meibes SOL-BASIS Quick start guide

Page 1

Universal controller for solar energy systems with

one collector array and one storage reservoir

COMMISSIONING

MANUAL

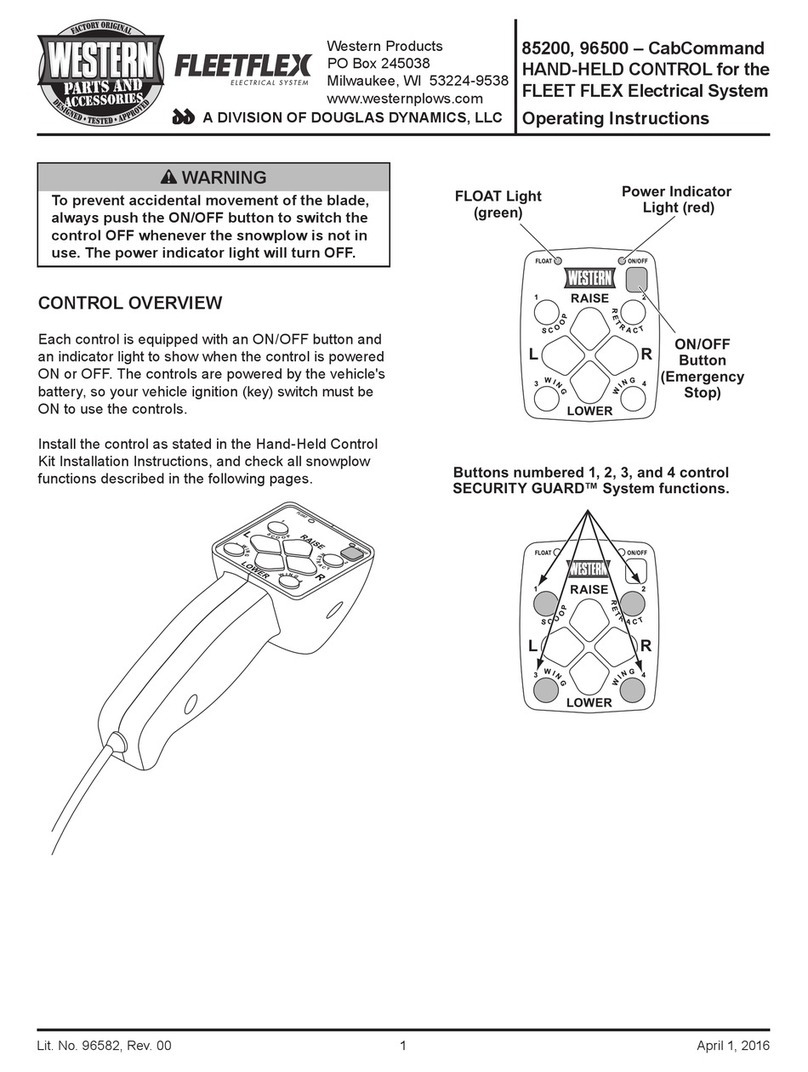

Page 2

!

Note!

Before beginning assembly or installation work, first read this commissioning manual and familiarise

yourself with its content in full! The safety instructions and working instructions in the operating

manual must also be observed! Take note of the settings which you make, at the respective places

provided for this purpose in this commissioning manual and in the operating manual!

Contents

1.

Product description .................................................................................................................................3

1.1.

eatures and functions.......................................................................................................................3

2.

Technical data.........................................................................................................................................4

3.

Safety instructions...................................................................................................................................4

4.

Transport and storage.............................................................................................................................5

5.

Installing and connecting the controller...................................................................................................5

5.1.

Proceed as follows – step by step......................................................................................................5

5.2.

Possible additional functions..............................................................................................................6

5.3.

Relay connector assignment..............................................................................................................6

5.4.

Sensor connector assignment............................................................................................................6

5.6.

Installing the controller .......................................................................................................................7

5.7.

Electrical connections ........................................................................................................................7

5.8.

Installing the collector sensor and storage reservoir sensor..............................................................8

5.9.

Dismantling and disposal ...................................................................................................................8

6.

Commissioning the controller..................................................................................................................9

6.1.

ront view of the controller with buttons and display .........................................................................9

6.2.

Structure of the start display ..............................................................................................................9

7.

The specialised mechanic level ............................................................................................................10

7.1.

Structure of submenus and navigation ............................................................................................10

8.

