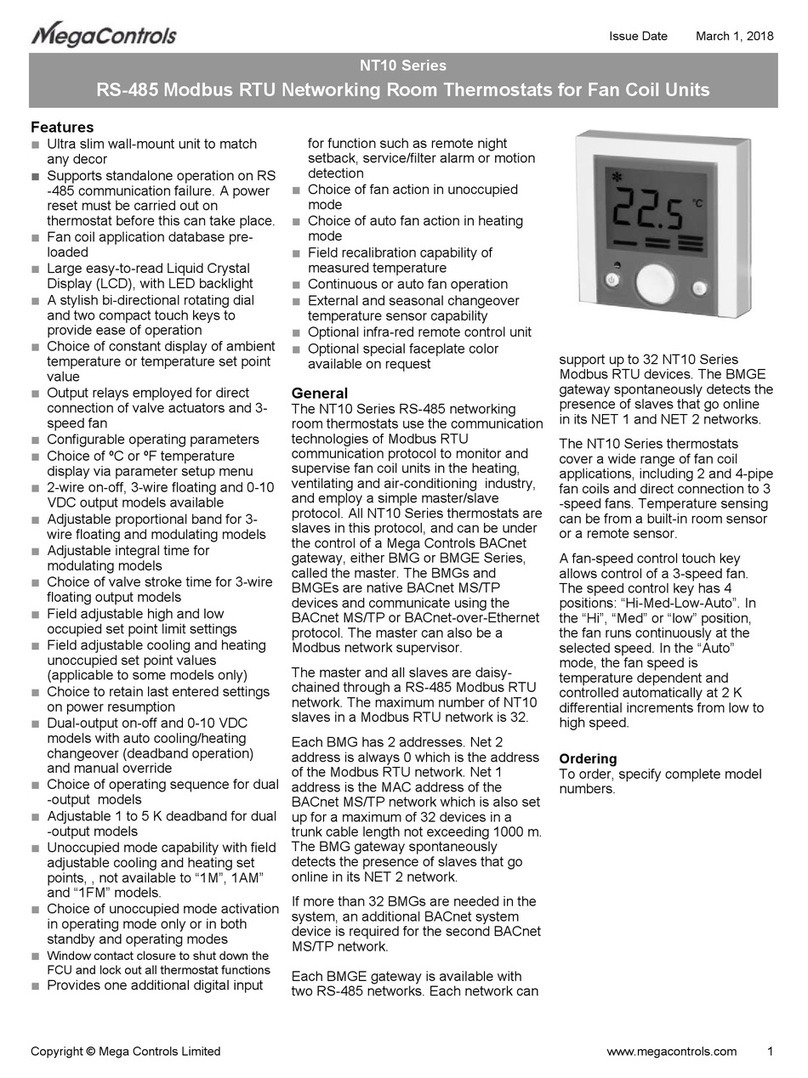

Features

■Ultra slim wall-mount unit to match

any décor

■Supports Modbus RTU protocol

■Supports standalone operation on RS

-485 communication failure

■Fan coil application database pre-

loaded

■Large easy-to-read Liquid Crystal

Display (LCD), with LED backlight

■A stylish bi-directional rotating dial

and two compact touch keys to

provide ease of operation

■Choice of constant display of ambient

temperature or temperature set point

value

■Output relays employed for direct

connection of valve actuators and 3-

speed fan

■Configurable operating parameters

■Choice of ºC or ºF temperature

display via parameter setup menu

■2-wire on-off, 3-wire floating and 0(2)-

10 VDC output models available

■Adjustable proportional band and

integral time for 3-wire floating and 0

(2)-10 VDC output models

■Choice of valve stroke time for 3-wire

floating output models

■Field adjustable high and low

occupied set point limit settings

■Field adjustable cooling and heating

unoccupied set point values

(applicable to some models only)

■Choice to retain last entered settings

on power resumption

■Dual-output on-off and 0-10 VDC

models with auto cooling/heating

changeover (deadband operation)

and manual override

■Choice of operating sequence for dual

-output models

■Adjustable 1 to 5 K deadband for dual

-output models

■Unoccupied mode capability with field

adjustable cooling and heating set

points, not available to “1M”, 1AM”

and “1FM” models.

