Merik 501M-1/2HP User manual

Garage Door Opener

Owner’s Manual

FOR RESIDENTIAL USE ONLY

1/2HP

Model 501M - 1/2HP

CAUTION! PLEASE READ THIS MANUAL CAREFULLY!

The MODEL NUMBER label is located on the front panel of your opener.

CONTENTS PAGE

Safety Rules ................................................................2

Features of Your Opener.............................................3

Specifications ..............................................................3

You'll Need Tools.........................................................3

Completed Installation Illustration................................4

Operation of Your Opener ...........................................5

Accessories .................................................................5

Care & Maintenance of Your Opener ..........................6

Assembly Instructions..................................................7

Installation Instructions ..............................................10

Travel Limit Adjustments ...........................................20

CONTENTS PAGE

Force Adjustments ......................................................21

Safety Reverse Test....................................................22

The Protector System™..............................................22

Code Programming Instructions..................................23

Having a Problem?......................................................24

Carton Contents & Hardware Illustrated .....................26

Repair Parts, Rail Assembly .......................................26

Repair Parts, Installation .............................................26

Repair Parts, Opener Assembly..................................27

How To Order Repair Parts.........................................28

Warranty......................................................................28

FASTEN THIS MANUAL NEAR THE GARAGE DOOR AFTER INSTALLATION.

PERIODIC CHECKS OF THE OPENER ARE REQUIRED TO INSURE SATISFACTORY OPERATION.

THESE SAFETY ALERT SYMBOLS MEAN CAUTION - PERSONAL SAFETY, PROPERTY DAMAGE OR

DANGER FROM ELECTRIC SHOCK. READ THESE INSTRUCTIONS CAREFULLY.

THIS GARAGE DOOR OPENER IS DESIGNED AND TESTED TO OFFER REASONABLY SAFE SERVICE

PROVIDED IT IS INSTALLED AND OPERATED IN STRICT ACCORDANCE WITH THE FOLLOWING SAFETY

INSTRUCTIONS.

FAILURE TO COMPLY WITH THE FOLLOWING INSTRUCTIONS MAY RESULT IN SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE.

CAUTION: IF YOUR GARAGE HAS NO SERVICE ENTRANCE DOOR, INSTALL MODEL 1702E EMERGENCY RELEASE

KEYLOCK. THIS ACCESSORY ALLOWS MANUAL OPERATION OF GARAGE DOOR FROM OUTSIDE IN CASE OF

POWER FAILURE.

KEEP GARAGE DOOR BALANCED. Sticking

or binding doors must be repaired. Garage

doors, door springs, cables, pulleys,

brackets and their hardware are under

extreme tension and can cause serious

personal injury. DO NOT ATTEMPT TO

LOOSEN, MOVE OR ADJUST THEM. Call for

garage door service.

DISCONNECT ELECTRIC POWER TO

GARAGE DOOR OPENER BEFORE MAKING

REPAIRS OR REMOVING COVERS.

To avoid serious personal injury from

entanglement, REMOVE ALL THE ROPES

CONNECTED TO GARAGE DOOR before

installing the garage door opener.

DO NOT WEAR RINGS, WATCHES OR

LOOSE CLOTHING while installing or

servicing a garage door opener.

DISENGAGE ALL EXISTING GARAGE DOOR

LOCKS to avoid damage to garage door.

Installation and wiring must be in

compliance with your local building and

electrical codes. CONNECT THE POWER

CORD ONLY TO A PROPERLY GROUNDED

OUTLET.

Fasten a CAUTION LABEL to the wall

adjacent to the Door Control and the other

to the garage door, as reminders of safe

operating procedures.

THE SAFETY REVERSE SYSTEM TEST IS

VERY IMPORTANT (page 22). Your garage

door MUST reverse on contact with a 25mm

obstacle placed on the floor. Failure to

properly adjust the opener may result in

serious personal injury from a closing

garage door. REPEAT THE TEST ONCE A

MONTH AND MAKE ANY NEEDED

ADJUSTMENTS.

LIGHTWEIGHT DOORS OF FIBERGLASS,

ALUMINUM OR STEEL MUST BE SUB-

STANTIALLY REINFORCED TO AVOID

DOOR DAMAGE. (See page 17.) The best

solution is to check with your garage door

manufacturer for an opener installation

reinforcement kit.

Install door control (or any additional push

buttons) IN A LOCATION WHERE GARAGE

DOOR IS VISIBLE, BUT OUT OF THE REACH

OF CHILDREN. DO NOT ALLOW CHILDREN

TO OPERATE PUSH BUTTON(S) OR

REMOTE CONTROL TRANSMITTER. Serious

personal injury from a closing garage door

may result from misuse of the opener.

CAUTION: Activate opener only when the

door is in full view, free of obstructions and

opener is properly adjusted. NO ONE

SHOULD ENTER OR LEAVE THE GARAGE

WHILE DOOR IS IN MOTION. DO NOT

ALLOW CHILDREN TO PLAY NEAR THE

DOOR.

Use the manual release ONLY to disengage

the trolley and, if possible, ONLY when the

door is closed. DO NOT USE THE RED

HANDLE TO PULL DOOR OPEN OR

CLOSED.

2

Start By Reading These Important Safety Rules

DO NOT USE THE FORCE ADJUSTMENTS

TO COMPENSATE FOR A BINDING OR

STICKING GARAGE DOOR. Excessive

force will interfere with the proper

operation of the safety reverse system or

damage the garage door (page 21).

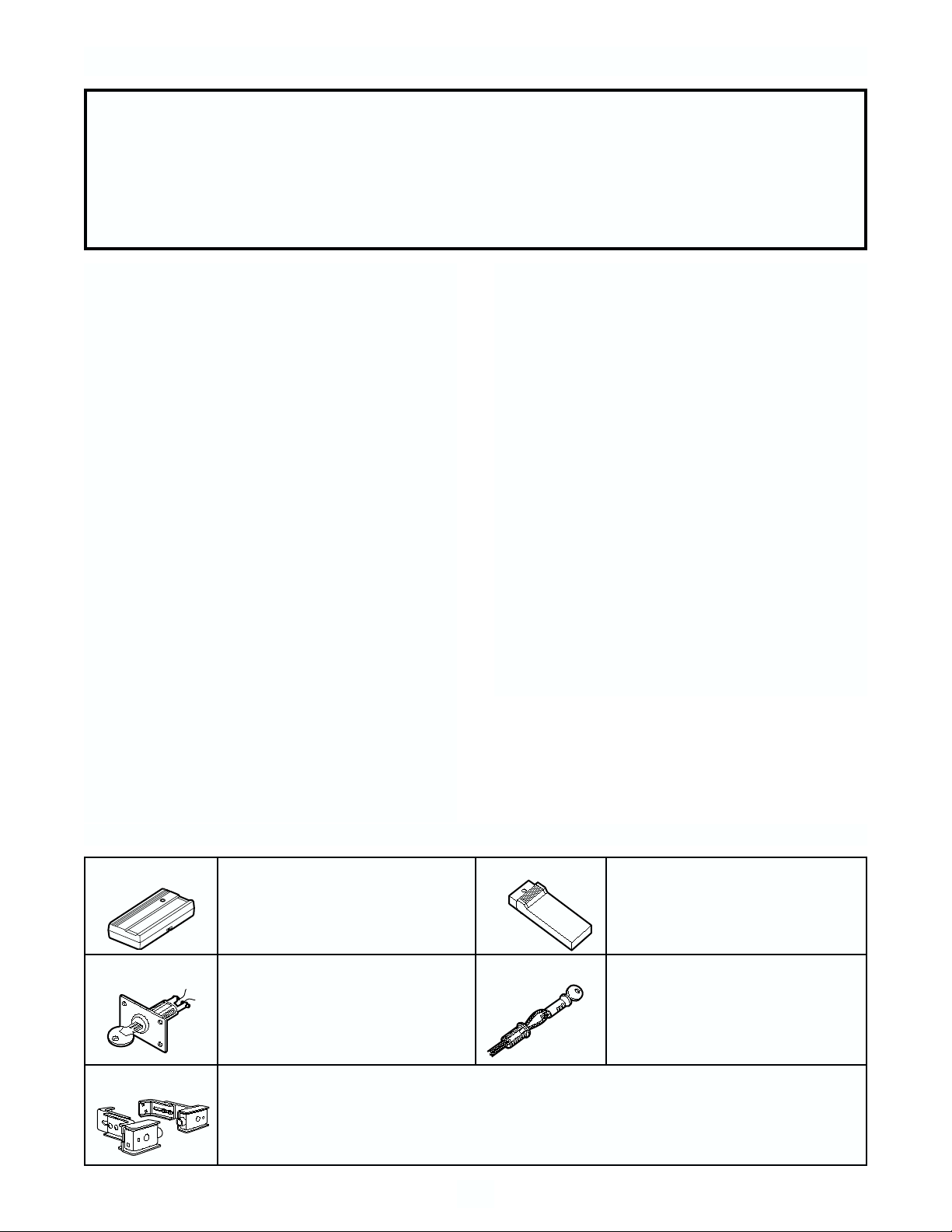

Before you begin, please check the contents of the cartons. Illustrations of parts and hardware are

shown on pages 26 and 27. Separate the hardware for assembly and installation as shown.