Reset of the factory setting ...................................................................................................................11

8.1.

System layout (1 collector array, 1 storage reservoir, 1 pump) .......................................................11

9.

Pump blockage protection ....................................................................................................................12

10.

Setting the additional functions.............................................................................................................12

10.1.

Additional function: low flow.............................................................................................................12

10.2.

Additional function: collector monitoring / tube function...................................................................12

10.3.

Additional function: emergency collector switch-off .........................................................................13

10.4.

Additional function: collector safety..................................................................................................13

10.5.

Additional function: storage reservoir safety....................................................................................13

10.6.

Additional function: collector frost protection ...................................................................................13

10.7.

Additional function: thermostat, e.g. for activation of the circulation pump......................................14

10.8.

Additional function: temperature comparison...................................................................................15

11.

System information menu .....................................................................................................................16

12.

Overview of all settings .........................................................................................................................17

13.

Relay test submenu “REL”....................................................................................................................18

14.

aults and troubleshooting....................................................................................................................18

Contents

Page 3

1. Product description

Your solar controller is a microprocessor-based controller, for control of solar energy systems with one collec-

tor array and one storage reservoir. The pump is controlled so as to optimise the heat energy obtained from

the solar collector array, according to the solar irradiation and the temperatures which arise in the solar energy

system. With the heat energy thus obtained, one storage reservoir can be loaded, e.g. a domestic water

storage tank or a swimming pool.

1.1. Features and functions

Large illuminated display (LCD) with universally understandable symbols

All key system data at a glance

Easy operation and programming

Modern design in a compact housing for wall-mounting

Predefined system layout

Temperature difference control of a solar energy system with one collector array and one storage reser-

voir

Low-flow concept for optimal stratified loading

rost protection function and protection from overheating for collectors and storage reservoirs

Thermostat and temperature comparison

System diagnostics

Product

description

Page 4

2. Technical data

Supply voltage

230 V AC 50 Hz

Power consumption

2.4 VA

use

1.6 AT, microfuse 5 mm x 20 mm

Inputs

4 inputs:

temperature sensor: Pt1000 (-20 °C to +150 °C)

Outputs

2 electromechanical relays: each 1 A, 250 V AC (ε)

Protection degree

IP 20 as per DIN EN 60529 (VDE 0470-1)

Mode of operation

type 1 Y (as per DIN EN 60730-1)

Insulation class

2

Ambient temperature

0 °C to + 50 °C

Power reserve

> 10 years at + 20 °C, with lithium battery

Installation

wall-mounted

Housing

plastic, PC / ABS

Dimensions

170 mm x 170 mm x 55 mm

Weight

0.65 kg

Conformity

The solar controller meets the requirements of the Electromagnetic Compatibility

Directive (2004/108/EC), the Low Voltage Directive (2006/95/EC) and the har-

monised standards DIN EN 60730-1 and DIN EN 60730-2-9. It bears the CE

label.

3. Safety instructions

DANG R

Danger of electrocution!

The controller is to be assembled, electrically installed, commissioned, inspected and repaired by

trained, competent and authorised persons (qualified electricians as per DIN VDE 1000-10 and

BGV A3) only!

Observe all applicable guidelines and regulations of the local electricity supplier!

Before beginning installation or repair work on electrical equipment, always ensure complete

disconnection from the mains and secure against reactivation!

Do not work on live parts!

The controller may only be installed and operated in:

dry environments which are not potentially explosive

closed rooms

rooms with a temperature between 0 °C and + 50 °C

Technical data

Page 5

4. Transport and storage

Thoroughly check whether the packaging or the controller shows any sign of damage.

Transport the controller in the original packaging only.

If the controller falls, even from a low height, it may get damaged.

Prevent impact and extreme temperatures (below 0 °C or above + 50 °C) during transport and storage.

The controller may only be stored in its original packaging and in a dry environment.

5. Installing and connecting the controller

5.1. Proceed as follows – step by step

1. Check whether you wish to use additional functions (see 5.2. Possible additional functions and 10.

Setting the additional functions [the individual additional functions are explained here]).

2. Check whether the desired additional functions can be realised, i.e. whether there are free sensors and

relays for the functions (see 5.3. Relay connector assignment and 5.4. Sensor connector assignment).

3. Install the controller at a suitable location and realise the electrical connections (see 5.6. Installing the

controller and 5. . Electrical connections).

