Meritor Heavy-Duty P Series User manual

Service Notes

Information contained in this publication was in effect at the time the publication was

approved for printing and is subject to change without notice or liability. Meritor Heavy

Vehicle Systems, LLC, reserves the right to revise the information presented or to

discontinue the production of parts described at any time.

Meritor Maintenance Manual MM-0440 (Issued 09-04)

About This Manual

This manual provides maintenance and service information for

Meritor heavy-duty P Series cam brakes.

Before You Begin

1. Read and understand all instructions and procedures before

you begin to service components.

2. Read and observe all Warning and Caution hazard alert

messages in this publication. They provide information that can

help prevent serious personal injury, damage to components,

or both.

3. Follow your company’s maintenance and service, installation,

and diagnostics guidelines.

4. Use special tools when required to help avoid serious personal

injury and damage to components.

Hazard Alert Messages and Torque

Symbols

WARNING

A Warning alerts you to an instruction or procedure that you

must follow exactly to avoid serious personal injury and

damage to components.

CAUTION

A Caution alerts you to an instruction or procedure that you

must follow exactly to avoid damage to components.

@This symbol alerts you to tighten fasteners to a specified torque

value.

How to Obtain Product and Service

Information

On the Web

Visit the DriveTrain Plus™ by Meritor Tech Library at meritor.com to

easily access product and service information. The Library also

offers an interactive and printable Literature Order Form.

Meritor’s Customer Service Center

Call Meritor’s Customer Service Center at 800-535-5560.

Technical Electronic Library on CD

The DriveTrain Plus™ by Meritor Technical Electronic Library on CD

contains product and service information for most Meritor and

Meritor WABCO products. $20. Specify TP-9853.

How to Obtain Tools and Supplies

Call Meritor’s Commercial Vehicle Aftermarket at 888-725-9355 to

obtain Meritor tools and supplies.

pg. pg.

Contents

iAsbestos and Non-Asbestos Fibers

1Section 1: Exploded View

2Section 2: Introduction

Description

Cam Brake Tips

3Section 3: Removal and Disassembly

Removal

Wheel Components

4BrakeShoes

Camshaft and Slack Adjuster

5Section 4: Prepare Parts for Assembly

Clean, Dry and Inspect Parts

Clean and Dry Parts

Corrosion Protection

Inspect Parts

8Section 5: Assembly and Installation

Installation

Camshaft Assemblies

9BrakeShoes

Slack Adjusters

12 Section 6: Adjustment

Adjust the Brakes

Measure Free Stroke

13 Commercial Vehicle Safety Alliance (CVSA) Guidelines

15 Section 7: Reline the Brakes

Reline the Brakes

Installing Linings with Rivets

16 Installing Linings with Bolts

Oversize Drums

17 Section 8: Maintenance

Lubrication

Brake Assembly Components

19 Slack Adjuster

Intervals

Applications

Adjust the Brakes

20 Reline the Brakes

Important Information on Linings and Primary Shoe

Locations

21 Major Overhaul

Inspection

Before You Return the Vehicle to Service

22 Section 9: Specifications

Torque Specifications

Asbestos and Non-Asbestos Fibers

i

Meritor Maintenance Manual MM-0440 (Issued 09-04)

Figure 0.1

ASBESTOS FIBERS WARNING

The followingproceduresfor servicingbrakesare recommendedto reduce exposure to

asbestosfiber dust, a cancer andlungdisease hazard. Material Safety Data Sheetsare

available from Meritor.

Hazard Summary

Becausesomebrakelinings contain asbestos, workers who servicebrakes must understandthe

potential hazards of asbestos andprecautions for reducing risks. Exposureto airborneasbestos

dust can causeserious andpossibly fatal diseases, including asbestosis (achronic lung disease)

andcancer, principally lung cancer andmesothelioma(acancer of thelining of thechest or

abdominal cavities). Somestudies show that therisk of lung cancer among persons who smoke

andwho areexposed to asbestos is much greater than therisk for non-smokers. Symptoms of

thesediseases may not becomeapparent for 15, 20 or moreyears after thefirst exposureto

asbestos.

Accordingly, workers must usecaution to avoidcreating andbreathing dust when servicing brakes.

Specific recommended work practices for reducing exposureto asbestos dust follow. Consult your

employer for moredetails.

Recommended Work Practices

1. SeparateWork Areas. Whenever feasible, servicebrakes in aseparatearea away from other

operations to reducerisks to unprotected persons. OSHA has set amaximum allowablelevel of

exposurefor asbestos of 0.1 f/cc as an 8-hour time-weighted averageand1.0 f/cc averaged over

a30-minuteperiod. Scientists disagree,however, to what extent adherenceto themaximum

allowableexposurelevels will eliminatetherisk of diseasethat can result from inhaling asbestos

dust. OSHA requires that thefollowing sign be posted at theentranceto areas whereexposures

exceed either of themaximum allowablelevels:

DANGER: ASBESTOS

CANCER AND LUNGDISEASE HAZARD

AUTHORIZED PERSONNEL ONLY

RESPIRATORSAND PROTECTIVE CLOTHING

ARE REQUIRED IN THISAREA.

2. Respiratory Protection. Wear arespirator equipped with ahigh-efficiency (HEPA) filter

approved by NIOSH or MSHA for usewith asbestos at all times when servicing brakes, beginning

with theremoval of thewheels.

3. Procedures for Servicing Brakes.

a. Enclosethebrakeassembly within anegativepressureenclosure. Theenclosureshouldbe

equipped with aHEPA vacuum andworker arm sleeves. With theenclosurein place, usethe

HEPA vacuum to loosen andvacuum residuefrom thebrakeparts.

b. As an alternativeprocedure, useacatch basin with water andabiodegradable,

non-phosphate, water-based detergent to wash thebrakedrum or rotor andother brake

parts. Thesolution shouldbe applied with low pressureto prevent dust from becoming

airborne. Allow thesolution to flow between thebrakedrum andthebrakesupport or the

brakerotor andcaliper. Thewheel hubandbrakeassembly components shouldbe thoroughly

wetted to suppress dust beforethebrakeshoes or brakepads areremoved. Wipethebrake

parts clean with acloth.

c. If an enclosed vacuum system or brakewashing equipment is not available, employers may

adopt their own written procedures for servicing brakes, provided that theexposurelevels

associated with theemployer’s procedures do not exceed thelevels associated with the

enclosed vacuum system or brakewashing equipment. Consult OSHA regulations for more

details.

d. Wear arespirator equipped with aHEPA filter approved by NIOSH or MSHA for usewith

asbestos when grinding or machining brakelinings. In addition, do such work in an area with

alocal exhaust ventilation system equipped with aHEPA filter.

e. NEVER usecompressed air by itself, dry brushing, or avacuum not equipped with aHEPA

filter when cleaning brakeparts or assemblies. NEVER usecarcinogenic solvents, flammable

solvents, or solvents that can damagebrakecomponents as wetting agents.

4. Cleaning Work Areas. Clean work areas with avacuum equipped with aHEPA filter or by wet

wiping. NEVER usecompressed air or dry sweeping to clean work areas. When you empty vacuum

cleaners andhandleused rags, wear arespirator equipped with aHEPA filter approved by NIOSH

or MSHA for usewith asbestos. When you replaceaHEPA filter, wet thefilter with afinemist of

water anddisposeof theused filter with care.

5. Worker Clean-Up. After servicing brakes, wash your hands beforeyou eat, drink or smoke.

Shower after work. Do not wear work clothes home. Useavacuum equipped with aHEPA filter to

vacuum work clothes after they areworn. Launder them separately. Do not shakeor use

compressed air to removedust from work clothes.

6. WasteDisposal. Disposeof discarded linings, used rags, cloths andHEPA filters with care,

such as in sealed plastic bags. Consult applicableEPA, stateandlocal regulations on waste

disposal.

Regulatory Guidance

References to OSHA, NIOSH, MSHA, andEPA, which areregulatory agencies in theUnited States,

aremade to provide further guidanceto employers andworkers employed within theUnited States.

Employers andworkers employed outside of theUnited States shouldconsult theregulations that

apply to them for further guidance.

NON-ASBESTOS FIBERS WARNING

The followingproceduresfor servicingbrakesare recommendedto reduce exposure to

non-asbestosfiber dust, a cancer andlungdisease hazard. Material Safety Data Sheets

are available from Meritor.