SPECIFICATIONS

Pliers

Wire Cutters

Claw Hammer

Hack Saw

Screwdriver Adjustable End Wrench

Socket Wrench

Electric Drill

Tape Measure

2

1

Stepladder

Carpenter’s

Level

Pencil

5 mm & 8mm

Drill Bits

YOU'LL NEED TOOLS

During assembly and installation of your opener, the instructions will call for the use of various hand

tools shown below.

FEATURES OF YOUR OPENER

1. Opener Lights: Turn on and off automatically

with 4-1/2 minute illumination for your safety and

convenience.

2.Manual Disconnect: Pull cord disconnect

permits manual door operation in case of an

emergency or power failure.

3. Automatic Reconnect: Trolley halves reconnect

for automatic operation when opener is activated

after a manual disconnect.

4. Safety System: Independent up and down force

adjustment. The door REVERSES automatically

when obstructed in DOWN direction. The door

STOPS when obstructed in UP direction.

5. Motor: Permanently lubricated with automatic

reset.

6. Easy Limit Adjustment: Limits of door opening

and closing adjusted by turning screws without

removing opener cover.

MOTOR

Type ............................Permanent split capacitor

Speed..........................1500 rpm

Volts ............................120 Volts AC - 60 Hz. Only

Current ........................4.5 Amperes

DRIVE MECHANISM

Gears ..........................16:1 worm gear reduction

Drive............................Chain and cable with one-piece

trolley on steel T-rail

Length of travel ...........Adjustable to 2.29m.

Travel rate ...................15-20cm per second

Lamp ...........................On when door starts to travel, off

4-1/2 minutes after stop.

Door linkage................Adjustable door arm. Pull cord

trolley release.

SAFETY

Personal.......................Push button and automatic reversal

in down direction. Push button and

automatic stop in UP direction

Electronic.....................Independent UP and DOWN force

adjustment screws

Electrical......................Motor overload protector & low

voltage push button wiring

Limit device..................Circuit actuated by limit nut

Limit adjustment ..........Screwdriver adjustment on side

panel

Start circuit...................Low voltage push button or radio

control

DIMENSIONS

Length (overall)............3.15m

Headroom required .....5cm

Hanging weight............14.5kg

3

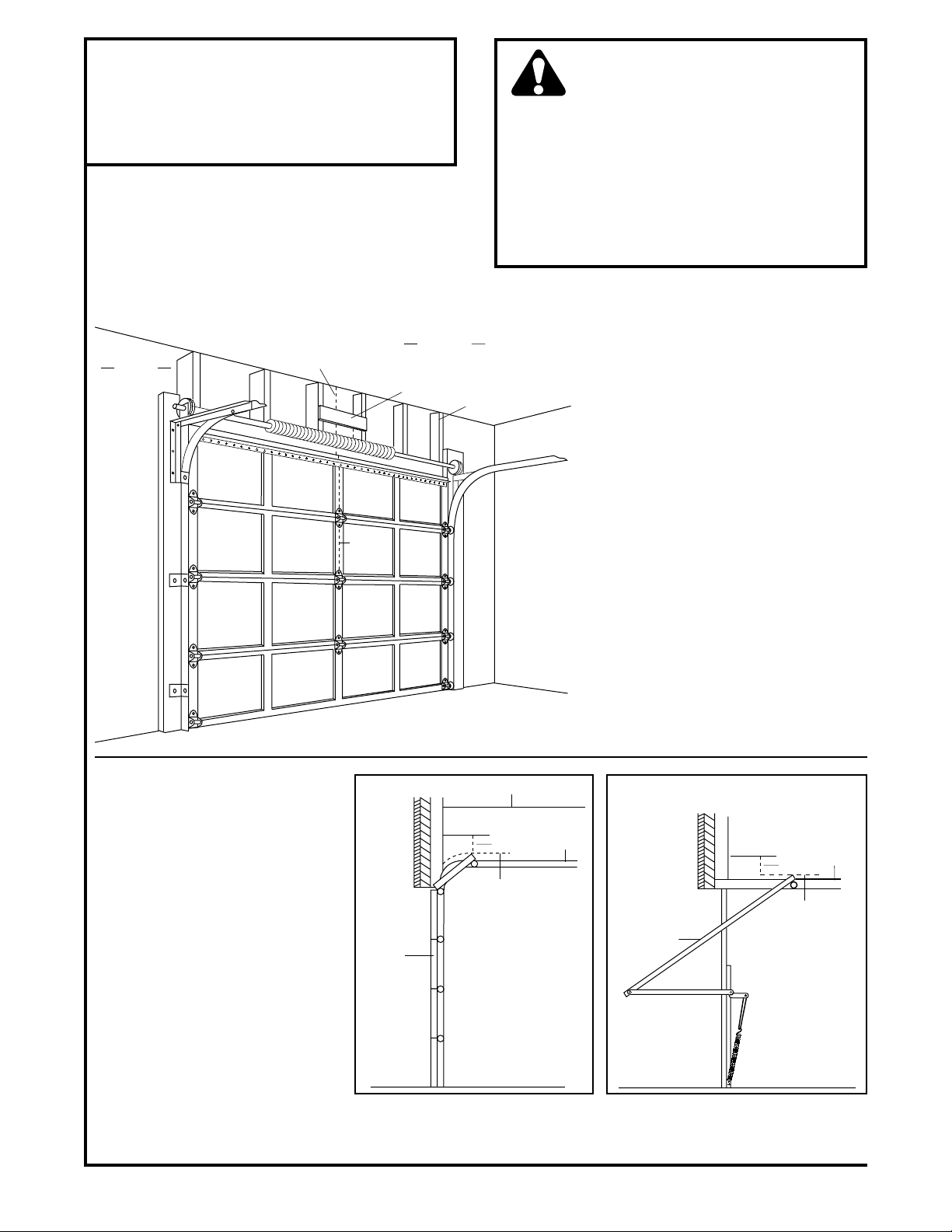

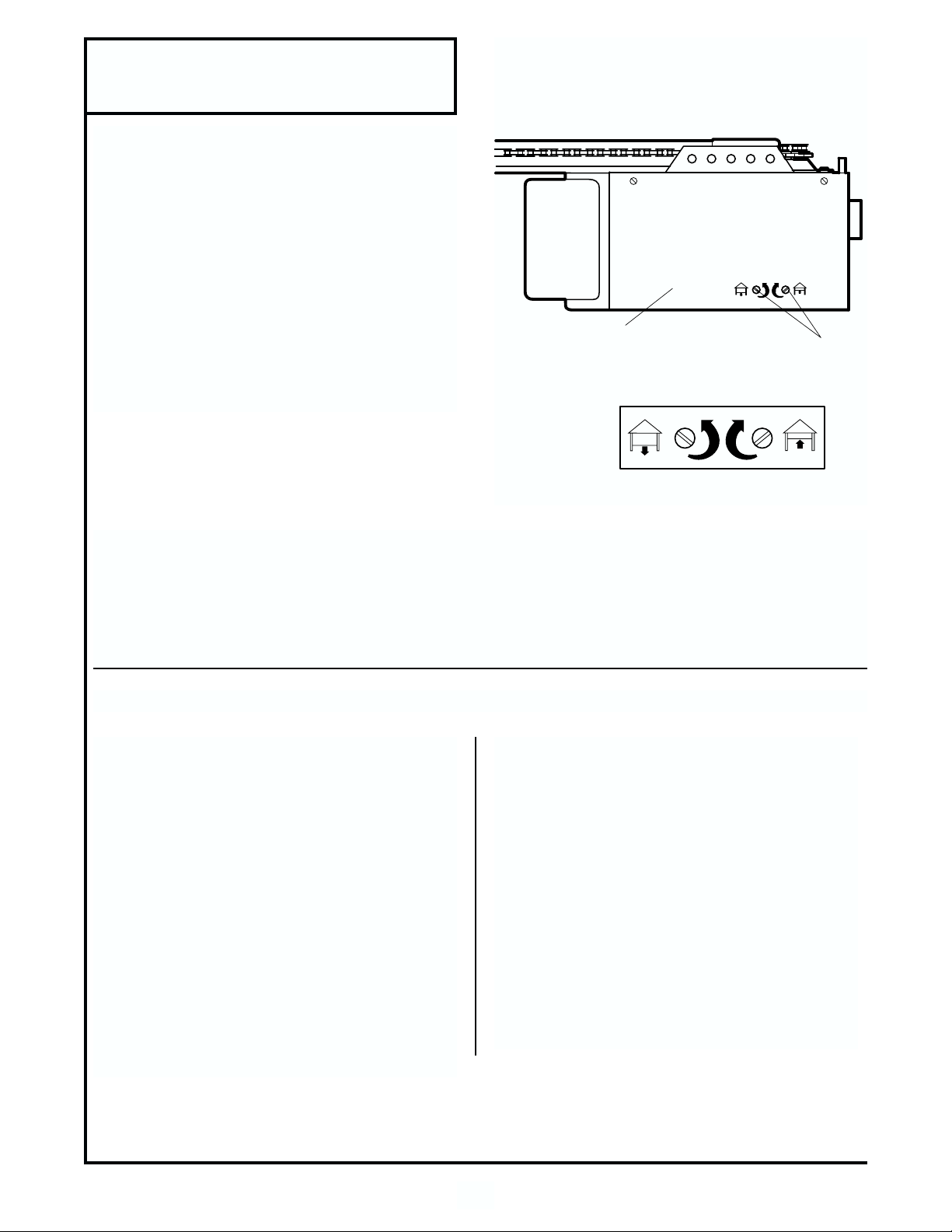

BEFORE YOU BEGIN, PLEASE TAKE SOME TIME TO CAREFULLY EXAMINE THE ILLUSTRATIONS OF AS

TYPICAL GARAGE DOOR OPENER INSTALLATION ON BOTH A SECTIONAL AND A ONE-PIECE DOOR.

