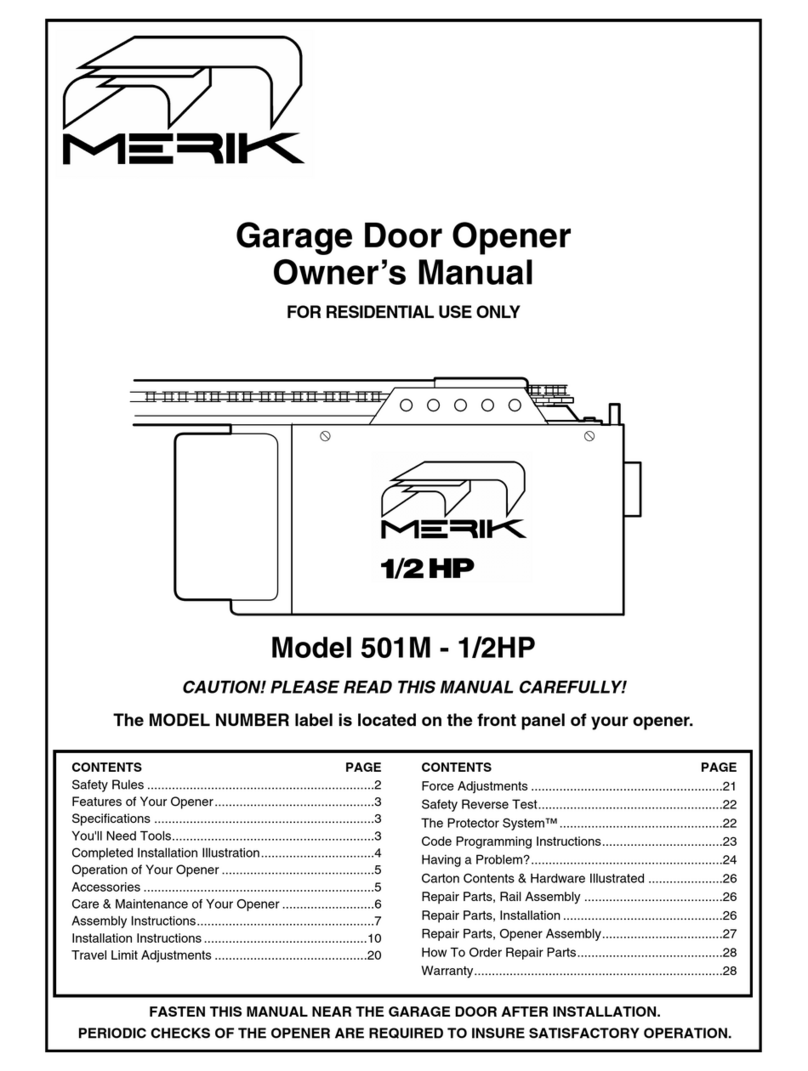

Merik 511MM FS2 User manual

Owner’s Manual

■Please read this manual and the enclosed safety materials carefully!

■Fasten the manual near the garage door after installation.

■Periodic checks of the opener are required to ensure safe operation.

■The model number label is located on the front panel of your opener.

®

GARAGE DOOR OPENER

Model 511MM FS2

For Residential Use Only

2

Introduction 2-8

Safety symbol and signal word review....................... 2

Preparing your garage door ....................................... 3

Tools needed.............................................................. 3

Planning ................................................................. 4-6

Carton inventory......................................................... 7

Hardware inventory .................................................... 8

Assembly 9-15

Assemble T-rail & attach the pulley bracket.......... 9-10

Install the trolley ........................................................11

Fasten the T-rail to the motor unit............................ 12

Install the chain/cable and chain spreader.......... 13-14

Tighten the chain and cable ..................................... 15

Installation 15-28

Installation safety instructions .................................. 15

Determine the header bracket location ............... 16-17

Install the header bracket......................................... 18

Attach the T-rail to the header bracket..................... 19

Position the opener .................................................. 20

Hang the opener....................................................... 21

Install the door control.............................................. 22

Install the light .......................................................... 23

Attach the emergency release rope and handle ...... 23

Electrical requirements............................................. 24

Fasten the door bracket ...................................... 25-26

Connect the door arm to the trolley..................... 27-28

Adjustment 29-31

Adjust the travel limits .............................................. 29

Adjust the force ........................................................ 30

Test the safety reversal system................................ 31

Operation 32-35

Operation safety instructions.................................... 32

Using your garage door opener ............................... 32

Using the wall-mounted door control........................ 33

To open the door manually....................................... 33

Care of your garage door opener............................. 34

Having a problem? ..............................................34-35

Programming 36-37

To add or reprogram an additional

hand-held remote control ......................................... 36

To erase all codes .................................................... 36

3-button remotes ...................................................... 36

To add, reprogram or change a Keyless Entry PIN . 37

Repair Parts 38

Accessories 39

Service Numbers 40

Warranty 40

TABLE OF CONTENTS

When you see these Safety Symbols and Signal Words on

the following pages, they will alert you to the possibility of

serious injury or death if you do not comply with the

warnings that accompany them. The hazard may come

from something mechanical or from electric shock. Read

the warnings carefully.

