ADDITIONAL INFORMATION ADDITIONAL INFORMATION

(Continued)

SPECIFICATIONS

Use extreme caution when operating in

• Cooling System - Inspect all hoses f shallow water or where underwater ob-

damage and deterioration; check all ho~ jects are known to be pre~~nt. Use

clamps for adequate tightness. extreme care to prevent stnklng sub-

merged objects while operating in RE-

VERSE. No impact protection is provided

in REVERSE.

17

• Before recovery. contact an Authorized

MerCruiser Dealer.

• After recovery, immediate service by

an Authorized MerCruiser Dealer is

required to prevent serious damage to

power package.

ATTENTION REQUIRED AFTER SUB-

MERSION

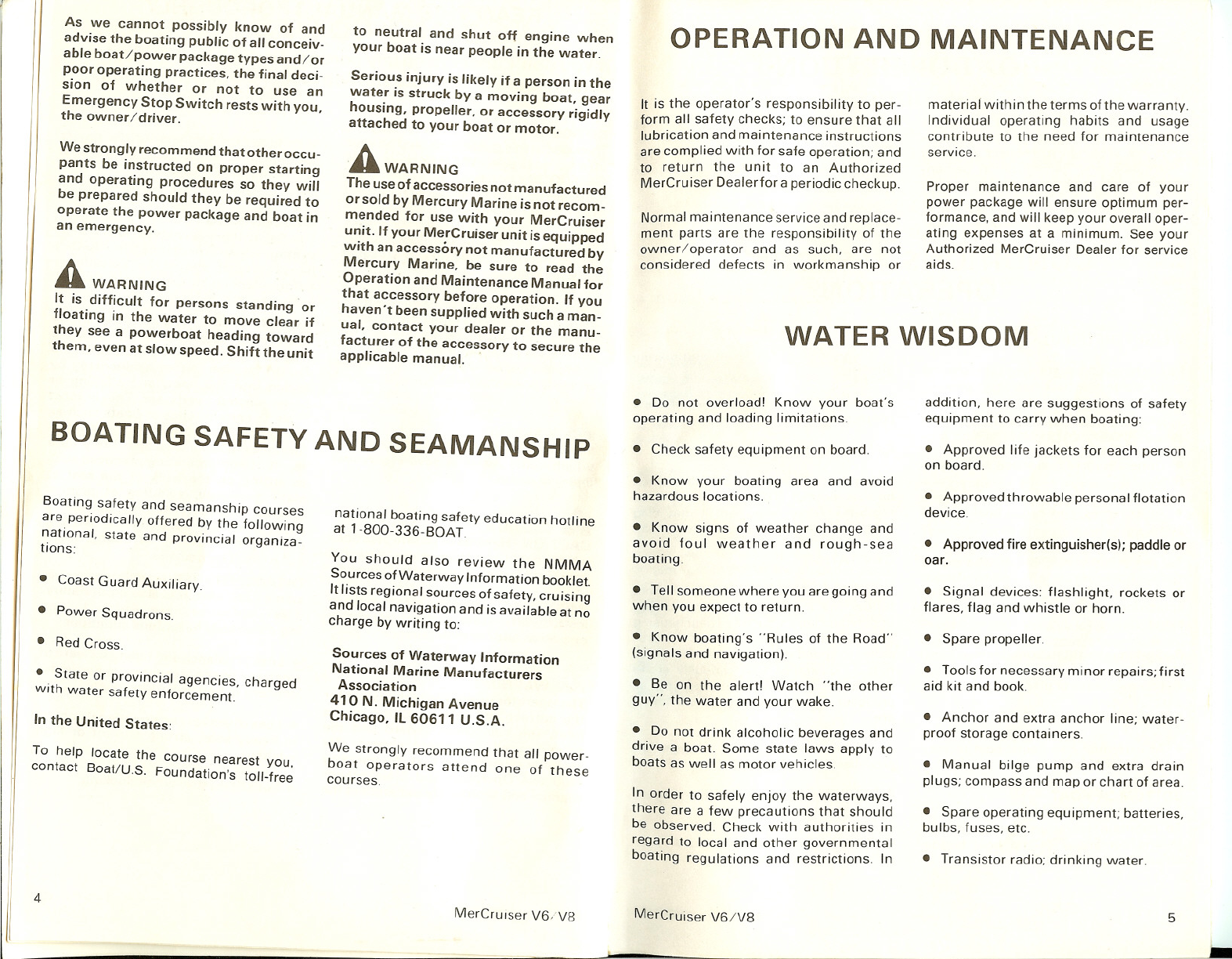

Boat can be trailered with drive unit in up

or down position. Adequate road clearance

is required between road and gear housing

skeg when trailering with drive unit in

down position.