Some installation instructions vary for sectional and one-piece doors. Follow only those instructions which apply

to your door type.

Do you have a finished ceiling in your garage? If so, you will need a support bracket and additional fastening

hardware. Refer to Step 5, Page 14 for specific requirements.

Do you have a lightweight or metal door (or does it have glass panels)? If so, horizontal and vertical

reinforcement is required. Refer to Step 10, Page 17.

If possible, install the door opener 2.1m or more above floor with the manual release handle mounted

1.8m above the floor.

4

Horiazontal &Vertical

Support - Not Supplied

(Needed Only for

Lightweight Garage

Door Installation)

Cable

Pulley

Bracket

Header Bracket

Trolley

Straight

Door

Arm Manual

Trolley

Release

Door Bracket

Door

Curved

Door

Arm

Garage

Dooor

Spring

Header

Chain

Horizaontal

Garage Door

Reinforcement

(if needed)

Vertical Garage Door

Reinforcement (if needed)

Support Bracket

and Fastening Hardware

(Not Supplied)

Cable Pulley

Bracket

Header

Bracket

Trolley

Straight

Door

Arm

Manual

Trolley

Release

Door Bracket

Curved

Door

Arm

Header Door

Chain

Cable

Cable

Support Bracket

and Fastening Hardware

(Not Supplied)

ONE-PIECE DOOR INSTALLATION

SECTIONAL DOOR INSTALLATION

Operation of Your Opener

CAUTION

TO ACTIVATE THE OPENER:

Use any of the following devices:

1. The Remote Control Transmitter. Hold the push

button down until the door starts to move.

2. The Door Control. Hold push button down until the

door starts to move.

3. Key Switch or Keyless Entry System accessories.

HOW TO OPERATE THE DOOR MANUALLY:

DOOR SHOULD BE FULLY CLOSED IF POSSIBLE.

WEAK OR BROKEN SPRINGS COULD ALLOW AN

OPEN DOOR TO FALL RAPIDLY. PROPERTY

DAMAGE OR SERIOUS PERSONAL INJURY

COULD RESULT. DO NOT USE MANUAL RELEASE

HANDLE TO PULL DOOR OPEN OR CLOSED.

Disconnect door from opener by pulling down sharply

on red handle. Lift door manually. To automatically

reconnect door to opener, press Door Control push

button.

LOCKOUT FEATURE: Prevents trolley from

reconnecting automatically. If you need to use this

feature, pull manual release handle down and back

(toward opener). Trolley will remain "Locked-Out" and

door can be raised and lowered manually. To reconnect

trolley, pull manual release handle straight down.

OPENER LIGHTS will turn on under the following

conditions: When the opener is initially plugged in;

when the power is interrupted; when the opener is

activated. Lights turn off automatically after 4-1/2

minutes or provide constant light when the Light

feature is activated. (75 watt maximum bulb.)

HOW DOOR MOVES WHEN OPENER ACTIVATES:

1. If open, door will close. If closed, the door will

open.

2. If closing, the door will reverse.

3. If opening, the door will stop (allowing space for

entry and exit of pets and for fresh air).

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructed while closing, the door will reverse.

6. If obstructed while opening, the door will stop.

7. The optional Protector System™ uses an invisible

beam which, when broken by an obstruction, causes

a closing door to open and prevents an open door

from closing. It is STRONGLY RECOMMENDED for

homeowners with young children.

•BEFORE YOU PROCEED, PLEASE READ

SAFETY RULES ON PAGE 2 AND THE

OPERATING INSTRUCTIONS ON THIS PAGE

CAREFULLY.

• TO AVOID DIFFICULTY DURING INSTALLATION,

DO NOT RUN OPENER UNTIL INSTRUCTED TO

DO SO.

• DO NOT PERMIT CHILDREN TO PLAY IN THE

AREA OF THE DOOR.

• OPERATE ONLY WHEN OPENER IS PROPERLY

ADJUSTED AND THE DOOR IS VISIBLE AND

UNOBSTRUCTED.

ACCESSORIES AVAILABLE FOR YOUR OPENER

“The Protector System”:

Provides auxiliary support to the safety features built into your opener. The system’s invisible beam,

when broken by an obstruction, causes a closing door to open and prevents an open door from

closing.

Outdoor Key Switch:

Opens the garage door automatically

from outside with the turn of a key

when transmitter is not handy.

Keyless Entry System:

Enables the homeowner to operate

garage door opener from outside by

entering code on specially designed

keypad.

Single Function Remote Control

Transmitter:

Standard size, with visor clip.

5

Emergency Release Keylock:

REQUIRED for a garage with NO

service door.

Allows manual operation of garage

door from outside in case of power

failure.

Model 870CB

Model 750CB

Model 760CB Model 7702CB

Model 740CB

CARE OF THE OPENER

When properly installed, opener will provide high

performance with a minimum of maintenance. The

opener does not require additional lubrication.

Most complaints of unsatisfactory opener operation

can be traced to problems with the door itself. When

operated manually, a properly balanced door will stay

in any point of travel while being supported entirely by

its springs.

THE OPENER IS NOT INTENDED TO CORRECT

ANY PROBLEMS THAT ARE CAUSED BY AN

UNBALANCED OR BINDING DOOR, BROKEN

DOOR SPRINGS OR BY FAULTY DOOR

HARDWARE.

LIMIT AND FORCE ADJUSTMENTS: These

adjustments must be checked and properly set when

opener is installed. Only a screwdriver is required.

Pages 20 and 21 refer to the limit and force

adjustments. Follow the instructions carefully.

REPEAT THE SAFETY REVERSE TEST AFTER

ANY ADJUSTMENT. Weather conditions may cause

some minor changes in the door operation, requiring

some readjustments, particularly during the first year

of operation.

THE SAFETY REVERSE SYSTEM IS IMPORTANT

(see page 22). GARAGE DOOR MUST REVERSE

ON CONTACT WITH A 25mm OBSTACLE

PLACED ON THE FLOOR. FAILURE TO

PROPERLY ADJUST OPENER MAY RESULT IN

SERIOUS PERSONAL INJURY FROM A CLOSING

GARAGE DOOR.

CHAIN TENSION ADJUSTMENT: After installation

of the opener and adjustment of forces and limits, the

chain may appear loose. This is normal.

TO CHECK THE CHAIN TENSION: Disconnect the

trolley by pulling the red manual release handle. If the

chain returns to the position described and illustrated

in Step 4 page 9, DO NOT make ANY further

adjustments.

REMOTE CONTROL TRANSMITTER: The portable

remote control may be secured to a car sun visor with

the clip provided. Additional remote transmitters can

be purchased at any time for use in all vehicles using

the garage. Refer to Accessories on page 5.

Any new remotes must be set to the same code as

the original remote. Code setting procedures are

described on page 23.

TRANSMITTER BATTERY: The 12 Volt battery

should produce power for at least one year. As long

as there is adequate power, the transmitter battery

test light will glow when the push button is pressed

(and the opener will operate). If light does not come

on, replace the battery. If transmission range lessens,

check the battery test light.

TO CHANGE BATTERY: Slide the battery

compartment cover back. Remove old battery and

position the new 12 Volt battery as directed.

ONCE A MONTH

MANUALLY OPERATE DOOR. If it is unbalanced or

binding, call professional garage door service.

CHECK TO BE SURE DOOR OPENS AND

CLOSES FULLY. Adjust Limits and/or Force if

necessary.

REPEAT SAFETY REVERSE TEST. Make any

necessary adjustments (see page 22).

6

MAINTENANCE OF YOUR OPENER

TWICE A YEAR

CHECK CHAIN TENSION. Adjust if necessary.

ONCE A YEAR

OIL DOOR ROLLERS, BEARINGS AND HINGES.

The opener does not require additional lubrication. Do

not grease the door tracks.