■Choice of unoccupied mode activation

in operating mode only or in both

standby and operating modes

■Provides one additional digital input

for function such as remote night

setback, service/filter alarm or motion

detection

■Choice of fan action in unoccupied

mode

■Choice of auto fan action in heating

mode

■Field recalibration capability of

measured temperature

■Continuous or auto fan operation

■External and seasonal changeover

temperature sensor capability

■Optional infra-red remote control unit

■Optional special faceplate color

available on request

General

The NT50 Series RS-485 networking

room thermostats use the

communication technologies of Modbus

RTU protocol to monitor and supervise

fan coil units in the heating, ventilating

and air-conditioning industry, and

employ a simple master/slave protocol.

All NT50 Series thermostats are slaves

in this protocol, and can be under the

control of a Mega Controls BACnet

gateway, of either BMG or BMGE

Series, called the master. The BMGs

and BMGEs are native BACnet devices

and communicate using the BACnet

MS/TP or BACnet-over-Ethernet

protocol.

Net 2 port of the BMG master and all

slaves are daisy-chained through a RS-

485 Modbus RTU network. The

maximum number of NT50 slaves in a

Modbus RTU network is 32.

Each BMG has 2 addresses. Net 2

address is always 0 which is the

address of the Modbus RTU network.

Net 1 address is the MAC address of

the BACnet MS/TP network which is

also set up for a maximum of 32

devices in a trunk cable length not

exceeding 1000 m. The BMG gateway

spontaneously detects the presence of

slaves that go online in its NET 2

network.

If more than 32 BMGs are needed in the

system, an additional BACnet system

device is required for the second

BACnet MS/TP network.

Each BMGE gateway is available with

two RS-485 networks. Each network

Specifications

Product model numbers See Fig.1: NT50 Series Model Number Selection Guide

Power requirements 110-230 V, +10% and -15%, 50/60 Hz

Operating temperature differential

(for 2-wire on-off models) Fixed at 1 K for both cooling and heating modes

0-10 VDC output impedance Minimum 10,000 Ω

Temperature display range 5-35ºCin 0.5 K increments: accuracy ±1 K (41-95ºF in 0.5 R increments, accuracy ±1 R)

Temperature setpoint range 5-35ºCin 0.5 K increments, initial factory setting at 22ºC (41-95ºF in 0.5 R increments)

Offset adjustment of temperature

indication (field recalibration) +2, +1, 0, -1 and -2 K (+2, +1, 0, -1 and -2 R) throughout the range, factory setting 0

Deadband of dual-output models Adjustable 1 to 5 K(2 to 10 R) between cooling Mode and heating Mode, factory set at 3 K(6 R)

Valve stroke time for 3-wire floating

models Accumulatively 10 to 240 s maximum in one direction in steps of 10 s, factory setting 180 s

Proportional band for PI control Adjustable 1 to 10 K (1-10 R) in 1 K (1 R) increments, factory setting 5 K (5 R)

Integral time for PI control Adjustable 0 to 30 minutes in 1 minute increments, factory setting 15 minutes. Setting = 0

means integral time being turned off.

Auto fan temperature differential At 2 K (2 R) increments. At >0 K, fan is on low speed in cooling mode and fan status in heating

mode depends on choice of auto fan action.

Sensing element NTC thermistor, 10 kΩ@25ºC; accuracy ±0.5 K@25ºC

Unoccupied mode Input signal from external voltage-free contact

Always runs at “Low” fan when in operation

Unoccupied temperature set point

range (not applicable to “1M” models) Field adjustable 5-35ºC (41-95ºF) in 1 K (1 R) increments separately for cooling and heating;

Factory settings: 16ºC (61ºF) for heating and 26ºC (79ºF) for cooling

Binary input 1 binary input for external voltage-free contacts

Digital outputs For direct connection of valve actuators (110-230 VAC)

1 relay output for 2-pipe models

2 relay outputs for 4-pipe models

For direct connection to 3-speed fans (110-230 VAC)

3 relay outputs

RS-485 communication speed Baud rate fixed at 19,200 bps

Device MAC addressing 01-32 via parameter setup menu, factory default setting 255 (displays as FF on thermostat

screen)

Proprietary Modbus RTU network

guideline Maximum 32 devices and maximum 1,000 m cable length

Enclosure Material: Self-extinguishing, molded ABS

Finish: Off white housing and dark grey faceplate

Electrical ratings Valve output relays 110-230 V, 3 A resistive, 1 A inductive, 50/60 Hz

