Mercury/Mariner 25 MARATHON User manual

MODELS

United States 0G044027 and Above. . . . . . .

Belgium 09807909 and Above. . . . . . . . . . .

With Serial Numbers

SERVICE

MANUAL

20 JET 20 25

Mercury/Mariner

25 MARATHON 25 SEAPRO

Printed in U.S.A. 1998, Mercury Marine 90-826883R2 JUNE 1998

90-826883R2 JUNE 1998 Page i

Notice

Throughoutthispublication,“Dangers”,“Warnings”and“Cautions”(accompaniedbytheIn-

ternationalHAZARDSymbol )areusedtoalertthemechanictospecialinstructionscon-

cerning a particular service or operation that may be hazardous if performed incorrectly or

carelessly. OBSERVE THEM CAREFULLY!

These“SafetyAlerts”alonecannoteliminatethehazardsthattheysignal.Strictcompliance

tothesespecialinstructionswhenperformingtheservice,plus“CommonSense”operation,

are major accident prevention measures.

DANGER

DANGER- Immediatehazards whichWILL resultin severepersonal injuryor death.

WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal in-

jury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with the servicing procedures of these prod-

ucts, or like or similar products manufactured and marketed by Mercury Marine, that they

have been trained in the recommended servicing procedures of these products which in-

cludestheuseofmechanics’commonhandtoolsandthespecialMercuryMarineorrecom-

mended tools from other suppliers.

We could not possibly know of and advise the service trade of all conceivable procedures

by which a service might be performed and of the possible hazards and/or results of each

method. We have not undertaken any such wide evaluation. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completelysatisfyhimselfthatneitherhis nor the products safety will be endangered by the

service procedure selected.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

Itshouldbekeptinmind,whileworkingontheproduct,thattheelectricalsystemandignition

systemarecapableofviolentanddamagingshortcircuitsorsevereelectricalshocks.When

performing any work where electrical terminals could possibly be grounded or touched by

the mechanic, the battery cables should be disconnected at the battery.

Anytimetheintakeorexhaustopeningsareexposedduringservicetheyshouldbecovered

toprotectagainstaccidentalentranceofforeignmaterialwhichcouldenterthecylindersand

cause extensive internal damage when the engine is started.

Page ii 90-826883R2 JUNE 1998

Itisimportanttonote,duringanymaintenanceprocedurereplacementfastenersmusthave

thesamemeasurementsandstrengthasthoseremoved.Numbersontheheadsofthemet-

ricbolts and on the surfaces of metric nuts indicatetheirstrength.Americanbolts use radial

lines for this purpose, while most American nuts do not have strength markings. Mis-

matched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury.Therefore,fastenersremovedshouldbesavedforreuseinthesamelocationswhen-

ever possible. Where the fasteners are not satisfactory for re-use, care should be taken to

select a replacement that matches the original.

Cleanliness and Care of Outboard Motor

A marine power product is a combination of many machined, honed, polished and lapped

surfaces with tolerances that are measured in the ten thousands of an inch/mm. When any

product component is serviced, care and cleanliness are important. Throughout this manu-

al, it should be understood that proper cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is considered standard shop practice

even if not specifically stated.

Whenever components are removed for service, they should be retained in order. At the

timeofinstallation, they should be installed in the same locations and withthesame mating

surfaces as when removed.

Personnelshouldnot work on or under an outboard which is suspended. Outboards should

be attached to work stands, or lowered to ground as soon as possible.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products de-

scribed in this manual.

Page Numbering

Twonumbergroupsappearatthebottomofeachpage.Theexamplebelowisself-explana-

tory.

EXAMPLE:

90-826883 R2 JUNE 1998 6A-7

Revision No. 2

Month of Printing

Year of Printing

Section Number

Part of Section Letter

Page Number

1

2

3

4

5

6

7

8

9

Important Information

Electrical

Fuel System

Powerhead

Mid-Section

Lower Unit

Attachment/Control Linkage

Manual Starter

90-826883R2 JUNE 1998 Page iii

Service Manual Outline

Section 1 - Important Information

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Carburetor/Fuel Pump

B - Emissions

Section 4 - Powerhead

Section 5 - Mid-Section

Section 6 - Lower Unit

A - Gear Housing

B - Jet Drive

Section 7 - Attachments/Control Linkage

A - Throttle/Shift Linkage

B - Tiller Handle

C - Side Shift

Section 8 - Manual Starter

1

A

SPECIFICATIONS

90-826883R2 JUNE 1998 Page 1A-1

IMPORTANT INFORMATION

Section 1A - Specifications

Table of Contents

Master Specifications 1A-2. . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

Page 1A-2 90-826883R2 JUNE 1998

Master Specifications

Model 15XD/20 Jet /20/25

HORSEPOWER

(KW) Model 20 Jet

Model 20

Model 25

20 (14.9)

20 (14.9

25 (18.7)

OUTBOARD

WEIGHT 15 in. (38 cm)

20 in. (51 cm)

20 Jet

114 lbs - 52 kg

117 lbs - 53 kg

124 lbs - 56 kg

CYLINDER

BLOCK Type

Displacement Two Cylinder - Two Cycle

24.4 cu. in. (400 cc)

STROKE Length 2.362 in. (60 mm)

CYLINDER

BORE Diameter (Standard)

Taper/Out of Round Maximum*

Bore Type:

S/N 0G202749 and Below

S/N 0G202750 and Above

2.562 in. (65.01 mm)

0.003 in. (0.08 mm)*

Chrome

Mercosil

CRANK SHAFT Top Main Bearing Journal

Center Main Bearing Journal

Bottom Main Bearing Journal

Connecting Rod Journal

End Play

1.251 in. (31.77 mm)

1.000 in. (25.40 mm)

1.125 in. (28.58 mm)

0.883 in. (22.43 mm)

0.004-0.019 (0.10-0.64 mm)

CONNECTING

ROD Piston Pin End (I.D.)