KG KG

1

3

9

75

1

3

9

75

KG KG

3

9

75

1

3

9

75

Adjustment Label Adjustment Label

7

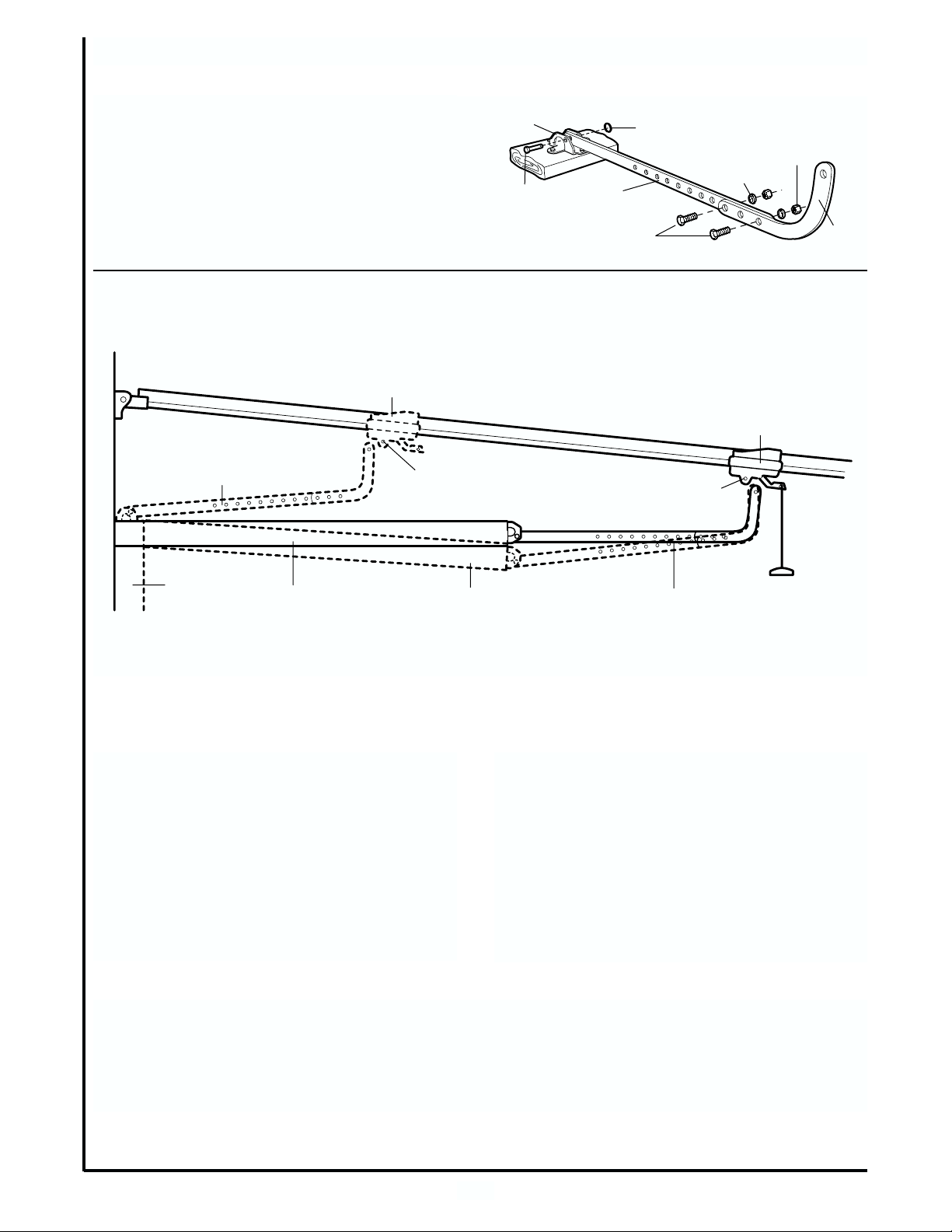

Assembly Step 1

Assemble the T-rail and

Attach Cable Pulley Bracket

PROCEDURE: Place the 3 T-rail sections on a flat

surface for assembly. THIS IS IMPORTANT. The

end sections are identical. THE CENTER SECTION

MUST BE POSITIONED WITH THE BRACES

AGAINST THE END SECTIONS AS SHOWN.

Make sure the "directional arrow" on the center

section is pointing toward the front (to door). Study

the illustration CAREFULLY.

(When assembled, T-rail has a front-to-back

position as shown.)

Bolt rail sections together with the hardware

illustrated and from the direction indicated.

T-rail

(Center Section)

1/4'' Lock Nut

T-RAIL FRONT

(TO DOOR)

Cable pulley bracket

attaches to FRONT

END of T-rail

T-rail

(End Section)

T-RAIL BACK

(TO OPENER)

T-rail

(End Section)

Carriage Bolt

1/4"-20x1/2"

Brace

Brace

Square Carriage

Bolt Holes

TO GARAGEDOOR

Tornillos

5/16"-18x7/8"

Polea final

El soporte y riel deben estar paraleles

Rondana

5/16" Tuerca

5/16"-18

The center rail section MUST

be connected to the end rails

from the direction shown.

Otherwise, trolley will hit

against the nut when installed.

Make sure bolt necks are seated in the

square holes and rails are aligned before you

tighten lock nuts. (See right and wrong

views). Improper assembly can cause jerky

trolley operation, noise and/or nuisance door

reversals.

Right Wrong

Right Wrong

When tightening

the screws, be

sure to keep

bracket parallel

to the rail.

Otherwise, the

rail may bow

when opener is

operated.

Lock Nut

1/4" - 20 x 7/16" Carriage Bolts

1/4" - 20 x 1/2"

Hex Screw

5/16" - 18 x 7/8" Nut

5/16" - 18 Lock washer

5/16"

Hardware Shown Actual Size

Position the cable pulley bracket on the front end of the

T-rail as shown. Fasten securely with the hardware

provided.

SQUARE NECKS ON THE CARRIAGE BOLTS

MUST BE SEATED IN THE SQUARE HOLES IN

RAIL SECTIONS.

Cable Pulley Bracket

Hex Screws

Lock Washer

5/16” Nut

5/16”

Rail Bracket & T-rail Must Be Aligned

TO AVOID INSTALLATION

DIFFICULTIES, DO NOT RUN THE

GARAGE DOOR OPENER UNTIL

INSTRUCTED TO DO SO.

WARNING

CAUTION

WARNING

WARNING

8

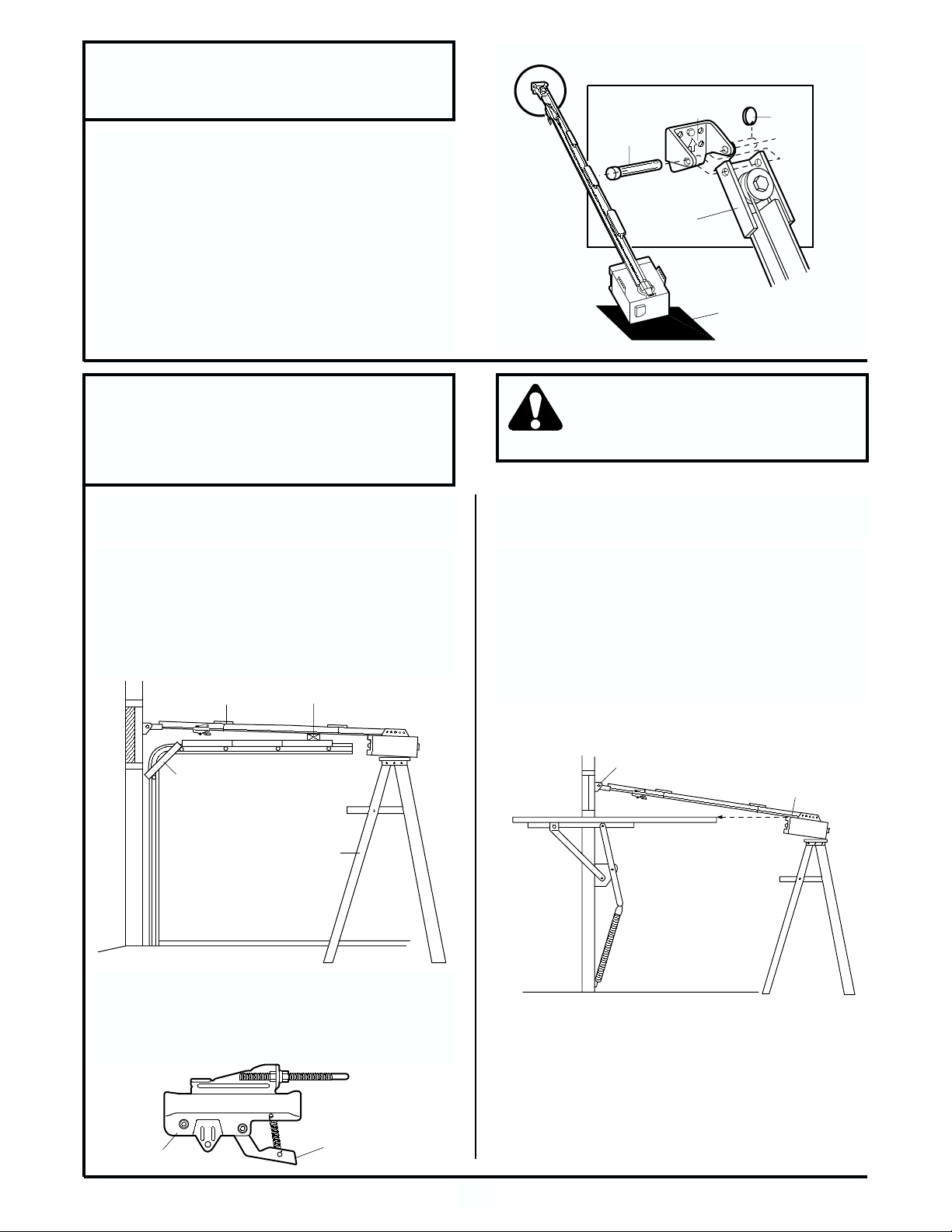

ASSEMBLY STEP 2

Install Trolley

AS A TEMPORARY STOP, INSERT A

SCREWDRIVER INTO HOLE IN FRONT END OF

T-RAIL.