When you see this Signal Word on the following pages, it

will alert you to the possibility of damage to your garage

door and/or the garage door opener if you do not comply

with the cautionary statements that accompany it. Read

them carefully.

Mechanical

Electrical

INTRODUCTION

Safety Symbol and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the instructions and warnings contained in this manual.

3

Pliers

Wire Cutters

Claw Hammer

Hack Saw

Screwdriver Adjustable End Wrench

1/2" and 7/16" Sockets

and Wrench

Drill

Tape Measure

2

1

Stepladder

Pencil

3/16", 5/16" and

5/32" Drill Bits

Carpenter’s

Level (Optional)

To prevent damage to garage door and opener:

• ALWAYS disable locks before installing and operating the

opener.

• ONLY operate garage door opener at 120V, 60 Hz to avoid

malfunction and damage.

To prevent possible SERIOUS INJURY OR DEATH:

• ALWAYS call a trained door systems technician if garage

door binds, sticks, or is out of balance. An unbalanced

garage door may NOT reverse when required.

• NEVER try to loosen, move or adjust garage door, door

springs, cables, pulleys, brackets or their hardware, ALL of

which are under EXTREME tension.

• Disable ALL locks and remove ALL ropes connected to

garage door BEFORE installing and operating garage door

opener to avoid entanglement.

Preparing your garage door

Before you begin:

• Disable locks.

• Remove any ropes connected to garage door.

• Complete the following test to make sure your garage

door is balanced and is not sticking or binding:

1. Lift the door about halfway as shown. Release the

door. If balanced, it should stay in place, supported

entirely by its springs.

2. Raise and lower the door to see if there is any

binding or sticking.

If your door binds, sticks, or is out of balance, call a

trained door systems technician.

Tools needed

During assembly, installation and adjustment of the

opener, instructions will call for hand tools as illustrated

below.

Sectional Door

One-Piece Door

Safety Reversing Sensor

Support bracket &

fastening hardware

is required.

See page 21.

— — — — — — — —

Header Wall

FINISHED CEILING

Torsion

Spring

Extension

Spring

OR

Safety Reversing Sensor

Gap between floor

and bottom of door

must not exceed 6 mm.

Access

Door

Wall-

mounted

Door

Control

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, steel, aluminum, door with

glass panels, etc.). See page 25 for details.

Motor unit

Slack in chain tension

is normal when

garage door is closed

(Optional Accessory)

(Optional Accessory)

Vertical

Centerline of

Garage Door

4

SECTIONAL DOOR INSTALLATION

Planning

Identify the type and height of your garage door. Survey

your garage area to see if any of the conditions below

apply to your installation. Additional materials may be

required. You may find it helpful to refer back to this page

and the accompanying illustrations as you proceed with

the installation of your opener.

Depending on your requirements, there are several

installation steps which may call for materials or hardware

not included in the carton.

• Installation Step 1 – Look at the wall or ceiling above

the garage door. The header bracket must be securely

fastened to structural supports.

• Installation Step 5 – Do you have a finished ceiling in

your garage? If so, a support bracket and additional

fastening hardware may be required.

• Do you have an access door in addition to the garage

door? If not, Model 7702CBOutside Quick Release is

required. See Accessories page.

Cable Pulley

Bracket

Header

Bracket Trolley

Straight

Door

Arm Emergency

Release

Rope & Handle

Door Bracket

Garage

Door

Curved

Door

Arm

Garage

Door

Spring

Header

Wall

CLOSED POSITION

Rail

Chain

• Look at the garage door where it meets the floor. Any

gap between the floor and the bottom of the door must

not exceed 6 mm. Otherwise, the safety reversal system

may not work properly. See Adjustment Step 3. Floor or

door should be repaired.

SECTIONAL DOOR INSTALLATIONS

• Do you have a steel, aluminum, fiberglass or glass panel

door? If so, horizontal and vertical reinforcement is

required (Installation Step 10).

• The opener should be installed above the center of the

door. If there is a torsion spring or center bearing plate in

the way of the header bracket, it may be installed within

1.2 m to the left or right of the door center. See

Installation Steps 1 and 10.