Crankpin End (I.D.) 0.897 in. (22.78 mm)

1.196 in. (30.38 mm)

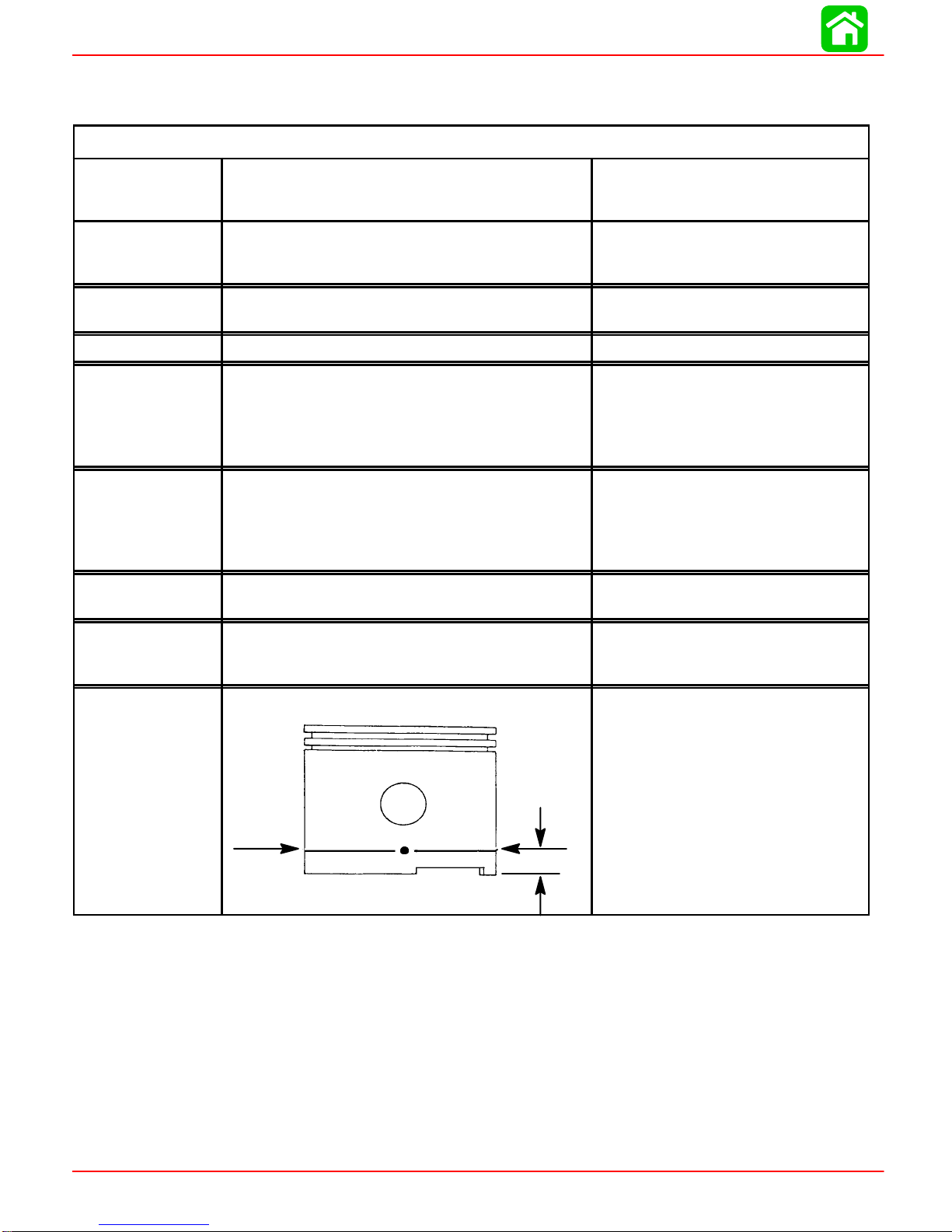

PISTON Piston Type

O.D. at Skirt (Standard)

Ring End Gap

Aluminum

2.5583 - 2.5593 (64.98 - 65.00)

0.011-0.025 (.28 mm - .64 mm)

PISTON DIA.

Dimension “A”

at Right Angle

(90°) to Pis-

ton Pin 0.50 in.

(12.7 mm)

2.5583 in. ±.0005 in.

(64.98 mm ±.0127 mm)Using a

micrometer, measure dimension

“A” at location shown. Dimension

“A” should be 2.5583 in. ±.0005 for

a STANDARD size piston (new) Di-

mension “A” will be 0.001 – 0.0015

less if coating is worn off piston

(used)

*Models S/N 0G202749 and Below:

NOTE: The cylinder bores are chrome and cannot be be rebored or efficiently honed.

Checkeachcylinderbore foranout-of-round “eggshaped”cylinder.Amaximumof0.003

in. (0076mm) is allowable.

*Models S/N 0G202750 and Above:

NOTE: The cylinder block is Mercosil and the cylinders can be rebored to 0.030 in. over-

sized. Check each cylinder bore for an out-of-round “egg shaped” cylinder. A maximum

of 0.003 in. (0.076mm) is allowed.

SPECIFICATIONS

90-826883R2 JUNE 1998 Page 1A-3

Master Specifications

GEAR

HOUSING Forward - Neutral - Reverse

Gear Ratio

Gearcase Capacity

Lubricant Type

Forward Gear - No. of Teeth-Type

Pinion Gear - No. of Teeth-Type

Pinion

Foreword Gear Backlash

Reverse Gear Backlash

Water Pressure @ RPM

Water Pressure With 120°Thermostat

Full Shift

2.25:1

8.8 fl.oz. (260 ml)

Quicksilver Gear Lube Premium

Blend

27

12

Not Adjustable

Not Adjustable

Not Adjustable

2-7 PSI @ 2000 RPM

0-6 PSI (SPORADIC) 2000 RPM

MID

SECTION Transom Height - Short Shaft

- Long Shaft 15 in. (38 cm)

20 in. (51 cm)

FUEL

SYSTEM Fuel Pump Type

Recommended Gasoline

Fuel Tank Capacity

Operating Fuel/Oil Ratio

Integral

Automotive Unleaded

with a Minimum Pump Posted

Octane Rating of 87

6.6 U.S. Gallons

50:1

OIL Recommended Oil (Pre-Mix @ 50:1) NMMA TC-W II or TC-W III

2-Cycle Outboard Oil

STARTING

SYSTEM Manual Start

Rope Length

Electric Start

Ampere Draw (cranking)

Recoil

66 in. (1676 mm)

12 Volt

55 amperes

CHARGING

SYSTEM Alternator Output

BLACK Stator - 2 Magnet Flywheel

(8 Pole)(4 Pulses)

RED Stator - 4 Magnet Flywheel

(10 Pole)(5 Pulses)

4 Amp. (48 Watt)

@ 6000 RPM

6 amp (72 Watt)

@ 6000 RPM

BATTERY Battery Rating 465 Marine Cranking Amps (MCA)

or 350 Cold Cranking Amps (CCA)

SPECIFICATIONS

Page 1A-4 90-826883R2 JUNE 1998

IGNITION

SYSTEM

Readings taken @

68°F (20°C).