TRAllERING BOAT

If adequate road clearance is a problem.

place drive unit in full trailer position and

support with an optional trailer kit which

is available from your Authorized Mer-

Cruiser Dealer.

• Starting and operating difficulties.

• Fuel permeation through flexible fuel

lines.

• Wear and damage of internal engine

parts.

The adverse effects of alcohol are more

severe with methyl alcohol (methanol)

and are worse with increasing alcohol

content.

Some of these adverse effects are due to

the tendency of gasolines containing

alcohol to absorb moisture from the air,

resulting in a phase of water and alcohol

separating from the gasoline in the fuel

tank.

MerCruiser V6/V8

If drive unit should strike a submerged

object, stop engine as soon as possible

and inspect drive unit for damage. If

damage is present or suspected, boat

should be taken to an Authorized Mer-

Cruiser Dealer for thorough inspection

and necessary repair. Operating a

damaged drive unit could cause additional

damage to other parts of drive unit, or

could affect control of boat. If continued

running is necessary, do so at greatly

reduced speeds.

IMPORTANT: Impact protection system

cannot be designed to ensure total pro-

tection from impact damage under all

conditions.

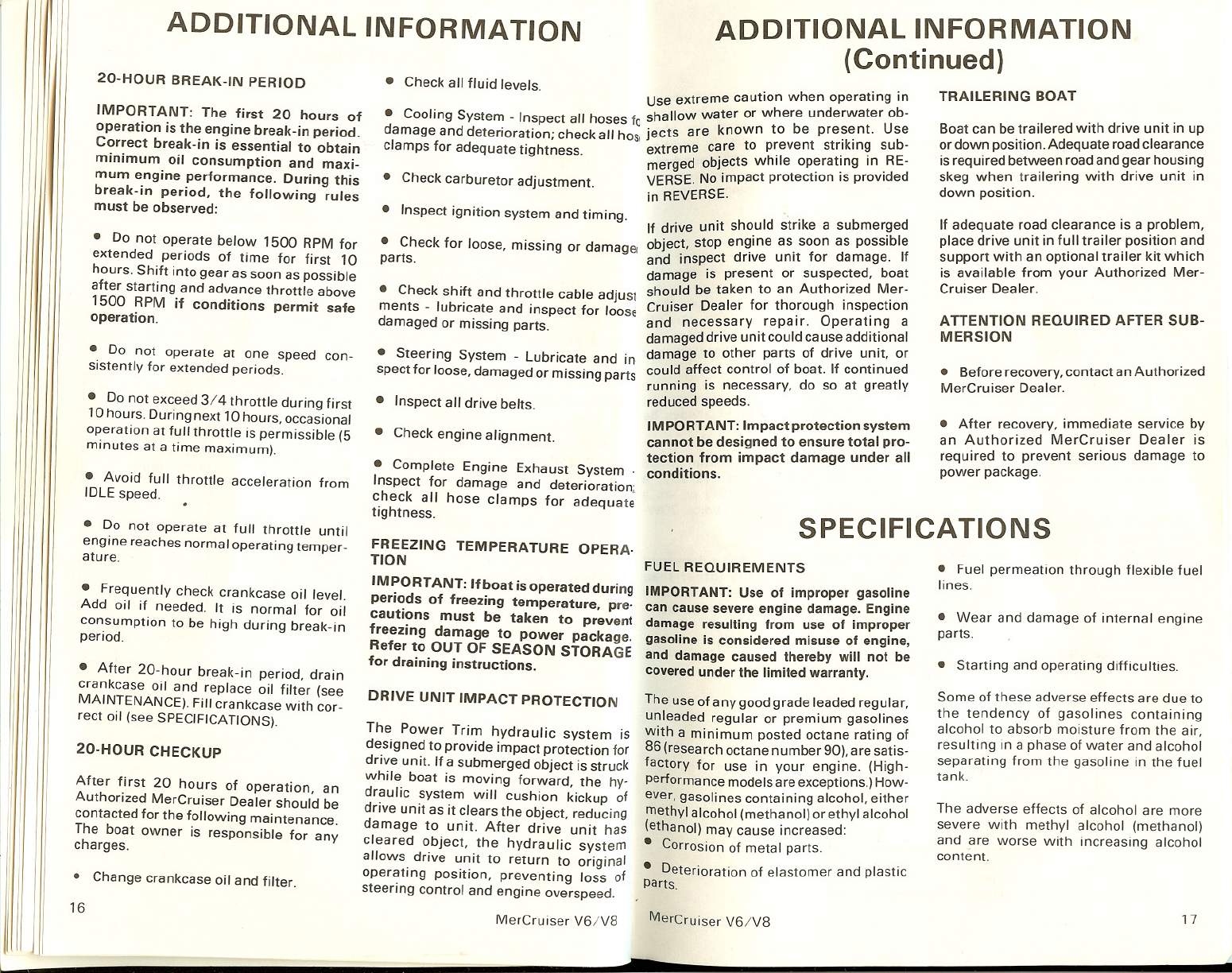

FUEL REQUIREMENTS

IMPORTANT: Use of improper gasoline

