MegaTech Solar series User manual

1

tech

36 00 5823 Issue 4

tech

Fitting and using the Megatech Solar unvented

mains pressure water heater

Solar

36005942 issue 4

2

2

techtech

Contents

SECTION PAGE

1 INTRODUCTION ........................................................................... 3

2 GENERAL REQUIREMENTS ...................................................... 4

3 INSTALLATION - GENERAL ......................................................... 6

4 INSTALLATION - SOLAR PRIMARY ............................................ 15

5 INSTALLATION - DIRECT UNITS ................................................. 16

6 INSTALLATION - AUXILLARY COIL (INDIRECT UNITS) ............ 18

7 COMMISSIONING ....................................................................... 23

8 USER INSTRUCTIONS................................................................ 25

9 MAINTENANCE ........................................................................... 27

10 FAULT FINDING & SERVICING .................................................. 29

11 DIMENSIONS & SPECIFICATIONS ........................................... 32

12 GUARANTEE ................................................................................ 35

13 CONTACTS ................................................................................... 36

Contents

Please read and understand these instructions before starting work.

The information contained in these instructions details how to connect

the Megatech Solar water heater to a solar primary circuit. Other

controls will be necessary to provide control over the primary circuit,

refer to the instructions supplied with the solar controls and ancillary

equipment for details of how to integrate them with the Megatech Solar

unit.

Please leave this leaflet with the user following installation

3

tech

1

Congratulations on your purchase of a Heatrae Sadia Megatech Solar unvented water

heater. The Megatech is manufactured in the UK from top quality materials and meets all

the latest relevant safety and constructional standards. The high grade Duplex stainless

steel cylinder offers exceptional strength and corrosion resistance which is backed by a 25

year guarantee. Its performance and insulation levels exceed the latest requirements of

Building Regulation Part L.

The Megatech unvented water heater can be fed directly from thecold water mains supply

to the property without the need for separate feed cisterns or vent pipes. It is supplied

complete with all the necessary inlet and safety controls, electric immersion heater(s) and,

for units fitted with an auxiliary heating coil, a cylinder thermostat, thermal cut-out , 2-port

motorised valve and wiring centre.

Generally its pressure and flowrate performance will far exceed that from a comparable

vented system, thermal store, multipoint instantaneous gas heater or combination boiler.

Introduction

Introduction

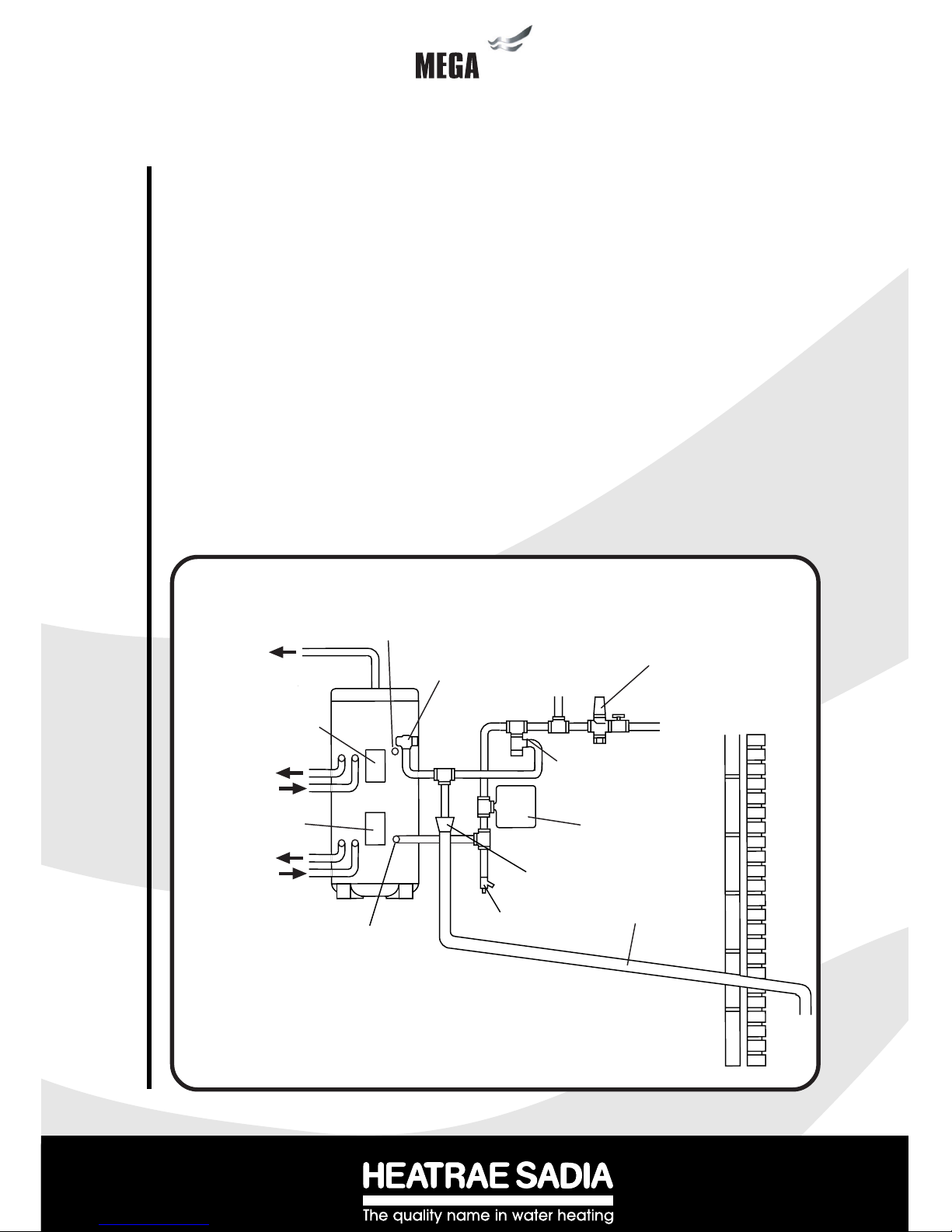

Diagram 1 - Schematic installation details

COLD WATER

COMBINATION

VALVE

BALANCED

COLD WATER

CONNECTION

(IF REQUIRED)

T&P RELIEF

VALVE

AUXILIARY

CONTROLS

HOUSING

AUXILIARY

PRIMARY RETURN

SOLAR PRIMARY

FLOW

INLET

DRAIN COCK DISCHARGE

PIPE

TUNDISH

SECONDARY RETURN

TAPPING (IF REQUIRED)

TO HOT

OUTLETS

MAINS

WATER

SUPPLY

EXPANSION VALVE

CORE UNIT (SEE

NOTE BELOW)

NOTE: FOR BALANCED PRESSURE COLD WATER SUPPLIES TEE OFF BETWEEN THE COLD

WATER COMBINATION VALVE AND THE EXPANSION VALVE CORE UNIT.

