MEGAlink ML2000 User manual

User manual for ML2000

19.10.2012 - V6.01 Troubleshooting 1

User manual for ML2000

Troubleshooting

Table of contents

7 Troubleshooting ........................................................................................................................... 2

7.1 Step 1.................................................................................................................................... 2

7.2 Step 2....................................................................................................................................

7.2.1 General .........................................................................................................................

7.2.2 Sensor unit.................................................................................................................... 4

7.2. Communication towards PC ........................................................................................ 4

7.2.4 Problems with the sound pressure values .................................................................... 4

7. Replacement units ................................................................................................................ 5

7. .1 Packaging and transportation ....................................................................................... 5

7. .2 Target controller unit (electronic card) for U-XXX targets ....................................... 5

7. . Target controller unit for 4K-XXX targets .................................................................. 5

7. .4 Replacing the motor on 4K- 00 ................................................................................... 6

7.4 Troubleshooting PC-software .............................................................................................. 6

7.4.1 Exchange between MLRange and MLRes ................................................................... 6

7.4.2 MLView ....................................................................................................................... 6

User manual for ML2000

19.10.2012 - V6.01 Troubleshooting 2

7 Troubleshooting

7.1 Step 1

Symptom Checkpoint/Problem/Correction

Black screen 1. Check that the connector is inserted correctly and the monitor

switch turned on

2. Check that the power supply is connected and 2 0V is present. A

LED on the PC-Connection box should indicate that 12V is

present.

. Check the contrast adjustment

4. If only one monitor is not working, try another connector

The display starts

directly in the shooting

screen

1. The display is in PC-control mode. Se the chapter “Use of

ML2000” for a manual procedure to bring the display back to

manual control.

The display will not

enter READY state

1. Check that the RJ45 cable for connecting the target network is

plugged into both contacts in the PC-connection box.

2.

Check that the target connection cabinet is correctly connected (in

particular the white RJ45 cable inside the cabinet)

. Verify that the battery is charged. A green LED in the target

connection cabinet should be on if there is sufficient voltage on

the battery. If the battery is discharged an emergency procedure

could be to disconnect the battery and try to run the targets with

the charger only (disconnect the cable shoe on the battery)

4. Check that the target cables are connected properly

5. Check that one display in the segment is configures as MASTER

(usually the display at lane 1).

6. Check that not more than one display is set up as MASTER

7. Check that the master is set up with correct values for the FROM

LANE and TO LANE parameters (first and last lane in the

segment)

8. Check that the other displays are configured as SLAVE and with

correct lane number

9. Check that you are connected to the correct segment (group of

targets sharing data line and target connection cabinet.

10. Check if the LED’s on the surge protection at shooting stand is

blinking and that the data LED inside the target connection

cabinet is blinking.

11. Try to connect the master display in the target connection cabinet

Shots arrive several

seconds after fired

1. Check that only one display is configured as MASTER within the

target segment.

Shots are marked on

wrong display

1. Check that only one display is configured as MASTER within the

target segment.

2. Check if the same lane number have been configured on several

displays

. Ensure that the display is not set up with a rapid fire program.

Select “New serie” and try again.

Faults in detection or

sporadic missing shots

1. Check the sound pressure values and/or the rubber or paper

bands. Maintain the target if necessary.

User manual for ML2000

19.10.2012 - V6.01 Troubleshooting

7.2 Step 2

7.2.1 General

• Try to disconnect the PC-adapter

• Check the indicators in the system:

o The on-screen indicator on the top middle of the screen should display READY if

connection is established with the target

o The +12V Power LED on the PC-connecting box should indicate that the power

supply in active

o LED for communication activity on the surge protection on the shooting stand (if

mounted):

Red LED when the master display unit is active

Green LED when the target unit responds

Normal state is continuous red and green flashing

o LED at the PC-connection box for activity on the target network (gravnett).

o LED on the first surge protection card in the target connection cabinet. The Led is

located between the fuses and indicates activity on the communication line.

o LED for communication on the large printed circuit board inside the target

connection cabinet. The Led indicates the following:

Red LED when the master display unit is active

Green LED when the target unit responds

Normal state is continuous red and green flashing

o Green LED for battery voltage

o LED in -step charger

o Green LED for power on the controller unit inside the sensor unit should be on

o Red LED for communication on the controller unit inside the sensor unit should give

short flashes

o Red LED for sensor on the controller unit inside the sensor unit should flash when

the microphones are tapped lightly with a finger

o LED for power, PC-activity and line activity on the PC-adapter

o LED for power, transmit and receive on the radio modem

• Cross replacement and minimizing the system:

o Try to swap units if only one lane is not working. Observe which component the

fault seems to be connected to.

o If the complete system is blocked or the communication is severely disturbed it

would be a good idea to try to remove components that are suspected to be broken.

The next step would be to remove most the system and start with a minimal

configuration. Then start to add more components while the operation of the system

is verified.

• Some faults could be found by measurement:

o The voltage to the monitors should be between 9 Volts and 15 Volts when measured

in the display connector box.

o The voltage to the target units should be between 9 Volts and 15 Volts. This voltage

should be measured on the inner terminal block on the large printed circuit board

inside the target connection cabinet.

o The voltage on the battery during charging (for a more or less fully charged battery)

should be approximately 1 – 14.5 Volts. Often a small increase in voltage can be

seen during charging and a decrease in voltage when not charging.

o Remove the fuses and measure the resistance (should be very low)

o Disconnect the data line in both ends and measure the resistance. The value should

be very low then the cable is short circuited in the other end and infinite when left

unconnected in the other end

User manual for ML2000

19.10.2012 - V6.01 Troubleshooting 4

o An active communication line will have a small DC voltage (approximately 0.

Volts)

o All communication lines should always be between 0 Volts and 5 Volts when

measured between ground and the communication wires (usually close to 0 Volts).

o Check that there is no ground faults in the 2 0 Volt systems. Be careful when

measuring on 2 0 Volts! Disconnect the target network cable in one end and

measure the AC voltage between the grounding and the wires in the target network

line.

• Communication fault detector

o The display will enter a communication fault detection mode if the D-button is

pressed and held when the display is switched on. The display units that are started

in this manner will give a short beep if communication faults are detected. Keep in

mind that not all faults are detected this way. The test could be very valuable to

identify faults due to wrong communication configuration, grounding faults or

damaged communication circuits after lightening damages.

7.2.2 Sensor unit

• Problems with the microphones are easily detected with the sound pressure values. If these

values are even and close to the normal values, the sensors and electronics is working

perfectly.

• If one target unit is not detecting shot even if it is in READY state the following procedure

can be performed:

o Expose the controller unit on the target unit (Lower the sensor unit under the target

unit for Uxxx targets. Look on the back side of the 4K targets).

o Observe the red sensor LED on the controller unit while tapping carefully on th

sensors. The LED should give a red flash when tapping on any of microphones

o Verify the configuration of sensor data. Observe the shout and error counters when

shooting or tapping the sensors.

7.2.3 Communication towards PC

• Verify that the power LED is on and the PC LED is flashing

• The LED for activity on the shooting stand network should flash on the PC connection box.

• Verify the connections from the PC-adapter to the PC-connection box and from the PC-

adapter to the PC. Check that the adapter is connected to the shooting stand network when

working with the monitors and the target network when working with the target units.

• Check that not other units are connected to the same network (e.g. remote range

management PC for practice printing)

• Check that only one instance of the PC-programs have been started (do not use MLAdmin

and MLLeder at the same time)

• Verify the setup of communication ports and range of lanes.

7.2.4 Problems with the sound pressure values

• Check rubber sheet, rubber or paper band and the parameters used for automatic band

advance

• Clean the sensors (usually not a cause to problems, but still…)

• If one sensor always gives different values than other sensors it might be a damaged sensor.

• Check the sensitivity setup for the target

User manual for ML2000

19.10.2012 - V6.01 Troubleshooting 5

7.3 Replacement units

7.3.1 Packaging and transportation

In case of damaged electronic components the parts can be demounted, packaged and sent to service

or replacement. The following procedure should be followed:

• The equipment should be packaged well to avoid damage during transportation.