Hazard Summary

Most recently manufactured brakelinings do not contain asbestos fibers. Thesebrakelinings may

contain oneor moreof avariety of ingredients, including glass fibers, mineral wool, aramidfibers,

ceramic fibers andsilicathat can present health risks if inhaled. Scientists disagree on theextent

of therisks from exposureto thesesubstances. Nonetheless, exposureto silicadust can cause

silicosis, anon-cancerous lung disease. Silicosis gradually reduces lung capacity andefficiency

andcan result in serious breathing difficulty. Somescientists believeother types of non-asbestos

fibers, when inhaled, can causesimilar diseases of thelung. In addition, silicadust andceramic

fiber dust areknown to theStateof Californiato causelung cancer. U.S. andinternational

agencies havealso determined that dust from mineral wool, ceramic fibers andsilicaarepotential

causes of cancer.

Accordingly, workers must usecaution to avoidcreating andbreathing dust when servicing brakes.

Specific recommended work practices for reducing exposureto non-asbestos dust follow. Consult

your employer for moredetails.

Recommended Work Practices

1. SeparateWork Areas. Whenever feasible, servicebrakes in aseparatearea away from other

operations to reducerisks to unprotected persons.

2. Respiratory Protection. OSHA has set amaximum allowablelevel of exposurefor silicaof

0.1 mg/m3 as an 8-hour time-weighted average. Somemanufacturers of non-asbestos brake

linings recommendthat exposures to other ingredients foundin non-asbestos brakelinings be

kept below 1.0 f/cc as an 8-hour time-weighted average. Scientists disagree, however, to what

extent adherenceto thesemaximum allowableexposurelevels will eliminatetherisk of disease

that can result from inhaling non-asbestos dust.

Therefore, wear respiratory protection at all times during brakeservicing, beginning with the

removal of thewheels. Wear arespirator equipped with ahigh-efficiency (HEPA) filter approved by

NIOSH or MSHA, if theexposurelevels may exceed OSHA or manufacturers’recommended

maximum levels. Even when exposures areexpected to be within themaximum allowablelevels,

wearing such arespirator at all times during brakeservicing will help minimizeexposure.

3. Procedures for Servicing Brakes.

a. Enclosethebrakeassembly within anegativepressureenclosure. Theenclosureshouldbe

equipped with aHEPA vacuum andworker arm sleeves. With theenclosurein place, usethe

HEPA vacuum to loosen andvacuum residuefrom thebrakeparts.

b. As an alternativeprocedure, useacatch basin with water andabiodegradable,

non-phosphate, water-based detergent to wash thebrakedrum or rotor andother brake

parts. Thesolution shouldbe applied with low pressureto prevent dust from becoming

airborne. Allow thesolution to flow between thebrakedrum andthebrakesupport or the

brakerotor andcaliper. Thewheel hubandbrakeassembly components shouldbe thoroughly

wetted to suppress dust beforethebrakeshoes or brakepads areremoved. Wipethebrake

parts clean with acloth.

c. If an enclosed vacuum system or brakewashing equipment is not available, carefully clean

thebrakeparts in theopen air. Wet theparts with asolution applied with apump-spray bottle

that creates afinemist. Useasolution containing water, and,if available, abiodegradable,

non-phosphate, water-based detergent. Thewheel hubandbrakeassembly components

shouldbe thoroughly wetted to suppress dust beforethebrakeshoes or brakepads are

removed. Wipethebrakeparts clean with acloth.

d. Wear arespirator equipped with aHEPA filter approved by NIOSH or MSHA when grinding or

machining brakelinings. In addition, do such work in an area with alocal exhaust ventilation

system equipped with aHEPA filter.

e. NEVER usecompressed air by itself, dry brushing, or avacuum not equipped with aHEPA

filter when cleaning brakeparts or assemblies. NEVER usecarcinogenic solvents, flammable

solvents, or solvents that can damagebrakecomponents as wetting agents.

4. Cleaning Work Areas. Clean work areas with avacuum equipped with aHEPA filter or by wet

wiping. NEVER usecompressed air or dry sweeping to clean work areas. When you empty vacuum

cleaners andhandleused rags, wear arespirator equipped with aHEPA filter approved by NIOSH

or MSHA, to minimizeexposure. When you replaceaHEPA filter, wet thefilter with afinemist of

water anddisposeof theused filter with care.

5. Worker Clean-Up. After servicing brakes, wash your hands beforeyou eat, drink or smoke.

Shower after work. Do not wear work clothes home. Useavacuum equipped with aHEPA filter to

vacuum work clothes after they areworn. Launder them separately. Do not shakeor use

compressed air to removedust from work clothes.

6. WasteDisposal. Disposeof discarded linings, used rags, cloths andHEPA filters with care,

such as in sealed plastic bags. Consult applicableEPA, stateandlocal regulations on waste

disposal.

Regulatory Guidance

References to OSHA, NIOSH, MSHA, andEPA, which areregulatory agencies in theUnited States,

aremade to provide further guidanceto employers andworkers employed within theUnited States.

Employers andworkers employed outside of theUnited States shouldconsult theregulations that

apply to them for further guidance.

1 Exploded View

1

Meritor Maintenance Manual MM-0440 (Issued 09-04)

1 Exploded View

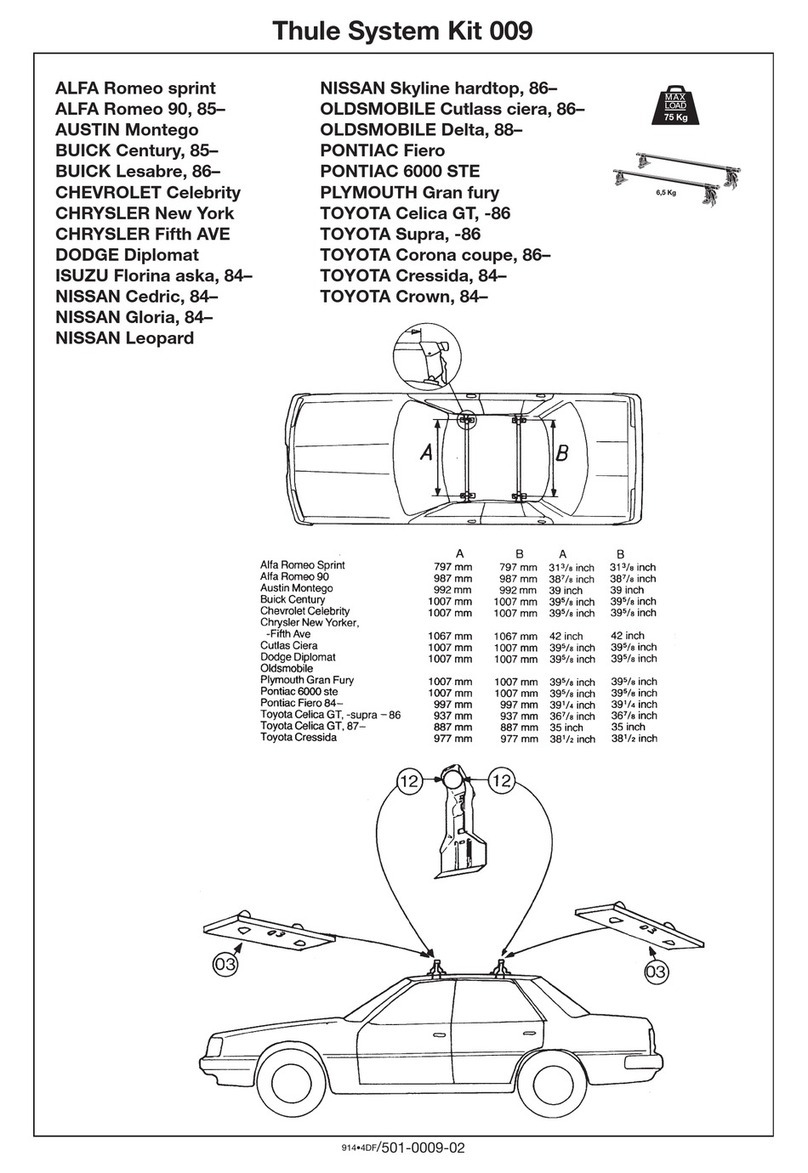

Figure 1.1

22

21

20

23

19

18

16

17

13

14

15

12

4004493a

11

10

9

6

7

8

12345

Item Description

1Camshaft and Chamber Bracket

2Bracket Capscrews

3Bracket Lock Washers

4Bracket-to-Spider Spacer

5Manual Slack Adjuster

6Cam Spacing Washer

7Cam Head Washer

8Small Spacing Washer

9Cam Needle Bearing

10 Shoe and Lining Assembly

11 Anchor Pin Lock Screw

12 Brake Spider

13 Brake Shoe Anchor Pin

14 Anchor Pin Lock

15 Anchor Pin Felt Retainer

16 Anchor Pin Felt

17 Shoe Return Spring

18 Double Head Cam

19 Clevis Pin

20 Cotter Pin

21 Chamber Stud Nut

22 Chamber Stud Washer

23 Air Chamber

Item Description

2 Introduction

2Meritor Maintenance Manual MM-0440 (Issued 09-04)