SOLAR PRIMARY

RETURN

AUXILIARY

PRIMARY FLOW

SOLAR CONTROLS

HOUSING EXPANSION

VESSEL

4

4

techtech

IMPORTANT : PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING

THE MEGATECH WATER HEATER. INCORRECT INSTALLATION MAY INVALIDATE GUARANTEE.

THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS (INCLUDING CHILDREN) WITH

REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR LACK OF KNOWLEDGE AND

EXPERIENCE, UNLESS THEY HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING

THE USE OF THE APPLIANCE BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

THE MEGATECH SOLAR MUST BE INSTALLED (SECTIONS 2 - 6), COMMISSIONED (SECTION 7)

AND MAINTAINED (SECTIONS 9 - 10) BY A COMPETENT INSTALLER IN ACCORDANCE WITH

BUILDING REGULATION G3 (ENGLAND AND WALES), TECHNICAL STANDARD P3 (SCOTLAND)

OR BUILDING REGULATION P5 (NORTHERN IRELAND) AND THE WATER FITTING REGULATIONS

(ENGLAND AND WALES) OR WATER BYELAWS (SCOTLAND). FOLLOWING INSTALLATION AND

COMMISSIONING, THE OPERATION OF THE HEATER SHOULD BE EXPLAINED TO THE USER

(SECTION 8) AND THESE INSTRUCTIONS LEFT WITH THEM FOR FUTURE REFERENCE.

2.1 COMPONENT CHECK LIST

Before commencing installation check that all the components for your Megatech Solar unit are

contained in the package. The following components are supplied as standard with your Megatech

unit :

•Factory fitted immersion heater (s) and thermal controls

•Cold Water Combination Valve (comprises Isolating Valve, Pressure Reducing Valve,

Strainer, and Check Valve).

•Expansion Core Unit (comprises Check Valve and Expansion Valve)

•Expansion Vessel (including wall mounting bracket)

•Factory fitted Temperature/Pressure Relief Valve (set at 90oC/10bar)

•T&P Relief Valve Insulation Set

•Drain Valve

•Wiring Centre (CL units only)

•Tundish (included in the Cold Water Combination Valve pack)

•Factory fitted Auxiliary heating coil Thermostat and Thermal Cut-out (CL units only)

•2-port Motorised Valve (CL units only)

•Lifting handle

2.2 SITING THE MEGATECH SOLAR (see Diagram 1)

The Megatech Solar unit must be vertically floor mounted. It can be placed anywhere convenient

provided the discharge pipe(s) from its safety valves can be correctly installed. Areas that are

subject to freezing must be avoided. Ensure that the floor is of sufficient strength to support the “full”

weight of the unit (refer to Tables 4 and 5 on page 33 for unit weights). Pipe runs should be kept as

short as possible for maximum economy. Access to associated controls, immersion heaters and

controls housings should be possible for servicing and maintenance of the system (Note: controls

housings hinge open to the left hand side).

Please do not install valves or pipework (except discharge pipe) within 50mm (2”) of the T&P relief

valve to allow your insulation set to be fitted. The insulation set is important to ensure heat and

energy conservation. See section 3.9 for more information.

To aid installation the Megatech Solar is provided with lifting points located in the base moulding and

a lifting handle. The lifting handle should be fully threaded onto the outlet boss before use. Once the

Megatech Solar is suitably positioned the lifting handle should be removed to allow connection of the

outlet pipework. The weights of the units are noted on the tables on page 33.

2General Requirements

General Requirements

5

tech

2.3 WATER SUPPLY

Bear in mind that the mains water supply to the property will be supplying both the hot and cold

water requirements simultaneously. It is recommended that the maximum water demand

be assessed and the water supply checked to ensure this demand can be met.

NOTE: A high mains water pressure will not always guarantee high flow rates.

Wherever possible the main supply pipe should be in 22mm. We suggest that the minimum

supply requirements should be 0.15 MPa (1.5 bar) working pressure and 20 litres per minute

flowrate. At these values outlet flowrates may be poor if several outlets are used simulta-

neously, the higher the available pressure and flowrate the better the system performance will

be.

The Megatech Solar has an operating pressure of 0.3 MPa (3 bar) which is controlled by the

Cold Water Combination Valve. The Cold Water Combination Valve can be connected to a

maximum mains supply pressure of 1.6 MPa (16 bar). The water supply must be of

wholesome water quality (Fluid Category 1 as defined by the Water Supply Regulations 1999).

2.4 OUTLET/TERMINAL FITTINGS (TAPS, ETC.)

The Megatech Solar can be used in conjunction with most types of terminal fittings. It is

advantageous in many mixer showers to have balanced hot and cold water supplies. In these

instances the balanced cold water supply should be teed off the supply to the Megatech

immediately after the Cold Water Combination Valve (see Diagrams 4 and 5). Branches to cold

drinking outlets should be taken before the valve.

Outlets situated higher than the Megatech Solar unit will give outlet pressures lower than that at

the heater, a 10m height difference will result in a 0.1 MPa (1 bar) pressure reduction at the

outlet fitting.

NOTE: Accessories should have a rated operating pressure of at least 0.8 MPa (8 bar).

2.5 LIMITATIONS

The Megatech Solar unvented water heater should not be used in any of the following

instances:

• Solid fuel boilers or any other boiler in which the energy input is not under effective

thermostatic control unless additional and appropriate safety measures are installed.

• Gravity circulation primaries.

• Steam heating plant unless additional and appropriate safety devices are installed.

• Ascending spray type bidets or any other Class 5 back syphonage risk requiring that a

Type AA, AB, AD or AG air gap be employed.

• Water supplies that have inadequate pressure or where the supply may be intermittent.

• Situations where it is not possible to safely pipe away any discharge from the safety

valves.

• Areas where the water consistently contains a high proportion of solids, eg. suspended

matter that could block the strainer, unless adequate filtration can be ensured.

• The installation must be carried out in accordance with the relevant requirements of:

• The appropriate Building Regulations: either The Building Regulations (England), The

Building Regulations (Scotland) or Building Regulations (Northern Ireland).

• The Water Fittings Regulations (England and Wales) or Water Byelaws (Scotland).

6

6

techtech

3

3.1 PIPE FITTINGS

All pipe connections to the Megatech Solar are made via 22mm compression fittings directly to the

unit (nuts and olives supplied). The fittings are also threaded 3/4” BSP male parallel should threaded

pipe connections be required.

3.2 COLD WATER SUPPLY

A 22mm cold water supply is recommended, however, if a 15mm (1/2”) supply exists which

provides sufficient flow (see section 2.3) this may be used. More flow noise may be experienced

from small bore pipes due to the increased water velocity through them.