5

Planning (Continued)

ONE-PIECE DOOR INSTALLATIONS

• Generally, a one-piece door does not require

reinforcement. If your door is lightweight, refer to the

information relating to sectional doors in Installation

Step 10.

• Depending on your door’s construction, you may need

additional mounting hardware for the door bracket

(Step 10).

Without a properly working safety reversal system, persons

(particularly small children) could be SERIOUSLY INJURED or

KILLED by a closing garage door.

• The gap between the bottom of the garage door and the floor

MUST NOT exceed 6 mm. Otherwise, the safety reversal

system may not work properly.

• The floor or the garage door MUST be repaired to eliminate

the gap.

Safety

Reversing Sensor

(Optional Accessory)

FINISHED CEILING

Support bracket

& fastening

hardware is required.

See page 21.

Slack in Chain Tension

is Normal When

Garage Door is Closed

Safety

Reversing Sensor

(Optional Accessory)

Header

Wall

Access

Door

Gap between floor and bottom

of door must not exceed 6 mm.

Wall-mounted

Door

Control

Motor Unit

ONE-PIECE DOOR WITHOUT TRACK

CLOSED POSITION

Access

Door

Gap between floor

and bottom of door

must not exceed 6 mm.

Safety Reversing

Sensor

Wall-

Mounted

Door

Control

Cable

Pulley Bracket

Door

Bracket

Straight

Door

Arm

Trolley

Header

Wall

Rail

Garage

Door

Emergency Release

Rope & Handle

Chain

Header

Bracket

Curved

Door Arm

Safety Reversing

Sensor

(Optional Accessory)

(Optional Accessory)

ONE-PIECE DOOR WITH TRACK

CLOSED POSITION

Cable

Pulley Bracket

Header

Bracket

Trolley

Straight

Door

Arm

Emergency

Release

Rope & Handle

Door

Bracket

Curved

Door

Arm

Header

Wall

Rail

Garage

Door

6

Safety Reversing Sensor

Safety Reversing Sensor

(Optional Accessory)

(Optional Accessory)

Header Wall

Safety Reversing Sensor

Safety Reversing Sensor

(Optional Accessory)

(Optional Accessory)

SLIDING GATE INSTALLATION

SWINGING GATE INSTALLATION

Planning (Continued)

GATE INSTALLATIONS

• It is recommended that you attach fine mesh or

screening across the inside of swinging or sliding gates

in order to prevent intruders from reaching through the

bars and releasing the trolley from the door arm or

pressing the door control button.

• The opener must be protected from rain and/or

moisture.

Without a properly working safety reversal system, persons

(particularly small children) could be SERIOUSLY INJURED or

KILLED by a closing gate.

• Activate gate ONLY when the gate is in full view and free

from any obstructions.

• ALWAYS keep gate in sight until completely closed. NEVER

permit anyone to cross the path of the moving gate.

• ALWAYS keep gate in good repair and make sure it moves

freely. An improperly maintained gate may NOT reverse when

required and could result in SEVERE PERSONAL INJURY or

DEATH.

7

41B2616

Cable Pulley

Bracket

41B4494-1

2-Conductor Bell Wire

White & White/Red

41A3489

Trolley

41A4353

Header Bracket

178B35

Curved Door

Arm Section

178B34

Straight Door

Arm Section

Safety Labels

and

Literature

12B350

Hanging Brackets

U

P

CEI

LIN

G M

O

U

NT ONL

Y

41A5047

Door Bracket

973-315MK

SECURITY✚®

Multi-function

Remote Control (2)

1B3117

T-rail

Center Section

OT G R

A AG

E DOO

R

183B110

T-rail End Section (each)

41A4208

Chain Spreader

and Screws

41A3473-2

Chain/Cable

Dispensing Carton

41A5577-1

Lighted Door

Control Button

108D79

Motor Unit and Light Lens

Your garage door opener is packaged in one carton which

contains the motor unit and the parts illustrated below.

Note that accessories will depend on the model

purchased. If anything is missing, carefully check the

packing material.

Parts may be stuck in the foam. Hardware for assembly

and installation is shown on the next page. Save the

carton and packing material until installation and

adjustment is complete.

Carton Inventory

Hardware Inventory

Separate all hardware and group as shown below for the assembly and installation procedures.