Type

Spark Plug Type (NGK)

Spark Plug Gap

Spark Plug Hex

Firing Order

20 Jet 19941/2THRU 1998

20/25 19941/2THRU 1996

Electronic Spark Advance

Idle @ 750 ±50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Setup Timing

Stator High Speed Winding

Stator Low Speed Winding

Diode Test

Ignition Coil Resistance:

Primary

Secondary (w/o Boots)

20 Jet 1999 and Newer

20/25 1997/98 Models

Mechanical Spark Advance

Idle @ 750 ±50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Stator High Speed Winding

Stator Low Speed Winding

Diode Test

Ignition Coil Resistance:

Primary

Secondary (w/o Boots)

Trigger

Capacitor Discharge Ignition

NGK BP8H-N-10

0.040 in. (1.0 mm)

18 mm

1-2

4°±2°B.T.D.C (Not Adjustable)

1400 RPM ±250 RPM

25°±1 @5500 RPM

28°B.T.D.C. @ 3000 ±200 R.P.M.

(Set-up timing of 28°B.T.D.C. will

be retarded to 25°B.T.D.C. @

5500 R.P.M.)

100 – 180 Ω (RED – BLK)

2900 – 3500 Ω (BLUE – BLACK)

2800 – 3400 Ω (RED – BLUE)

0 Ω

850 – 1200 Ω

6°±1°B.T.D.C

1500 RPM ±200 RPM

25°±1 @5500 RPM

120 - 180 Ω(BLK/WHT - GRD)

3200 - 3800 Ω(BLK/YEL - GRD)

3100 – 3700 Ω(BLK/YEL - BLK/

WHT)

0.02 - 0.04 Ω

8000 - 11000 Ω

6500 - 8500 Ω

JET DRIVE Impeller Liner Clearance 0.030 in. (0.8 mm)

* Use NGK BPZ8H-N-10 Where Radio Frequency Interference (RFI) Suppression is

Required.

SPECIFICATIONS

90-826883R2 JUNE 1998 Page 1A-5

Master Specifications

CARBURETOR

SPECIFI-

CATIONS

Idle RPM (In Forward Gear)

Wide Open Throttle (WOT) RPM

20

25

Idle Mixture Screw

Adjustment (Preset-Turns Out)

20

20 Jet

25/25 Seapro/25 Marathon

Float Level

Main Jet Size

19941/2thru 1996

-20 (WMC-44)

-25/20 Jet (WMC-45)

-25 Seapro/Marathon (WMC-46)

-25 Seapro/Marathon (WMC-46A)

1997 and Newer

-20 Jet (WMC-45)

-20 (WMC-52)

-25 (WMC-53)

-25 Seapro/Marathon (WMC-54)

750 ±50

4500 - 5500

5000 - 6000

1 ±1/4 Turn

1-1/2 ±1/2 Turn

1-1/4 ±1/4 Turn

1.0 in. (25.4 mm)

0.044 in. (1.12 mm)

0.076 in. (1.93 mm)

0.076 in. (1.93 mm)

0.080 in. (2.03 mm)

0.076 in. (1.93 mm)

0.044 in. (1.12 mm)

0.076 in. (1.93 mm)

0.080 in. (2.03 mm)

TIMING

SPECIFI-

CATIONS

20 Jet 19941/2THRU 1998

20/25 19941/2THRU 1996

Electronic Spark Advance

Idle @ 750 ±50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

Setup Timing

20/25 1997 AND NEWER

20 Jet 1999 AND NEWER

Mechanical Spark Advance

Idle @ 750 ±50 RPM (In Forward

Gear)

Fast Idle Speed

Maximum BTDC (Running)

4°±2°B.T.D.C (Not Adjustable)

1400 RPM ±250 RPM

25°±1 @5500 RPM

28°B.T.D.C. @ 3000 ±200 R.P.M.

(Set-up timing of 28°B.T.D.C. will

be retarded to 25°B.T.D.C. @

5500 R.P.M.)

6°±1°B.T.D.C

1500 RPM ±200 RPM

25°±1 @5500 RPM

1

B

MAINTENANCE

90-826883R2 JUNE1998 Page 1B-1

IMPORTANTINFORMATION

Section 1B-Maintenance

TableofContents

Table ofContents1B-1............................

Specifications1B-1...............................

GearCase LubricantCapacity1B-1..............

SpecialTools1B-1.............................

QuicksilverLubricant/Sealant1B-2...............

Inspection and MaintenanceSchedule 1B-3..........

BeforeEachUse 1B-3.........................

AfterEachUse 1B-3...........................

Every100 HoursofUse orOnceYearly,

WhicheverOccursFirst1B-3....................

Every300 HoursofUse orThree Years1B-3......

Flushing The Cooling System1B-4.................

FuelSystem1B-5................................

FuelLine Inspection 1B-5.......................

Engine FuelFilter1B-5.........................

Corrosion ControlAnode 1B-6.....................

SparkPlug Inspection 1B-7........................

BatteryInspection 1B-7...........................

FuseReplacement-- ElectricStartRemote

ControlModels1B-8..............................

Lubrication Points1B-8...........................

GearCase Lubrication 1B-10......................

GearCase LubricantCapacity1B-10.............

Draining GearCase 1B-10......................

Draining GearCase 1B-11......................

Checking LubricantLeveland Refilling

GearCase 1B-11..............................

Storage Preparations1B-12.......................

FuelSystem1B-12............................

Protecting ExternalEngine Components1B-12....

Protecting InternalEngine Components1B-12.....

GearCase 1B-13..............................

Positioning OutboardforStorage 1B-13..........

BatteryStorage 1B-13.........................

