MEP Max Motion Installation and operating instructions

BUYER’S GUIDE

INSTALLATION & MAINTENANCE INSTRUCTIONS

AC INDUCTION MOTORS

***

Installation & Maintenance Instruction Manual

MAX MOTION Induction Motors

This INSTRUCTION MANUAL has been prepared for personnel authorized to install, operate

and maintain MAX MOTION three phase induction motor SAFELY and PROPERLY.

RECEIVING INSPECTION and HANDLING

1. Immediately check the motor for external damage that may have occurred during

shipment and if any is found, inform the nearest representative of MAX MOTION

without delay.

2. Check the nameplate data, specially the voltage and winding connection.

3. Turn shaft by to check it turns freely.

4. WARNING! The motor should be lifted by the lifting eyebolts or the lugs. Those are

provided for lifting the motor only and must not be used for lifting other equipment

that may be attached to the motor. All eyebolts must be fully tightened. When lifting

the motor be careful not to damage other parts such as shaft extension, fan cover, fan,

windings etc..

WARNING !!!! The following safety precautions must be observed.

1. Rotating parts of motor and high voltage connections can cause serious even fatal

injury if improperly installed, operated or maintained. Responsible personnel should

be familiar with NEMA MG2 (Safety Standards for Construction and Guide

Selection, Installation and Use of Electric Motors and Generators), the National

Electrical Code (NEC) and all local safety regulations.

2. When servicing, all power sources to the motor and accessory devices should be de-

energized and disconnected and all rotating parts should be inactive..

3. Lifting devices, when supplied are intended for lifting the motor only. When two

devices are supplied with the motor, a dual chain must be used.

4. Suitable protection must be used when working near machinery with high noise

levels.

5. Safety means and protection MUST NOT be by-passed or rendered inoperative.

6. The electric motor frame must be grounded in accordance with National Electrical

Code and the local applicable regulations.

7. A suitable enclosure should be provided to prevent access to the motor by other than

authorized personnel. Extra caution should be observed around motors that are

automatically controlled or have automatic reset relays; the motor could restart

unexpectedly and cause serious injuries.

8. When belts are used to drive the equipment, belt guard should be used to prevent

injuries that could be caused by belts breaking.

9. Shaft must be free to turn before motor is started.

INSTALLATION / MOUNTING

The motor foundation must be sufficiently rigid as to minimize vibration and maintain alignment

between the motor and the driven equipment. Motors are dynamically balanced at the factory to

NEMA Standards on Vibration Limit. However, vibration at the motor and the driven equipment

can occur if the base they are mounted on is not rigid enough. To minimize vibration, a strong

and rigid base must be provided for the motor and driven equipment.

Only trained personnel should perform installation of the motor.

Direct Drive application : Direct connected motors may be coupled to the load through flexible

coupling. Coupling half should not be installed by hammering, unless the opposite end of shaft

can be backed up to prevent damages to the bearings. Accurate mechanical lineup is essential for

successful operation. Align shafts accurately. If reverse rotation can cause damage to the driven

equipment, CHECK ROTATION before connecting the motor to the load. See Start Up.

V-belt Drive application :

1. Mount motor sheave close to the bearing housing.

2. Allow sufficient clearance for rotor endplay.

3. The sheave diameter should not be less than NEMA recommended values. See

NEMA MG-1-14.42.

4. Align sheaves carefully. Tighten belt only enough to prevent slippage.

Condensation Drain Holes: On MaxMotion Cast Iron TEFC motors, Condensation drain holes

are located at each end of the stator housing where the feet are located, and on the face of output

flanged motors (TC, JM, JP). The drain hole plugs inserted at the factory must be removed to

prevent condensation water build up. On horizontal foot mounted F1 or F2 installations, remove

plugs located at each end of stator. In vertical output shaft down flange mounted installations,

remove plugs located on face of output flange.

Foot mounted motor : Motor should be installed on a rigid foundation to prevent excessive

vibration and should be fasten securely to a base with maximum size bolts.

Flanged motor : All fits are accurately machined to match with the driven equipment. Matching

surfaces should be free from dirt or burrs and solidly engaged. The complete assembly should

turn freely without stressing shaft and bearings from misalignment and thrust.