The Cold Water Combination Valve supplied with the Megatech Solar incorporates a full flow

isolating valve which will enable the Megatech to be isolated from the mains supply for maintenance

or servicing. To close the valve the black handle should be turned so that it lies at 90oto the direction

of flow. To open turn the handle so that it lies parallel to the direction of flow.

3.3 COLD WATER COMBINATION VALVE (see Diagram 2)

The Cold Water Combination Valve can be connected anywhere on the cold water mains supply

prior to the Megatech Solar unit. There is no requirement to site it close to the unit, it can be located

at a point where the mains supply enters the premises if this is more convenient. The Expansion

Valve connection must not be used for any other purpose.

The Cold Water Combination Valve can be installed as a complete one-piece unit. The valve

incorporates a factory set, non-adjustable Pressure Reducer/Strainer, an Expansion Valve

connection and a single Check Valve. The valve can be fitted in any orientation to suit the

installation, however, ensure that the Valve is installed with the direction of flow arrows (stamped on

the side of the brass body) pointing towards the Megatech heater. Should you wish to site the

Expansion Valve on the Cold Water Combination Valve this can be done by unscrewing the

connection nut beneath the Expansion Valve on the Expansion Core Unit and removing the

Expansion Valve. The connecting nut and blanking plug should then be unscrewed from the Cold

Water Combination Valve and replaced with the Expansion Valve. NOTE: IF THE EXPANSION

VALVE IS FITTED TO THE COLD WATER COMBINATION VALVE THE EXPANSION CORE

UNIT SHOULD NOT BE USED AS THE CHECK VALVE WITHIN IT WILL PREVENT FREE

PASSAGE OF EXPANDED WATER TO THE EXPANSION VALVE. Ensure the discharge from

the Expansion Valve can be correctly installed.

If a balanced pressure cold water supply is required to a thermostatic shower mixer valve this may

be teed off the supply to the Megatech immediately after the Cold Water Combination Valve (see

Diagram 5). Branches to drinking water outlets should be taken before the valve to avoid

the possibility of warm expanded water being drawn from the tap.

3.4 EXPANSION CORE UNIT (see Diagram 3)

Should a balanced pressure cold water supply be required for other cold water outlets the

Expansion Core Unit supplied should be used. The Core Unit should be fitted into the pipework

Installation - General

Installation - General

7

tech

between the Cold Water Combination Valve and the Megatech Solar (Note direction of flow

arrows). The cold water balanced draw off connection should be taken from between the Cold

Water Combination Valve and the Expansion Core Unit (see Diagram 4). The Expansion

Valve connection on the Cold Water Combination Valve should remain blanked off using the

blanking nut and seal provided. Ensure the discharge from the Expansion Valve can be

correctly installed.

Diagram 2 - Cold Water Combination Valve

Diagram 3 - Expansion Core Unit

ISOLATING VALVE

MAINS IN

22MM

COMPRESSION

CONNECTION

PRESSURE REDUCING

VALVE HOUSING

PRESSURE REDUCING

VALVE CARTRIDGE

(3 BAR)

22MM

COMPRESSION

CONNECTION

OUTLET TO

MEGAFLO

EXPANSION VALVE

CONNECTION (IF

ONE-PIECE VALVE

IS REQUIRED)

TAKE NOTE OF

FLOW DIRECTION

EXPANSION RELIEF VALVE

DISCHARGE CONNECTION

EXPANSION RELIEF VALVE

FROM COLD

WATER

COMBINATION

VALVE

OUTLET TO

MEGAFLO

22MM COMPRESSION

CONNECTION

EXPANSION CORE UNIT

(INCORPORATES

CHECK VALVE)

MOUNTING NUT 22MM COMPRESSION

CONNECTION

TAKE NOTE OF

FLOW DIRECTION

8

8

techtech

Tundish

Megatech

Solar

Discharge pipe to atmosphere

(See Section 3.9 “Discharge

Pipework“)