Specifications

GearCase LubricantCapacity

Gear Case Ratio Capacity

2.25:1 8.8fl.oz.(260.0ml)

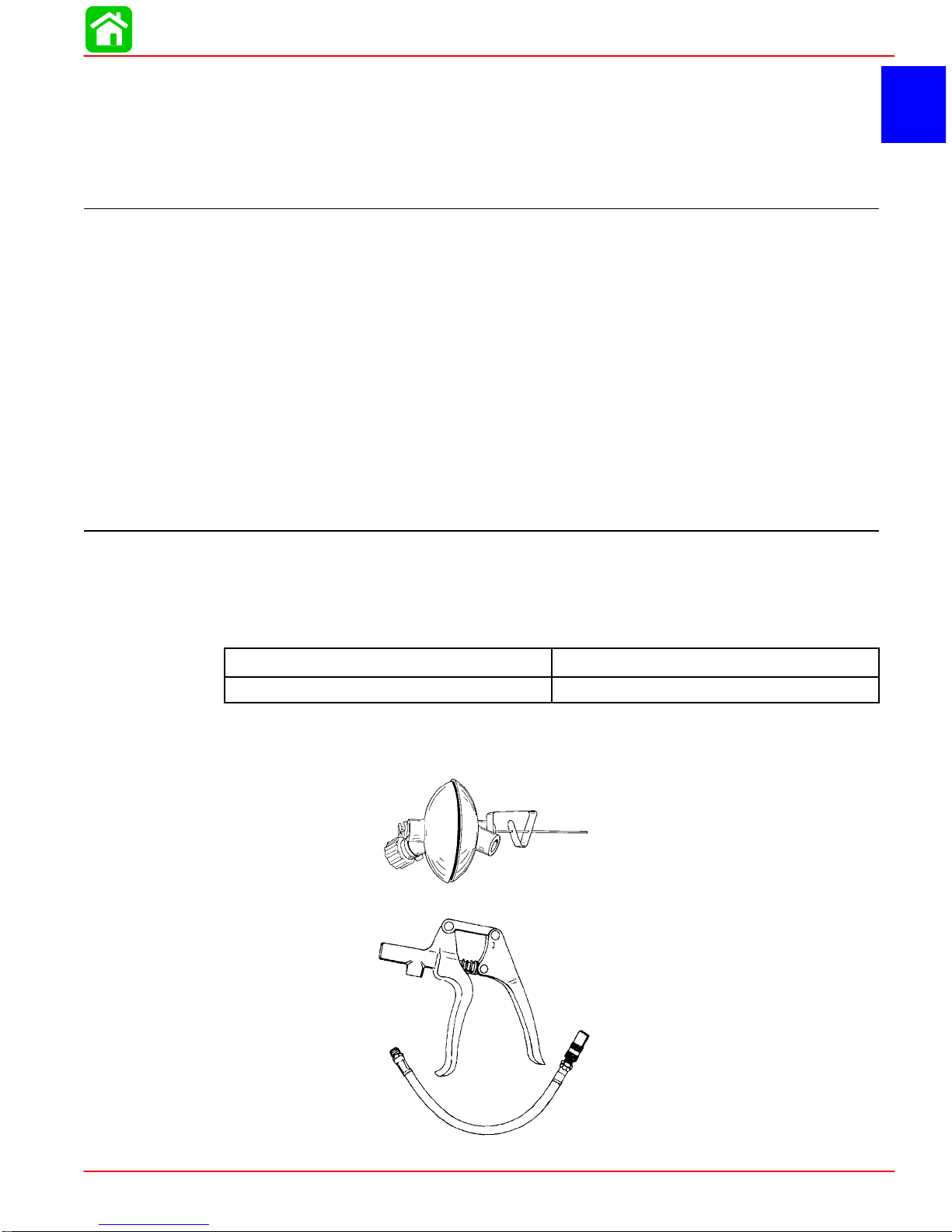

SpecialTools

1.Flushing Attachment44357A2

2.GreaseGun 91-37299A1

MAINTENANCE

Page 1B-2 90-826883R2 JUNE1998

QuicksilverLubricant/Sealant

1.QuicksilverAnti-Corrosion GreaseP/N92-78376A6

2.2-4-CMarine LubricantwithTeflon P/N92-825407A12

3.SAE 30WMotorOil P/N92-97959

4.QuicksilverGearLubricantP/N92-19007A24

MAINTENANCE

90-826883R2 JUNE1998 Page 1B-3

Inspection and Maintenance Schedule

BeforeEachUse

1.Check thatlanyardstop switchstopsthe engine.

2.Visuallyinspect the fuelsystemfordeterioration orleaks.

3.Check outboardfortightness on transom.

4.Check steering systemforbinding orloosecomponents.

5.Visually check steering linkrod fastenersforpropertightness.

6.Check propellerbladesfordamage.

AfterEachUse

1.Flush out the outboardcooling systemifoperating insaltorpolluted water.

2.Wash off all saltdepositsand flush out the exhaustoutletof the propellerand gear

casewithfreshwaterifoperating insaltwater.

Every 100 HoursofUse orOnce Yearly,WhicheverOccursFirst

1.Lubricate all lubrication points.Lubricatemorefrequentlywhen used insaltwater.

2. Inspectand clean sparkplugs.

3.Check fuel line filterforcontaminants.

4.Check carburetoradjustments,ifrequired.

5.Check corrosion controlanodes.Check morefrequentlywhen used insaltwater.

6.Drain and replace gearcaselubricant.

7.Lubricatesplineson the driveshaft.*

8.Electric startmodels-- Inspectbattery.

9.Remotecontrolmodels-- Check controlcable adjustments.*

10.Remove engine depositswithQuicksilverPowerTune Engine Cleaner.

11.Check tightness ofbolts,nuts,and otherfasteners.

12.Clean fueltankpick up filter.

Every 300 HoursofUse orThree Years

1.Replacewaterpumpimpeller (more often ifoverheating occursor reduced water

pressureisnoted).*

*Theseitems should be serviced byan authorized dealer.