LOCATION

1. Drip-proof motors are intended for use where atmosphere is relatively clean, dry and

non-corrosive. Keep windings clean with a soft brush, cloth or vacuum.

2. Totally-enclosed motors may be installed where dirt, moisture and corrosion are

present. NOTE : in all cases, NO surrounding structure should obstruct normal flow

of ventilating air through or over motor.

3. WARNING! DO NOT INSTALL General Purpose motors where hazardous,

inflammable or combustible vapors or dust are present, due to the possibility of

explosions or fire and damage to property or injury to personnel.

ELECTRICAL CONNECTIONS

1. connect motor to correct power supply according to nameplate.

2. Motor and control wiring, overload protection and grounding should be done in

accordance with the National Electric Code and local regulations.

3. Identify motor auxiliary device such as space heater or temperature sensors. These

should have their own isolated circuits insulated separate from the motor power

cables.

START UP

1. WARNING! The insulation resistance of the motor winding should be checked before

energizing the motor.

2. It is recommended that the motor be initially started uncoupled from load. Check

direction of rotation. If rotation must be changed, ALLOW THE MOTOR TO COME

TO A COMPLETE STOP, and interchange any two leads on a three phase motor. Fan

on fan-cooled motors that have directional rotation nameplates must be reversed on

the mounting shaft if the rotation is changed.

3. Connect load. The motor should start quickly and run smoothly, if not, shut off the

power at once. Recheck the assembly including all connections before restarting.

4. If excessive vibration is noted, check for loose mounting bolts, a motor supports

structure that is too flexible, or transmitted vibration from adjacent machinery.

Periodic vibration checks should be made as foundation settle.

5. Operate under load condition for a short period of time. Check operating current

against nameplate.

6. On frame 320T and higher, remove shaft support sheath from the drive end of the

motor before energizing.

LUBRICATION OF BALL OR ROLLER BEARINGS

Grease lubricated bearings as supplied, are adequate for a long period of operation without

relubrication. A good maintenance schedule for regreasing will vary depending on motor size,

speed, duty and environment.

FREQUENCY OR RELUBRICATION

The following table suggests relubrication intervals for motor on normal, steady running, light

duty indoor load in relatively clean atmosphere at 40C (104F) ambient temperature or less.

Enclosure Insulation Frames 143-215T Frames 254T +

TEFC F NOT GREASABLE 6 months

Frame sizes 143 through 215T, inclusive have permanently lubricated sealed bearings.

NOTE :

Frequency shown above should be reduced by:

1/2 For motors above 1800 RPM

1/2 For Heavy-Duty, Dusty locations.

1/3 For Severe-Duty, High Vibration & Shock

TYPE OF GREASE

Use Polyrex EM Polyurea grease or equivalent unless a special grease is specified on the

nameplate.

PROCEDURE FOR RELUBRICATION

When regreasing, stop motor, remove outlet plug and add amount of grease per reference table

below, with hand level gun only. Discontinue at once if grease appears at outlet plug. This may

occur before specified amount is used.

Run for about ten minutes before replacing outlet plug.

Volume Reference Table:

Shaft diameter (at face of bearing) Grease amount (ounce)

0.8in to 1.2in 1.5g to 2.8g (0.05 to 0.1)

1.4in to 1.8in 3.1g to 5.7g (0.11 to 0.2)

2.0in to 2.2in 12.3g to 17g (0.43 to 0.6)

2.4in to 3.3in 32.8g to 45g (1.16 to 1.6)

Caution : over-greasing is a major cause of bearing and motor failure. Make sure that dirt and

contaminants are not introduced when adding grease.

INVERTER DUTY APPLICATION

Please refer your application to MAX MOTION or its nearest distributor for instruction.

STORAGE

If the motor is not packaged for long-term storage and is not to be put into service immediately,

certain precautions should be taken to protect it. If at all possible, place the motor under cover in

a clean and dry location.

During storage, the winding should be protected from excessive moisture absortion by some safe

and reliable method of heating. Space heaters, if supplied, may be used for this purpose. The

temperature of the winding should be always maintained a few degrees above the temperature of

the surrounding air.