Attach trolley threaded shaft to trolley with lock

washer and nuts as shown.

ASSEMBLY STEP 3

Fasten T-Rail to Opener and

Attach Chain Spreader

PROCEDURE: Place the opener on packing

material to protect the cover. For convenience,

place a support under the chain pulley bracket.

Remove the (2) 5/16"-18x1/2" washered screws

mounted in the top of the opener. Align holes in

back end of T-rail with holes in opener. Fasten the

rail with the (2) washered screws previously

removed and tighten securely.

CAUTION: USE ONLY THESE SCREWS! Use of

any other screws will cause serious damage to

door opener.

Attach chain spreader with #8x1" hex screws and

washers as shown

Insert a 5/16"-18x7/8" hex screw into trolley stop

hole in T-rail as shown. Tighten securely with a

5/16" lock washer and nut.

USE ONLY THOSE SCREWS MOUNTED

IN TOP OF OPENER. FAILURE TO DO SO

WILL CAUSE SERIOUS DAMAGE TO

OPENER.

Temporary Stop

Screwdriver

Trolley

TOGARAGEDOOR

Trolley

Threaded

Shaft

Lock Washer

5/16"

Outer Nut

5/16"

Inner Nut

5/16"

Trolley

USE ONLY THIS

TYPE AND SIZE

SCREW

Washered Screws

5/16"-18x1/2"

T-rail

(Back Section)

Trolley

Stop Hole

Hex Screw

5/16"-18x7/8"

Nut

5/16"-18

Lock Washer

5/16"

Chain Spreader

#8x1" Hex Screws

Washers

Slide trolley assembly along rail to screwdriver stop.

NOTE: If trolley hits against nut on T-rail, bolts

and nuts were attached from the wrong side and

must be repositioned. Review Step 1.

ASSEMBLY STEP 4

Install Chain/Cable

Detach the cable loop from carton and fasten to flat end of

trolley with a master link from coin envelope.

MASTER LINK PROCEDURE: Push pins of master link

bar through cable loop and hole in front end of trolley (A).

Push cap over pins and into notches. Slide clip-on spring

over cap and into pin notches until both pins are securely

locked.

Caution: Keep the chain and cable taut during

installation to help prevent kinking.

9

With trolley against screwdriver,

dispense the cable around the cable pulley and forward to

the opener sprocket and chain spreader (B). The opener

sprocket teeth must engage the chain. Continue

dispensing chain forward to the trolley (C).

(See illustrations to the right for chain installation for

6- and 8-tooth sprocket based on door type.)

Use the second master link to connect chain to flat end of

threaded shaft.

Check to make sure chain is not twisted.

REMOVE SCREWDRIVER.

Cable

Pulley

Cable

Loop

Master

Link Bar

Trolley

T-rail

Pin

Pin Notch

Chain

Flat End of

Threaded Trolley Shaft

Master

Link Cap

Master Link

Clip-On Spring

Install Chain and Cable

in This Direction

A

CMaster

Link Cap

Master Link

Clip-On Spring

One-Piece Doors

6-TOOTH SPROCKET APPLICATION

6-Tooth

Sprocket Opener

Mounting Plate

Chain

Spreader

8-Tooth

Sprocket

Opener

Mounting Plate

Chain

Spreader

Sectional Door with Curved Track

8-TOOTH SPROCKET APPLICATION

• Spin the inner nut and lock washer down the threaded

shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction shown.

As you turn the nut, keep the chain from twisting.

• When the chain is approximately 13mm above the base of

the T-rail at its midpoint, re-tighten the inner nut to secure

the adjustment.

Sprocket noise can result if chain is either too loose or

too tight.

When installation is complete, you may notice some chain

droop with the door closed. This is normal. If the chain

returns to the position shown when the door is open, do not

re-adjust the chain.

Lock

Washer

To Tighten Outer Nut Inner Nut

Trolley

Chain

Base of T-rail

13mm

To Tighten

Inner Nut

Outer Nut

(6-tooth sprocket can be used if slower

travel speed is desired.)

ASSEMBLY OF YOUR GARAGE DOOR OPENER IS NOW COMPLETE

Tighten The Chain & Cable

Opener

Sprocket

Install Cable & Chain

in This Direction

Chain

Spreader

B

10

Vertical

Guideline

Finished

Ceiling

Vertical

Guideline

Header

Wall 2x4 Structural

Supports

SECTIONAL DOOR AND ONE-PIECE

DOOR WITH TRACK(S)

• Close the door and mark the inside

vertical centerline of the garage door.

• Extend the line onto the header wall

above the door.

Remember, you can fasten the

header bracket within 60cm of the

left or right of the door center only if

a torsion spring or center bearing

plate is in the way; or you can attach

it to the ceiling (refer to page 12)

when clearance is minimal.

If you need to install the header bracket

on a 25mm board (on wall or ceiling),

use lag screws (not supplied) to

securely fasten the 25mm board to

structural supports.

INSTALLATION STEP 1

Determine Header Bracket Location

Installation procedures vary according to

garage door types. Follow the instructions

which apply to your door.

IF THE HEADER BRACKET IS NOT

RIGIDLY FASTENED TO A STRUCTURAL

SUPPORT ON THE HEADER WALL OR

CEILING, THE SAFETY REVERSE SYSTEM

MAY NOT WORK PROPERLY (SEE PAGE 22). THE

DOOR MIGHT NOT REVERSE WHEN REQUIRED, AND

COULD CAUSE SERIOUS INJURY OR DEATH.

THE GARAGE DOOR SPRINGS, CABLES, PULLEYS,

BRACKETS AND THEIR HARDWARE ARE UNDER

EXTREME TENSION. DO NOT ATTEMPT TO

LOOSEN, MOVE OR ADJUST THEM YOURSELF.

SERIOUS PERSONAL INJURY OR DEATH COULD

RESULT. CALL FOR GARAGE DOOR SERVICE.

• Open your door to the highest

point of travel as shown. Draw

an intersecting horizontal line

on the header wall 5cm above

the high point. This height will

provide travel clearance for the

top edge of the door.

Header

Wall

Ceiling

Track

Highest Point

of Travel

Door

2"

Proceed to Step 2, page 12.

Door

Track

Header

Wall

Highest Point

of Travel

2"

Sectional door

with curved track One-piece door

with horizontal track

Door

Highest Point

of Travel

Header

Wall

Pivot

Distance

Header Wall Vertical

Centerline

Vertical

Centerline of

Garage Door

25mm board

Unfinished

Ceiling

Structural

Support

25mm board

OPTIONAL CEILING MOUNT

• Close the door and mark the

inside vertical centerline of

your garage door. Extend the

line onto the header wall

above door.

If headroom clearance is

minimal, you can install the

header bracket on the ceiling.

See page 12.

• If you need to install the

header bracket on a 25mm

board (on wall or ceiling), use

lag screws (not supplied) to

securely fasten the 25mm to

structural supports as shown.

EXAMPLE

Distance from top of door

(at highest point of travel) to floor.....................234cm

Actual height of door........................................-224cm

Remainder..........................................................10cm

Add .....................................................................20cm

Bracket height on header wall ..........................=30cm

(Measure UP from top of CLOSED door.)

Proceed to Step 2, page 12.

11

Header Wall

Highest Point

of Travel

Door

Distance

Jamb

Hardware

ONE-PIECE DOOR WITHOUT TRACK

•Open your door to the highest point of travel as

shown. Measure the distance from the top of the

door to the floor. Subtract the actual height of the

door. Add 20cm to the remainder. (See Example).

•Close the door and draw an intersecting horizontal

line on the header wall at the determined height.

If the total number of centimeters exceeds the

height available in your garage, use the

maximum height possible, or refer to page 12 for

ceiling installation.

One-piece door without track

pivot hardware

One-piece door without track

jamb hardware

Please read and comply with the warnings on page 10. They apply to the installation of the header

bracket regardless of door type.