2 Introduction

Description

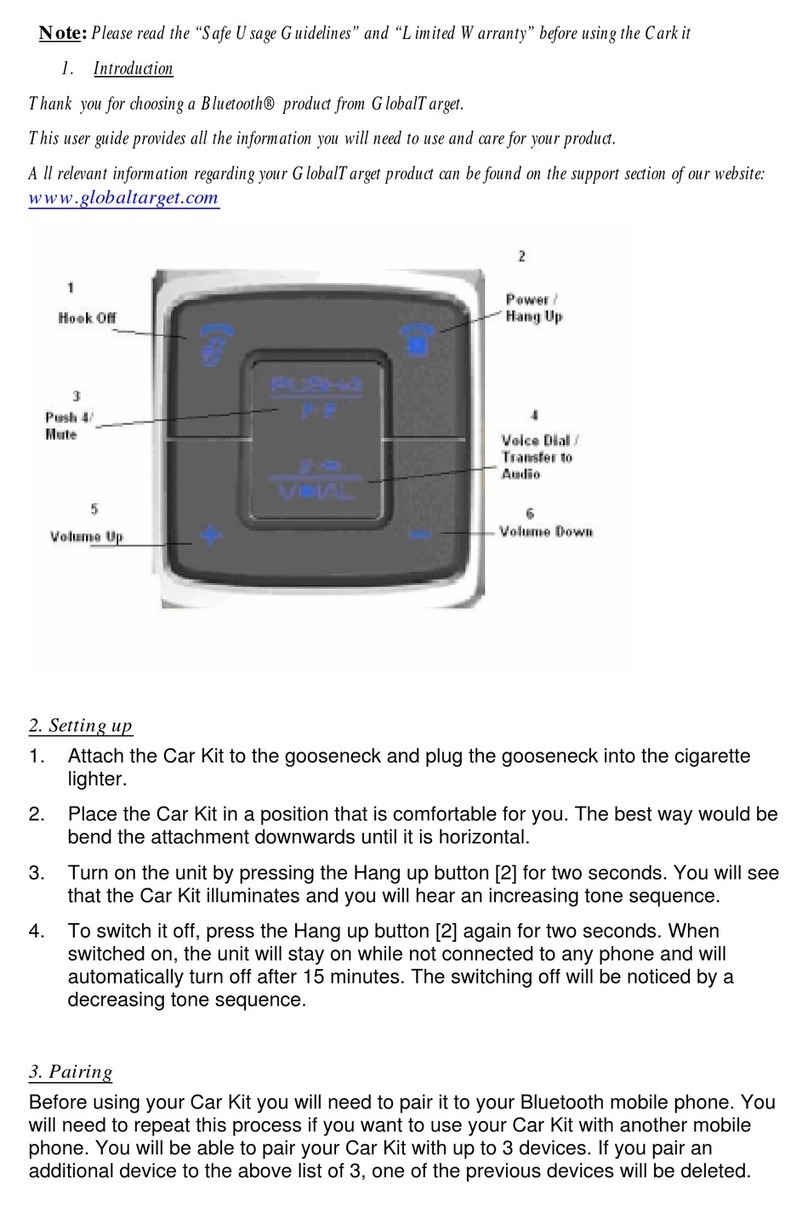

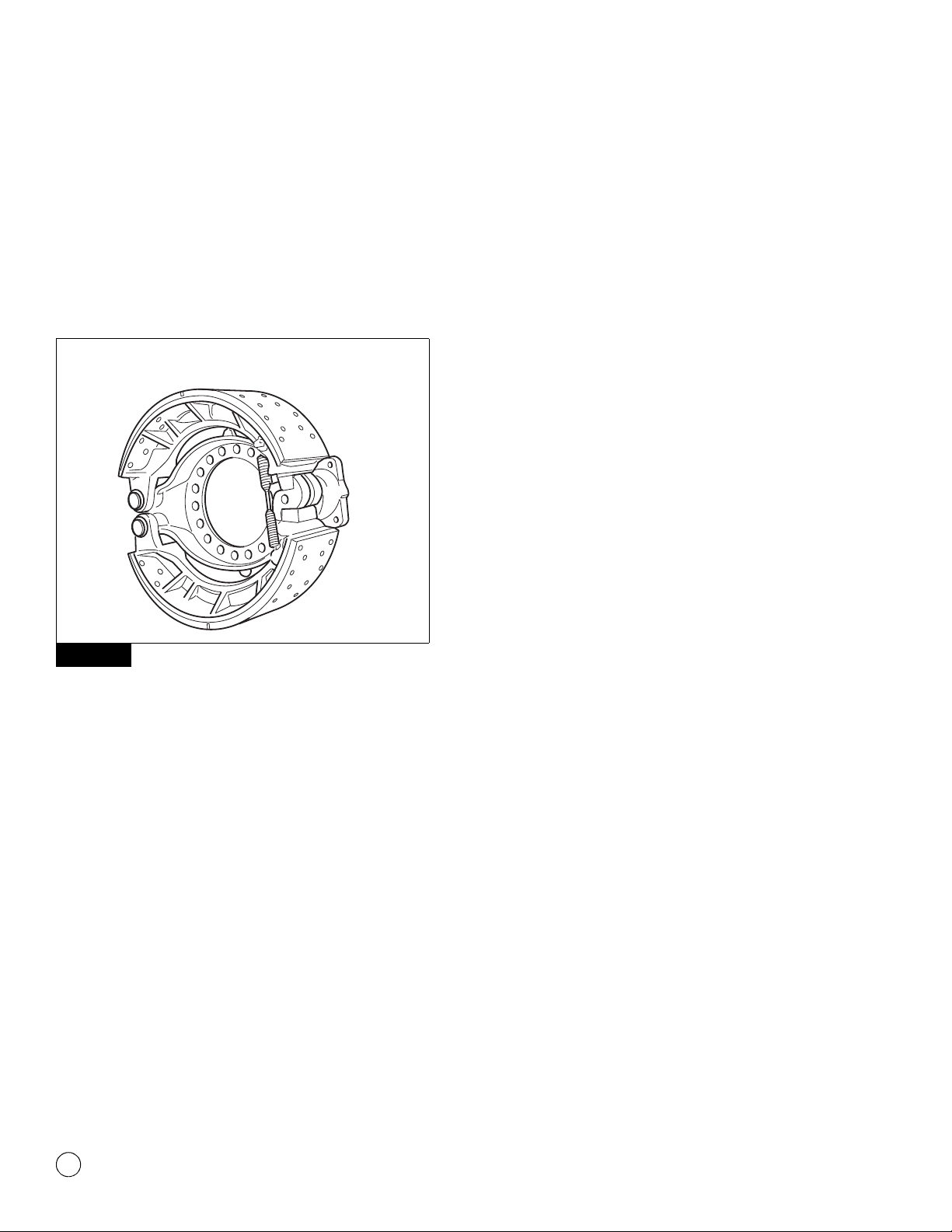

Meritor P Series cam brakes are air actuated and cam operated with

two brake shoes – each mounted on a separate anchor. The brakes

are designed for heavy-duty on- or off-highway applications and

special equipment where larger shoe and drum areas are

necessary. Brake diameters of 20.25-inches and 22-inches are

available with automatic or manual adjustment. The brakes can be

assembled with auxiliary spring brakes. Figure 2.1.

Figure 2.1

Cam Brake Tips

Air Chambers

To ensure correct brake balance, all brake chambers on the same

axle must be the same size and type to help ensure a balanced

brake system for maximum lining wear and drum life.

Brake Kits

Meritor brake shoes, rollers, camshafts and shoe return springs are

designed to perform as a system. Always install original equipment

manufacturer spec-level components during maintenance or when

you upgrade from standard to long-life brakes to help ensure correct

brake performance and maximum lining life.

Cam Heads

Cam heads can look the same, but that doesn’t mean they will

perform the same in your brake system. Two cam head profiles can

appear to be identical, but very small differences in cams from

different manufacturers can be significant enough to affect the

performance of your brakes. To ensure a balanced brake system

and optimum lining and drum life, always install the correct

replacement cam.

Cam Rollers

To avoid flat spots, lubricate a cam roller directly in the web roller

pocket and not at the cam-to-roller contact area. Flat spots can

affect brake adjustment and result in premature brake wear or

reduced braking performance.