MAINTENANCE

Page 1B-4 90-826883R2 JUNE1998

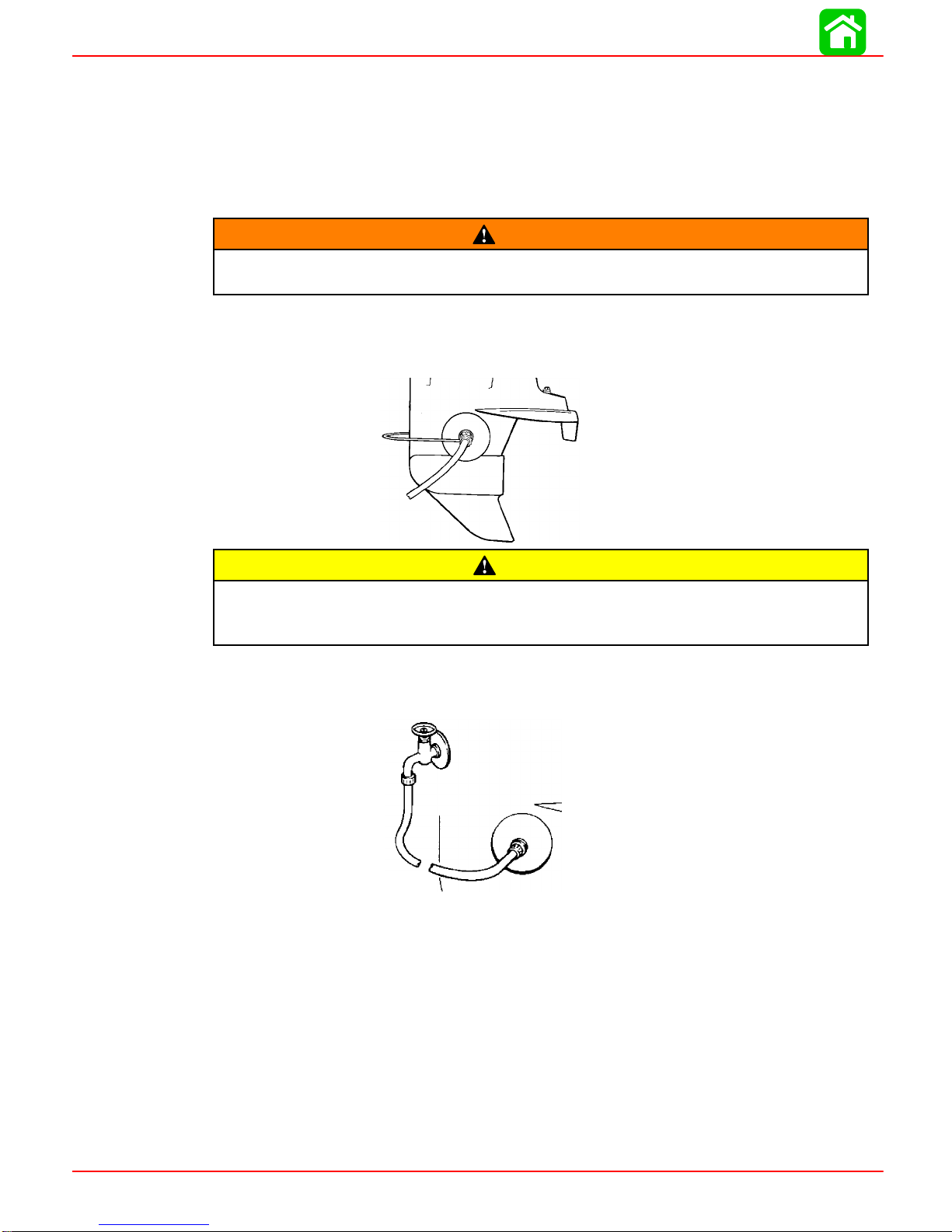

Flushing TheCooling System

Flushthe internalwaterpassagesof the outboardwithfreshwateraftereach useinsalt,

polluted,ormuddywater.Thiswill help preventa buildup ofdepositsfromclogging the

internalwaterpassages.

Use a Quicksilveraccessory(orequivalent)flushing attachment.

WARNING

To avoid possibleinjurywhenflushing,remove thepropeller.RefertoPropeller

Replacement.

1.Removepropeller(refertoPropellerReplacement).Installtheflushingattachmentso

the rubbercupsfit tightlyoverthe cooling waterintake holes.

CAUTION

Neverstartor run youroutboard(evenmomentarily)withoutwatercirculating

through the cooling waterintake inthegearcase to preventdamagetothewater

pump(running dry)oroverheating of the engine.

2.Attachawaterhosetothe flushingattachment. Turn on thewaterandadjust theflow

sowaterisleakingaroundtherubbercupstoensuretheenginereceivesanadequate

supplyofcooling water.

3.Start the engine and run itatidlespeed in neutralshift position.

MAINTENANCE

90-826883R2 JUNE1998 Page 1B-5

4.Adjustwaterflow(ifnecessary)so excess watercontinuesleaking out fromaround

therubbercupstoensuretheengineisreceivinganadequatesupplyofcoolingwater.

5.Checkforasteadystreamofwaterflowingoutof thewaterpumpindicatorhole.Con-

tinue flushing the outboardfor3to 5 minutes,carefullymonitoring watersupplyatall

times.

6.Stoptheengine,turnoffthe water,andremovethe flushing attachment. Reinstallthe

propeller.

FuelSystem

WARNING

Avoidseriousinjuryordeathfromgasolinefireorexplosion.Carefullyfollowall

fuelsystemservice instructions.Always stop the engine and DONOTsmoke or

allowopenflames orsparks inthe area while servicing anypartof thefuelsys-

tem.

Beforeservicinganypartofthefuelsystem,stopengineanddisconnectthebattery.Drain

the fuelsystemcompletely.Use an approved containertocollectand storefuel.Wipe up

any spillage immediately.Materialused tocontainspillage mustbe disposed ofin an ap-

proved receptacle.Anyfuelsystemservicemustbe performed in a well ventilated area.

Inspectany completed serviceworkforsign of fuel leakage.

FuelLineInspection

Visuallyinspectthefuellineandprimerbulbforcracks,swelling,leaks,hardnessorother

signsofdeteriorationordamage.Ifanyoftheseconditionsisfound,thefuellineorprimer

bulbmustbe replaced.