can cause severe engine damage. Engine

damage resulting from use of improper

gasoline is considered misuse of engine,

and damage caused thereby will not be

covered under the limited warranty.

The use of any good grade leaded regular,

unleaded regular or premium gasolines

with a minimum posted octane rating of

86 (research octane number 90), are satis-

factory for use in your engine. (High-

performance models are exceptions.) How-

ever, gasolines containing alcohol, either

methyl alcohol (methanol) or ethyl alcohol

(ethanol) may cause increased:

• Corrosion of metal parts.

• Deterioration of elastomer and plastic

parts.

• Check all fluid levels.

• Check carburetor adjustment.

• Inspect ignition system and timing.

• Check for loose, missing or damagel

parts.

• Check shift and throttle cable adjust

ments - lubricate and inspect for loose

damaged or missing parts.

• Steering System - Lubricate and in

spect for loose, damaged or missing parts

• Inspect all drive belts.

• Check engine alignment.

• Complete Engine Exhaust System .

Inspect for damage and deterioration;

check all hose clamps for adequate

tightness.

FREEZING TEMPERATURE OPERA-

TION

IMPORTANT: If boat is operated during

periods of freezing temperature. pre.

cautions must be taken to prevent

freezing damage to power package.

Refer to OUT OF SEASON STORAGE

for draining instructions.