Lag Screws

5/16"x9x1-5/8"

Highest

Point of Travel

(of Garage Door)

Vertical

Center

Line

Header

Wall

Garage

Door

UP

CEILING MOUNT ONLY

Wall

Mounting Holes

Optional

Wall Mounting

Holes

The nail hole is for positioning

only. You must use lag screws to

mount the header bracket.

UP

CEILING MOUNT ONLY

2"

Door

Spring

Header

Bracket

2x4

Structural

Support

Vertical

Center

Line

12

UP

CEILING MOUNT ONLY

Ceiling Mounting Holes

The nail hole is for positioning only.

You must use lag screws to mount

the header bracket.

You can attach the header bracket either to the

wall above the garage door, or to the ceiling.

Follow the instructions which will work best for

your particular requirements.

FASTEN THE HEADER BRACKET TO THE WALL

• Center the bracket on the vertical guideline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

• Mark either set of bracket holes (do not use the

holes designated for ceiling mount). Drill 5mm pilot

holes and fasten the bracket securely with the

hardware provided.

• Extend the vertical guideline onto the ceiling as

shown.

• Center the bracket on the vertical mark no more

than 15cm from the wall. Make sure the arrow is

pointing toward the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark holes designated for ceiling mount only. Drill

5mm pilot holes and fasten bracket with the

hardware provided.

FASTEN THE HEADER BRACKET TO THE CEILING

INSTALLATION STEP 2

Install the Header Bracket

UP

Lag Screws

5/16"x9x1-5/8"

Garage

Door

Vertical

Center Line

Header

Wall

Finished

Ceiling

Header

Bracket

6" Maximum

Vertical

Center Line

Door

Spring

INSTALLATION STEP 3

Attach T-rail to Header Bracket

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door

type as illustrated.

TO PREVENT DAMAGE TO ALL LIGHT-

WEIGHT DOORS AND DOORS WITH

WINDOWS, DO NOT REST THE OPENER

ON THE DOOR.

SECTIONAL DOOR & 1-PIECE DOOR

WITH TRACK

NOTE: A 25mm board is convenient for setting

an ideal door-to-T-rail distance. It is not necessary

when headroom is insufficient.

PROCEDURE: Raise the opener onto a stepladder.

Open garage door. Place a 25mm board on the top

section of door near centerline as shown. Rest T-rail

on board as shown.

1-PIECE DOOR

WITHOUT TRACK

PROCEDURE: Measure the distance from floor to

top of door (in fully open position and parallel to the

floor). Using a stepladder as a support, raise opener

to the same distance from the floor (it will have a

slight angle as shown).

The top of the door should be level with the top of

opener. For maximum efficiency, do not position

opener more than 5cm above this point.

13

T-rail 25mm board

Door

Stepladder

Opener

Header Bracket

PROCEDURE: Position opener on garage floor

below header bracket. Use packing material as a

protective base.

NOTE: To enable T-rail to clear sectional door

springs, it may be necessary to lift opener onto

a temporary support.

CAUTION: The opener must either be secured to a

support or held firmly in place by another person.

Raise T-rail until pulley and header brackets come

together. Align bracket holes and join with clevis pin

as shown. Insert ring fastener to secure.

If the top panel hits the trolley when you raise

the door, pull down on the trolley release arm to

disconnect the inner and outer sections. The

trolley can remain disconnected until Step 11 is

completed.

Clevis Pin

5/16"x2-3/4 "

Fastener

Ring

Header

Bracket

Cable

Pulley

Bracket

Packing

Material

Trolley

Trolley

Release Arm

INSTALLATION STEP 5

Hang the Opener

Measure

Distrance

Lag Screws

5/16"x1-7/8"

5/16"-18x7/8" Screw

Structural

Supports

5/16" Lock Washer

5/16"-18 Nut

14

Figure 1

THE OPENER MUST BE SECURELY FASTENED

TO A STRUCTURAL SUPPORT OF THE GARAGE.

Two representative installations are shown. Yours may be different. Hanging brackets should be angled

(Figure 1) to provide rigid support. On finished ceilings (Figure 2) attach a sturdy metal bracket (not supplied)

to structural supports before installing opener.

PROCEDURE: Measure the distance from EACH

side of the opener to structural support.

Cut both pieces of the hanging bracket to required

lengths. Flatten one end of each bracket and bend

or twist to fit the fastening angles. Do not bend at

the brackets holes. Drill 5mm pilot holes in the

structural supports. Attach flattened ends of

brackets to supports with 5/16"x1-7/8" lag screws.

Lift opener and fasten to hanging bracket as shown.

Check to make sure T-rail is centered over door.

REMOVE 25mm board. Operate door manually. If

door hits the rail, raise header bracket.

INSTALLATION STEP 6

Attach Manual Release Rope & Handle

USE MANUAL RELEASE ROPE ONLY TO

DISENGAGE TROLLEY. DO NOT USE

ROPE AND HANDLE TO PULL DOOR

OPEN OR CLOSED.

PROCEDURE: Thread one end of rope through hole

in top of red handle so "NOTICE" reads right side up

as shown. Secure with an overhand knot.

NOTE: Knot should be at least 25mm from the

end of the rope to prevent slipping.

Thread other end of rope through hole in release arm

of outer trolley. Adjust rope length so that handle is

1.8m above the floor. Secure with an overhand knot

as above.

NOTE: If it is necessary to cut rope, heat seal cut

end with a match or lighter to prevent fraying

and/or raveling.

Trolley

NOTICE

Overhand

Knot

Manual

Release Handle

Rope

Overhand

Knot

Trolley

Release Arm

Bracket

(Not Supplied)

Lag Screws

5/16"x1-7/8"

(Not Supplied)

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

–Finished Ceiling –

Hidden

Support

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

Figure 2

LOCATE DOOR CONTROL PANEL (OR ANY ADDITIONAL PUSH BUTTONS) WHERE THE GARAGE DOOR

IS VISIBLE, AWAY FROM DOOR AND DOOR HARDWARE AND OUT OF THE REACH OF CHILDREN.

SERIOUS PERSONAL INJURY FROM A MOVING GARAGE DOOR MAY RESULT FROM MISUSE OF

OPENER. DO NOT ALLOW CHILDREN TO OPERATE DOOR CONTROL BUTTON(S) OR REMOTE

CONTROL TRANSMITTER.

FASTEN THE CAUTION LABEL ON THE WALL NEAR DOOR CONTROL PANEL AS A REMINDER OF

SAFE OPERATING PROCEDURES.

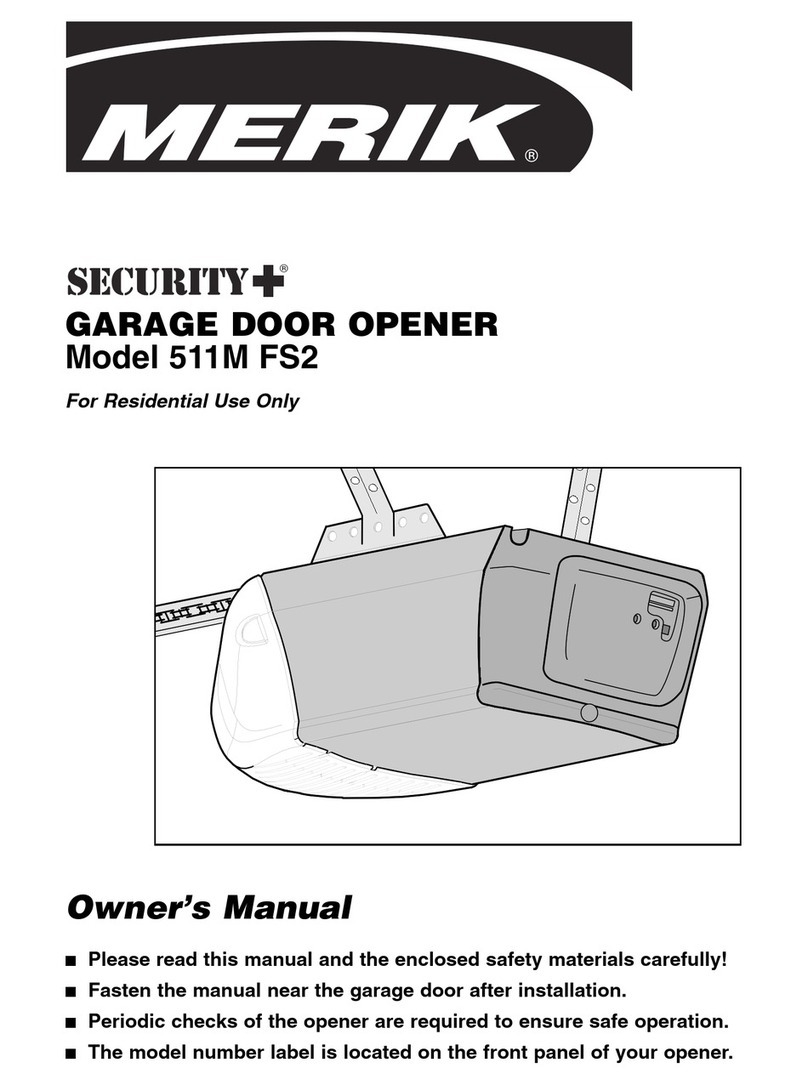

INSTALLATION STEP 7

Install Multi-Function Door Control Panel

Remove about 6mm of insulation from both ends of

2-strand bell wire. Connect one end to terminal

screws on back of door control as follows: the white

wire to the white terminal screw, and the white/red

wire to the red terminal screw.