8

Hex Bolt

5/16"-18x7/8" (4)

Screw

6ABx1-1/4" (2)

Lock Washer

5/16" (4)

Nut

5/16"-18 (4)

Clevis Pin

5/16"x2-3/4" (1)

NOTICE

Handle

Insulated

Staples (10)

Assembly Hardware 41A3534

Installation Hardware 41A3475-30

Drywall Anchors (2)

Clevis Pin

5/16"x1" (2)

Rope

Lock Nut

1/4"-20x7/16" (12)

Nut

5/16"-18 (5)

Washered Bolt

5/16"-18x1/2" (2)

(mounted in opener)

Carriage Bolt

1/4"-20x1/2" (12)

Hex Bolt

5/16"-18x7/8" (3)

Master Link (2)

Ring Fastener (3)

Trolley

Threaded Shaft (1)

Lock Washer

5/16" (4)

Lag Screw

5/16"-9x1-5/8" (4)

Self-Threading Screw

1/4"-14x5/8" (2)

9

ASSEMBLY STEP 1

For Sectional and

One-Piece Doors ONLY

Assemble the T-Rail and

Attach the Cable Pulley Bracket

To avoid installation difficulties, do not run the garage

door opener until instructed to do so.

1. Place the 3 T-rail sections on a flat

surface for assembly. The end sections

are identical. The center section must be

positioned with the braces against the

end sections as shown. Make sure the

"directional arrow"on the center section

is pointing toward the front (to door).

Study the illustration carefully.

2. Bolt rail sections together with the

hardware illustrated and from the

direction indicated. (When assembled,

T-rail has a front-to-back position as shown.)

NOTE: If T-rail is not assembled exactly as shown,

trolley will not travel smoothly along length of rail or it

will hit against nuts.

3. Position the cable pulley bracket on the front end of the

T-rail as shown. Fasten securely with the hardware

provided.

NOTE: When tightening the bolts be sure to keep

bracket parallel to the rail. Otherwise, the rail may bow

when the opener is operated.

Lock Nut

1/4"-20

Carriage Bolts

1/4"-20x1/2"

Hex Bolt

5/16"-18x7/8"

Nut

5/16"-18 Lock Washer

5/16"

HARDWARE

SHOWN ACTUAL SIZE

Rail

(Center Section)

1/4'' Lock Nut

RAIL FRONT

(TO DOOR)

Cable pulley bracket

attaches to FRONT

END of Rail

Rail

(End Section)

RAIL BACK

(TO OPENER)

Rail

(End Section)

Carriage Bolt

1/4"-20x1/2"

Brace

Brace

Square Carriage

Bolt Holes

OT G RA GA D

E OOR

Hex Bolts

5/16"-18x7/8"

dengilAeBtsuMlia

&tekcarBliaR

Lock Washer

5/16"

Nut

5/16"

Cable Pulley

Bracket

R

Hex Bolts

5/16"-18x7/8"

dengilAeBtsuMlia

&tekcarBliaR

Lock Washer

5/16"

Nut

5/16"

Cable Pulley

Bracket

R

11 mm Socket Wrench

13 mm Socket Wrench

10

ASSEMBLY STEP 1

For Sliding and Swinging Gates ONLY

Assemble the T-Rail and

Attach the Cable Pulley Bracket

To avoid installation difficulties, do

not run the garage door opener until

instructed to do so.

1. Place the 3 T-rail sections on a flat

surface for assembly. The end sections

are identical. Make sure the “arrow label”

on the center section is pointing in the

direction shown in the illustration.

2. Connect the center section and the 1/4"

lock nuts to the end sections from the

same side, as shown.

NOTE: If T-rail is not assembled exactly as shown,

trolley will not travel smoothly along length of rail or it

will hit against nuts.

3. Insert the carriage bolts from the opposite side of the

end sections. Tighten the nuts. When assembled, T-rail

has a front-to-back position as shown.

4. Position the cable pulley bracket on the front end of the

T-rail as shown. Fasten securely with the hardware

provided.

NOTE: When tightening the bolts be sure to keep

bracket parallel to the rail. Otherwise, the rail may bow

when the opener is operated.

Lock Nut

1/4"-20

Carriage Bolts

1/4"-20x1/2"

Hex Bolt

5/16"-18x7/8"

Nut

5/16"-18 Lock Washer

5/16"

HARDWARE

SHOWN ACTUAL SIZE

Rail

(Center Section)

1/4'' Lock Nut

Cable pulley bracket

attaches to this

end of rail.

Rail

(End Section)

Carriage Bolt

1/4"-20x1/2"

Brace

Square Carriage

Bolt Holes

ROODEGARAGOT

AWAY FROM

OPENER

Brace

Rail

(End Section)

Rail connects to

opener at this end. Tuerca de 1/4" Riel en "T"

(Sección Extrema)

El sostén de la polea

del cable se fija a este

extremo del riel en "T".