Fan output relays

For on-off and floating models 110-230 V, 3 A resistive, 1 A inductive, 50/60 Hz

For 0-10 VDC models 110-230 V, 5 A resistive, 2 A inductive, 50/60 Hz

Total rating 110 -230 V, 5 A maximum, 50/60 Hz

Ambient/storage temperature limits 0 to 55ºC/-30 to 50ºC, 10 to 90% RH non-condensing

Connectors Non-removable line-voltage terminal blocks and removable low-voltage wire plugs

Power wires Wire size 1 mm2 or 18 AWG solid copper recommended

RS-485 Communication Wires 22 or 24 AWG Twisted Shielded Pair Double-insulated Cable

Ethernet communication wires Cat 5e cable (twisted pairs)

Sensor wires 22 AWG twisted shielded pair double-insulated cable

Accessories and options See Figure 8: Optional Accessories

Agency approval CE Mark compliant to EMC and Low Voltage Directives

Shipping weight 0.2 kg (0.44 lb)

Dimensions See Figure 4: Dimensions in mm

The performance specifications above are nominal and subject to tolerances and application variables of generally acceptable industry standards.

The manufacturer shall not be liable for damages resulting from misapplication or misuse of its products.

2 NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin

Figure 1: NT50 Series Model Number Selection Guide

NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin 3

NT50 Series RS-485 Networking Room Thermostats Model Number Selection Guide

(Complete Sets)

NT5 0–1M R

Product Type Power Supply Separator Control Type Options

NT5 = NT50 Series 0 = 110-230 VAC 1 = Single 2-wire on-off output, R = with infra-

RS-485 cool only or heat only red receiver

Networking 1M = Single 2-wire on-off output, for RCU-1

Room manual cool/heat changeover B = without

Thermostats 1A = Single 0(2)-10 VDC output, buzzer for

cool only or heat only key touch

1AM = Single 0(2)-10 VDC output, sounding

manual cool/heat changeover W = with white

1F = Single 3-wire floating output, color

cool only or heat only faceplate

1FM = Single 3-wire floating output,

manual cool/heat changeover

2 = Dual 2-wire on-off outputs,

manual or Auto cool/heat

changeover

2A = Dual 0(2)-10 VDC outputs,

manual or Auto cool/heat

changeover

Model

Numbers

Outputs Applications Cooling/Heating

Mode

External

Seasonal

Changeover

System

Modes

Fan Control Unoccupied

Mode

NT50-1Single

2-Wire

On-Off

Cooling Only

or Heating Only

(2-Pipe System)

Auto Only

Yes Cool or Heat-Fan

Only-Off Hi-Med-Low-Auto Yes

NT50-1M Single

2-Wire

On-Off

Cooling/Heating

(2-Pipe System) Manual Only No Cool or Heat-Fan

Only-Off Hi-Med-Low-Auto Yes

NT50-1F Single

3-Wire

Floating

Cooling Only

or Heating Only

(2-Pipe System)

Auto Only

Yes Cool or Heat-Fan

Only-Off Hi-Med-Low-Auto Yes

NT50-1FM Single

Line-Voltage

3-Wire

Floating

Cooling/Heating

(2-Pipe System) Manual Only No Cool or Heat-Fan

Only-Off Hi-Med-Low-Auto Yes

NT50-1A Single

0-10 VDC Cooling Only

or Heating Only

(2-Pipe System)

Auto Only

Yes Cool or Heat-Fan

Only-Off Hi-Med-Low-Auto Yes

NT50-1AM Single

0-10 VDC Cooling/Heating

(2-Pipe System) Manual Only No Cool or Heat-Fan

Only-Off Hi-Med-Low-Auto Yes

NT50-2Dual

2-Wire

On-Off

Cooling and

Heating

(4-Pipe System)

Manual

or Auto No Cool-Heat-Auto-

Fan Only-Off

Or

Auto-Off

Hi-Med-Low-Auto Yes

NT50-2A Dual

0-10 VDC Cooling and

Heating

(4-Pipe System)

Manual

or Auto No Cool-Heat-Auto-

Fan Only-Off

Or

Auto-Off

Hi-Med-Low-Auto Yes

Figure 2: NT50 Series Application Guide

4 NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin

Figure 3: Dimensions in mm

Remote Control Unit

Front View

Back View

Figure 4: Mounting Details

Figure 5: Optional Accessories

Description Part No.