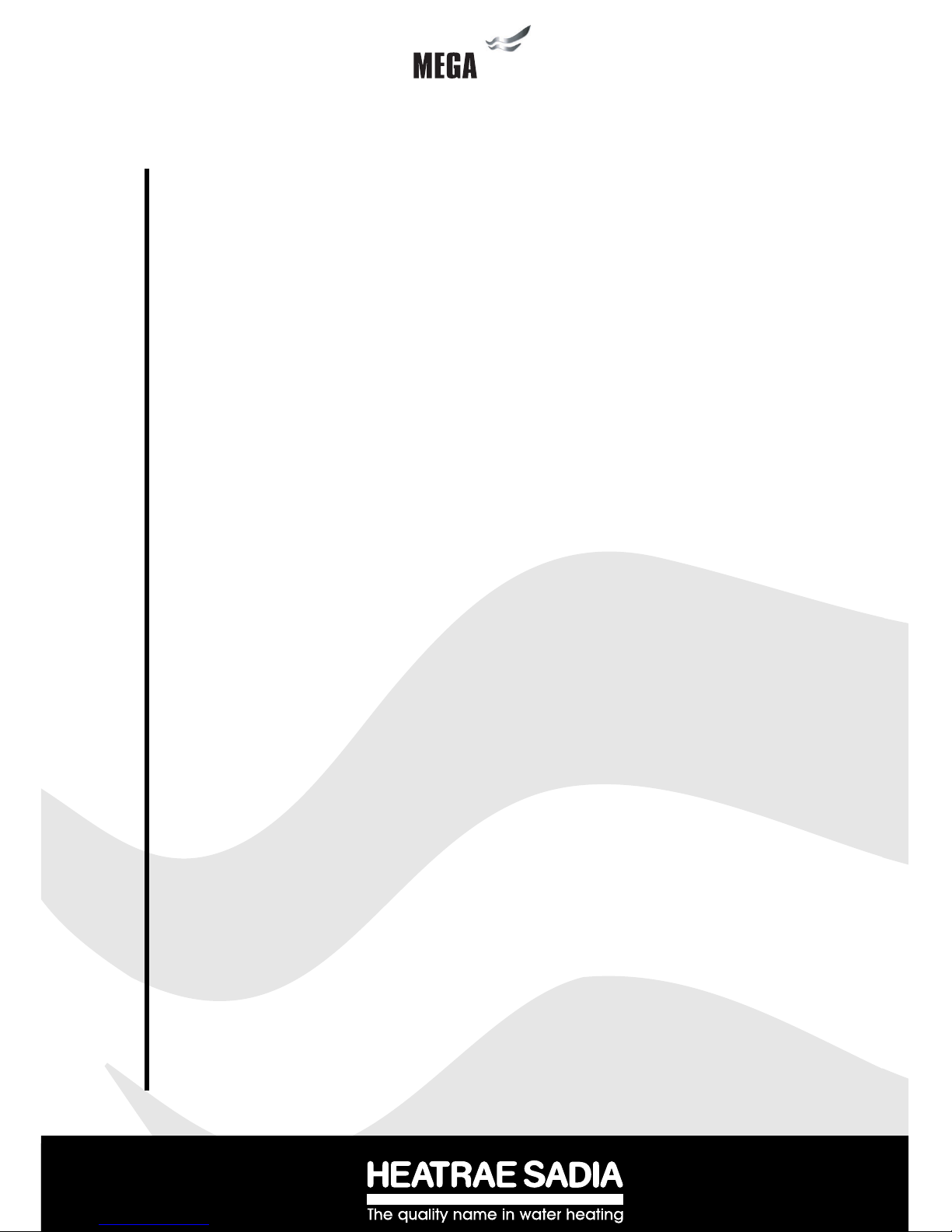

KEY

MCWS Mains cold water supply

HWS Hot water service

SC Stop Cock

DOC Drain Off Cock

Temperature/Pressure

Relief Valve

Balanced cold water

draw off

Balanced HWS and

MCWS to bathrooms,

showers,cloakrooms,

etc.

Isolating/Regulating

Valves as required

HWS supply

Expansion Core

Unit (combined

Expansion Relief

Valve/Check Valve)

SC

SC

DOC

EXPANSION

VESSEL

Incoming Cold

Water Main

MCWS to Kitchen

(unbalanced cold

mains supply)

Cold Water Combination

Valve incorporating

Pressure Reducing Valve,

Isolating Valve, Strainer

and Check Valve

NB Expansion Valve

tapping must be blanked

off

DOC DOC DOC

Diagram 4 - Schematic installation diagram using Cold Water Combination Valve in

conjunction with Expansion Core Unit

Installation - General

9

tech

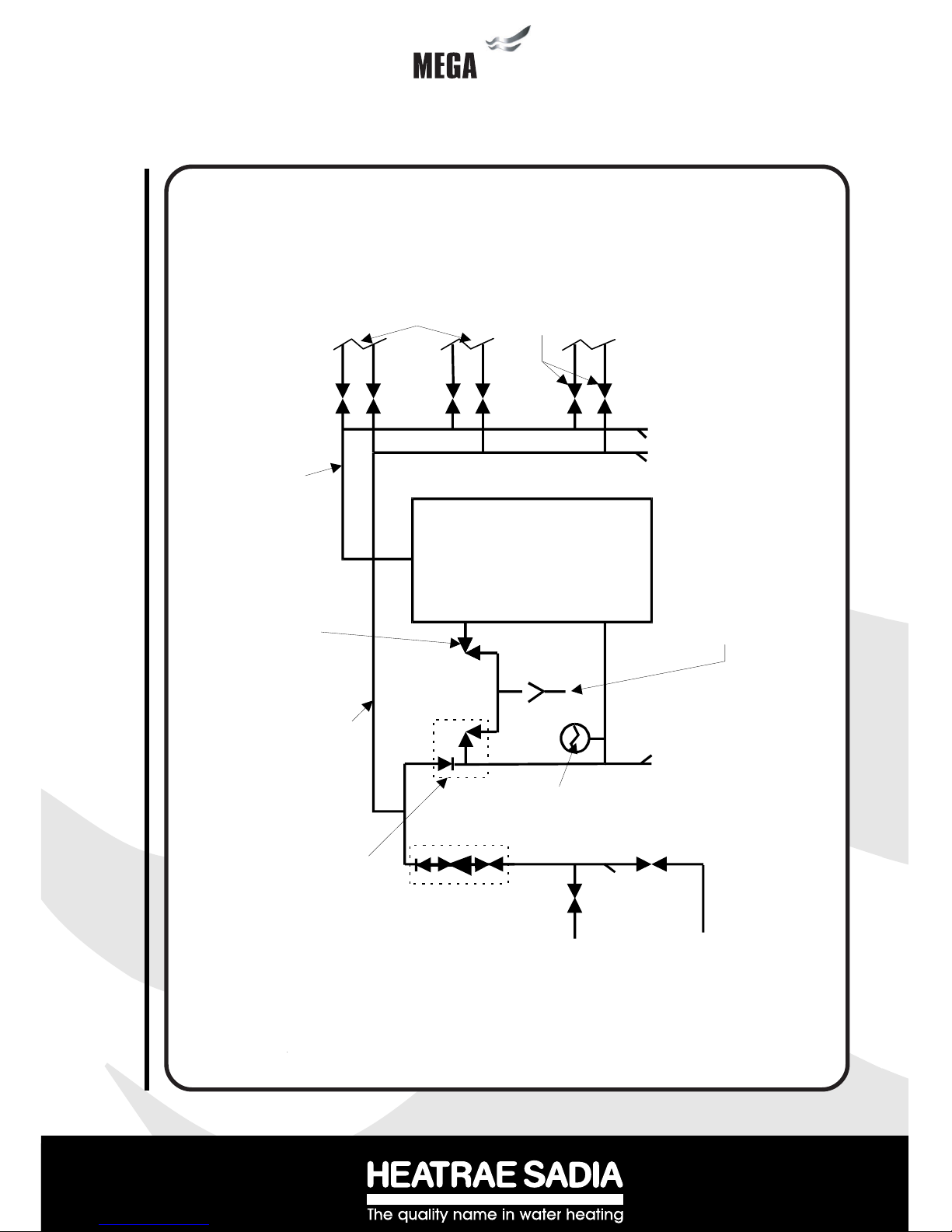

Diagram 5 - Schematic installation diagram using Cold Water Combination Valve

Tundish

Megatech

Solar

Discharge pipe to atmosphere

(See Section 3.8 “Discharge

Pipework“)

KEY

MCWS Mains cold water supply

HWS Hot water service

SC Stop Cock

DOC Drain Off Cock

Temperature/Pressure

Relief Valve

Balanced cold water

draw off to shower

mixer valves (Note:

tapping must be min.

3m from Megaflo

inlet connection)

Balanced HWS and

MCWS to each

shower.

Isolating/Regulating

Valves as required

HWS supply

SC

SC

DOC

Incoming Cold

Water Main

Incoming Cold

Water Main

MCWS to Kitchen

and drinking water

outlets (unbalanced

cold mains supply)

Cold Water Combination

Valve incorporating

Pressure Reducing Valve,

Isolating Valve, Strainer

and Check Valve and

Expansion Relief Valve

DOC DOC DOC

EXPANSION

VESSEL

10

10

techtech

3.5 DRAIN TAP

A draining tap is supplied and should be installed in the cold water supply to the Megatech Solar unit

between the Cold Water Combination Valve (or Expansion Core Unit if being used) and the heater

at as low a level as possible (see Diagram 1). It is recommended that the outlet point of the drain

pipe work be at least 1 metre below the level of the heater (this can be achieved by attaching a hose

pipe to the drain tap outlet spigot). The drain tap supplied provides very good water flow control and

blanking cap for extra security.