Hex Bolts

5/16"-18x7/8"

Cable Pulley

Bracket

dengilAeBtsuMlia

&tekcarBliaR

Lock Washer

5/16"

Nut

5/16"

R

13 mm Socket Wrench

11 mm Socket Wrench

Hex Bolts

5/16"-18x7/8"

Cable Pulley

Bracket

dengilAeBtsuMlia

&tekcarBliaR

Lock Washer

5/16"

Nut

5/16"

R

ASSEMBLY STEP 2

For Sectional and One-Piece Doors Only

Install the Trolley

• Attach the trolley threaded shaft to the trolley with the

lock washer and nuts as shown.

• As a temporary stop, insert a screwdriver into the hole

in the front end of the T-rail.

• Slide the trolley assembly along the rail to the

screwdriver stop.

NOTE: If trolley hits against any nuts on the

T-rail, the bolts and nuts were attached from

the wrong side and must be repositioned.

Review Assembly Step 1.

Trolley

Threaded

Shaft

Lock Washer

5/16"

Outer Nut

5/16"-18

Inner Nut

5/16"-18

Trolley

Trolley

Temporary Stop

Screwdriver

Lock Washer

5/16" Nut

5/16"-18

HARDWARE SHOWN ACTUAL SIZE

ASSEMBLY STEP 2

For Sliding and Swinging Gates Only

Install the Trolley

• Attach the trolley threaded shaft to the trolley with the

lock washer and nuts as shown.

• Insert a hex bolt into the hole in the front end of the

T-rail.

• Slide the trolley assembly along the rail until it rests

against the hex bolt (trolley stop).

NOTE: If trolley hits against any nuts on the T-rail,

the bolts and nuts were attached from the wrong

side and must be repositioned. Review

Assembly Step 1.

Trolley

Threaded

Shaft

Lock Washer

5/16"

Outer Nut

5/16"-18

Inner Nut

5/16"-18

Trolley

Hex Bolt

Trolley Stop

Hex Bolt

5/16"-18x7/8"

Nut

5/16"-18

Lock Washer

5/16"

Cable Pulley

Bracket

Nut

5/16"-18 Lockwasher

5/16"

Hex Bolt

5/16"-18x7/8"

HARDWARE SHOWN ACTUAL SIZE

11

12

ASSEMBLY STEP 3

Fasten the T-Rail to the Motor Unit

• Place the opener on packing material to protect the

cover. For convenience, put a support under the cable

pulley bracket.

• Remove the two 5/16"-18x1/2"washered bolts mounted

in the top of the motor unit.

• Align the holes in the back section of the T-rail with the

holes in the motor unit.

• Fasten the rail with the two washered bolts previously

removed. Tighten securely. Remember to use only

these bolts! Any other bolts will cause serious

damage to the opener.

• Insert a 5/16"-18x7/8"hex bolt into the cover protection

bolt hole in the T-rail as shown. Tighten securely with a

5/16"lock washer and nut.

NOTE: This bolt prevents trolley over-travel. Keep a 38 mm

minimum between the trolley and this bolt when adjusting

travel limits (see page 29).

• Attach chain spreader with #8x1"hex screws and

washers as shown.

Washered Bolt

5/16"-18x1/2"

Rail

(Back

Section)

Cover

Protection

Bolt Hole

Nut

5/16"-18

HexBolt

5/16"-18x7/8"

Lock Washer

5/16"

USE ONLY THIS

TYPE AND SIZE

BOLT

Chain

Spreader

#8x1"

HexScrews

Washers

Nut

5/16"-18 Lock Washer

5/16"

Hex Bolt

5/16"-18x7/8"

HARDWARE SHOWN ACTUAL SIZE

To avoid serious damage to opener, ONLY use bolts/fasteners

mounted in top of motor unit.

ASSEMBLY STEP 4

For Sectional and One-Piece Doors Only

Install the Chain/Cable

1. Pull the cable loop from the

carton and fasten it to the

trolley with a master link

from the hardware bag

(Figure 1).

• Push pins of master link

bar through cable loop and

hole in front end of trolley.

• Push master link cap over

pins and past pin notches.

• Slide clip-on spring over cap and onto pin notches

until both pins are securely locked in place.

2. With the trolley against the screwdriver, dispense the

cable around the pulley.

3. Continue along the rail and around the motor unit

sprocket (Figure 2). Proceed back around the correct

groove in the chain spreader (Figure 3). The sprocket

teeth must engage the chain.

4. Use the second master link to connect the chain to

the flat end of the shaft (Figure 1). Check to make

sure the chain is not twisted.

5. Remove the screwdriver.

13

To avoid possible SERIOUS INJURY to fingers from moving

garage door opener:

• ALWAYS keep hand clear of sprocket while operating opener.

• Securely attach sprocket cover BEFORE operating.