Remote control unit RCU-1

Probe temperature sensor TE10-1

Duct temperature sensor TE10-2

With infra-red receiver capability NT50-xxxR

Without buzzer capability NT50-xxxB

With white-color faceplate NT50-xxxW

Bottom View

Item Description

Network Trunk Cabling It is recommended to use networking cabling that matches the following specifications:

• Balanced 100 to 120 ohms nominal impedance, 22 or 24 AWG Twisted Shielded Pair (TSP) Cable

• Nominal capacitance of 52 pF/m or lower

• Nominal velocity of propagation of 66% or higher

• Terminating the shield to ground at one end only for each isolated segment will prevent ground loops in the

shield and drain RF energy to ground. Grounding at the BACnet router or controller is preferred.

10Base-T Cabling Cat 5e cable with twisted pairs are recommended.

Topology Ensure the BACnet MS/TP or Modbus RTU network cable is installed as a daisy chain from one device to the

next.

Maximum Nodes The maximum number of devices per BACnet MS/TP or Modbus RTU network is 32.

Terminator A terminator of 120-ohm impedance must be installed at each end of network segment, or two per network.

Ensure that this requirement is not overlooked in laying out the network architecture and when ordering

product.

Cable Shielding Use a shielded, twisted pair cable for communications. Never directly ground wire in more than one point on

the shield. Doing so can induce large currents and result in communication problem.

Repeater A repeater is not necessary unless the BACnet MS/TP or Modbus RTU network is extended beyond 1,000 m.

Step-down Transformer A separate isolated double-wound transformer is recommended for supplying 24 VAC power to each BMG or

BMGE. If and when the same transformer is shared with other devices, observe the polarities of the power

supply of all devices including the BMG or BMGE.

Network, Cabling and Step-down Transformer Requirements

To ensure network stability and reliable communications, it is imperative that the following network, cabling and step-

down transformer requirements are adhered to:

Mounting

The thermostat can be surface mounted or secured

to a standard European 75 x 75 x 47 mm (strongly

recommended) electrical box. Two mounting screws

are included.

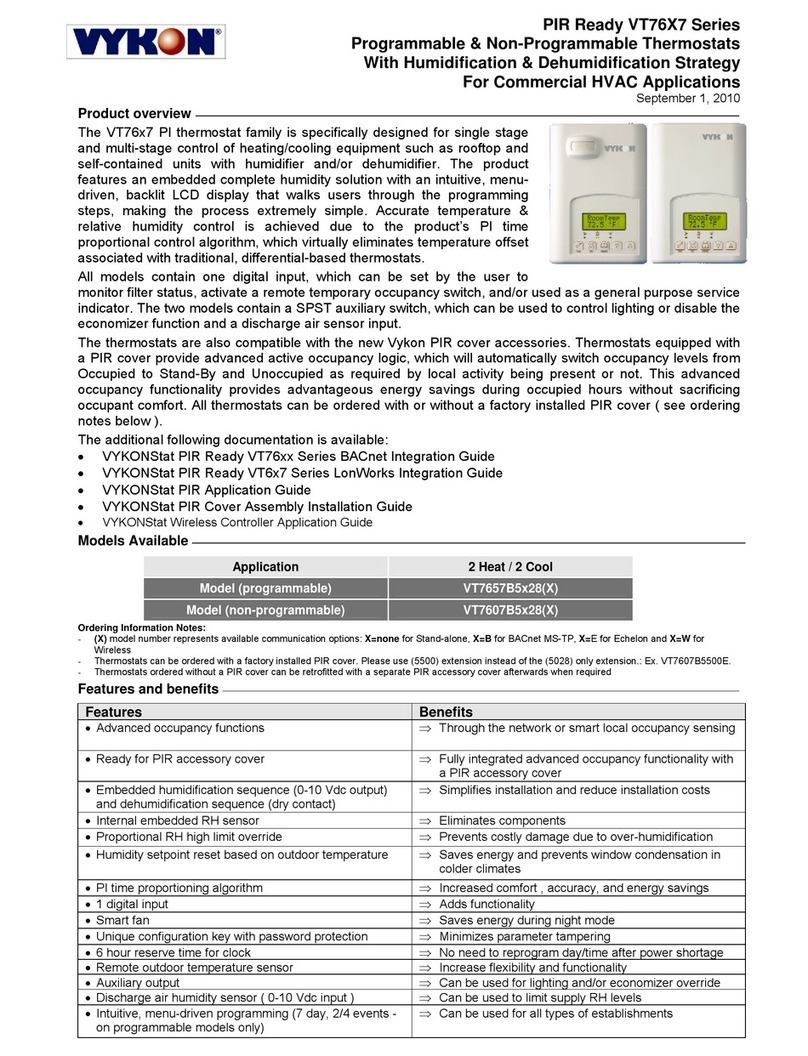

Figure 6: Network Configuration

Modbus RTU Network Notes:

1. Ensure the recommended balanced

cable is used.