3.6 OUTLET PIPEWORK

Ideally the pipework from the Megatech Solar to the outlet fittings should be in 22mm pipe with short

runs of 15mm pipe to showers and basin taps. Small bore pipe can also be used to suit some taps,

but runs should be of minimum length. Pipe sizes may vary due to system design.

3.7 EXPANSION VESSEL

The Expansion Vessel accommodates expansion that results from heating the water inside the unit. The

unit is pre-charged at 0.35 MPa (3.5 bar). The Expansion Vessel must be connected between the Cold

Water Combination Valve and the Megatech Solar (see Diagram 1). The location of the Expansion

Vessel should allow access to recharge the pressure as and when necessary, this can be done using

a normal car foot pump. It is recommended that the Expansion Vessel is adequately supported. An

Expansion Vessel wall mounting bracket is supplied for this purpose.

NOTE: DO NOT USE THE POTABLE WATER EXPANSION VESSEL SUPPLIED WITH THE

MEGATECH SOLAR FOR ANY OTHER PURPOSE. IT MUST NOT BE USED IN PLACE OF

THE SOLAR PRIMARY SYSTEM EXPANSION VESSEL.

3.8 SECONDARY CIRCULATION

If a secondary circulation system is required it should be connected to the Megatech Solar as

shown in Diagram 6 via the connection provided. The secondary return pipe should be in 15mm

pipe and incorporate a check valve to prevent backflow.A suitable WRAS approved bronze

circulation pump will be required. On large systems, due to the increase in system water content, it

may be necessary to fit additional expansion volume to the system by fitting an external expansion

vessel to the secondary circuit. This should be done if the capacity of the secondary circuit exceeds

10 litres.

Pipe capacities (copper)

15mm o/d = 0.13 litres per metre run (10 litres = 77m)

22mm o/d = 0.38 litres per metre run (10 litres = 26m)

28mm o/d = 0.55 litres per metre run (10 litres = 18m)

Secondary circulation is NOT recommended for direct electric units being used on Off

Peak electricity tariffs. The secondary circulation return must not be connected to the inlet

as this would lead to indirect heating of the dedicated solar buffer volume.

Installation - General

11

tech

Diagram 6 - Secondary circulation connection

3.9 T&P RELIEF VALVE INSULATION

A set of insulating components is supplied with the Megaflo water heater and should be installed to

gain maximum heat and energy saving benefits. See Diagram 7 for installation instructions.

3.10 WARNINGS

i) Under no circumstances should the factory fitted Temperature/Pressure Relief Valve

be removed other than by Authorised Heatrae Sadia personnel. To do so will

invalidate any guarantee or claim.

ii) The Cold Water Combination Valve must be fitted to the mains

water supply to the Megatech unit.

iii) No control or safety valves should be tampered with.

iv) Water may drip from the discharge pipe of the pressure relief device (Expansion

Valve) and this pipe must be left open to atmosphere. The discharge pipe should not

be blocked or used for any other purpose.

SECONDARY RETURN

CONNECTION

CHECK VALVE

SECONDARY

CIRCULATION PUMP

OUTLET

SECONDARY

RETURN

T&P RELIEF

VALV E

DISCHARGE

PIPEWORK

TO TUNDISH

'FEMALE'

INSULATING

PIECE

'MALE'

INSULATING

PIECE

DISCHARGE

PIPE

PLASTIC

COVER

CLIP

INTO

PLACE!

AB

CD

Diagram 7 - Installation of T&P Insulating set

12

12

techtech

3.11 DISCHARGE PIPEWORK

It is a requirement of Building Regulations that any discharge from an unvented system is conveyed to

where it is visible, but will not cause danger to persons in or about the building. The tundish and discharge

pipes should be fitted in accordance with the requirements and guidance notes of Building Regulations.

Building Regulation G3 Requirements and Guidance section 3.9 are reproduced in the following sec-

tions.

Information Sheet No. 33 available from the British Board of Agrément gives further advice on discharge

pipe installation. For discharge pipe arrangements not covered by G3 Guidance or BBA Info Sheet

No.33 advice should be sought from your local Building Control Officer.

Any discharge pipe connected to the pressure relief devices (Expansion Valve and Temperature/

Pressure Relief Valve) must be installed in a continuously downward direction and in a frost free

environment.

G3 REQUIREMENT

“...there shall be precautions...to ensure that the hot water discharged from safety devices is safely

conveyed to where it is visible but will not cause danger to persons in or about the building.”

G3 GUIDANCE SECTION 3.9

The discharge pipe (D1) from the vessel up to and including the tundish is generally supplied by the

manufacturer of the hot water storage system. Where otherwise, the installation should include the

discharge pipe(s) (D1) from the safety device(s). In either case the tundish should be vertical, located in

the same space as the unvented hot water storage system and be fitted as close as possible and within

500mm of the safety device e.g. the temperature relief valve.

The discharge pipe (D2) from the tundish should terminate in a safe place where there is no risk to

persons in the vicinity of the discharge, preferably be of metal and:

a. be at least one pipe size larger than the nominal outlet size of the safety device unless its total

equivalent hydraulic resistance exceeds that of a straight pipe 9m long i.e. discharge pipes between 9m

and 18m equivalent resistance length should be at least two sizes larger than the nominal outlet size of

the safety device, between 18 and 27m at least 3 sizes larger , and so on. Bends must be taken into

account in calculating the flow resistance. Refer to Diagram 7, Table 1 and the worked example.

An alternative approach for sizing discharge pipes would be to follow BS 6700:1987 Specification for

design, installation, testing and maintenance of services supplying water for domestic use within

buildings and their curtilages, Appendix E, section E2 and table 21.

b. have a vertical section of pipe at least 300mm long below the tundish before any elbows or bends in

the pipework.

c. be installed with a continuous fall.

d. have discharges visible at both the tundish and the final point of discharge, but where this is not

possible or is practically difficult there should be clear visibility at one or other of these locations.

Installation - General

13

tech

Examples of acceptable discharge arrangements are:

i. ideally below a fixed grating and above the water seal in a trapped gully.

ii. downward discharges at low level; i.e. up to 100mm above external surfaces such as car

parks, hard standings, grassed areas etc. are acceptable providing that where children may play

or otherwise come into contact with discharges a wire cage or similar guard is positioned to prevent

contact, whilst maintaining visibility.

iii. discharges at high level; e.g. into a metal hopper and metal down pipe with the end of the

discharge pipe clearly visible (tundish visible or not) or onto a roof capable of withstanding high

temperature discharges of water and 3m from any plastics guttering system that would collect such

discharges (tundish visible).

iv. where a single pipe serves a number of discharges, such as in blocks of flats, the number

served should be limited to not more than 6 systems so that any instalation discharging can be

traced reasonably easily. The single common discharge pipe should be at least one pipe size larger

than the largest individual discharge pipe (D2) to be connected. If unvented hot water storage

systems are installed where discharges from safety devices may not be apparent i.e. in dwellings

occupied by blind, infirm or disabled people, consideration should be given to the installation of an

electronically operated device to warn when discharge takes place.