Motor Unit

Sprocket

Install Chain

In This Direction

Chain

Spreader

Figure 2

Cable

Pulley

Cable

Loop

Master

Link Bar

Master Link

Clip-On Spring

Pin

Pin

Notch

Chain

Flat end

of Trolley

Threaded

Shaft

Master Link Cap

Master

Link Cap

Master Link

Clip-On Spring

Install Chain & Cable

In This Direction

Figure 1

Leave Chain

& Cable

Inside Carton to

Prevent Kinking

Keep Chain

Taut When Dispensing

6-Tooth

Sprocket

Opener

Mounting Plate

Chain

Spreader

8-Tooth

Sprocket

Opener

Mounting Plate

Chain

Spreader

Figure 3

One-Piece Doors

6- Tooth Sprocket Application

Sectional Doors

8-Tooth Sprocket Application

(6-tooth sprocket can be used if slower travel speed is

desired.)

14

ASSEMBLY STEP 4

For Sliding and Swinging Gates Only

Install the Chain/Cable

1. Pull the cable loop from the

carton and fasten it to the

trolley with a master link from

the hardware bag (Figure 1).

• Push pins of master link bar

through cable loop and hole

in front end of trolley.

• Push master link cap over

pins and past pin notches.

• Slide clip-on spring over cap and onto pin notches until

both pins are securely locked in place.

2. To prevent the trolley from jamming against the opener

during operation, position trolley 5 to 15 cm from the

stop hole as shown. Then dispense the chain around

the opener sprocket (Figure 1). Make sure the sprocket

teeth engage the chain.

• Proceed around to the pulley bracket and forward to

the threaded trolley shaft.

3. Use the second master link to connect the chain to the

flat end of the shaft (Figure 1). Check to make sure the

chain is not twisted.

To avoid possible SERIOUS INJURY to fingers from moving

opener:

• ALWAYS keep hand clear of sprocket while operating opener.

• Securely attach sprocket cover BEFORE operating.

Leave Chain

& Cable

Inside Carton to

Prevent Kinking

Keep Chain

Taut When Dispensing

Sprocket

Motor Unit

Mounting

Plate

Install Chain

and Cable

in this Direction

Cable Loop

Master

Link Pin

Master Link

Clip-On Spring

Master Link

Clip-On Spring

Flat End

of Trolley

Trolley Pin Notch

Flat End of

Threaded Shaft

Master

Link Cap

Cable

Rail

Master

Link Cap

Chain

Chain Link

Trolley Stop

(Hex Bolt)

mc51-5

Pin Notch

Master

Link

Pin

Figure 1

15

ASSEMBLY STEP 5

Tighten the Chain and Cable

• Spin the inner nut and lock washer down the trolley

threaded shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction

shown. AS YOU TURN THE NUT, KEEP THE CHAIN

FROM TWISTING.

• When the chain is approximately 13 mm above the base

of the T-rail at its midpoint, re-tighten the inner nut to

secure the adjustment.

Sprocket noise can result if chain is either too loose

or too tight.

NOTE: When installation is complete, you may notice

some chain droop with the door closed. This is normal. If

the chain returns to the position shown when the door is

open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS pull the

emergency release handle to disconnect trolley before

adjusting chain.

You have now finished assembling your garage door

opener. Please read the following warnings before

proceeding to the installation section.

Lock

Washer

To Tighten Outer Nut

Inner Nut

Chain

Base of Rail

13 mm

To Tighten

Inner Nut

Outer Nut

IMPORTANT INSTALLATION INSTRUCTIONS

1. READ AND FOLLOW ALL INSTALLATION WARNINGS

AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balanced

and lubricated garage door. An improperly balanced door

may NOT reverse when required and could result in

SEVERE INJURY or DEATH.

3. ALL repairs to cables, spring assemblies and other

hardware MUST be made by a trained door systems

technician BEFORE installing opener.

4. Disable ALL locks and remove ALL ropes connected to

garage door BEFORE installing opener to avoid

entanglement.

5. Install garage door opener 2.1 m or more above floor.

6. Mount the emergency release within reach, but at least

1.8 m above the floor and avoiding contact with vehicles

to avoid accidental release.

7. NEVER connect garage door opener to power source

until instructed to do so.

8. NEVER wear watches, rings or loose clothing while

installing or servicing opener. They could be caught in

garage door or opener mechanisms.

9. Install wall-mounted garage door control:

• within sight of the garage door

• out of reach of children at minimum height of 1.5 m

• away from ALL moving parts of the door.

10. Place entrapment warning label on wall next to garage

door control.

11. Place manual release/safety reverse test label in plain

view on inside of garage door.