Fasten the door control panel on an inside garage wall.

If installing into drywall, drill 4mm diameter holes for

anchors. A convenient place is alongside the service

door and OUT OF THE REACH OF CHILDREN.

Run bell wire up the wall and across the ceiling to

the opener. Secure with insulated staples.

Receiver terminals and antenna are located on back

panel of opener. Position antenna wire as shown.

Then connect the white wire to terminal screw 2 and

the white/red wire to terminal screw 1.

15

WIRING INSTRUCTIONS FOR ACCESSORIES

The Protector System™

To opener terminal screws:

White to 2 and Black to 3

Outdoor Key Switch:

To opener terminal screws:

Red to 1 and White to 2

TO PROGRAM RECEIVER CODE

FOR EACH REMOTE CONTROL

1. Press and HOLD remote control

transmitter push button.

2. Press receiver code button. The opener

light will flash once.

3. Release transmnitter button. Opener

has learned code.

TO ERASE ALL RECEIVER CODES

1. Press and HOLD receiver code button.

Green indicator light alongside will turn

ON.

2. When light turns OFF (about 6

seconds) ALL codes are erased from

opener memory.

Opener

Terminal

Screws

Antenna

Back Panel

of Opener

KG KG

1

3

9

75

PAT. #RE29,525; 4,750,201; 4,806,930 Other Patents Pending.

1

3

9

75

23

1

Staples

Metal Screws

6ABx1-1/2"

Lighted Door

Control Button

M.D.C. CERT. NO. 132C2105-1

PART NO: NºDE PIÈCE:

D.O.C. CERT. NO. DATE:

AVERTISSEMENT: Pour réduire les risques de

blessures mortelles par happement, après tout

réglage de la force de déclenchement ou des

seuils de fin de course s'assurer que le sens de

la course s'inverse lorsque la porte entre en

contact avec un object de 13 mm (1 po) de

hauteur (ou un madrier de 2 x 4 de section, à

plat) posésur le sol. Effectuer les reglages

selon les procédures décrites dans la notice.

Sears Roebuck & Co.

Sears Canada Inc., Toronto

Assembled in Mexico - Assemblédu Mexique

Lighted Door

Control Terminal

Screws

2-Strand

Bell Wire

WHT

RED

2

1

OPERATION OF

LIGHTED DOOR CONTROL BUTTON

Press to open or close door.

Press again to REVERSE door during the

CLOSING cycle or to STOP door during OPENING

cycle.

INSTALLATION STEP 9

Connect Electric Power

TO AVOID SERIOUS PERSONAL INJURY

FROM ENTANGLEMENT, REMOVE ALL

ROPES CONNECTED TO THE GARAGE

DOOR BEFORE OPERATING OPENER.

TO AVOID DAMAGE TO GARAGE DOOR

AND OPENER, MAKE DOOR LOCKS

INOPERATIVE BEFORE CONNECTING

ELECTRIC POWER. USE A WOOD SCREW

OR NAIL TO HOLD THE LOCKS IN “OPEN”

(UNLOCKED) POSITION.

INSTALLATION AND WIRING MUST BE IN

COMPLIANCE WITH LOCAL ELECTRICAL AND

BUILDING CODES.

OPERATING AT OTHER THAN 120V 60Hz WILL

CAUSE OPENER MALFUNCTION AND DAMAGE.

PROCEDURE FOR PERMANENT WIRING (if required by local codes)

16

DISCONNECT THE POWER AT THE FUSE

BOX BEFORE PROCEEDING.

Refer to illustration. Make connection through the

22mm diameter hole in top of opener.

1. Remove opener cover screws and set cover

aside.

2. Remove attached 3-prong cord.

3. Connect black (line) wire to black wire on terminal

block; white (neutral) wire to white terminal wire;

ground wire to green ground screw.

CAUTION: BE SURE THAT THE UNIT IS

GROUNDED ACCORDING TO LOCAL CODE.

IMPORTANT NOTE: TO AVOID INSTALLATION

DIFFICULTIES, DO NOT RUN OPENER NOW.

Ground Tab

Green Ground

Screw

Ground Wire

Black

Wire

PERMANENT WIRING

CONNECTION

White

Wire

INSTALLATION STEP 8

Install Light and Lens

Install a 75 watt maximum light bulb in each socket.

Lights will turn ON and remain lit for 4-1/2 minutes

when power is connected. After 4-1/2 minutes, they

will turn OFF.

If bulb burns out prematurely due to vibration,

replace with a standard-neck “Garage Door

Opener”bulb.

INSTALL LENS: Slide lens into guides as shown.

Snap bottom tabs into lens slots.

Opener MUST be permanently wired or plugged into

a grounded 3-prong receptacle wired according to

local electrical codes. DO NOT use a 2-wire

adapter. DO NOT USE an extension cord.

Lens

75 Watt Max.

Light Bulb

Lens

Slot

Lens

Guide

RIGHT WRONG

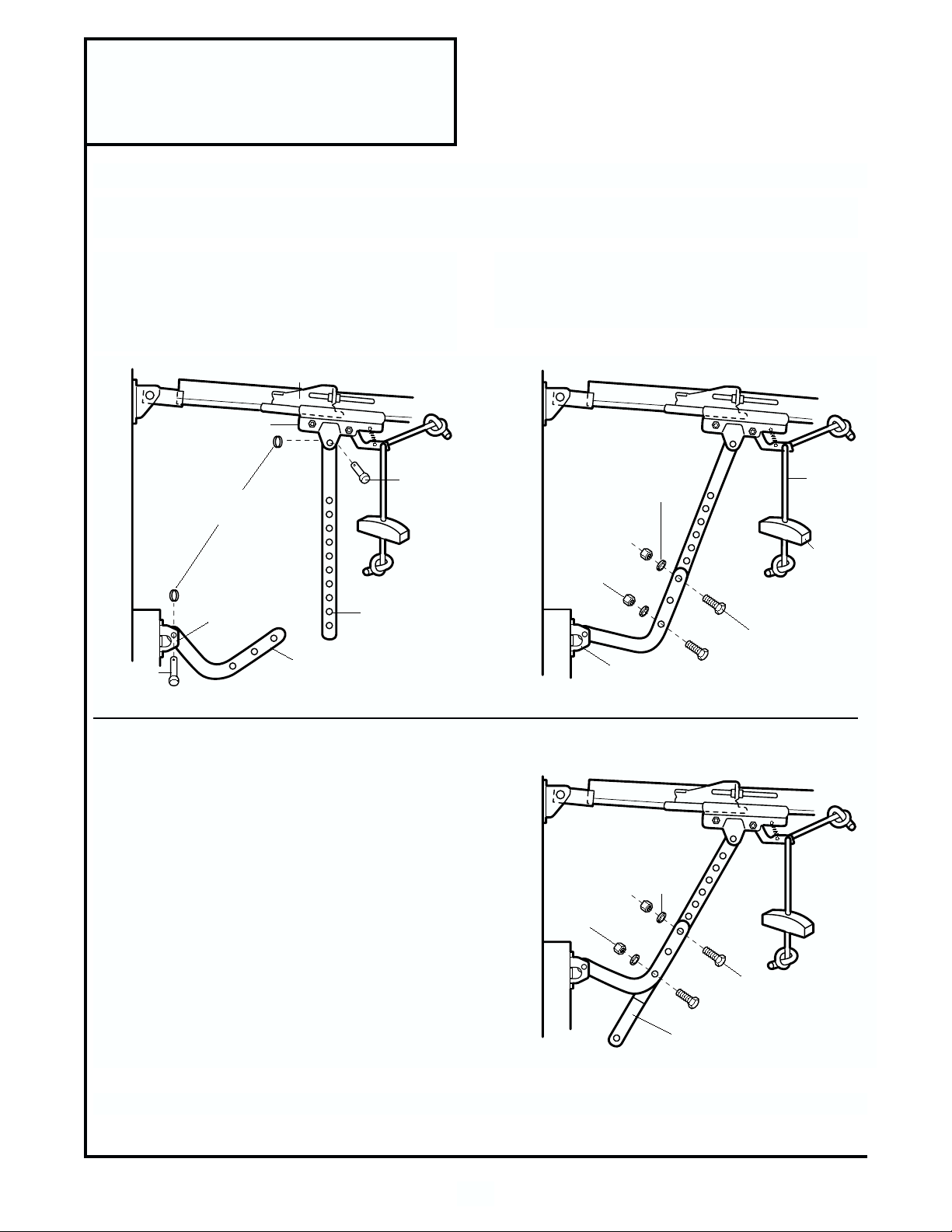

INSTALLATION STEP 10

Fasten Door Bracket

Follow instructions which apply to your door

type as illustrated below.