Note: The discharge will consist of scalding water and steam. Asphalt, roofing felt and non-metallic

rainwater goods may be damaged by such discharges.

Worked example of discharge pipe sizing

The example below is for a G1/2 temperature relief valve with a discharge pipe (D2) having 4

No. elbows and length of 7m from the tundish to the point of discharge.

From Table 1:

Maximum resistance allowed for a straight length of 22mm copper discharge pipe (D2) from a

G1/2 temperature relief valve is 9.0m.

Subtract the resistance for 4 No. 22mm elbows at 0.8m each = 3.2m

Therefore the permitted length equates to: 5.8m

5.8m is less than the actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm pipe (D2) from a G1/2 temperature

relief valve equates to 18m.

Subtract the resistance of 4 No. 28mm elbows at 1.0m each = 4.0m

Therefore the maximum permitted length equates to: 14m

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

14

14

techtech

Installation - General

Valve outlet size Minimum size of

discharge pipe

D1

Minimum size of

discharge pipe

D2 from tundish

Maximum

re sista n ce

allowed,

expressed as a

length of straight

pipe (i.e. no

elbows or bends)

Re si sta n ce

created by each

elbow or bend

G1/2 15mm

22mm

28mm

35mm

up to 9m

up to 18m

up to 27m

0.8m

1.0m

1.4m

G3/4 22mm

28mm

35mm

42mm

up to 9m

up to 18m

up to 27m

1.0m

1.4m

1.7m

G1 28mm

35mm

42mm

54mm

up to 9m

up to 18m

up to 27m

1.4m

1.7m

2.3m

Fixed grating

Discharge below

fixed grating

(Building Regulation

G3 section 3.9d gives

alternative points

of discharge)

Trapped

gully

Discharge pipe (D2) from tundish,

with continuous fall. See Building

Regulation G3 section 3.9d i-iv,

Table 4 and worked example

300mm

minimum

500mm maximum

Metal discharge pipe (D1) from

Temperature relief valve to tundish

Tundish

Safety device

(e.g. Temperature

relief valve)

Table 1 - Sizing of copper discharge pipe (D2) for common T&P relief valve sizes

Diagram 8 - Schematic discharge pipe arrangement

15

tech

4

Installation - Solar Primary

Installation - Solar Primary

4.1 CONNECTION TO SOLAR PRIMARY CIRCUIT

The lower (solar) coil of the Megatech Solar must be connected to a fully pumped solar primary

circuit. The connections (see diagram 17) are suitable for 22mm copper pipe direct to the compres-

sion fittings provided. The connections are also threaded 3/4” BSP male parallel should BSP

connections be required.

The solar primary circuit must have its own dedicated circulating pump, thermal and safety controls

which must be installed as per the manufacturer’s instructions.

4.2 CONTROL OF SOLAR PRIMARY CIRCUIT

Temperature control of the Megatech Solar must be carried out using a suitable proprietary solar

differential temperature controller. The cylinder temperature sensing probe (usually supplied with the

solar differential temperature controller) should be inserted into the pocket provided on the Megatech

Solar (see diagram 9) and its cable secured using the cable clamp supplied.

The solar controller and solar primary circulation pump must be wired via the over-temperature cut-

out mounted in the lower solar controls housing (see diagram 9). This will ensure that the heat input

to the solar coil is interrupted in the event of the cylinder over-heating. There must also be suitable

Check (non-return) valves installed in the solar primary flow and return to prevent the possibility of

any thermo-syphoning if the solar circulation is stopped.

Connection to the solar differential temperature controller should be in accordance with the

manufacturer’s instructions. The controller should be set to give a recommended cylinder tempera-

ture of approx. 60oC. The maximum setting should not exceed 70oC otherwise nuisance operation of

the thermal cut-outs may occur.