Drums

To help ensure balanced braking, even lining and drum wear, and

correct function of the automatic slack adjuster, do not install a cast

drum and a composite drum on the same axle.

A cast drum and a composite drum each absorbs and dissipates

heat differently. When drum types and weights are mixed, different

rates of heat absorption and dissipation occur that can affect the

brake system.

Hardware

When you service cam brakes, replace all the springs, anchor pins,

bushings and rollers — not just the shoe return springs — to help

ensure maximum braking performance.

Linings

Insist on the same brand of quality original equipment manufacturer

friction lining material to help ensure fewer relines and compatibility

with your present system.

Replacement Parts

Always use original equipment manufacturer quality standard parts.

Meritor brakes work as a system, and when you replace original

parts with will-fit parts, you can compromise the performance of the

entire system.

Return Springs

Replace cam brake return springs at every cam brake reline. The

return spring is critical to alignment, accurate return of the brake

away from the drum and correct automatic slack adjustment.

Trailer Cam Brakes

Long-life bushings require correct lubrication for maximum

performance and bushing life. Although you do not have to replace

spider cam bushings on trailer axles as frequently, Meritor

recommends that you lubricate the bushings at least four times

during the life of your brake lining.

Automatic Slack Adjusters

Automatic doesn’t mean maintenance-free. Correctly installed and

lubricated automatic slack adjusters help to ensure maximum brake

system performance.

Never mix automatic slack adjusters on the same axle. When you

replace automatic slack adjusters, always use replacement parts

that were originally designed for the brake system to help ensure

even brake wear, balanced braking and maximum brake

performance.

Figure 2.1

4004873b

HEAVY-DUTY “P” SERIES BRAKE

3 Removal and Disassembly

3

Meritor Maintenance Manual MM-0440 (Issued 09-04)

3 Rem oval and Disa ssembl y

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

ASBESTOS AND NON-ASBESTOS

FIBERS WARNING

Some brake linings contain asbestos fibers, a cancer and lung

disease hazard. Some brake linings contain non-asbestos

fibers, whose long-term effects to health are unknown. You

must use caution when you handle both asbestos and

non-asbestos materials.

Removal

Wheel Components

WARNING

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip or fall over. Serious personal injury and

damage to components can result.

1. Park the vehicle on a level surface. Block the wheels to prevent

the vehicle from moving.

2. Use a jack to raise the vehicle so that the wheels to be serviced

are off the ground. Support the vehicle with safety stands.

WARNING

Before you service a spring chamber, carefully follow the

manufacturer’s instructions to compress and lock the spring to

completely release the brake. Verify that no air pressure

remains in the service chamber before you proceed. Sudden

release of compressed air can cause serious personal injury

and damage to components.

3. If the brake has spring chambers, carefully cage and lock the

spring, so that the spring cannot actuate during assembly.

NOTE: For complete maintenance and service information on

Meritor automatic slack adjusters, refer to Maintenance Manual 4,

Cam Brakes and Automatic Slack Adjuster. To obtain this

publication, refer to the Service Notes page on the front inside cover

of this manual.

If the slack adjuster is not a Meritor automatic slack adjuster, refer

to the manufacturer’s literature for the correct service procedures.

4. Fully release the slack adjusters so the shoes retract and the

drums will clear the linings.

CAUTION

You must disengage a pull pawl or remove a conventional pawl

before rotating the manual adjusting nut, or you will damage

the pawl teeth. A damaged pawl will not allow the slack

adjuster to automatically adjust brake clearance. Replace

damaged pawls before putting the vehicle in service.

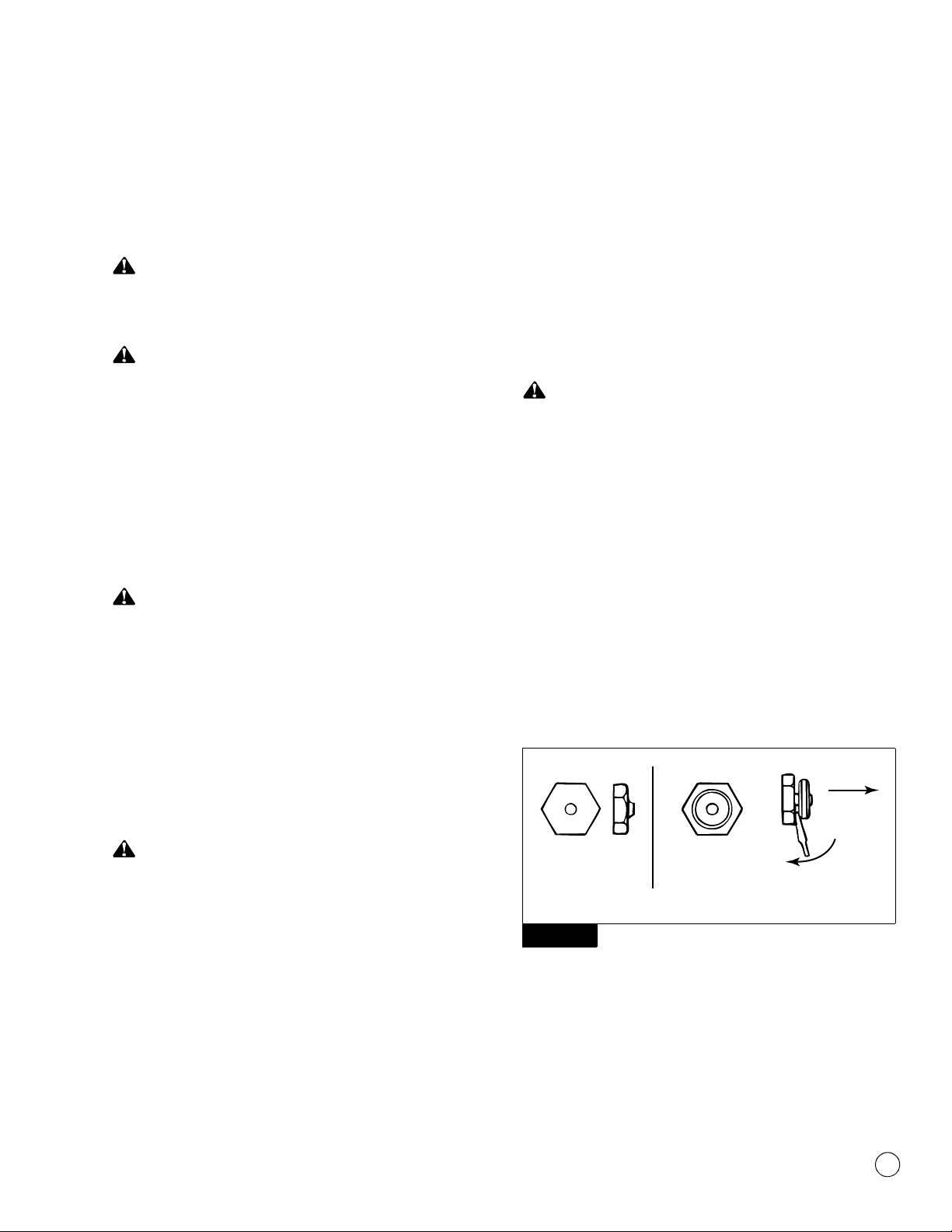

A. Disengage the pawl.

앫If the slack adjuster has a pull pawl: Use a

screwdriver or equivalent tool to pry the pull pawl at

least 0.03125-inch (0.8 mm) to disengage the teeth.