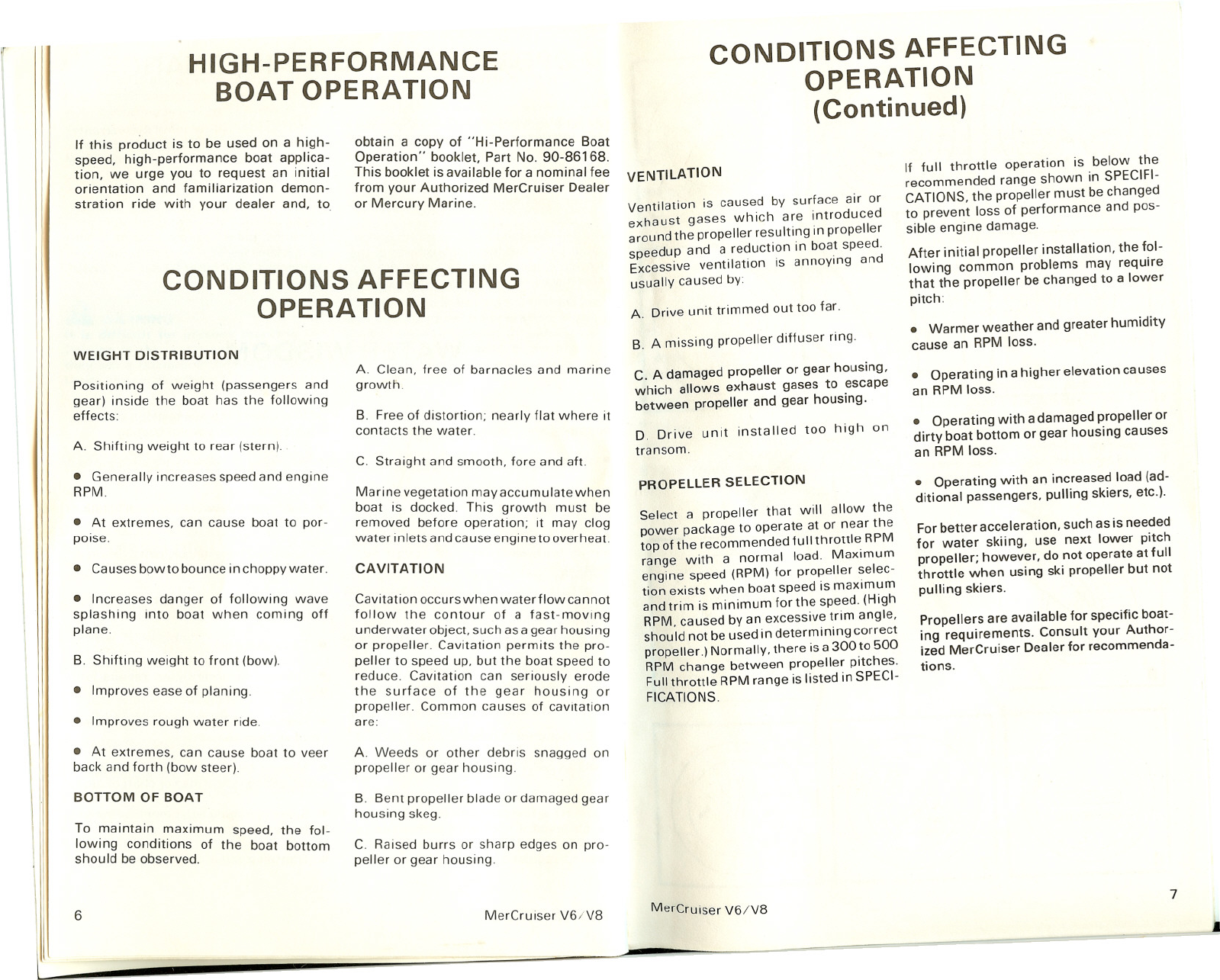

DRIVE UNIT IMPACT PROTECTION

The Power Trim hydraulic system is

designed to provide impact protection for

drive unit. If a submerged object is struck

while boat is moving forward, the hy-

draulic system will cushion kickup of

drive unit as it clears the object, reducing

damage to unit. After drive unit has

cleared object, the hydraulic system

allows drive unit to return to original

operating position, preventing loss of

steering control and engine overspeed.