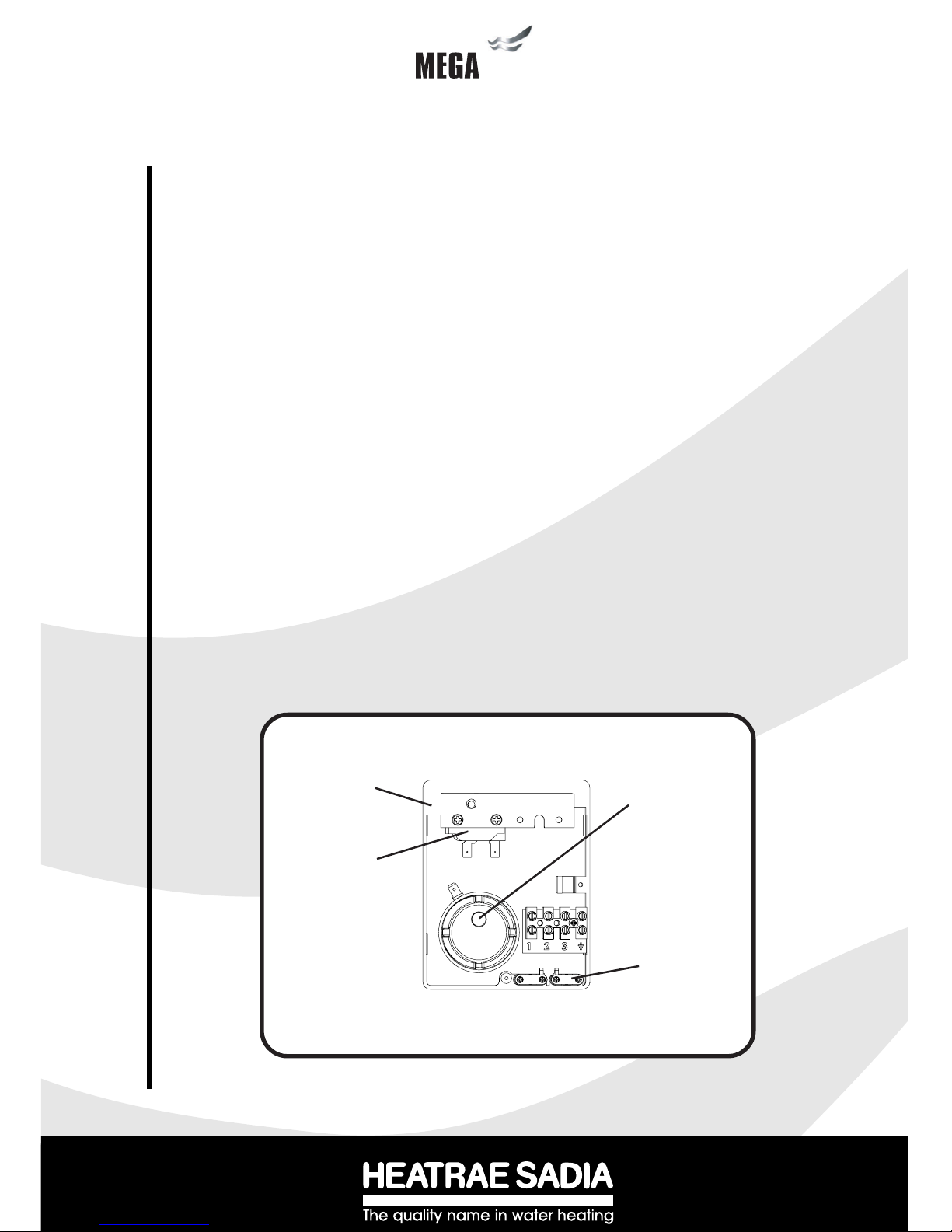

Diagram 9 - Solar Coil Control Connections

Cylinder Temperature

Control Probe Pocket

Cable Clamp

Solar Cylinder

Controls Housing

Over Temperature

cut out

Note: wires removed from diagram for clarity

16

16

techtech

Installation - Direct units

5.1 IMMERSION HEATER(S)

The Megatech Solar Direct is supplied with two factory fitted immersion heaters. Each immersion

heater is rated 3kW at 240V.

To remove the immersion heater:

Ensure the cylinder is drained of water first. Open the cover to the upper immersion heater. Unplug

the thermostat from the element by gently pulling the thermostat outwards. Unscrew the brass

backnut using the key spanner provided. Remove the immersion heater assembly and sealing

gasket from the boss.

Replacement:

Insert the immersion heater and sealing gasket into the required boss. Ensure that the sealing gasket

is not displaced when inserting. It may be helpful to support the immersion heater using a round

bladed screwdriver inserted into one of the thermostat pockets. Hand tighten the brass backnut.

Secure the immersion heater in position by tightening with the key spanner provided. Insert the

blanking plate into the remaining boss ensuring the sealing gasket is not displaced when inserting.

Hand tighten the brass backnut. Secure in position by tightening with the key spanner provided.

If an additional immersion heater is required order Part No. 95 970 510.

5.2 WIRING (see Diagram 10)

All electrical wiring should be carried out by a competent electrician and be in accordance with the

latest I.E.E. Wiring Regulations. Each circuit must be protected by a suitable fuse and double

pole isolating switch with a contact separation of at least 3mm in both poles.

The immersion heater(s) should be wired in accordance with Diagram 10. The immersion heaters

MUST be earthed. The supply cable should be 1.5mm23 core HOFR sheathed and must be routed

through the cable gland provided with the outer sheath of the cable firmly secured by tightening the

screw on the cable gland. Replace the immersion heater cover(s) before operating ensuring that the

threaded edge clip is in position to provide a suitable thread for the cover screw.

DO NOT OPERATE THE IMMERSION HEATER(S) UNTIL THE MEGATECH SOLAR HAS

BEEN FILLED WITH WATER..

5.3 OPERATION

It is recommended that the immersion heater thermostats are set to between position 4 and 5 (60o-

65oC), however they can be set between 1 and 5 (10o and 70oC). The thermostat incorporates a

thermal cut-out that will switch off the immersion heater in the event of a thermostat failure. The

thermal cut-out reset button position is indicated on Diagram 10. DO NOT bypass the thermal cut-out

in any circumstances.

5Installation - Direct units

17

tech

5.4 SAFETY

DO NOT BYPASS THE THERMAL CUT-OUT(S) IN ANY CIRCUMSTANCES.

DISCONNECT FROM THE MAINS SUPPLY BEFORE REMOVING ANY COVERS.

NEVER ATTEMPT TO REPLACE AN IMMERSION HEATER OTHER THAN WITH THE

RECOMMENDED HEATRAE SADIA MEGATECH SOLAR SPARE PART.

Diagram 10 -

Schematic wiring

diagram - Direct

immersion

heaters

THERMOSTAT

FUSED (13A) DOUBLE

POLE ISOLATING

SWITCH

Diagram 11 - Immersion heater details

1.5mm23 CORE

HOFR SHEATHED

CABLE

BROWN

BLUE

GREEN/YELLOW

THERMAL CUT-OUT

RESET BUTTON

ELECTRICAL

TERMINATIONS

CUSTOMER

EARTHING

TERMINAL

CABLE GLAND

NOTE: FOR CLARITY THE EARTH LINK WIRE BETWEEN CUSTOMER EARTHING

TERMINAL AND EARTHING TAG NOT SHOWN.THIS MUST NOT BE REMOVED!

EARTHING TAG

THERMOSTAT

ADJUSTMENT

THERMOSTAT

THREADED EDGE CLIP

EARTH

CONNECTION

18

18

techtech

Installation - Auxiliary coil

6.1 BOILER SELECTION

The Megatech Solar Indirect (CL) models are supplied with an auxiliary heating coil suitable for use

with most gas or oil fired boilers compatible with unvented systems i.e. fitted with a temperature

control thermostat and thermal cut-out.

If in doubt consult the boiler manufacturer.

Solid fuel boilers or any other boiler in which the energy input is not under effective thermostatic

control unless additional and appropriate safety measures are installed should NOT be used.

The boiler used can either be a sealed system or open vented type, maximum primary circuit

pressure 0.3 MPa (3 bar).

The primary flow from the boiler MUST be pumped. Gravity circulation will not work due to the

special design of the primary heat exchanger. It is recommended that an air bleed point or automatic

air vent is incorporated in the primary return pipework close to the Megatech Solar unit.

The boiler flow temperature should usually be set to 82oC (maximum flow temperature to primary

heat exchanger 90oC).

The boiler cannot be vented through the Megatech Solar unit.

6.2 INDIRECT THERMAL CUT-OUT AND 2-PORT MOTORISED VALVE

To comply with Building Regulations and to prevent the Megatech Solar from overheating the 2-port

motorised valve supplied MUST be fitted to the primary flow to the auxiliary heating coil (see

Diagram 12).

6.3 WIRING

All electrical wiring should be carried out by a competent electrician and be in accordance with the

latest I.E.E. Wiring Regulations.