4. Install the required sensors (see 5.8. Installing the collector sensor and storage reservoir sensor).

5. Connect the required sensors to the controller and assign the relays according to your requirements

(see 5.3. Relay connector assignment and 5.4. Sensor connector assignment).

6. Switch on the controller by pressing and holding the button for at least 5 seconds.

7. amiliarise yourself with the controller’s menu navigation (see 6.1. Front view of the controller with

buttons and display and the detailed description in the operating manual).

8. Configure any additional functions (see 10. Setting the additional functions).

9. Record your settings in the respective sections of this commissioning manual under “Selection”

(10. Setting the additional functions).

Transport and storage

esc

Page 6

5.2. Possible additional functions

This table shows you the additional functions which can be used. One relay can be assigned individually.

Funktion Described in section

Low- low 10.1.

Collector monitoring / tube function 10.2.

Collector safety function 10.4.

Collector frost protection function 10.6.

Storage reservoir safety function * 10.5.

Thermostat function (circulation

pump)*

/

**

10.7.

Temperature comparison func-

tion*

/

**

10.8.

* ree relay required

** or these functions, it is also possible to use a relay which is already assigned.

5.3. Relay connector assignment

A solar pump must be connected to relay R1. The relay R2 is free and can be assigned individually.

!

Note!

Safety extra-low voltage is not to be connected with the relays on the high-voltage side (R1 to R2).

5.4. Sensor connector assignment

The following table shows whether the selected additional functions can be realised:

1 must be connected to the collector array

2 is free and can be assigned individually

3 can be connected to the upper part of the storage reservoir, otherwise it can be

assigned individually

4 must be connected to the lower part of the storage reservoir

or the additional functions thermostat and temperature comparison the sensors can be configured freely and

activated on the specialised mechanic level.

Installing and connecting the controller

Page 7

5.6. Installing the controller

140mm

130mm

esc

-

+

ok

1. Choose a suitable installation location.

2. Remove the collector’s terminal cover.

3. Mark and drill (Ø 6 mm) the central upper fastening hole. Insert the provided rawlplug and a screw.

4. Hang the controller on the screw and align it.

5. Mark the lower fastening holes (140 mm between holes). Remove the controller once more.

6. Drill the two lower holes (Ø 6 mm).

7. Insert rawlplugs and hang up the controller once more.

8. Screw the controller firmly in place at the two fastening holes.

Risk of injury!

Do not use the controller as a drilling template!

DANG R

Connection diagram

5.7. lectrical connections

Danger of electrocution!

Every time the terminal cover is opened, the controller is to be disconnected from the power

supply beforehand!

Ensure that it cannot be reactivated!

The type of current (alternating current) and the voltage must match the specifications in the

connection diagram.

Connect the controller as shown in the connection diagram.

DANG R

Installing and connecting the controller

Upper fastening hole (for hanging)

Terminal cover Lower fastening holes

Page 8

Electrical connections are to be realised with screw terminals (single wire / fine wire, max. 1.5 mm²).

The mains supply’s protective earth connector is to be connected to the 5-pole terminal block ( ).

Protective earth connection of loads (pumps etc.) is to be realised at the 5-pole terminal block provided for this

purpose. In so doing, it must be ensured that the mains supply’s protective earth connector is also connected

to this terminal block. Each terminal may only be connected to one connecting wire.

Adequate strain relief must be ensured!

Only use the Pt1000 temperature sensors approved for use with the controller. All cables which carry low

voltage (e.g. sensor cables) are to be routed in such a way that they are kept separate from cables which

carry mains voltage.

The polarity of the sensor cables is arbitrary.

!

Note!

Safety extra-low voltage is not to be connected with the relays on the high-voltage side (R1 to R2).

After the electrical connection work, replace the terminal cover.

5.8. Installing the collector sensor and storage reservoir sensor

!

Note!

Do not route sensor cables together with cables which carry more than 50 V (low voltage)!

Shield sensor cables sufficiently.

Thermally insulate sensors and piping.

Installing the collector sensor:

Insert the collector sensor into the provided opening on the collector array and fasten it in place (refer to the

installation instructions from the collector manufacturer).

Installing the storage reservoir sensor:

Insert the storage reservoir sensor into the provided opening at the storage reservoir and fasten it in place

(refer to the installation instructions from the storage reservoir manufacturer).

Sensor cables can be extended to a maximum length of 100 m.

!

Note!