• If electronic cards are sent without casing (e.g. controller cards from the sensor unit), the

unit must be wrapped in an ESD safe packaging material. Use ESD bags for PC equipment

etc. if available. Avoid ordinary plastic. If no other material is available we would prefer

carton boxes.

• Mark the package with the text ”Repair”

• Insert a note with returning address, contact person and description of the symptom.

Remember to do this even if the problem has been discussed with Megalink personnel. The

equipment for repair is often handled by other personnel.

• Use the repair form that can be found in the appendices

• Send the equipment as registered package and not by mail if the contents represent

significant value.

7.3.2 arget controller unit (electronic card) for 3U-XXX targets

Below follows a description of how demount the controller electronics from the sensor bar in the

big bore targets ( Uxxx).

• Disconnect the target cables

• Lower the sensor unit under the target unit. Be careful with the microphones and the

temperature sensor.

• Put the sensor unit in a location with as friendly electrostatic environment as possible (avoid

carpets etc.). Touch the aluminium parts before and/or during the work to discharge as much

EDS as possible. Avoid touching directly on the components. Grip the card on connectors or

edges.

• Remove the bottom part:

o For wooden bottom: Remove the three bolts, washers and distance pieces

o For plastic profile: Remove the locking screws and loosen the profile in one end

before pulling it off the aluminium bar.

• Remove the two screws from the aluminium cover that holds the electronic card. Pull the

card carefully out of the sensor bar with a firm grip on the aluminium cover.

• Remove the locking screws for the microphone cable and pull out the connector

• Release the card completely

The mounting is mainly the reverse procedure. Observe:

• The microphone cables should be led on the back side of the card inside the sensor bar.

Check that the cables are not squeezed when inserting the card

Try to mount the aluminium bar sideways in the centre of the bottom part

7.3.3 arget controller unit for 4K-XXX targets

Demounting:

• Remove the target cables

• Put the sensor unit in a location with as friendly electrostatic environment as possible (avoid

carpets etc.). Touch the aluminium parts before and/or during the work to discharge as much

EDS as possible. Avoid touching directly on the components. Grip the card on connectors or

edges.

• Remove the cover over the controller (use a screwdriver with PZ1 bit)

• Loosen the screws on the fastening bracket for the card

User manual for ML2000

19.10.2012 - V6.01 Troubleshooting 6

• Pull the card out of the connector for the temperature sensor. Be careful with the motor

cables.

• Remove the locking screws for the microphone cable and pull out the connector

• Release the card completely

Mounting is the exact opposite procedure. Remember that you might have to configure the replaced

unit after mounting.

7.3.4 Replacing the motor on 4K-300

Demounting:

• Run the motor until the lock screw on the driving shaft is accessible

• Remove the pressure roller and remove the springs for the hinged holders

• Disconnect the motor wires from the terminal block (please note the polarity)

• Remove the screws for the complete advancing unit (the horizontal aluminium bracket

across the target). Lift out the advancing unit.

• Loosen the lock screw on the driving shaft

• Remove the right hand side screw on the grip rod

• Remove the screws for the right hand side roller bracket

• Remove all three rollers

• Remove the screws for the motor and remove it

Mounting is the exact opposite procedure. Prepare the mounting with checking the position of the

flat part of the driving shaft on the motor. Hold the motor wires directly on the battery to turn the

shaft into the desired position.