The Megatech Solar Indirect Thermostat and Thermal Cut-out are factory pre-wired. The 2-port

motorised valve supplied MUST be wired in series with the Indirect controls such that the power

supply to the valve is interrupted should either the Thermostat or Thermal Cut-out operate. The Wiring

Diagrams 14 or 15 detail the wiring required between these controls and the motorised valve. Wiring

to external controls is made via the terminal block fitted. The cable should be routed through the

aperture in the terminal cover and secured using the cable clamp provided. The Indirect Thermal

Cut-out MUST NOT be bypassed.

6.4 HEATING SYSTEM CONTROLS

The controls provided with the Megatech Solar will ensure the safe operation of the Megatech Solar

within a central heating system. Other controls will be necessary to control the space heating

requirements and times that the system is required to function. Depending on the boiler selected,

heating circuit design and controls used it may be beneficial to incorporate a system bypass in the

heating system pipework.

6Installation - Auxiliary coil

(Indirect units)

19

tech

The Megatech Solar is compatible with most heating controls, examples of electrical circuits are

given in Diagrams 14 and 15. However, other systems may be suitable, refer to the

controls manufacturer’s instructions, supplied with the controls selected, for

alternative system wiring schemes.

5.5 IMMERSION HEATER

The Megatech Solar indirect units (CL models) are supplied with an immersion heater which

can be used as an alternative heat source should the boiler supply need to be isolated from the

Megatech unit. The immersion heater is located within the controls housing. Refer to Sections

4.2 and 4.3 and Diagram 10 for details of wiring and operation of the immersion heater.

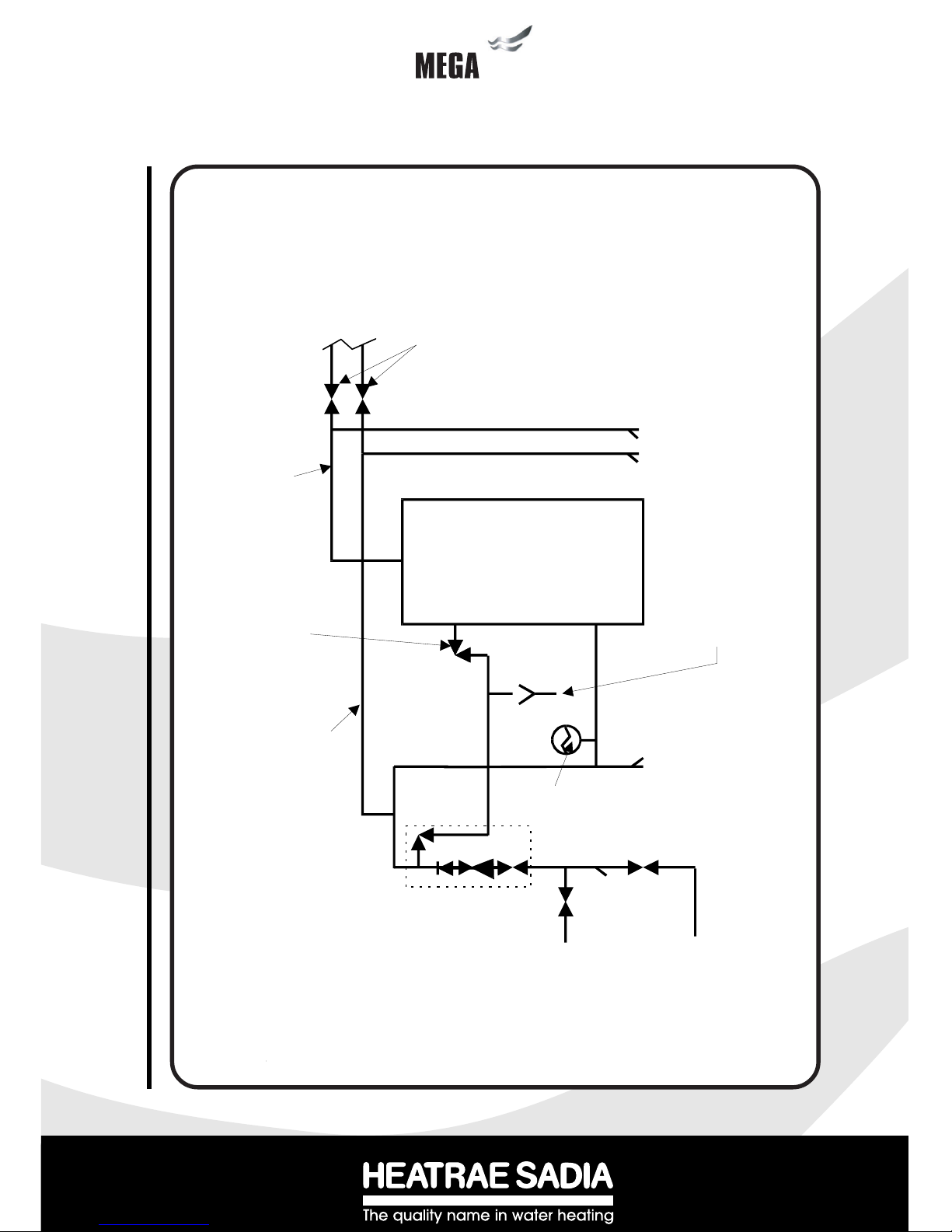

Diagram 12 - Primary connections to indirect (CL) units

TO HOT

OUTLETS

PRIMARY

RETURN

PRIMARY

FLOW

AIR

VENT

2 PORT MOTORISED

VALVE (SUPPLIED) INLET

AUXILLARY

HEAT SOURCE

PRIMARY

RETURN

PRIMARY

FLOW

SOLAR

PRIMARY

CIRCUIT

20

20

techtech

CABLE CLAMPS TERMINAL BLOCK

INDIRECT

THERMOSTAT

THERMOSTAT

ADJUSTMENT

INDIRECT

THERMAL

CUT-OUT

INDIRECT THERMAL

CUT-OUT RESET

BUTTON

NOTE:

THE HOUSING COVER AND ELEMENT ASSEMBLY HAVE BEEN REMOVED

FROM THIS VIEW FOR CLARITY

Diagram 13 - Indirect controls housing details

Installation - Indirect units

Table of contents

Popular Water Heater manuals by other brands

Raypak

Raypak WH 0135A Installation & operating instructions

Quietside

Quietside DPW-199C user manual

A.O. Smith

A.O. Smith GPS-75 instruction manual

Strom-Electrical

Strom-Electrical SEUS6L installation manual

PVI Industries

PVI Industries QuickDraw Installation & maintenance manual

Spheros

Spheros Thermo S 230 Workshop manual

State Water Heaters

State Water Heaters 184671-000 instruction manual

Main

Main MULTIPOINT FF User operating, installation and servicing instructions

Bradford White

Bradford White Copper Brute II BWCH 2000 Installation and operating instructions

Takagi

Takagi T-K1 Installation manual and owner's guide

PVI Industries

PVI Industries COBREX Installation & maintenance manual

Aspes

Aspes ATE51D user manual