2. Ensure the cable is installed as a daisy

chain from one device to the next

(1,000 m maximum) and the shield is

grounded at one single point of the

network only.

3. Ensure a terminator is installed on each

end of each Modbus RTU network.

4. The maximum nodes per Modbus RTU

network is 32

BACnet MS/TP Network Notes:

1. Ensure the recommended balanced

cable is used.

2. Ensure the cable is installed as a daisy

chain from one device to the next

(1,000 m maximum) and the shield is

grounded at one single point of the

network only.

3. Ensure a MS/TP terminator is installed

on each end of each MS/TP network.

4. The maximum nodes per MS/TP

network is 32 without a repeater.

With BMGE BACnet-over-Ethernet Gateway

With BMG BACnet MSTP Gateway

NT50 NT50 NT50 NT50

BMG

(Master)

BMG

(Master)

To BACnet MS/TP

Slaves

NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin 5

NT50 NT50 NT50 NT50

BMGE

(Master)

NT50 NT50 NT50 NT50

Slaves

Slaves

Figure 7: Jumper Settings

The models NT50-2 and NT50-2A can be re-configured in the field to other model numbers by a qualified servicing agent,

if necessary, by changing the jumper positions of JP2 and JP3. The locations of these jumpers can be found after

removing the thermostat cover from its baseplate.

Operation Notes

Model Number Jumper Settings of JP2 and JP3

JP2 JP3

NT50-1Cut Cut

NT50-1M Cut Cut

NT50-2Uncut Uncut

NT50-1F Cut Uncut

NT50-1FM Cut Uncut

NT50-1A Cut Cut

NT50-1AM Cut Cut

NT50-2A Uncut Uncut

Jumper Settings of JP1 and JP4

Jumper Cut Uncut

JP1 With Exter-

nal Sensor

With Built-

in Sensor

JP4

For 2-10

VDC

Output

For 0-10

VDC

Output

Note: JP4 is available in 0-10

VDC/2-10 VDC output models

only. Factory setting is 0-10 VDC.

Note: Terminals V1+, GND and

V2+ are only available in 0(2)-10

VDC output models.