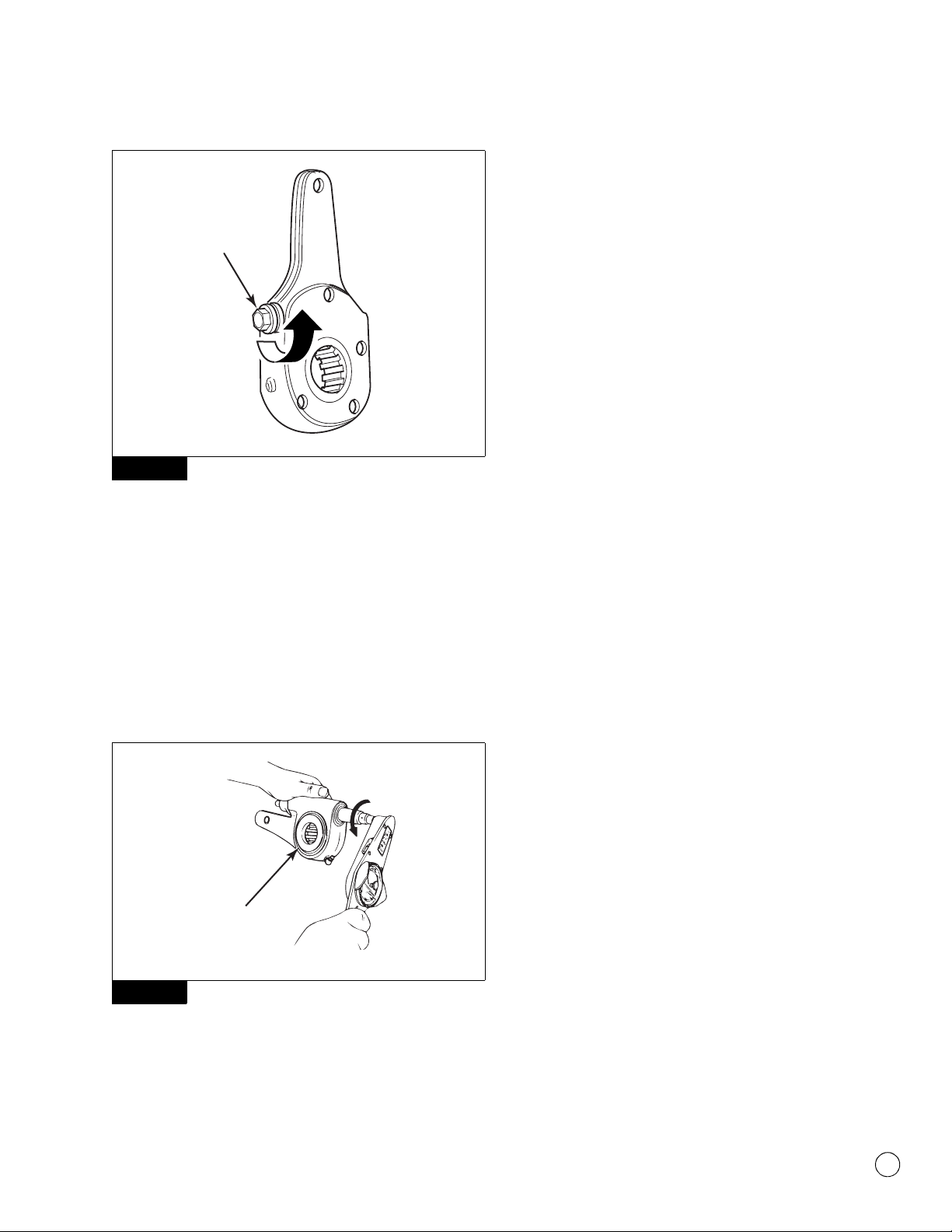

Figure 3.1.

앫If the slack adjuster has a conventional pawl:

Remove the pawl assembly, pressure relief capscrew,

spring and pawl, from the side of the slack adjuster

housing. Figure 3.2.

Figure 3.1

Figure 3.1

CONVENTIONAL

PAWL

PULL PAWL

PRY UP

PAWL

4000331b

3 Removal and Disassembly

4Meritor Maintenance Manual MM-0440 (Issued 09-04)

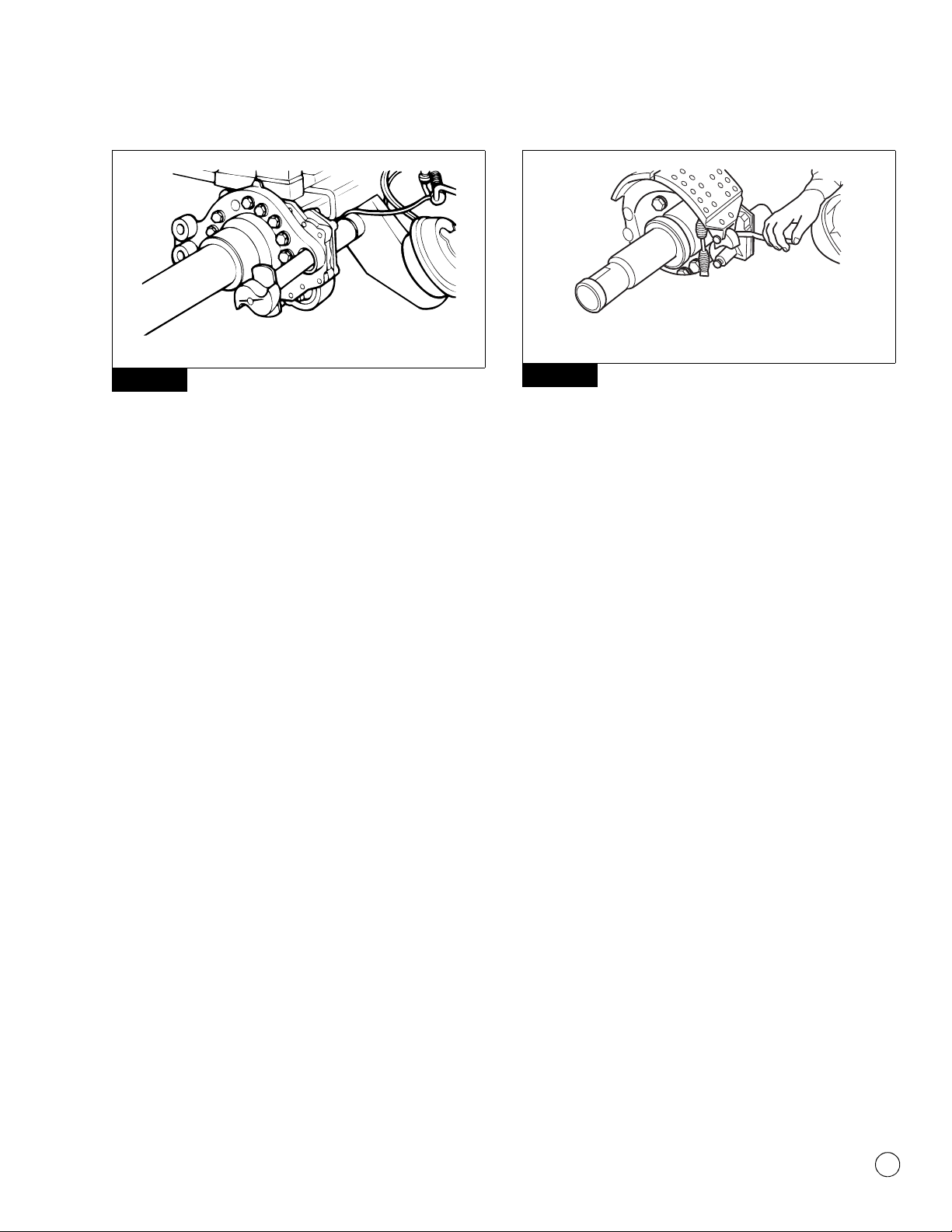

Figure 3.2

B. Use a wrench to turn the manual adjusting nut

CLOCKWISE until the brake shoes are fully retracted, and

the lining clears the drum.

C. Install the pawl into the slack adjuster housing.

5. Follow the manufacturer’s instructions to remove the wheel

and drum from the axle.

Brake Shoes

1. Remove the brake shoe return springs.

2. Remove the lock rings, retainers and felt seals from the anchor

pins.

3. Cut the lock wire and remove the anchor pin lock screws from

the brake spider. Figure 3.3.

Figure 3.3

4. Remove the anchor pins and the brake shoe assemblies.

Camshaft and Slack Adjuster

1. Remove the two clevis pins from the clevis on the air chamber

push rod.

2. Remove the slack adjuster from the camshaft.

3. Check the up-and-down and side-to-side end play of the

camshaft. Figure 3.4. If end play exceeds XX.XX, replace the

needle bearings. Use a press with the correct size driver to

remove the needle bearing assemblies.

Figure 3.4

4. Remove the washers, retainers and spacers from the

camshaft.

5. Pull the camshaft from the spider and bracket.

Figure 3.2

4004494a

PAW L

ASSEMBLY

MANUAL

ADJUSTING

NUT

Figure 3.3

Figure 3.4

4004495a

LOCK

SCREWS

4000342a

0.030"

(0.76 MM)

4 Prepare Parts for Assembly

5

Meritor Maintenance Manual MM-0440 (Issued 09-04)

4 Prepare Parts for Assembly

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

ASBESTOS AND NON-ASBESTOS

FIBERS WARNING

Some brake linings contain asbestos fibers, a cancer and lung

disease hazard. Some brake linings contain non-asbestos

fibers, whose long-term effects to health are unknown. You

must use caution when you handle both asbestos and

non-asbestos materials.

