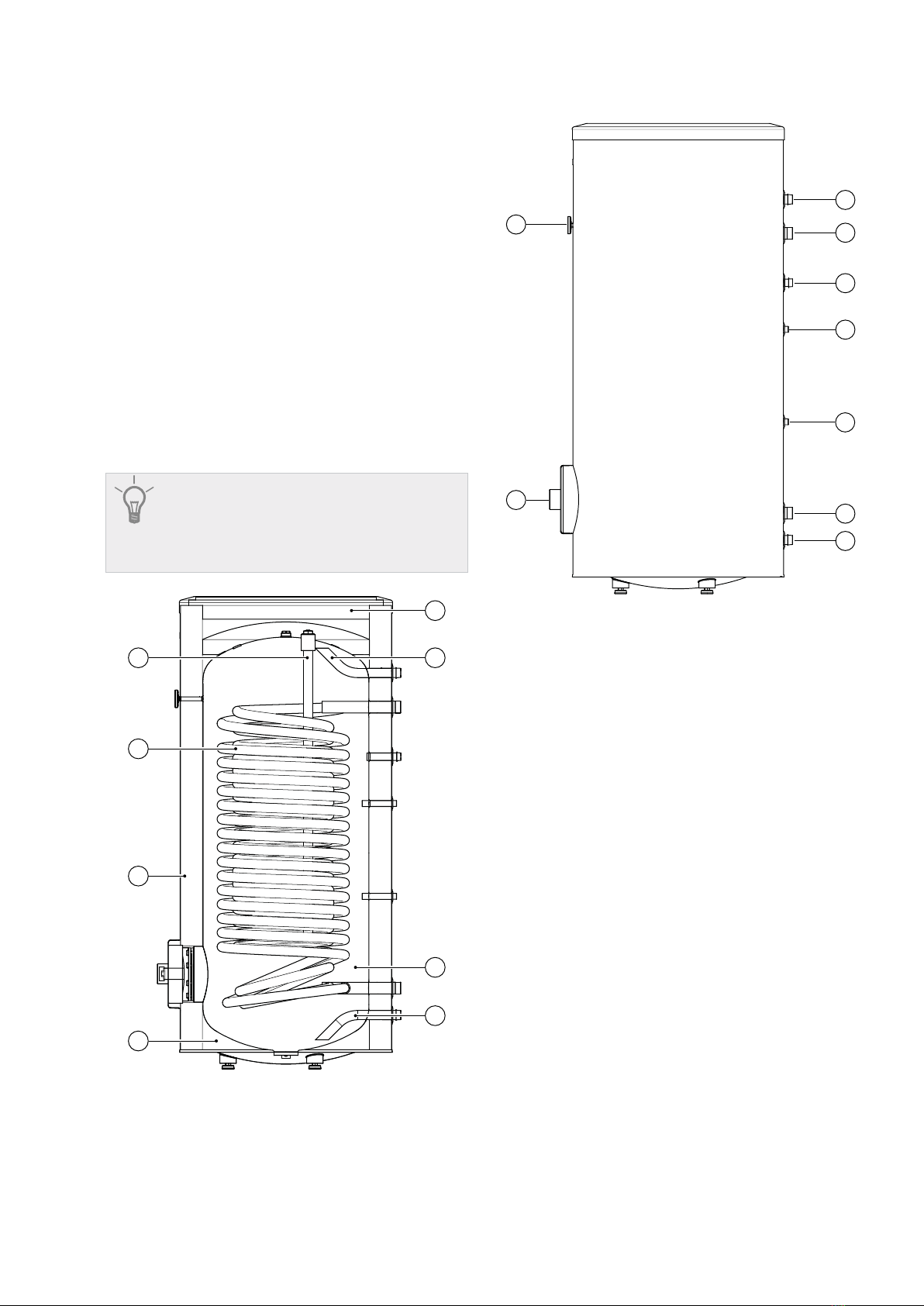

10 Chapter 5 | Maintenance Hot Water Storage Tank with large surface coil

BA-ST 9030- 1FEDC

BA-ST 9040- 1FEDC

BA-ST 9050- 1FEDC

1

Cleaning of

the Storage Tank

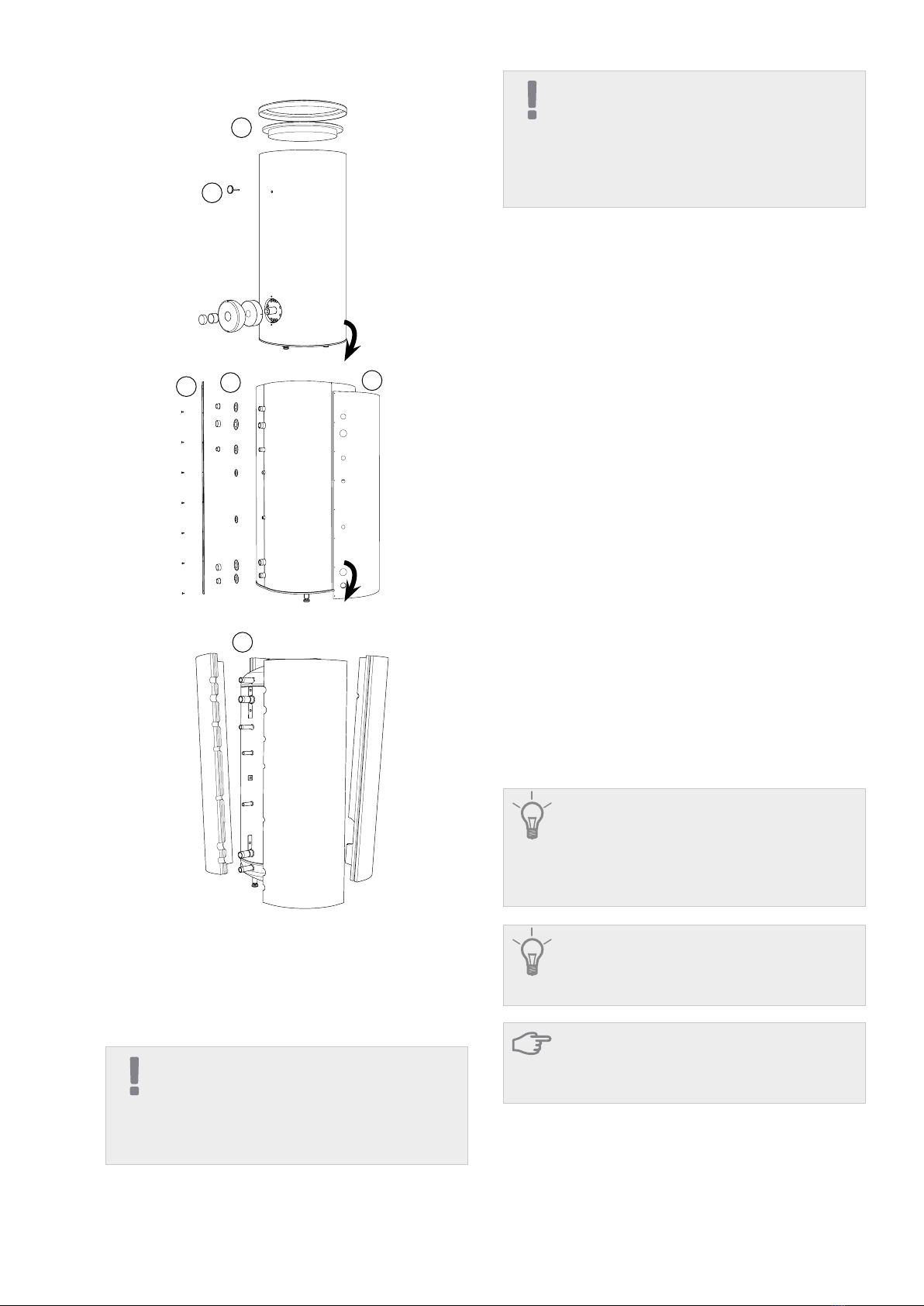

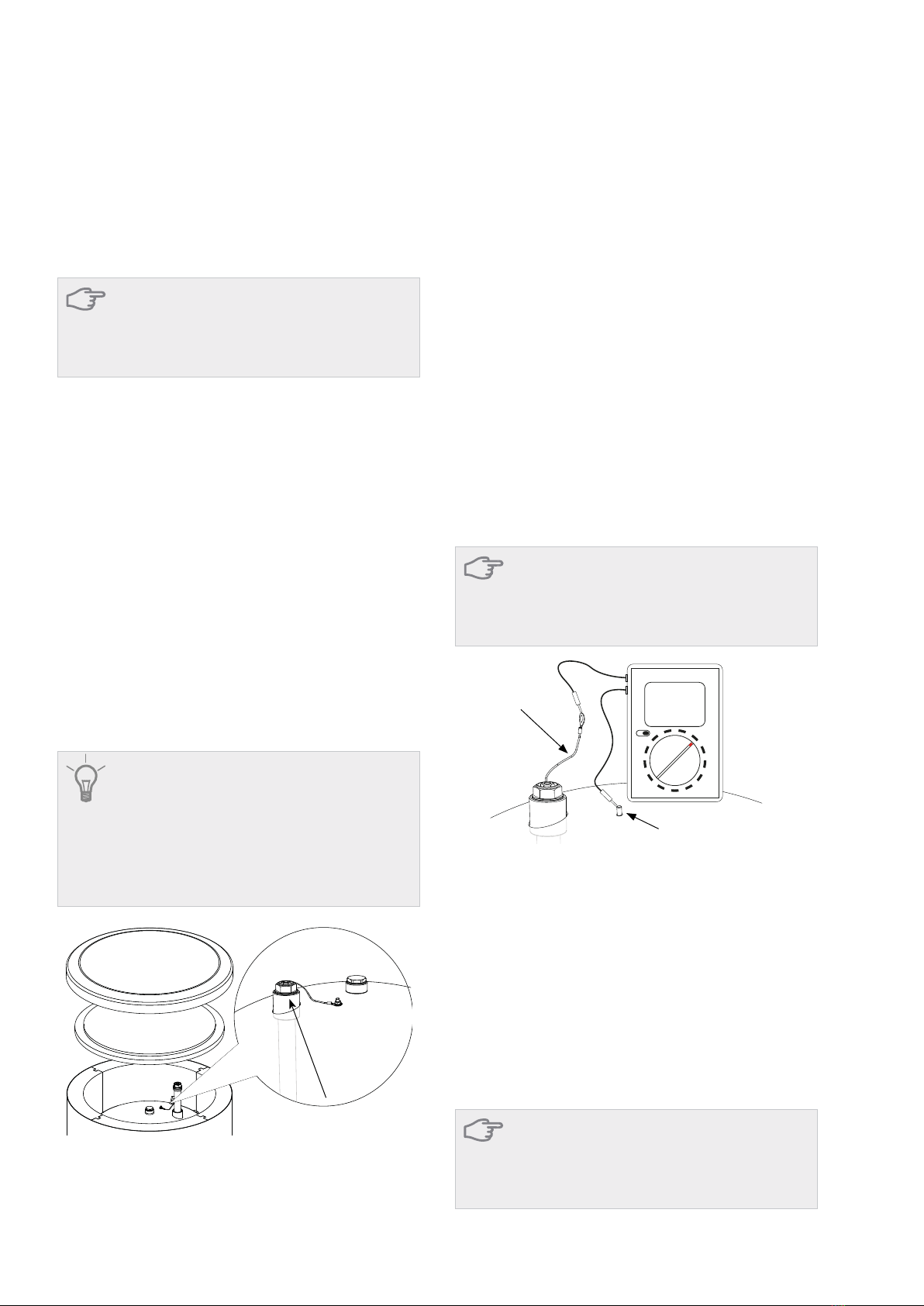

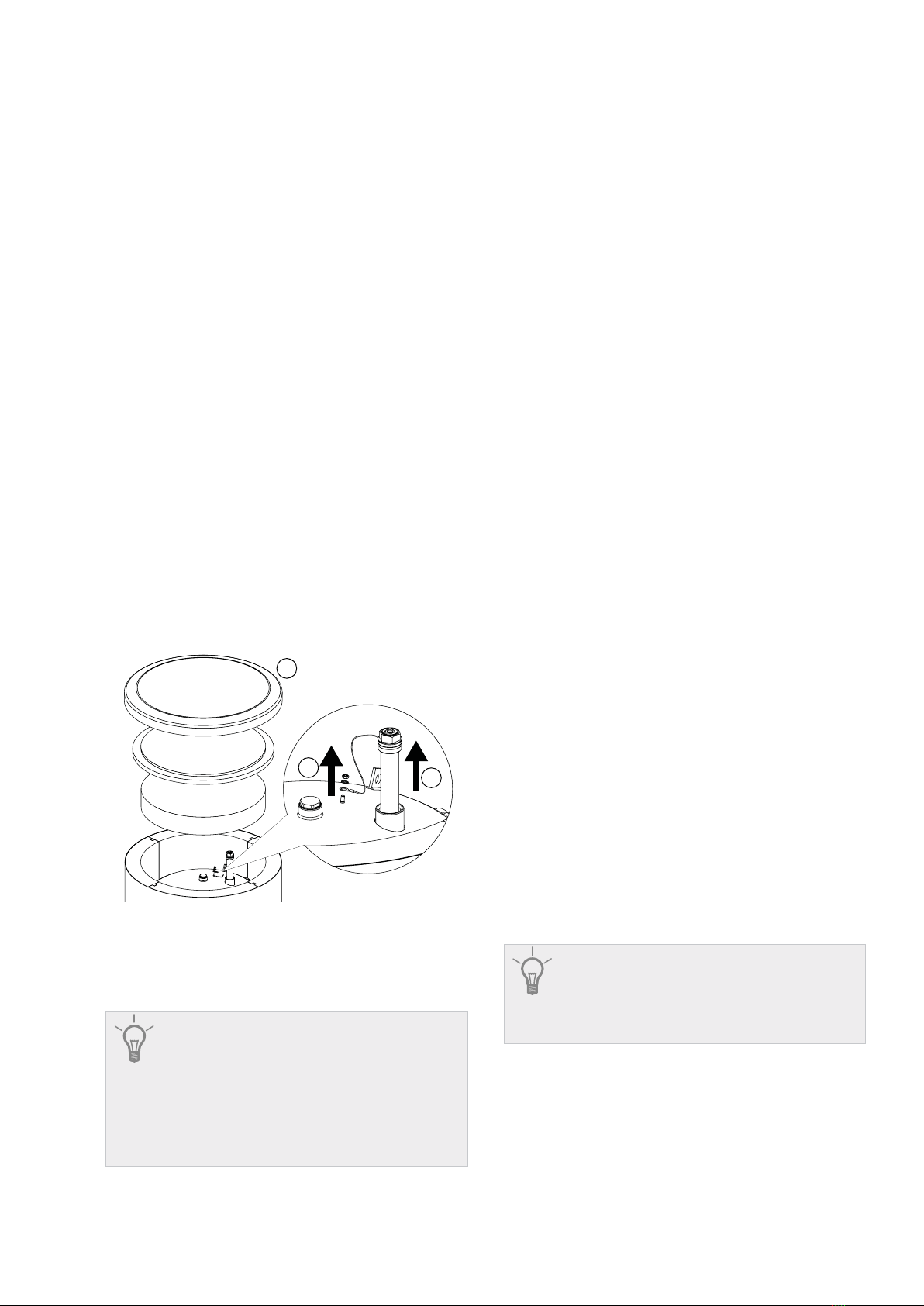

When replacing the magnesium anode, follow the

procedure below (see Fig. 10):

1. In units with the electric heating unit installed,

disconnect power from the unit first.

2. Switch the storage tank coil heaters OFF and

wait until the water inside cools down.

3. Cut-off the hot water supply and drain some

water from the tank through the drain valve (see

Fig. 7 item 4).

4. Remove the housing cover together with ther-

mal insulation (1).

5. Remove the anode protective conductor (2).

6. Remove the worn magnesium anode (3).

7. Screw the new magnesium anode.

8. Connect the anode protective conductor to the

storage tank.