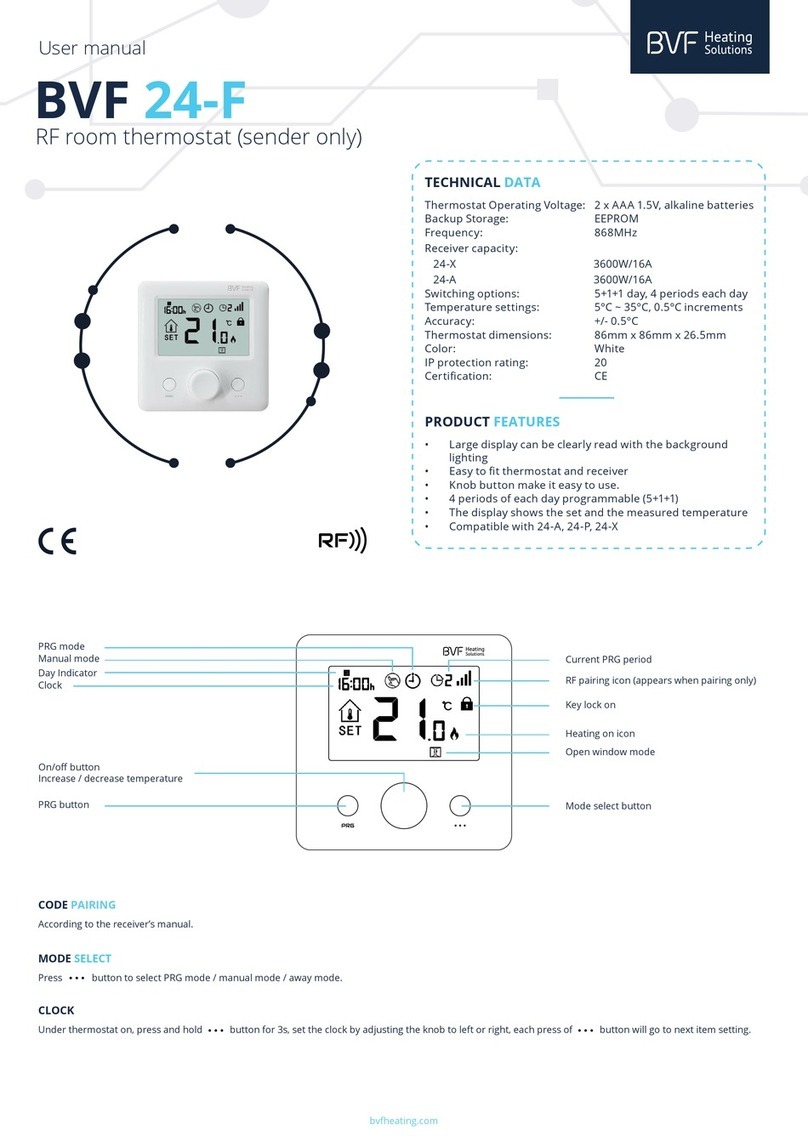

Operation

■LCD shows ambient temperature constantly except when set point adjustment is being made.

■Press the system key Ф to enter into the desired operating mode: Cool-Heat-Auto-Fan Only-Off, etc.

■Press the fan key to change the fan speed mode: High-Med-Low-Auto.

■Increase or decrease temperature set point by rotating the adjustment dial clockwise or counter-clockwise. When the

dial is rotated, the LCD shows the existing setpoint setting.

Unoccupied Mode

■When the unoccupied contact closes, it will override the operating mode and operate the thermostat in energy saving

mode despite the thermostat being in operating or standby mode, depending on activation setting of unoccupied mode

in setup menu.

■In unoccupied mode, the factory-set temperature cut-in points are 26°C for cooling and 16°C for heating. Meanwhile, all

operating keys are locked out until the unoccupied contact opens.

■During unoccupied mode, the default fan speed is set at “low” when pre-set cut-in temperature is reached, or otherwise

the fan output is always “off”.

■Unoccupied mode can be activated in the following manner when the unoccupied contact closes:

For 2-pipe models with auto seasonal changeover, the unoccupied cooling or heating mode is determined by the

status of the SR2 seasonal changeover sensor and the valve output is activated according to the measured

temperature.

For 2-pipe models with manual seasonal changeover, the unoccupied cooling or heating status is determined by the

last status of the occupied mode and the valve output is controlled according to the measured temperature.

For 4-pipe models, the unoccupied cooling or heating mode is always determined by the measured temperature and

valve output is also activated according to the measured temperature.

Unoccupied mode activation in operating mode only or in both standby and operating mode will be determined by

activation setting in setup menu. Low fan will run according to fan action setting in setup menu.

Parameter Setup Mode

■The thermostat allows authorized service agent to change a number of operating parameters in the field. Refer to the

parameter setup manual for details.

Error reporting

■All valve and fan outputs will be shut down when error is reported.