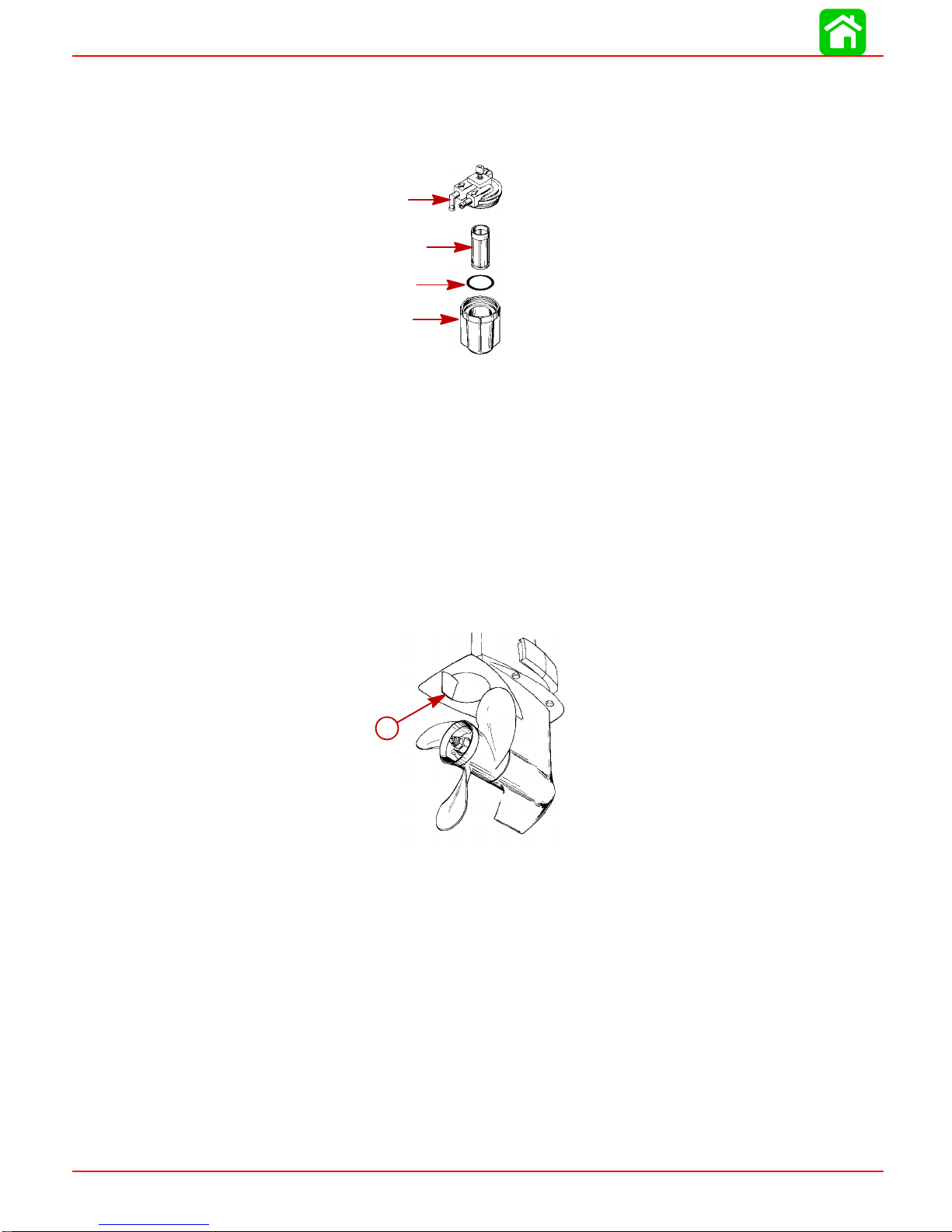

EngineFuelFilter

Inspectthesightbowlforwateraccumulationandinspect the filterelement forsediment.

Clean filterasfollows.

REMOVAL1.Hold ontothe coverto preventit fromturning.

2.Turn off the sightbowl.

3.Pull out the filterelementand washitwithcleaning solvent.

MAINTENANCE

Page 1B-6 90-826883R2 JUNE1998

INSTALLATION1.Pushthe filterelement(with open end towardcover) intocover.

2.Placethe O-ring seal intothe sightbowland screwthe sightbowlhand tightintothe

cover.

2

3/4

5

1

3.Visuallyinspect forfuel leakage around the sightbowlby squeezing the primerbulb

until firm, forcing fuel intothe sightbowl.

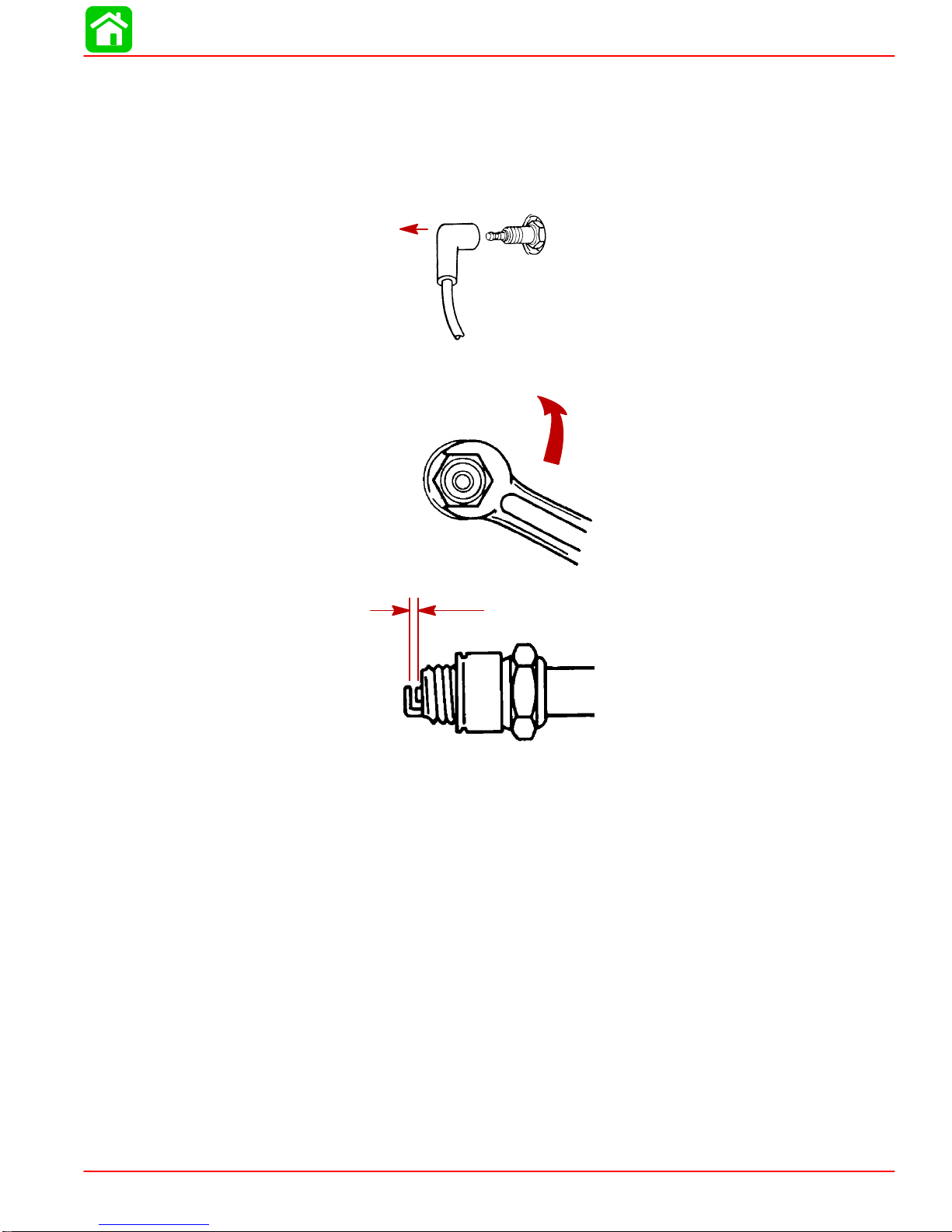

Corrosion Control Anode

Youroutboard hasacorrosion controlanode installed tothe gearcase.An anode helps

protecttheoutboardagainstgalvaniccorrosionbysacrificingitsmetaltobeslowlyeroded

instead of the outboardmetals.