As temperatures of up to + 90 °C arise in the domestic water storage reservoir, a thermal hot water

mixer must be installed (German Heating Installation Regulation HeizAnlV § 8 para. 2)!

In order to protect the storage reservoir from high temperatures, or to limit loading to the storage

reservoir’s maximum temperature, the collector safety function (KS ) can be set to “no” on the

operating level E3-6 / 2.

5.9. Dismantling and disposal

DANG R

Danger of electrocution!

Disconnect the controller from the power supply before dismantling!

Ensure that it cannot be reactivated!

To dismantle the controller, follow the installation instructions in reverse order.

Disposal must comply with the German Electrical and Electronic Equipment Act (ElektroG), which

governs the sale, return and environmentally sound disposal of electrical and electronic equip-

ment.

Installing and connecting the controller

Page 9

6. Commissioning the controller

6.1. Front view of the controller with buttons and display

Note!

If “O ” appears in the display, the controller has been switched off. Switch the controller back on by

pressing and holding the button for at least 5 seconds. As soon as the start display appears,

the controller has been reactivated. In order to switch off the controller, press and hold the

button for another 5 seconds.

!

6.2. Structure of the start display

Please note that other symbols or values which are not pictured above can also appear in your controller’s

start display.

Commissioning the controller

:

Return to previous menu

Discard change and restore previous value

Delete input

:

Apply current setting

Open a submenu

OK

:

On the normal

level:

Select a submenu

Within a menu: Scroll

: or settings: Change value

}

+

–

esc

e

sc

esc

Page 10

7. The specialised mechanic level

The specialised mechanic level contains the settings which must be set during commissioning (possibly only

once).

To open the specialised mechanic level, press and hold the buttons and simultane-

ously for five seconds while in the normal start display.

To enter the various sublevels (E3-1 to E3-10), use the or button. Press the button to

view the sublevels’ settings.

!

Note!

Settings which deviate from the factory settings are indicated by flashing underscore lines. These

disappear if the value is set to the factory setting once more.

7.1. Structure of submenus and navigation

Several functions can be set within each submenu. These functions are numbered sequentially and marked by

the symbol N

O

. This numbering can be found in the tables regarding configuration of the system layout and

additional functions (e.g.: E3-3 / 2):

Example:

In the submenu, scroll through the individual values with the buttons and .

If you wish to change a value, press the button.

The symbol appears in the display. Change the value with the buttons and . Press the

button to apply the new value. Pressing discards the new value; the original value then reap-

pears in the display.

In a submenu, only those values possible in the selected configuration are displayed. Relays and sensors can

only be allocated if they have not already all been assigned.

To leave a menu, press the button.

= change value 65 °C = set value

The specialised mechanic level

E3-3 = number of the submenu

TCS = function’s identifier

+

–

+

–

OK

esc

+

–

N_ = number of the function

OK

+

–

OK

esc

Page 11

8. Reset of the factory setting

Open the specialised mechanic level (press and hold the buttons and simultaneously for five

seconds) and use the or button to select the sublevel E3-1. Confirm your selection with

. In the display “RES” appears. Press the button to reset the factory setting.

When the symbol appears in the display, the adjustment or the shown value can be changed.

8.1. System layout (1 collector array, 1 storage reservoir, 1 pump)

Description of the system layout:

The solar controller compares the temperature from collector

sensor 1 (TC) with the temperature from the storage reservoir

sensor 4. If the measured temperature difference exceeds the

switch-on temperature difference TDE the speed-controlled solar

pump R1 is switched on and the storage reservoir is loaded.

F1

R1

(F3)

F4

The following settings are possible in this system layout:

Level

Display

Function

Factory

setting

Range

Selection

AE

MAX

Maximum loading temperature

MAX for the storage reservoir.

70 °C

10 °C to 90 °C

AE SPA Activation/deactivation of the

storage reservoir

YES YES / no

E3-1 / 1

RES

Reset of the factory setting.

no YES / no

E3-1 / 13

SSP

Upper storage reservoir sensor

3 present, see section 5.4.

YES

YES / no

E3-2 / 1

TDE

Switch-on temperature differ-

ence between 1 and 4 (not

less than switch-off temperature

difference + 1 K).

8 K

1 K to 20 K

E3-2 / 2

TDA

Switch-off temperature differ-

ence between 1 and 4 (not

greater than switch-on tempera-

ture difference - 1 K).