MerCruiser V6/V8

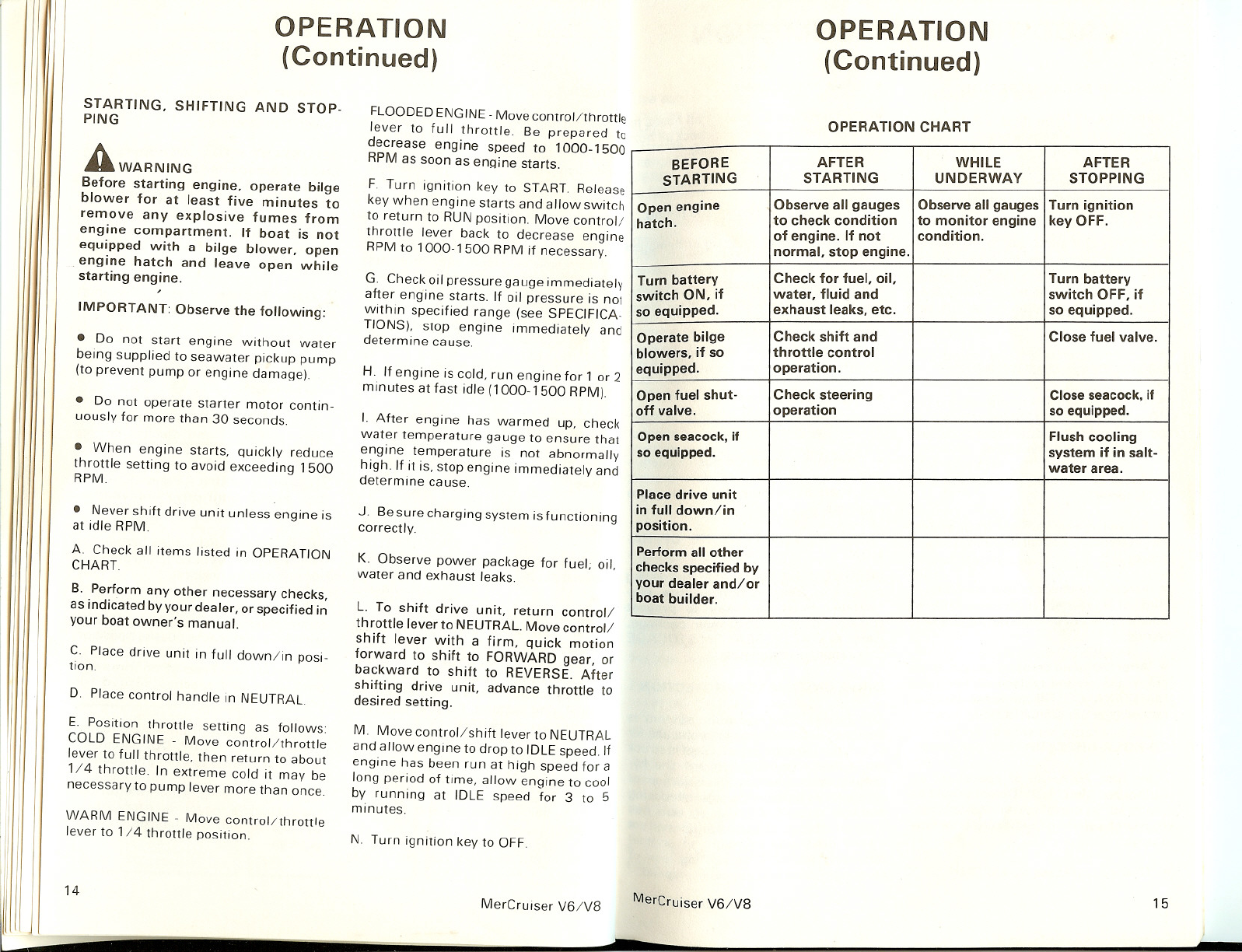

20-HOUR BREAK-IN PERIOD

IMPORTANT: The first 20 hours of

operation is the engine break-in period.

Correct break-in is essential to obtain

minimum oil consumption and maxi-

mum engine performance. During this

break-in period. the following rules

must be observed:

• Do not operate below 1500 RPM for

extended periods of time for first 10

hours. Shift into gear as soon as possible

after starting and advance throttle above

1500 RPM if conditions permit safe

operation.

• Do not operate at one speed con-

sistently for extended periods.

• Do not exceed 3/4 throttle during first

10 hours. During next 10 hours. occasional

operation at full throttle is permissible (5

minutes at a time maximum).

• Avoid full throttle acceleration from

IDLE speed.

• Do not operate at full throttle until

engine reaches normal operating temper-

ature.

• Frequently check crankcase oil level.

Add oil if needed. It is normal for oil

consumption to be high during break-in

period.

• After 20-hour break-in period, drain

crankcase oil and replace oil filter (see

MAINTENANCE). Fill crankcase with cor-

rect oil (see SPECIFICATIONS).

20-HOUR CHECKUP

After first 20 hours of operation, an

Authorized MerCruiser Dealer should be

contacted for the fOllowing maintenance.

The boat owner is responsible for any

charges.

• Change crankcase oil and filter.

16