The anode requiresperiodicinspection especiallyinsaltwaterwhichwill acceleratethe

erosion.Tomaintainthis corrosion protection,always replacetheanodebeforeitiscom-

pletelyeroded.Neverpaintorapplya protectivecoating on the anode asthiswill reduce

effectiveness of the anode.

a

a-Anode

MAINTENANCE

90-826883R2 JUNE1998 Page 1B-7

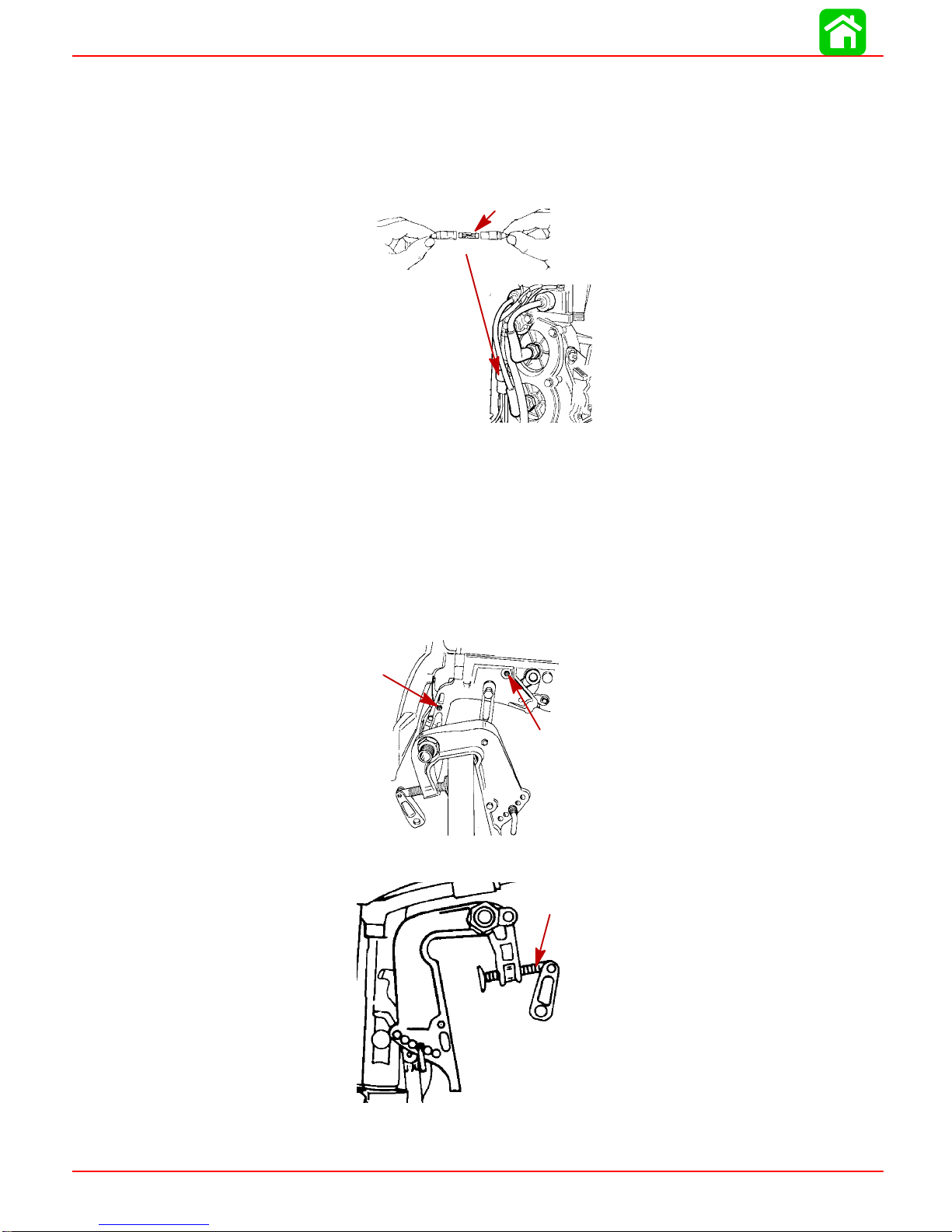

SparkPlug Inspection

Inspectsparkplugsat the recommended intervals.

1.Removethe sparkplug leadsbytwisting the rubberboots slightlyand pull off.

2.Removethesparkplugstoinspectand clean.Replacesparkplug ifelectrode isworn

orthe insulatorisrough,cracked,broken,blistered orfouled.

3.Set the sparkplug gap.See Specification ChartinGeneralInformation Section.

4.Beforereinstalling sparkplugs,clean awaydirton the sparkplug seats. Install plugs

fingertight, and tighten 1/4turn ortorque to 20 lb. ft. (27.1N·m).

BatteryInspection

Thebatteryshouldbe inspectedatperiodicintervalstoensure properengine starting ca-

pability.

IMPORTANT:Readthe safety and maintenance instructionswhichaccompany

yourbattery.

1.Turn off the engine beforeservicing the battery.

2.Add waterasnecessarytokeep the batteryfull.

3.Makesurethe batteryis secure againstmovement.

4.Batterycableterminalsshouldbeclean,tight,andcorrectlyinstalled.Positivetoposi-

tive and negativeto negative.

5.Makesurethe batteryisequipped with a nonconductiveshieldto preventaccidental

shorting ofbatteryterminals.

MAINTENANCE

Page 1B-8 90-826883R2 JUNE1998

Fuse Replacement -- ElectricStartRemote ControlModels

The electric starting circuitisprotected fromoverload byaSFE20 AMPfuse. If the fuse

isblown, the electric startermotorwill notoperate.Trytolocate and correct the cause of

the overload. If the causeisnot found, the fusemayblowagain.Replacethe fusewith

afuse of the samerating.

Replacewith a newSFE20 AMPfuse.