9. Fill the tank with water and vent it as described

in par. Start-Up.

10. Check tightness of the installed anode.

11. Reinstall the thermal insulation and the housing

cover.

Boiler scale is precipitated from the heated water

during the storage tank operation. The amount of de-

posited scale depends on the water hardness, the

operating temperature and operating time. Heating

surfaces covered with boiler scale reduce the heat

output of the storage tank, increase power consump-

tion and extend the heating time. It is recommended

to clean the storage tank from deposits at least once

every two years. In the case of hard or very hard wa-

ter, cleaning should be carried out at shorter intervals.

Storage tank cleaning procedure:

1. Prepare a new inspection opening gasket. The

old gasket may not be reused (for the list of the

inspection opening gaskets, see Section 6 Acces-

sories and Spare Parts).

2. In storage tanks with the electric heating unit in-

stalled, disconnect power from the unit first.

3. Switch the storage tank coil heaters OFF and

wait until the water inside cools down.

4. Cut-off the hot water supply and drain the storage

tank through the drain valve (see Fig. 7 item 4).

5. Remove the inspection opening blanking plate

and gasket.

6. Remove the inspection opening screws and

flanged cover and flush the storage tank and re-

move accumulated sludge and lime slurry. If nec-

essary, remove lime deposits from the coil – this

guarantees a proper heat exchange. Pay special

attention to not damage the ceramic enamel

coating.

7. Replace a new gasket and the inspection open-

ing flanged cover. Screw tightening torque: 25±5

Nm.

8. Fill the tank with water and vent it as described

in par. Start-Up.

9. Check tightness of the inspection opening.

10. Replace the insulation and inspection opening

blanking plate.

Fig. 10 Replacement of the protective magnesium

anode.

Once making the above steps, the storage tank is

ready to use. Ensure that the anode protective con-

ductor is connected to the storage tank top head

after installing the new isolated magnesium anode.

Lack of contact between the anode and the tank will

interfere operation of the anode and the tank will not

be protected against corrosion.

Once cleaned, the unit is ready to use.

Connect the anode protective conductor to the M5

pin fixed to the top head of the storage tank.

23

TIP

Ensure that the anode protective conductor

is connected to the storage tank top head

after installing the new isolated magnesium

anode. Lack of contact between the anode

and the tank will interfere operation of the

anode and the tank will not be protected

against corrosion.

TIP

During mechanical cleaning, be careful to

not damage the enamel. In the case of

chemical cleaning, pay special attention to

neutralize the chemicals used for cleaning.