Clean, Dry and Inspect Parts

Clean and Dry Parts

WARNING

Solvent cleaners can be flammable, poisonous and cause

burns. Examples of solvent cleaners are carbon tetrachloride,

and emulsion-type and petroleum-base cleaners. Read the

manufacturer’s instructions before using a solvent cleaner,

then carefully follow the instructions. Also follow the

procedures below.

앫Wear safe eye protection.

앫Wear clothing that protects your skin.

앫Work in a well-ventilated area.

앫Do not use gasoline, or solvents that contain gasoline.

Gasoline can explode.

앫You must use hot solution tanks or alkaline solutions

correctly. Read the manufacturer’s instructions before

using hot solution tanks and alkaline solutions. Then

carefully follow the instructions.

CAUTION

Do not use hot solution tanks or water and alkaline solutions to

clean ground or polished parts. Damage to parts can result.

Use soap and water to clean non-metal parts. Dry parts immediately

after cleaning with soft, clean paper or cloth, or compressed air.

Corrosion Protection

1. If you assemble parts immediately after you clean them,

lubricate parts with grease to prevent corrosion. Parts must be

clean and dry before you lubricate them. Do not apply grease

to the brake linings or the brake drums.

2. If you store parts after you clean them, apply a

corrosion-preventive material. Do not apply the material to the

brake linings or the brake drums. Store parts in a special paper

or other material that prevents corrosion.

Inspect Parts

1. Check the spider for expanded anchor pin holes and for cracks.

Replace damaged spiders and anchor pin bushings.

2. Check the camshaft bracket for broken welds, cracks and

correct alignment. Replace damaged brackets.

3. Check the anchor pins for corrosion and wear. Replace worn or

damaged anchor pins.

4. Check the brake shoes for rust, expanded rivet holes, broken

welds and correct alignment. Replace a shoe with any of the

above conditions.

5. Check the camshaft for cracks, wear and corrosion. Check the

cam head, bearing journals and splines. Replace worn or

damaged camshafts.

6. Inspect the large and small clevis pins for wear and damage.

Replace worn or damaged parts.

CAUTION

Always replace used clevis pin retainer clips with new ones

when you service an automatic slack adjuster or chamber. Do

not reuse retainer clips. Discard used clips. When you remove

a retainer clip, it can bend or “gap apart” and lose retention.

Damage to components can result.

NOTE: If you remove cotter pins from a slack adjuster during

maintenance and service procedures, Meritor recommends that you

install clevis pin retainer clips at assembly.

7. Inspect the clevis pin retainer clips or cotter pins for wear and

damage. Replace worn or damaged retainer clips and cotter

pins. Do not reuse clevis pin retainer clips. Always replace

used retainer clips with new ones. Discard used clips.

4 Prepare Parts for Assembly

6Meritor Maintenance Manual MM-0440 (Issued 09-04)

WARNING

Do not operate the vehicle with the brake drum worn or

machined beyond the discard dimension indicated on the

drum. The brake system may not operate correctly. Damage to

components and serious personal injury can result.

CAUTION

Replace the brake drum if it is out-of-round. Do not turn or

rebore a brake drum, which decreases the strength and

capacity of the drum. Damage to components can result.

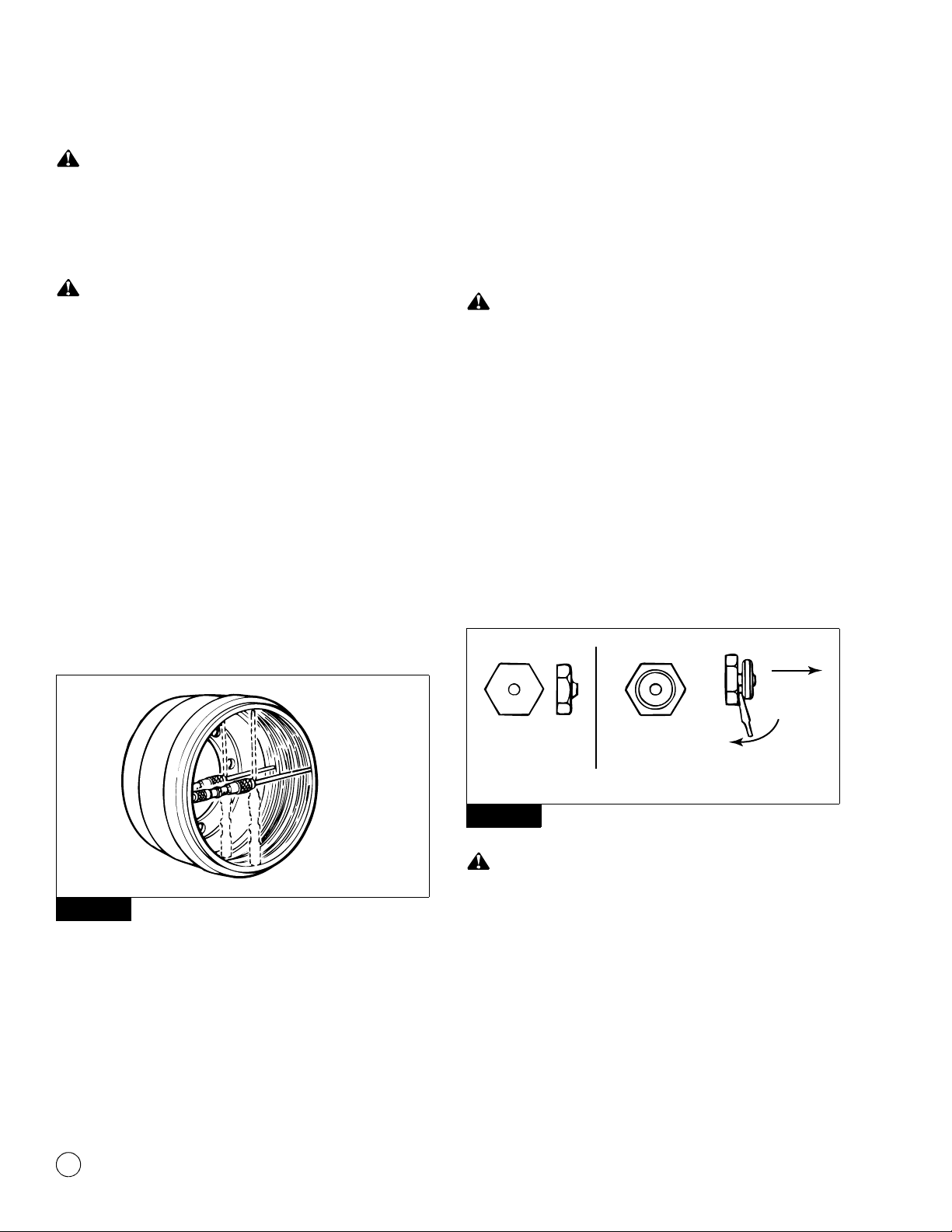

8. Use the following procedure to inspect the brake drums.

A. Check the brake drums for cracks, severe heat checking,

heat spotting, scoring, pitting and distortion. Replace

drums as required. Do not turn or rebore brake drums,

which decreases the strength and heat capacity of the

drum.

B. Measure the inside diameter of the drum in several

locations with a drum caliper or internal micrometer.

Figure 4.1.

앫If the diameter exceeds the specifications

supplied by the drum manufacturer: Replace the

drum.

Figure 4.1

9. Check the dust shields for wear and damage. Repair or replace

worn or damaged parts as necessary.

Slack Adjusters

1. If the slack adjuster has a quick connect clevis, check the gap

between the clevis and the collar.

앫If the gap exceeds 0.060-inch (1.52 mm): Replace the

clevis with a one-piece threaded clevis.

2. Check the clevis pins, clips and bushing in the slack adjuster

arm for wear and damage. Replace worn or damaged parts.

Check the bushing diameter to ensure it does not exceed

0.531-inch (13.5 mm).

앫If the bushing diameter exceeds 0.531-inch (13.5 mm):

Replace the bushing.

CAUTION

You must disengage a pull pawl or remove a conventional pawl

before rotating the manual adjusting nut, or you will damage

the pawl teeth. A damaged pawl will not allow the slack

adjuster to automatically adjust brake clearance. Replace

damaged pawls before putting the vehicle in service.

NOTE: When you service an automatic slack adjuster with a

conventional pawl, replace the conventional pawl with a pull pawl.

3. Disengage the pull pawl. Use a screwdriver or equivalent tool to

pry the pull pawl at least 1/32-inch (0.8 mm) to disengage the

teeth. Figure 4.2.

앫If the slack adjuster has a conventional pawl: Remove

the pawl. Figure 4.2.