TO PREVENT DAMAGE TO LIGHTWEIGHT

AND METAL GARAGE DOORS (OR ONES

WITH GLASS PANELS), ALWAYS REIN-

FORCE THE INSIDE OF DOOR, BOTH

VERTICALLY AND HORIZONTALLY, WITH

ANGLE IRON OR 25mm BOARDS.

The horizontal brace should be at least 1.8m long. The vertical brace should cover height of top panel. The best

solution is to check with your garage door manufacturer for a door reinforcement kit for an opener installation.

SECTIONAL DOOR INSTALLATION PROCEDURE

Assemble door bracket as shown. Center bracket on

previously marked vertical guideline used for header

bracket installation. Position the bracket assembly on the

face of the door within the following limits:

A. The top edge of the bracket 5cm–10cm below top

edge of door.

B. Directly below any structural support across top

of door.

Placement depends on your particular needs.

Mark and drill 8mm top and bottom fastening holes.

Secure bracket as shown.

ONE-PIECE DOOR INSTALLATION PROCEDURE

Center bracket on top edge of door as shown. Mark holes.

Drill 8mm holes and fasten the door bracket with

hardware supplied.

NOTE: If the door has no exposed framing, drill 5mm

pilot holes and use 5/16"x1-1/2" lag screws (not

supplied) to fasten bracket to top of door.

NOTE: The door bracket may be installed on face of

door if required for your installation. (Refer to dotted

line drawing.) HOWEVER, drill 5mm pilot holes and

substitute 5/16"x1-1/2" lag screws (not supplied) to

fasten the bracket to the door.

17

Header

Bracket

Vertical

Center

Line Door Bracket Top of

Door

Reinforcement

Board for

Lightweight Doors

Header Wall

Door

Bracket

Optional

Face of Door

Installation

Vertical

Center

Line

Header

Bracket

Door

Bracket

Top Edge

of Door

(Inside)

Carriage Bolt

5/16"-18x2-1/2"

(Optional)

Lock Washer

5/16"

Nut

5/16"-18

Nut

5/16"-18

Inside Edge of Door

or

Reinforcement Board

Carriage Bolt

5/16"-18x2-1/2"

Lock Washer

5/16"

Door Bracket

SECTIONAL DOOR

ONE-PIECE DOOR

Ring

Fastener

Door

Bracket

Clevis Pin

5/16"x1-1/4"

Curved

Door Arm

Straight

Door Arm

Clevis Pin

5/16"x1"

Lock

Washers

5/16"

Nuts

5/16"-18

Door Bracket

Screws

5/16"-18x7/8"

Manual

Release

Handle

Rope

Lock

Washers

5/16"

Nuts

5/16"-18

Screws

5/16"-18x7/8"

Cut This End

Inner Trolley

Outer Trolley

INSTALLATION STEP 11

Connect Door Arm to Trolley

Follow only those instructions which apply to

your door type.

SECTIONAL DOORS ONLY

Make sure garage door is closed tight. Pull the manual release handle to disconnect the outer trolley from the

inner trolley. Slide the outer trolley back (away from the door) about 2" as shown in figures A, B and C.

Figure A: Fasten straight door arm section to outer

trolley with the 5/16"x1" clevis pin. Secure the

connection with a ring fastener. Fasten curved

section to the door bracket in the same way, using

the 5/16"x1-1/4" clevis pin.

Figure B: Bring arm sections together. Find two

pairs of holes that line up and join sections. Select

holes as far apart as possible to increase door arm

rigidity.

Figure C: If holes in curved arm are above holes in

straight arm, disconnect straight arm. Cut about

15cm from the solid end. Reconnect to trolley with

cut end down as shown.

Bring arm sections together. Find two pairs of holes

that line up and join with screws, lock washers, and

nuts.

18

Proceed to Step 1, page 20. Trolley will re-engage automatically when opener is operated.

A B

C

Nuts

5/16"-18

Lock

Washers

5/16"

Ring

Fastener

Straight

Arm

Screws

5/16"-18x7/8

Door

Bracket

Clevis Pin

5/16"x1-1/4"

Curved

Door Arm

Door Arm

Fully Open

Trolley

Door Arm

Connector Hole

Closed

Door Open Door Door with

Backward Slant

Door Arm

Connector Hole

Fully Closed

Trolley

Door Arm

ONE-PIECE DOORS

ASSEMBLE DOOR ARM: Fasten straight and

curved door arm sections together to their longest

possible length (with a 2 or 3 hole overlap). With

door closed, connect straight door arm section to

door bracket with the 5/16"x1-1/4" clevis pin. Secure

with a ring fastener.

Before connecting door arm to trolley, limits of travel must be adjusted on one-piece doors. Limit adjustment

screws are located on left side panel as shown in illustration on page 20. Follow procedures below.

ADJUSTMENT PROCEDURES

OPEN DOOR ADJUSTMENT

Decrease UP limit. Turn UP limit adjustment screw

counterclockwise 5-1/2 turns.

Press door control button. Trolley will travel to full

open position.

Manually raise door arm to open position (parallel to

floor) and lift door arm to trolley. The arm should

touch trolley just in back of door arm connector hole

as shown in solid line drawing. If arm does not

extend far enough, adjust limit further. One full turn

equals 5cm of door travel.

CLOSED DOOR ADJUSTMENT

Decrease DOWN limit. Turn DOWN limit adjustment

screw clockwise 5 complete turns.

Press door control button. Trolley will travel to full

closed position.

Manually close door and lift door arm to trolley. The

arm should touch trolley just ahead of door arm

connector hole as shown in dotted line drawing. If

arm is behind the connector hole, adjust limit further.

One full turn equals 5cm of door travel.

CONNECT DOOR ARM TO TROLLEY: With door closed, join curved arm to connector hole in trolley with

remaining clevis pin. Secure with ring fastener. NOTE: It may be necessary to lift door slightly to make

connection.

Run opener through a complete travel cycle. If door has a slight ‘backward’ slant in full open position, decrease

UP limits until door is parallel to floor.

19

ADJUSTMENT STEP 1

Adjust UP and DOWN Limits

LIMIT ADJUSTMENT settings regulate the points at

which the door will stop when moving up or down.

NOTE: Door STOPS in the UP direction if

anything interferes with door travel. Door

REVERSES in the DOWN direction if anything

interferes with the door travel (including binding

or unbalanced doors)

PROCEDURE: To operate the opener, press the

Door Push Button or remote control. Run the opener

through a COMPLETE TRAVEL CYCLE. No limit

adjustments are necessary when the door opens

and closes completely and doesn’t reverse

unintentionally when fully closed.

The following chart outlines adjustments procedures. Run the opener through a COMPLETE TRAVEL

CYCLE AFTER AFTER EACH ADJUSTMENT.

NOTE: REPEATED OPERATION OF THE OPENER DURING ADJUSTMENT PROCEDURES MAY CAUSE

MOTOR TO OVERHEAT AND SHUT OFF. SIMPLY WAIT 15 MINUTES AND TRY AGAIN.

Read the chart carefully before proceeding to step 2. Use a screwdriver to make limit adjustments.

IF DOOR DOES NOT OPEN COMPLETELY

BUT OPENS AT LEAST 1.5m

Increase UP travel. Turn the UP LIMIT adjustment

screw clockwise. One turn equals 5cm of travel.

If door does not open at least 1.5m: Adjust UP

(OPEN) FORCE as explained in step 2.

IF DOOR DOES NOT CLOSE COMPLETELY

Increase DOWN travel. Turn down limit adjustment

screw counterclockwise. One turn equals 5cm of

travel.

If the door still will not close completely, the header

bracket is positioned too high. See Step 1, page 10.

IF OPENER REVERSES IN FULLY

CLOSED POSITION

Decrease DOWN travel. Turn down limit adjustment

screw clockwise. One turn equals 5cm inches of

travel.

IF DOOR REVERSES WHEN CLOSING AND

THERE IS NO INTERFERENCE TO TRAVEL CYCLE

Test door for binding: Pull manual release

handle. Manually open and close door. If door is

binding, call for garage door service. If door is not

binding or unbalanced, adjust DOWN (CLOSE)

FORCE. See Step 2.

20

LIMIT ADJUSTMENT CHART

Left Side

Panel Limit

Adjustment

Screws

Adjustment Label

Table of contents

Languages:

Other Merik Garage Door Opener manuals

Merik

Merik 511M FS2 User manual

Merik

Merik LiftMaster PREMIUM Series User manual

Merik

Merik Security+ 411M User manual

Merik

Merik 511MM FS2 User manual

Merik

Merik LiftMaster 7511LMK User manual

Merik

Merik 711MB User manual

Merik

Merik 790LMK User manual

Merik

Merik 511MM FS2 User manual

Merik

Merik Security+ 711MD User manual

Merik

Merik 511M FS2 User manual