12. Upon completion of installation, test safety reversal

system. Door MUST reverse on contact with a 38 mm

obstruction on the floor.

To reduce the risk of SEVERE INJURY or DEATH:

WARNING

INSTALLATION

16

INSTALLATION STEP 1

Determine the Header Bracket

Location

Installation procedures vary according to garage door

types. Follow the instructions which apply to your door.

If your door is a canopy or dual-track style garage door, a

door arm conversion kit is REQUIRED. Follow the

installation instructions included with the replacement door

arm sectional.

SECTIONAL DOOR AND

ONE-PIECE DOOR WITH TRACK

1. Close the door and mark the inside vertical centerline of

the garage door.

2. Extend the line onto the header wall above the door.

You can fasten the header bracket within 1.2 m of

the left or right of the door center only if a torsion

spring or center bearing plate is in the way; or you

can attach it to the ceiling (see page 17) when

clearance is minimal. (It may be mounted on the wall

upside down if necessary, to gain approximately

1 cm .)

If you need to install the header bracket on a 38 mm

board (on wall or ceiling), use lag screws (not provided)

to securely fasten the 38 mm board to structural

supports as shown here and on page 17.

3. Open your door to the highest point of travel as shown.

Draw an intersecting horizontal line on the header wall

5 cm above the high point. This height will provide travel

clearance for the top edge of the door.

Proceed to Step 2, page 18.

To prevent possible SERIOUS INJURY or DEATH:

• Header bracket MUST be RIGIDLY fastened to structural

support on header wall or ceiling, otherwise garage door

might NOT reverse when required. DO NOT install header

bracket over drywall.

• Concrete anchors MUST be used if mounting header bracket

or 38 mm board into masonry.

• NEVER try to loosen, move or adjust garage door, springs,

cables, pulleys, brackets, or their hardware, ALL of which are

under EXTREME tension.

• ALWAYS call a trained door systems technician if garage

door binds, sticks, or is out of balance. An unbalanced

garage door might NOT reverse when required.

Finished

Ceiling

Header

Wall

38 mm

Board Structural

Supports

Vertical

Centerline of

Garage Door

Header

Wall

Ceiling

SECTIONAL DOOR

WITH CURVED TRACK

Track

Highest Point

of Travel

Door

Header

Wall

Door Track

Jamb

Hardware

Highest Point

of Travel

ONE-PIECE DOOR

WITH HORIZONTAL

TRACK & JAMB

HARDWARE

Highest Point

of Travel

Door

Track

Garage

Exterior

Track

Header

Wall

Highest Point

of Travel

Door

Track

CANOPY ONE-PIECE

DOOR WITH

VERTICAL TRACK

Header

Wall

ONE-PIECE DOOR

WITH HORIZONTAL &

VERTICAL TRACK

EXAMPLE

Distance from top of door

(at highest point of travel)to floor ......... 234 cm

Actual height of door ............................ -224 cm

Remainder............................................... 10 cm

Add ........................................................ +20 cm

Bracket height on header wall............... =30 cm

(Measure UP from top of CLOSED door.)

Proceed to Step 2, page 18.

17

Header Wall

Vertical

Centerline

of Garage

Door

2x4

Unfinished

Ceiling

2x4

OPTIONAL

CEILING MOUNT

FOR

HEADER BRACKET

Structural

Supports

ONE-PIECE DOOR WITHOUT TRACK

1. Close the door and mark the inside vertical centerline of

your garage door. Extend the line onto the header wall

above door, as shown.

If headroom clearance is minimal, you can install the

header bracket on the ceiling. (See page 18).

If you need to install the header bracket on a 38 mm

board (on wall or ceiling), use lag screws (not provided)

to securely fasten the 38 mm board to structural

supports as shown.

2. Open your door to the highest point of travel as shown.

Measure the distance from the top of the door to the

floor. Subtract the actual height of the door. Add 20 cm

to the remainder. (See Example).

3. Close the door and draw an intersecting horizontal line

on the header wall at the determined height.

NOTE: If the total number of centimeters exceeds the

height available in your garage, use the maximum height

possible, or refer to page 18 for ceiling installation.

Door

Highest Point

of Travel

Header Wall

Pivot

Distance

Floor

One-piece door without track:

pivot hardware

Header Wall

Highest Point

of Travel

Door

Floor

Distance

Jamb

Hardware

One-piece door without track:

jamb hardware

18

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall above

the garage door, or to the ceiling. Follow the instructions

which will work best for your particular requirements. Do

not install the header bracket over drywall. If installing

into masonry, use concrete anchors (not provided).

WALL HEADER BRACKET INSTALLATION

• Center the bracket on the vertical centerline with the

bottom edge of the bracket on the horizontal line as

shown (with the arrow pointing toward the ceiling).