4 K

1 K to 20 K

Additional functions:

See the overviews in section 5.2. Possible additional functions, section 5.3. Relay connector assignment and

section 5.4. Sensor connector assignment.

or detailed descriptions of the individual additional functions, see section 10. Setting the additional functions.

Reset of the factory setting

+

–

+

–

OK

OK

Page 12

9. Pump blockage protection

If the pumps have been deactivated for a long time, there is a risk that they will block when reactivated, due

to accumulated dirt or limescale. In order to prevent such blockages, the pumps are switched on for 10 sec-

onds at a certain time each day.

10. Setting the additional functions

!

Note!

Mark the additional functions which you have selected, as follows:

.

10.1. Additional function: low flow

In order to optimise the loading process, loading of the selected storage reservoir is only enabled once the

collector temperature TCS (which is set here) is reached. When selecting this function, it is important to ensure

that the loading pumps’ minimum speeds are set to values below 100%, i.e. that speed control is possible.

Level Display Function Factory

setting

Range Selection

E3-3 / 1 L

Activation of low-flow function.

no YES / no

E3-3 / 2

TCS

Collector temperature which

enables loading of the selected

storage reservoir.

65 °C

10 °C to 90 °C

10.2. Additional function: collector monitoring / tube function

The collector’s temperature is monitored.

If the measured temperature exceeds the value TCW (which is set here) and if the length of time defined by

the PAUS setting has passed without the solar pump operating, the solar pump is switched on for the length of

time defined by the PAN setting.

Level Display Function Factory

setting

Range Selection

E3-3 / 4

CW

Activation of the collector moni-

toring function.

no

YES / no

E3-3 / 5

TCW

Minimum collector temperature

during monitoring.

35 °C

10 °C to 90 °C

E3-3 / 6

PAN

Solar pump’s runtime.

10 sec.

10 sec. to 60 sec.

E3-3 / 7

PAUS

Solar pump’s idle time.

60 min.

10 min. to 60 min.

P

ump blockage protection

Page 13

10.3. Additional function: emergency collector switch-off

If collector temperature exceeds the maximum value NOT (which is set here) for longer than 5 minutes, the

solar pump is switched off and will not resume operation until the collector temperature has fallen below NOT -

10 K.

Level

Display Function Factory

setting

Range Selection

E3-6 / 1

NOT

Emergency collector switch-off

110 °C

90 °C to 127 °C

10.4. Additional function: collector safety

If the collector temperature exceeds the maximum value TCM (which is set here), the storage reservoir shall

be loaded until the emergency storage reservoir switch-off temperature is reached (fixed value: 90 °C).

Level

Display Function Factory

setting

Range Selection

E3-6 / 2

KS

Activation of the collector safety

function.

YES

YES / no

E3-6 / 3

TCM

Maximum temperature for

collector (above which the

collector safety function is

activated automatically).

90 °C

10 °C to 127 °C

10.5. Additional function: storage reservoir safety

If the storage reservoir temperature ( 3) exceeds the maximum storage reservoir loading temperature MAX

(which is set on the user level) by 2 K, heat is dissipated out of the storage reservoirs (e.g. into the heating

system).

Level

Display Function Factory

setting

Range Selection

E3-6 / 4

SS

Selection of relay for the storage

reservoir safety function.

0: no relay allocated (function is

not enabled)

1 to 2: relay is allocated (func-

tion is enabled)

0 0 to 2

10.6. Additional function: collector frost protection

If the collector temperature falls below the frost protection temperature of + 2 °C, the solar pump is activated

until the collector has been heated to + 5 °C by the storage reservoir water.

Level

Display Function Factory

setting

Range Selection

E3-6 / 5

S

Activation of the collector frost

protection function.

no

YES / no

Setting the additional functions

Page 14

10.7. Additional function: thermostat, e.g. for activation of the circulation pump

The sensor input and relay output are freely selectable.

Additional function

Level

Display Function Factory

setting

Range Selection

E3-7 / 1

STH

Selection of sensor for the

thermostat function. The num-

ber of any sensor which is still

free is accentuated by flashing

underscore lines.

If the selected sensor is already

assigned to another function,

the corresponding number is

displayed within brackets.

0: no sensor allocated (function

is not enabled)

1 to 4: sensor is allocated

(function is enabled)

0 0 to 4

E3-7 / 2

RTH

Allocation of relay for the ther-

mostat function. Any relay can

be selected. If the selected relay

is already assigned, the func-

tions are combined in an OR

relationship.