Figure 4.2

CAUTION

You must turn the adjusting nut COUNTERCLOCKWISE when

you check gear torque on an automatic slack adjuster. If you

turn the adjusting nut incorrectly, you will damage the pawl

teeth. A damaged pawl will prevent the slack adjuster from

automatically adjusting the clearance between the linings and

drum. Damage to components can result.

4. Check manual slack adjusters by rotating the adjustment nut of

the worm shaft to verify that the worm drive is free. Figure 4.3.

Replace the slack adjuster if the worm drive does not operate

correctly. Do NOT repair a manual slack adjuster.

Figure 4.1

4000343a

Figure 4.2

CONVENTIONAL

PAWL

PULL PAWL

PRY UP

PAWL

4000331b

4 Prepare Parts for Assembly

7

Meritor Maintenance Manual MM-0440 (Issued 09-04)

Figure 4.3

5. Use a lb-in torque wrench and turn the adjusting nut

COUNTERCLOCKWISE to rotate the gear 360 degrees, or 22

turns of the wrench, as you read the torque scale on the

wrench. The value should be less than 25 lb-in (2.83 N폷m) as

you rotate the gear. Figure 4.4.

앫If the torque value is less than 25 lb-in (2.8 N폷m) as

you rotate the gear: The slack adjuster is operating

correctly.

앫If the torque value exceeds 25 lb-in (2.8 N폷m) as you

rotate the gear: Replace the slack adjuster.

Figure 4.4

6. Re-engage the pull pawl. Remove the screwdriver or equivalent

tool. The pull pawl will re-engage automatically.

앫If the slack adjuster has a conventional pawl: Install the

pawl assembly into the housing. Tighten the capscrew to

12-17 lb-ft (16-23 N폷m). @

NOTE: If necessary, install a camshaft into the slack adjuster gear

to minimize grease flow through the gear holes.

7. Use a grease gun to apply Meritor specification O-616-A,

O-692 or O-645 lubricant to the slack adjuster grease fitting,

until grease flows from around the camshaft splines and pawl

assembly. Refer to Section 8 for more lubricant information.

Figure 4.3

Figure 4.4

4004496a

ADJUSTMENT

NUT

22 TURNS

ROTATE GEAR 360

4000344a

5 Assembly and Installation

8Meritor Maintenance Manual MM-0440 (Issued 09-04)

5 Assembly a nd Installation

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

ASBESTOS AND NON-ASBESTOS

FIBERS WARNING

Some brake linings contain asbestos fibers, a cancer and lung

disease hazard. Some brake linings contain non-asbestos

fibers, whose long-term effects to health are unknown. You

must use caution when you handle both asbestos and

non-asbestos materials.

Installation

Camshaft Assemblies

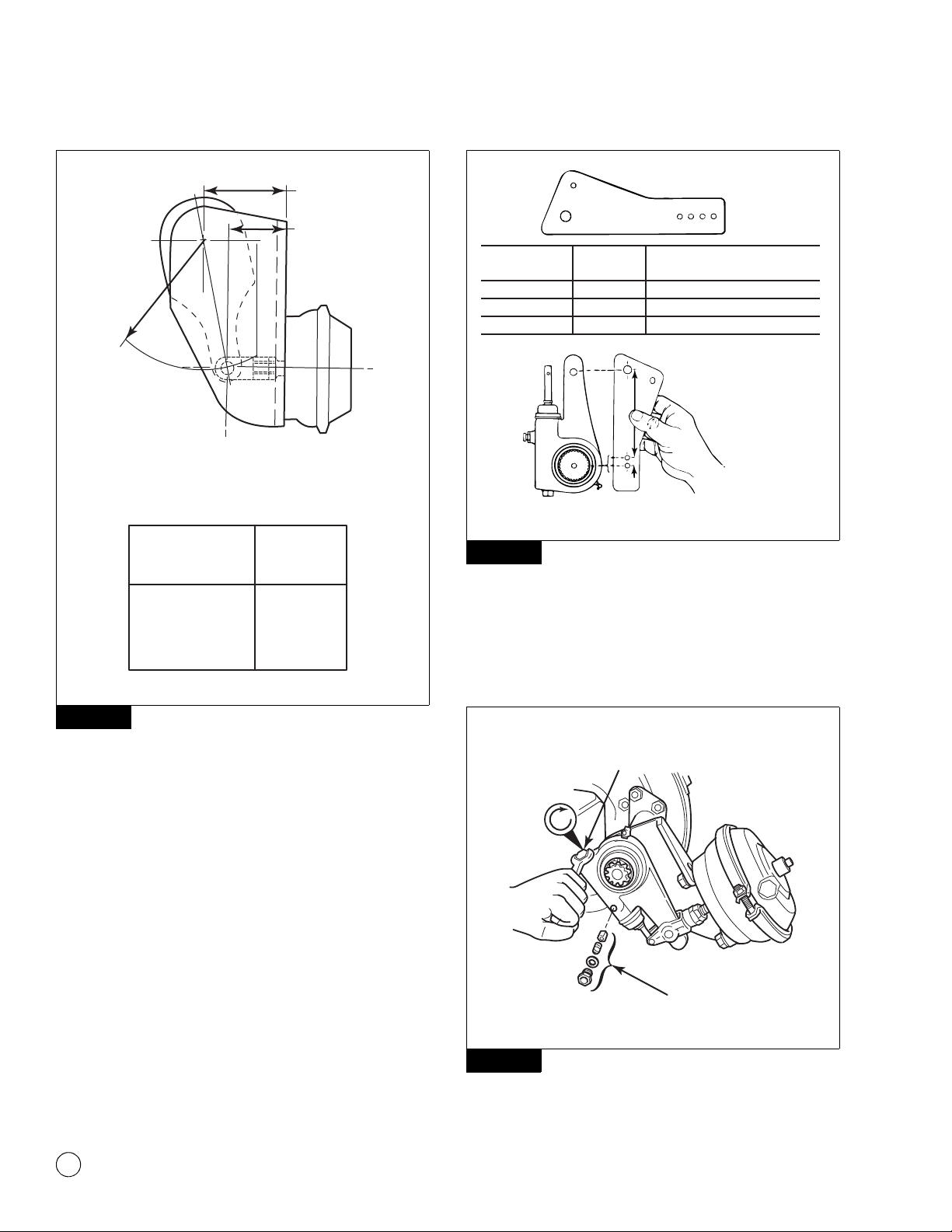

1. Tighten all the spider bolts to the specified torque. Figure 5.1.

Figure 5.1

2. Install new camshaft seals into the spider and camshaft

bracket with a seal driver. Figure 5.2. Install both seals with

their lips toward the slack adjuster. Figure 5.3.

Figure 5.2

Figure 5.3

3. If necessary, install new cage and needle bearing assemblies.

4. If the camshaft bracket was removed, install the gasket and

bracket to the spider. Tighten the capscrews to the correct

torque as specified in Section 9.

5. Install the cam head thrust washer onto the camshaft. Apply

Meritor specification O-617-A or O-617-B grease to the

camshaft needle bearings and journals.

6. Install the camshaft through the spider and bracket so that the

camshaft turns freely by hand. Figure 5.4.

Figure 5.1

4004497a

T

TORQUE

BOLT

SIZE

7/16"-20

1/2"-20

9/16"-18

5/8"-18

60-75 LB-FT

85-115 LB-FT

130-165 LB-FT

180-230 LB-FT

81-102 N·m

115-156 N·m

176-224 N·m

244-312 N·m

Figure 5.2

Figure 5.3

4000346a

SPIDER

CAMSHAFT

BRACKET

SEAL

LIP

SEAL

LIP

4000347a

5 Assembly and Installation

9

Meritor Maintenance Manual MM-0440 (Issued 09-04)

Figure 5.4

Brake Shoes

NOTE: Meritor recommends that you replace the springs, rollers

and anchor pins at each reline.

When the brake is disassembled, or when necessary, lubricate the

anchor pins and rollers where these parts touch the brake shoes.

Do not allow grease to contact the area of the camshaft roller that

touches the camshaft head.

1. Lubricate the camshaft roller pin and anchor pin with Meritor

specification O-617-A or O-617-B grease.

2. Install the brake shoes onto the spider with the anchor pins.

Verify that the flat sides of the anchor pins are aligned with the

lock screw holes in the spider.

3. Install the anchor pin felt seals, retainers and lock rings.

4. Install the anchor pin lock screws and tighten to 10-15 lb-ft

(13.56-20.34 N폷m). Install the lock wire for the lock screws.

@

5. Install new shoe return springs.

Slack Adjusters

1. Apply Meritor specification O-637 or other rust preventive

grease to the camshaft splines.

2. Install the slack adjuster spacer washer on the splined end of

the camshaft followed by the slack adjuster.