6 NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin

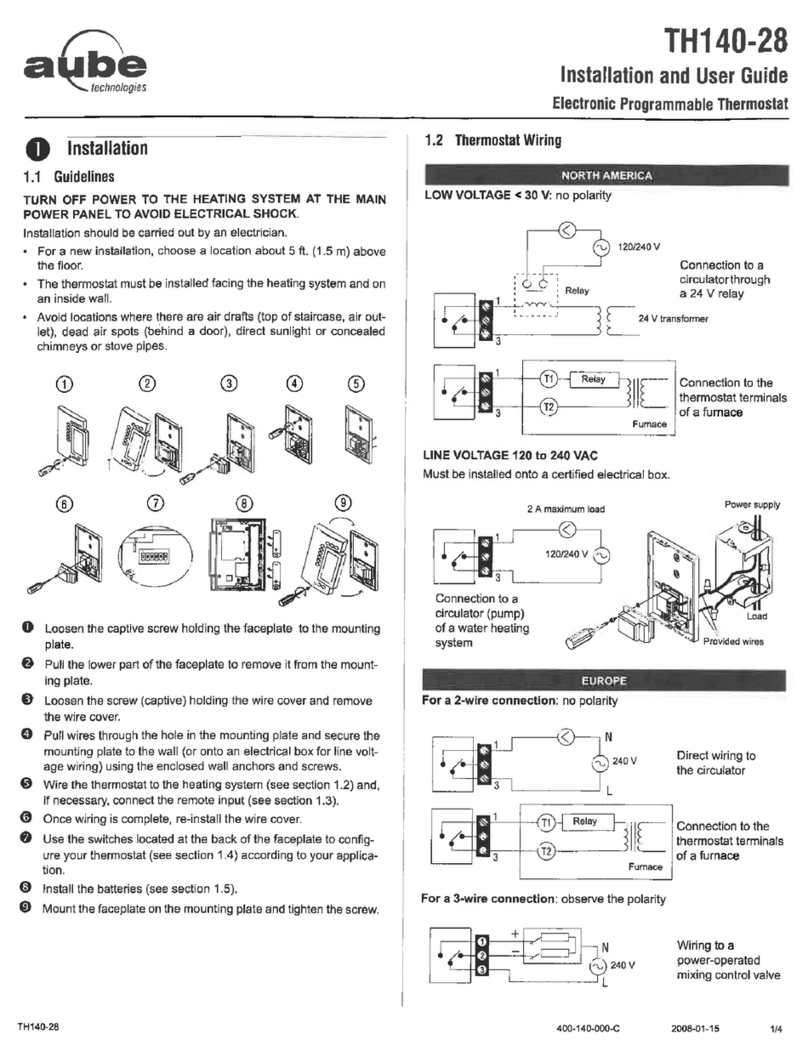

Figure 9: Wiring Diagrams and Application Notes

Wiring and Application Notes

■Cut jumper JP1 open if an external sensor is wired to

SR1 and GND. Run the wiring away from any electrical

motors or power wiring. Failure to do so may result in

poor thermostat performance due to electrical noise.

■22 or 24 AWG twisted shielded pair double-insulated

cable must be used as RS-485 communication wiring

and its length must not exceed 1,000 m without a re-

peater

■22 or 24 AWG twisted shielded pair double-insulated

cable is recommended as RS485 communication and

remote sensor wiring and the remote sensor cable

length must not exceed 25 m.

■Do not bundle and run power wiring and RS485 com-

munication/remote sensor wiring in the same conduit and

cross-wiring in the same junction boxes is prohibited.

■The seasonal changeover sensor should be wrapped

around the supply water pipe when associated with a wa-

ter system. When the changeover sensor temperature ex-

ceeds 30 ºC, the thermostat enters into heating mode.

■External seasonal changeover sensor or switch is applica-

ble to heat only or cool only 2-pipe models only.

■Unoccupied contact closure activates unoccupied mode.

■Hidden-line wiring is applicable to dual-output models on-

ly.

■The thermostat outputs of on-off models are designed for

controlling zone valves. If used for controlling electric

heaters, external contactors must be used.

NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin 7

Figure 8: Network Control Unit and LCD Layout

Figure 10: NT50 Series RS-485 Networking Room Thermostat Wiring Diagrams

Piping Notes:

1. On a single-output unit, V1 can be either a 2-wire

spring-return cooling or heating valve.

2. On a dual-output unit, V1 must be a 2-wire spring-

return cooling valve and V2 a 2-wire spring-return heat-

ing valve.

3. V3 must be a 3-wire floating valve. In cooling mode,

Terminal 6 output opens valve on temperature rise and

Terminal 7 output closes valve on temperature drop.

The action in heating mode is reversed.

4. On a single-output unit, V4 can be either a 0-10 VDC

cooling or heating valve.

5. On a dual-output unit, V4 must be a 0-10 VDC cooling

valve and V5 a 0-10 VDC heating valve.

WARNING

Incorrect wiring connection may cause permanent equip-

ment damages to the thermostat.

Connections of Sensors and Contacts

Wiring Diagram for Single and

Dual 2-Wire On-Off Valve Outputs

V1 and V2 are 2-wire on-off spring-return valves

Wiring Diagram for Single 3-Wire

Floating Valve Output

V3 is a 3-wire floating valve

Mega Controls Limited

Room 1225, Star House

3 Salisbury Road, Tsimshatsui, Kowloon, Hong Kong

NT50, 23-11(Mega)

Wiring Diagram for Single and Dual 0(2)-10 VDC Valve Outputs

V4 and V5 are 0(2)-10 VDC valves

8 NT50 Series RS-485 Modbus RTU Room Thermostats Product Bulletin

This manual suits for next models

8

Table of contents

Other MegaControls Thermostat manuals