0 0 to 2

E3-7 / 3

ETH

Switch-on temperature for the

thermostat function.

40 °C

10 °C to 127 °C

E3-7 / 4

ATH

Switch-off temperature for the

thermostat function.

45 °C

10 °C to 127 °C

Setting the additional functions

Page 15

10.8. Additional function: temperature comparison

Sensor inputs and relay outputs can be freely selected for an additional temperature comparison function.

Level

Display Function Factory

setting

Range Selection

E3-8 / 1

VSA

Selection of the first sensor

input.

0: no sensor allocated (function

is not enabled)

1 to 4: sensor is allocated

(function is enabled)

The number of any sensor

which is still free is accentuated

by flashing underscore lines. If

the selected sensor is already

assigned to another function,

the corresponding number is

displayed within brackets.

0 0 to 4

E3-8 / 2

VSB

Selection of the second sensor

input (see above).

0 0 to 4

E3-8 / 3

VR

Selection of the relay output.

Any relay can be selected. If the

selected relay is already as-

signed, the functions are com-

bined in an OR relationship.

0 0 to 2

E3-8 / 4

VDE Switch-on temperature differ-

ence for the temperature com-

parison function (cannot be set

to less than VDA + 1 K).

2 K

1 K to 20 K

E3-8 / 5

VDA

Switch-off temperature differ-

ence for the temperature com-

parison function (cannot be set

to greater than VDE - 1 K).

1 K

1 K to 20 K

Setting the additional functions

Page 16

11. System information menu

Here, you can read information about the solar controller and define system settings.

Level Display Function Factory

setting

Range Selection

E3-10 / 1

SO

Display of software version.

E3-10 / 2

HAR

Display of hardware version.

E3-10 / 3

LP

Display of circuit board version.

E3-10 / 7

SER

Setting for service operation /

normal operation.

no: normal operation (all tem-

perature filter functions are

switched on)

YES: service operation (all

temperature filter functions are

switched off)

no

YES / no

System information menu

Page 17

12. Overview of all settings

Level Dis-

play

Function Factory

setting

Range

AE MAX Maximum loading temperature MAX for the

storage reservoir .

70 °C

10 °C to 90 °C

AE SPA Activation/deactivation of the storage reservoir YES YES / no

E3-1 / 1 RES Reset of the factory setting.

no YES / no

E3-1 / 13 SSP Upper storage reservoir sensor 3 present. YES YES / no

E3-2 / 1 TDE Switch-on temp. difference between 1 and 4. 8 K 1 K to 20 K

E3-2 / 2 TDA Switch-off temp. difference between 1 and 4.

4 K 1 K to 20 K

E3-3 / 1 L Activation of low-flow function. no YES / no

E3-3 / 2 TCS Collector temperature which enables loading of the

selected storage reservoir.

65 °C 10 °C to 90 °C

E3-3 / 4 CW Activation of the collector monitoring function. no YES / no

E3-3 / 5 TCW Minimum collector temperature during monitoring. 35 °C 10 °C to 90 °C

E3-3 / 6 PAN Solar pump’s runtime.

10 sec. 10 sec. to 60 sec.

E3-3 / 7 PAUS Solar pump’s idle time.

60 min. 10 min. to 60 min.

E3-6 / 1 NOT Emergency collector switch-off 110 °C 90 °C to 127 °C

E3-6 / 2 KS Activation of the collector safety function. YES YES / no

E3-6 / 3 TCM Maximum temperature for collector.

90 °C 10 °C to 127 °C

E3-6 / 4 SS Selection of relay for the storage reservoir safety

function.

0 0 to 2

E3-6 / 5 S Activation of the collector frost protection function. no YES / no

E3-7 / 1 STH Selection of sensor for the thermostat function. 0 0 to 4

E3-7 / 2 RTH Allocation of relay for the thermostat function. 0 0 to 2

E3-7 / 3 ETH Switch-on temperature for the thermostat function. 40 °C 10 °C to 127 °C

E3-7 / 4 ATH Switch-off temperature for the thermostat function. 45 °C 10 °C to 127 °C

E3-8 / 1 VSA Selection of the first sensor input.

0 0 to 4

E3-8 / 2 VSB Selection of the second sensor input.

0 0 to 4

E3-8 / 3 VR Selection of the relay output.

