3

The customer is responsible for any squeal related problems due to pad

selection.

APPLICATION DISCLAMER

Most 17” wheels will clear the outer diameter of the caliper of the 332mm kit and most 18” wheels

will clear the 355mm kit. However, the more critical clearance is the gap between the spokes of the

wheel and the face of the caliper. Do not assume a 19, 20 or even 24 inch wheel will clear the face

of the caliper. A minimum distance of 60.3 mm, measured from the rotor face to the inside face of

the wheel spokes is needed for the 332mm kit and 60.3 mm for the 355mm kit. We recommend at

least 2mm of additional clearance. See the Brake Outline Drawing page on our website for more

specic measurements at www.stoptech.com.

Final tment of the wheel to the caliper is the responsibility of the customer.

Wheel Spacers

Wheel spacers can provide extra clearance to the outer face of the caliper. This will also space out

the entire wheel, widening the track width of the vehicle. Fender clearances should be checked on

lowered cars, and longer lug studs or wheel bolts are usually required. Note: The Wheel Industry

Council has issued guidelines advising wheel spacers not be used.

It is the responsibility of the customer to insure wheel spacers are properly

specied and installed.

Brake Vibration - THIS IS IMPORTANT!

The most common cause of brake vibration is improper bedding of pads and rotors or improper pad

selection for the specic driving environment. Rotor runout may also cause vibration, but precision

manufacturing and inspection typically means runout is not an issue. Double disc grinding insures

the rotor runout is within +/- 0.002” when installed on our aluminum hat and controls thickness

variation within 0.0003”. Under the most extreme conditions, any rotor may warp, but uneven pad

deposition is a more typical vibration cause. If the system is not properly bedded in, or street pads

are run on an open track, uneven pad deposits will occur causing an ever worsening vibration. Fail-

ure to immediately address a pad deposition/vibration issue may lead to permanent damage to the

rotors. Please read and understand the bed-in procedures included with this manual. If you have

any questions, please contact the StopTech Customer Service Department for assistance.

STOPTECH is not liable for vibrations caused by extreme usage or improper break-in

procedures.

Brake Noise

Certain brake pad compounds make more noise than others. Proper anti-squeal shim plates between

the caliper pistons and backing plate of the pad help reduce the problem. Anti-squeal lubricants

are also available to reduce some of the noise. The reality is, performance pads are more prone to

brake squeal.

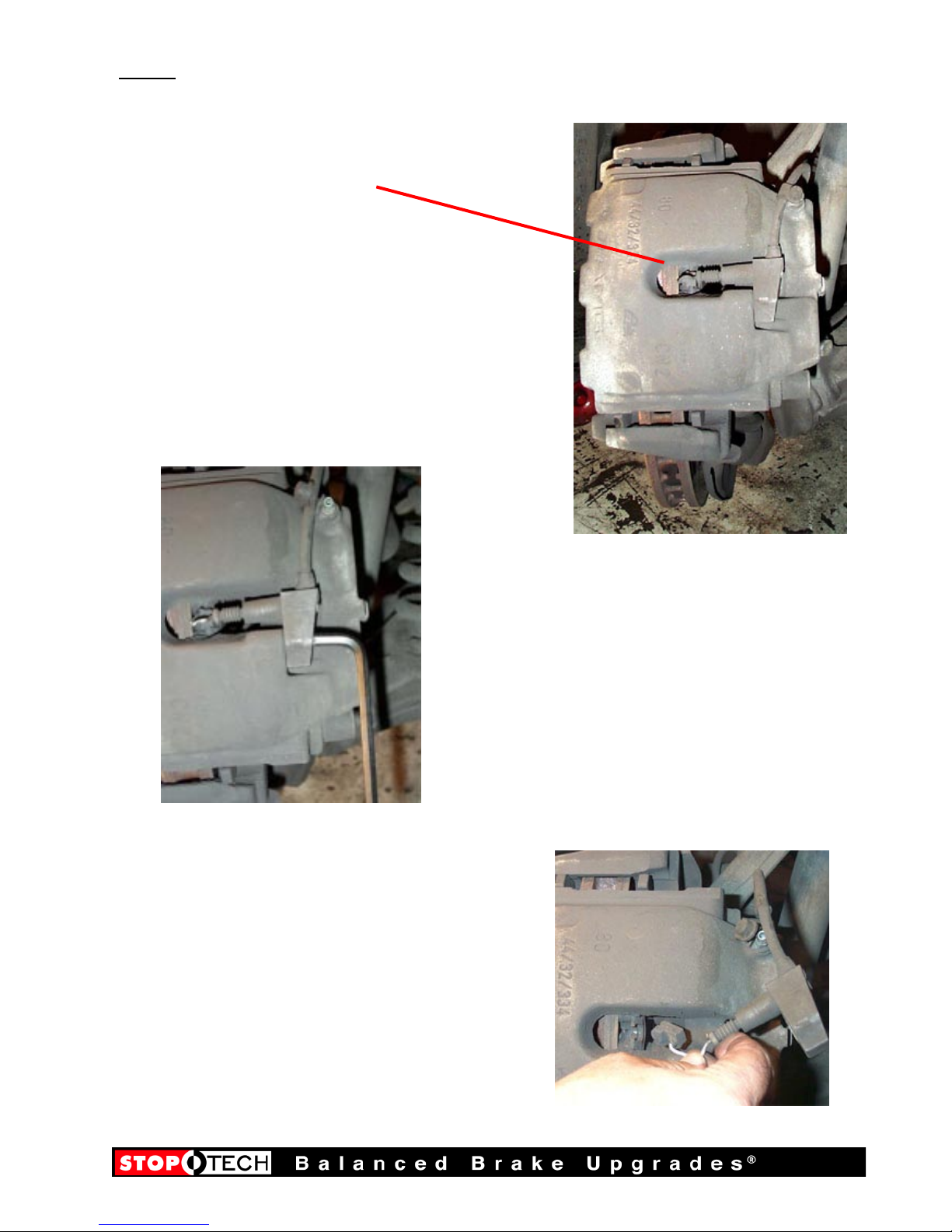

Caliper Clearance