7.4 Troubleshooting PC-software

7.4.1 Exchange between MLRange and MLRes

• Check that exchange is activated under the electronics flip in MLRes

• Check that there actually is valid results in MLRange

• Check the relay numbers are corresponding between MLRange and MLRes

• Verify that the shooting programs corresponds between MLRange and MLRes

• Check the directory reference in MLRange (verify through the file manager)

• Check the Prefix in MLRes and MLRange (e.g. M1)

• Verify that the network is operational

• Check that you have the necessary permissions for network resources

7.4.2 MLView

• Verify the directory reference to the shooting stand directory

• Check the picture and profile values

• Verify that the network is operational

• Check that you have the necessary permissions for network resources

Other manuals for ML2000

10

Table of contents

Other MEGAlink Sport & Outdoor manuals

Popular Sport & Outdoor manuals by other brands

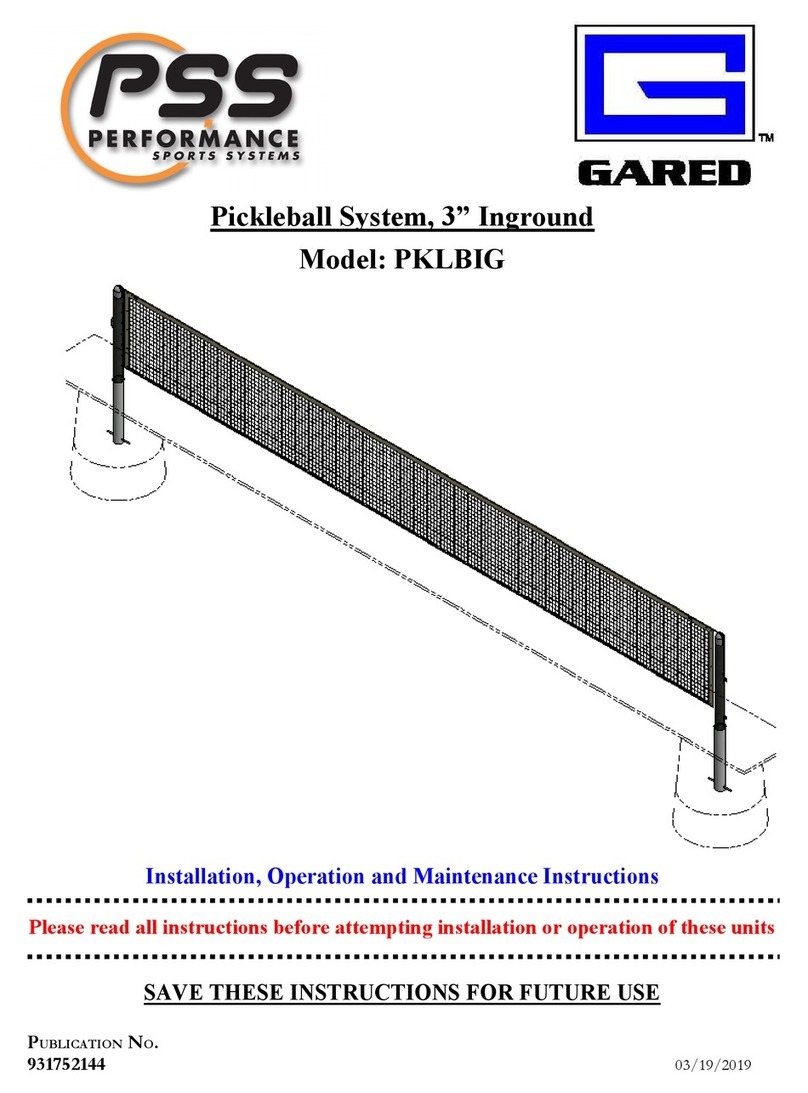

PSS

PSS GARED PKLBIG Installation, operation and maintenance instructions

SPORTNOW

SPORTNOW A90-332V00 Assembly instruction

Super Tramp

Super Tramp King 110 user guide

Sport-thieme

Sport-thieme 115 8032 User manual and assembly instructions

Klarfit

Klarfit Rocketbaby instructions

LifeSpan Kids

LifeSpan Kids HYPERJUMP 2 owner's manual

Bestway

Bestway Soccer Splash Set owner's manual

Bison

Bison VB1253W instruction manual

MARIMEX

MARIMEX Premium In-ground 19000426 installation manual

TAAROA

TAAROA UP 1250 ALUMINIUM user guide

The Garden Gym

The Garden Gym Dip station installation guide

Sport-thieme

Sport-thieme 145 7618 Operating & assembly instructions