0 0 to 2

E3-8 / 4 VDE Switch-on temperature difference for the tempera-

ture comparison function.

2 K 1 K to 20 K

E3-8 / 5 VDA Switch-off temperature difference for the tempera-

ture comparison function.

1 K 1 K to 20 K

E3-10 / 1 SO Display of software version.

E3-10 / 2 HAR Display of hardware version.

E3-10 / 3 LP Display of circuit board version.

E3-10 / 7 SER Setting for service operation / normal operation.

Overview of all settings

Page 18

13. Relay test submenu “R L”

To navigate to the submenu for “manual adjustment” of relays, press or repeatedly until “REL”

appears in the display. Call up the “relay test” sublevel by pressing the button. This causes all outputs

(relays) to be switched off!

The individual relays are selected by pressing or .

Here, the relay number (1 to 2), the switching state (O , On) are displayed.

Switching the relays (numbers 1 to 2) on or off:

Once the button has been pressed to select the relay, the symbol appears. The relay’s switching

state can now be changed by pressing the buttons and . The relay’s switching state thus set will

then remain in effect until the relay test level is abandoned.

14. Faults and troubleshooting

If your controller ever ceases to function properly, please check the following points:

1. Power supply:

If anything appears in the display, there is no problem with the power supply. If nothing appears in the display,

please check the mains voltage and the device fuse.

2. Sensors and sensor cables:

If realistic temperatures are shown in the display (normal display and information level), there is no problem

with the sensors or sensor cables. “H °C” appears in the event of a sensor interrupt and “L °C” in the event of

a sensor short circuit.

If the displayed temperatures are unrealistic, you can use an ohmmeter to check that the resistance values

correspond to those in the following table:

Pt1000 temperature sensor resistance table

-20 °C

922 ohms 20 °C

1078 ohms 60 °C

1232 ohms 100 °C

1385 ohms

-10 °C

961 ohms 30 °C

1117 ohms 70 °C

1271 ohms 110 °C

1423 ohms

0 °C

1000 ohms 40 °C

1155 ohms 80 °C

1309 ohms 120 °C

1461 ohms

10 °C

1039 ohms 50 °C

1194 ohms 90 °C

1347 ohms 130 °C

1498 ohms

3. Switching output:

If the solar controller does not switch on the appropriate loading pump, please check the relay output by

means of the relay test submenu.

If it is not possible to remove the fault by means of the points mentioned above, the solar controller should be

replaced.

DANG R

Danger of electrocution!

The heating controller is to be assembled, electrically installed, commissioned, inspected and

repaired by trained, competent and authorised persons (qualified electricians as per DIN VDE

1000-10 and BGV A3) only!

Observe all applicable guidelines and regulations of the local electricity supplier!

Before beginning installation or repair work on electrical equipment, always ensure complete

disconnection from the mains and secure against reactivation!

Do not work on live parts!

Relay test submenu “R L”

+

–

OK

+

–

OK

+

–

Page 19

Notes:

Page 20

The descriptions, performance specifications and graphics in this ma

n-

ual are non-binding. Subject to technical alterations. This manual may

not be duplicated, distributed, altered, passed on, translated into

another language or used in any other way, without the express permis-

sion of the manufacturer. The content of this manual has been carefully

checked. Nevertheless, the manufacturer cannot be held liable for any

errors in this manual. Furthermore, if this commissioning manual or the

operating manual is not adhered to, or is only partly adhered to, the

manufacturer assumes no liability for any resulting damage.

Art-Nr: 14-03263-01/11

Table of contents

Other meibes Controllers manuals

Popular Controllers manuals by other brands

Johnson Controls

Johnson Controls P77 Series manual

Johnson Controls

Johnson Controls F4-CV Series installation guide

Weidmüller

Weidmüller WEIDOS-MKR1010-A1 manual

Johnson Controls

Johnson Controls tyco iSTAR Ultra Installation and configuration guide

Lincoln Electric

Lincoln Electric POWER FEED IM849 Operator's manual

Prolon

Prolon VC2000 Installation and startup guide

Mitsubishi Electric

Mitsubishi Electric AG-150A Instruction book

Allen-Bradley

Allen-Bradley 1769 CompactLogix user manual

Chargery

Chargery BMS24T Series manual

ECKELMANN

ECKELMANN VS 300 operating instructions

Douglas Dynamics

Douglas Dynamics Western 85200 operating instructions

Simex

Simex PUR-94 user manual