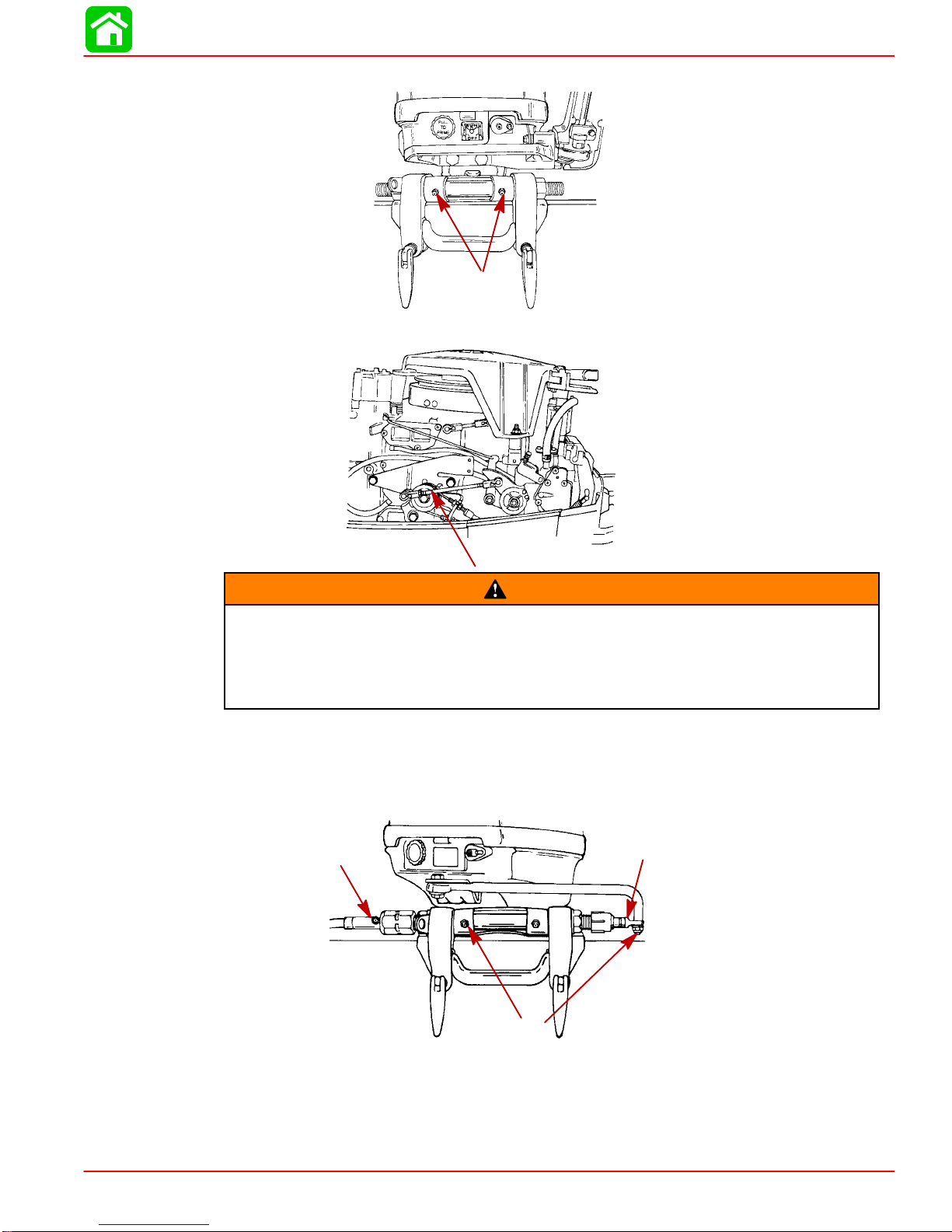

Lubrication Points

LubricatePoints 1 thru6withQuicksilver2-4-CMarineLubricantwith Teflon or

SpecialLubricant101.

1.Steering Friction AdjustmentShaft (TillerHandleModels) -- Lubricatefitting.

2.SwivelBracket-- Lubricatefitting.

1

2

3.TransomClampScrews-- Lubricatethreads.

MAINTENANCE

90-826883R2 JUNE1998 Page 1B-9

4.TiltTube -- Lubricatefittings.

5.Lubricatethe throttle and shaft cables,moving componentsand pivotlocations.

WARNING

The end of the steering cablemustbefullyretractedintotheoutboardtilt tube

before adding lubricant.Adding lubricant tosteering cablewhenfully extended

couldcause steering cableto becomehydraulicallylocked.An hydraulically

lockedsteeringcablewillcauselossofsteeringcontrol, possiblyresulting inse-

riousinjuryordeath.

6.SteeringCableGreaseFitting(IfEquipped) -- Rotatesteeringwheeltofullyretractthe

steering cable end (a)intothe outboardtilt tube.Lubricatethrough fitting (b).

Lubricatepoints 7 With LightWeightOil

7.Steering LinkRod PivotPoints-- Lubricate points.

7

6-b6-a

MAINTENANCE

Page 1B-10 90-826883R2 JUNE1998

LubricatePoint8withQuicksilverAnti-Corrosion Grease or2-4-CMarineLubri-

cantwith Teflon.

8.PropellerShaft -- RefertoPropellerReplacement for removaland installation of the

propeller.Coat the entire propellershaft withlubricant to prevent the propellerhub

fromcorroding tothe shaft.

8

GearCase Lubrication

GearCase LubricantCapacity

Gear Case Ratio Capacity

2.25:1 8.8fl.oz.(260.0ml)

Draining GearCase

When adding orchanging gearcaselubricant, visually check forthe presence ofwater

inthelubricant.Ifwaterispresent,itmayhavesettledtothebottomandwilldrainoutprior

tothelubricant,oritmaybemixedwiththelubricant,givingitamilkycoloredappearance.

Ifwaterisnoticed,havethegearcasecheckedbyyourdealer.Waterinthelubricantmay

resultinprematurebearingfailureor,infreezingtemperatures,willturntoiceanddamage

the gearcase.

Wheneveryou removethe fill/drain plug,examine the magneticend formetalparticles.

Asmall amountofmetalfilingsorfine metalparticlesindicatesnormalgearwear.An ex-

cessive amountofmetalfilingsorlargerparticles(chips)mayindicate abnormalgear

wearand should be checked byan authorized dealer.

MAINTENANCE

90-826883R2 JUNE1998 Page 1B-11

Draining GearCase

1.Place outboardin a verticaloperating position.

2.Place drain pan belowoutboard.

3.Removefill/drain plug (a)and ventplug (b)and drainlubricant.

a

b

Checking LubricantLeveland Refilling GearCase

1.Place outboardin a verticaloperating position.

2.Removeventplug fromventhole(a).

3.Placelubricant tube intothe fill hole(b)and add lubricantuntil itappearsat the vent

hole(a).

a

b

4.Stop adding lubricant. Install the ventplug and sealing washerbeforeremoving the

lubricant tube.

Other manuals for 25 MARATHON

1

Table of contents