Montréal:

10500 Boul. du Golf, Anjou, P. Qué., H1J 2Y7

TÉL. : (514) 352-1229 ou (800) 361-2347

Télécopie : (514) 352-7803, Courriel : inf[email protected]

Toronto:

2831 Bristol Circle, Unit 3, Oakville, Ont, L6H 6X5

Tel.: (905) 812-7788 Toll Free:1-877-812-7788

Fax: (905) 829-8155 Email: information@mep.ca

Table of contents

Other MEP Engine manuals

Popular Engine manuals by other brands

GOSS Power Products

GOSS Power Products AP156F operating instructions

Simu

Simu T5 E Hz instructions

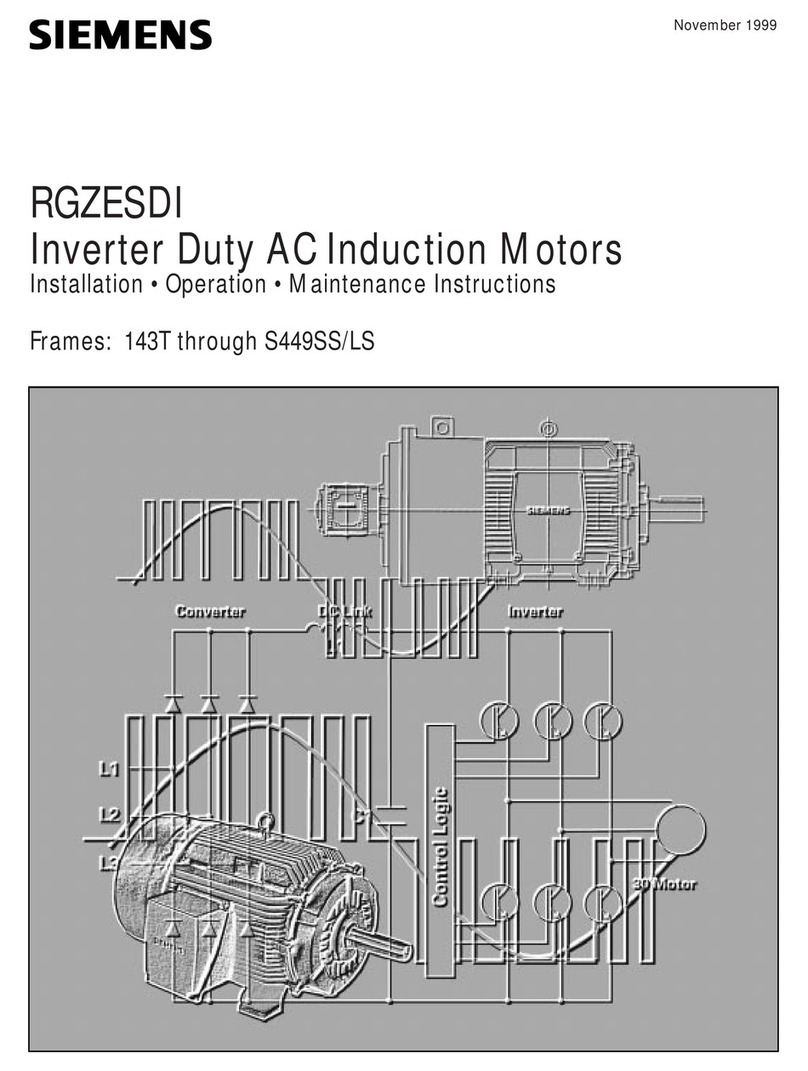

Siemens

Siemens RGZESDI Installation and operation manual

LinMot

LinMot P10-70 installation guide

TECHTOP

TECHTOP MS1/MS2 Series Installation, operation, maintenance and safety manual

Konect

Konect FUSION instruction manual

LCI

LCI Above Floor Slide-out owner's manual

Siemens

Siemens SIMOTICS FD 1LP1 operating instructions

SOMFY

SOMFY Tilt Only 50 RTS Central Pack instructions

Briggs & Stratton

Briggs & Stratton 120000 Operating & maintenance instructions

GGP ITALY SPA

GGP ITALY SPA SV200 Operator's manual

Yanmar

Yanmar 6LP-DTE Service manual