• Mark the vertical set of bracket holes (do not use the

holes designated for ceiling mount). Drill 5 mm pilot

holes and fasten the bracket securely to a structural

support with the hardware provided.

Lag Screw

5/16"-9x1-5/8"

HARDWARE SHOWN ACTUAL SIZE

Lag Screws

5/16"x9x1-5/8"

Highest Point of

Garage Door Travel

Vertical

Centerline of

Garage Door

Header

Wall

Garage

Door

UP

CEILING MOUNT ONLY

Wall Mounting Holes

Optional

Wall Mounting Holes

The nail hole is for

positioning only.

You must use lag screws

to mount the header bracket.

UP

CEILINGMOUNTONLY

Door Spring

Header

Bracket

38 mm

Board

Vertical Centerline

of Garage Door

UP

CEILING MOUNT ONLY

Ceiling Mounting Holes

The nail hole is for

positioning only.

You must use lag screws

to mount the header bracket.

UP

Lag Screws

5/16"x9x1-5/8"

Garage Door

Vertical Centerline

of Garage Door

Header Wall

– Finished Ceiling –

Header

Bracket

15 cm Maximum

Vertical

Centerline of

Garage Door

Door

Spring

CEILING HEADER BRACKET INSTALLATION

• Extend the vertical centerline onto the ceiling as shown.

• Center the bracket on the vertical mark, no more than

15 cm from the wall. Make sure the arrow is pointing

toward the wall. The bracket can be mounted flush

against the ceiling when clearance is minimal.

• Mark the side holes. Drill 5 mm pilot holes and fasten

bracket securely to a structural support with the

hardware provided.

Clevis Pin

5/16"x2-3/4" Ring Fastener

HARDWARE SHOWN ACTUAL SIZE

Header Bracket

Chain Pulley

Bracket

Temporary

Support

Header Wall

Garage

Door

Rail

Clevis Pin

5/16"x2-3/4"

Ring Fastener

Header Bracket

Chain

Pulley

Bracket

Rail

19

INSTALLATION STEP 3

Attach the T-Rail to the Header Bracket

• Position the opener on the garage floor below the

header bracket. Use packing material as a protective

base.

NOTE: If the door spring is in the way you’ll need help.

Have someone hold the opener securely on a temporary

support to allow the rail to clear the spring.

• Position the rail bracket against the header bracket.

• Align the bracket holes and join with a clevis pin

as shown.

• Insert a ring fastener to secure.

20

ONE-PIECE DOOR WITHOUT TRACK

A 38 mm board is convenient for setting an ideal door-to-

T-rail distance.

• With the door fully open and parallel to the floor,

measure the distance from the floor to the top of the

door.

• Using a stepladder as a support, raise the top of the

opener to this height.

• The top of the door should be level with the top of the

motor unit. Do not position the opener more than 5 cm

above this point.

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type as

illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH

TRACK

A 38 mm board is convenient for setting an ideal door-to-

T-rail distance.

• Raise the opener onto a stepladder. You will need help

at this point if the ladder is not tall enough.

• Open the door all the way and place a 38 mm board on

the top section beneath the T-rail.

• If the top section or panel hits the trolley when you raise

the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the outer

trolley toward the motor unit. The trolley can remain

disconnected until Installation Step 11 is completed.

Rail

38 mm

Board

Door

Header

Bracket

Trolley

Release Arm

ENGAGED RELEASED

To prevent damage to garage door, rest garage door opener

rail on 38 mm board placed on top section of door.

Top of Motor Unit

Header

Bracket

Top of Door

38 mm

Board

Other manuals for 511MM FS2

1

Table of contents

Other Merik Garage Door Opener manuals

Merik

Merik LiftMaster 7511LMK User manual

Merik

Merik 501M-1/2HP User manual

Merik

Merik 511MM FS2 User manual

Merik

Merik Security+ 711MD User manual

Merik

Merik Security+ 411M User manual

Merik

Merik 511M FS2 User manual

Merik

Merik 511M FS2 User manual

Merik

Merik 350 H User manual

Merik

Merik 790LMK User manual

Merik

Merik 711MB User manual

Popular Garage Door Opener manuals by other brands

Serai

Serai MT/B6 installation manual

Chamberlain

Chamberlain LiftMaster LM800A-2 Technical data

Beninca

Beninca JM.3PRO Operating instructions and spare parts catalogue

Nice

Nice SO2000 instructions

Wayne-Dalton

Wayne-Dalton TORQUEMASTER 5140 Installation instructions and owner's manual

Bernal

Bernal SenTAC Operation & instruction manual