3. Add spacer washers to limit the slack adjuster end play to

0.060-inch (1.5 mm) maximum. Figure 5.5.

Figure 5.5

4. Install a new camshaft lock ring.

5. Connect the slack adjuster to the air chamber push rod.

Manual Slack Adjusters

1. If the clevis was not replaced, install new clevis pins.

2. Install and adjust the slack adjuster to match the Brake Slack

Adjuster Position (BSAP). Figure 5.6.

Figure 5.4

4000348a

Figure 5.5

4004499a

Check end play.

5 Assembly and Installation

10 Meritor Maintenance Manual MM-0440 (Issued 09-04)

Figure 5.6

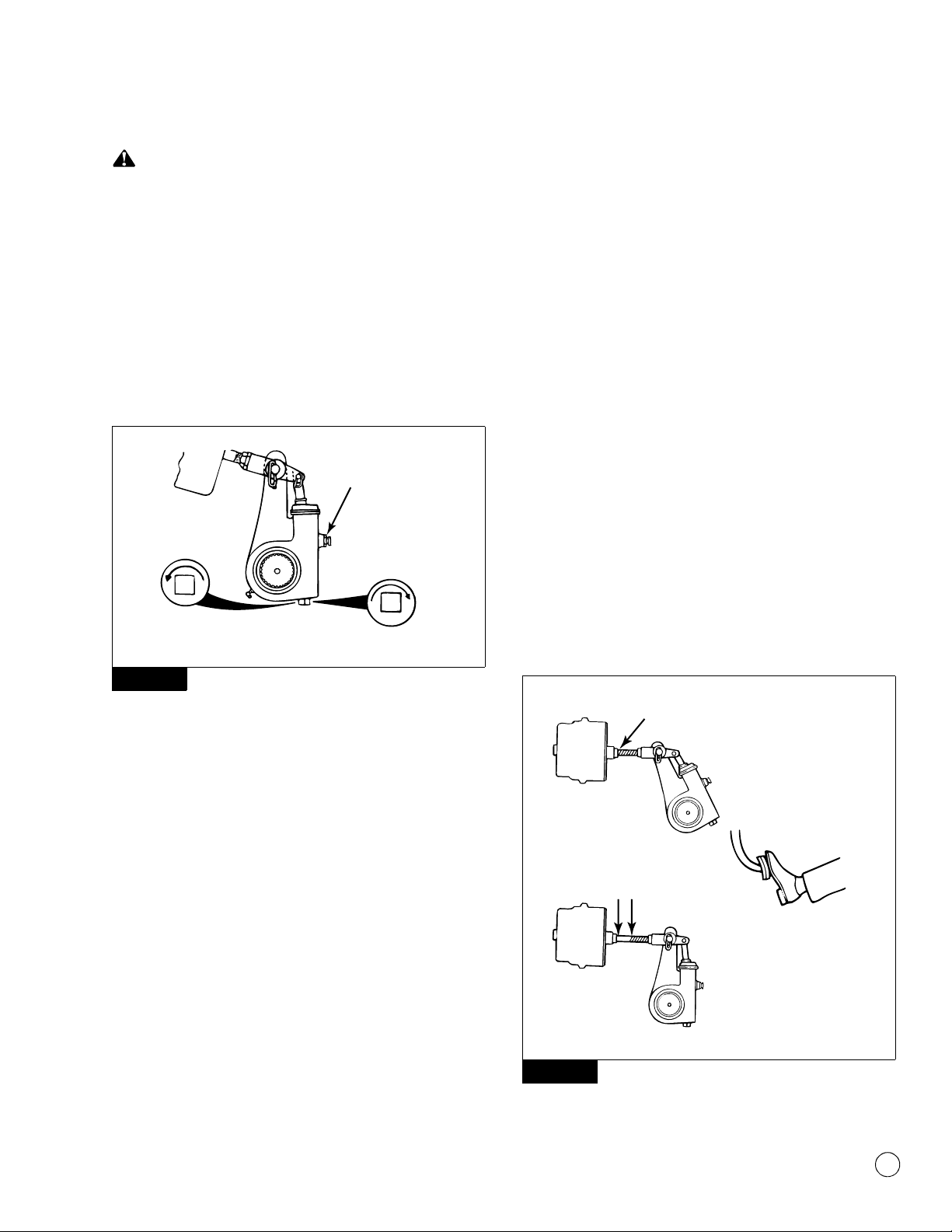

Automatic Slack Adjusters

1. If you install the same slack adjuster that was removed, install

the clevis on the push rod in the position you marked when you

removed the clevis. Check the position of the clevis with the

Installation template. Figure 5.7.

앫If you are installing a new slack adjuster: Verify it is the

same length as the one you are replacing. Install the clevis

on the push rod. Check the position of the clevis with the

Installation template. Figure 5.7.

Figure 5.7

2. Remove the pawl assembly and align the slack adjuster arm

with the clevis. Turn the manual adjusting nut to the left until

the clevis pin hole in the slack adjuster arm is aligned with the

large hole in the clevis. Assemble with the large clevis pin and

fasten with a cotter pin. Figure 5.8 and Figure 5.9.

Figure 5.8

Figure 5.6

4004498a

3.750 AND 3.812

BRACKET

OFFSET

BSAP ± 0.062

SLACK

LENGTH

CORRECT POSITION OF MANUAL SLACK

ADJUSTER 3.750" AND 3.812" OFFSETS ONLY

(FOR OTHER BRACKET OFFSETS, REFERTO

THE VEHICLE MANUFACTURER’S

SPECIFICATIONS)

5.00

5.50

6.00

6.50

5.00

5.50

6.00

6.50

2.84

2.75

2.67

2.59

SLACK

ADJUSTMENT

SIZE

± 0.062

BSAP

Figure 5.7

Figure 5.8

Color of

Template

Part

Number Applications

Dark brown TP-4786 Truck or tractor drum brake

Tan TP-4787 Trailer drum brake

White TP-4781 Coach drum brake

Measure the slack

adjuster

arm length.

CAMSHAFT CENTER

4000369b

4004500a

PAW L

ASSEMBLY

MANUAL

ADJUSTING

NUT

5 Assembly and Installation

11

Meritor Maintenance Manual MM-0440 (Issued 09-04)

Figure 5.9

3. Pull on the actuator rod until the hole in the top of the rod is

aligned with the small hole in the clevis. Install the small clevis

pin and fasten with a cotter pin.

4. Install the pawl assembly.

5. Apply the brakes and permit the push rods to extend fully.

There must be clearance between the slack adjuster and all

chassis components.

NOTE: Refer to Maintenance Manual 4, Cam Brakes and Automatic

Slack Adjuster, for complete installation instructions.

6. Release the brakes and verify that the manual adjusting nut

rotates to the left as the push rods fully retract.

Figure 5.9

CLEVIS LARGE CLEVIS PIN

AND

RETAINER CLIP

ACTUATOR

ROD

SMALL CLEVIS PIN

AND RETAINER CLIP

LARGE CLEVIS PIN

RETAINER CLIP

P/N 2257-D-1174

SMALL CLEVIS PIN

RETAINER CLIP

P/N 2257-C-1173

The clevis pin retainer

clips must be fully

installed and positioned

around the SIDE of the

clevis pin.

4001487a

6 Adjustment

12 Meritor Maintenance Manual MM-0440 (Issued 09-04)

6 Adjustment

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Before you service a spring chamber, carefully follow the

manufacturer’s instructions to compress and lock the spring to

completely release the brake. Verify that no air pressure

remains in the service chamber before you proceed. Sudden

release of compressed air can cause serious personal injury

and damage to components.

ASBESTOS AND NON-ASBESTOS

FIBERS WARNING

Some brake linings contain asbestos fibers, a cancer and lung

disease hazard. Some brake linings contain non-asbestos

fibers, whose long-term effects to health are unknown. You

must use caution when you handle both asbestos and

non-asbestos materials.

Adjust the Brakes

Measure Free Stroke

When you perform preventive maintenance procedures on an

in-service brake, check both the free stroke and adjusted chamber

stroke. Refer to the procedures in this section.

Free stroke sets the clearance between the linings and drum. The

in-service free stroke may be slightly longer than 0.5-0.625-inch

(12.7-15.9 mm) specified in this procedure. This is acceptable if the

adjusted chamber stroke is within the limits shown in Table A and

Table B.

CAUTION

You must disengage a pull pawl or remove a conventional pawl

before rotating the manual adjusting nut, or you will damage

the pawl teeth. A damaged pawl will not allow the slack

adjuster to automatically adjust brake clearance. Replace

damaged pawls before putting the vehicle in service.

1. Disengage a pull pawl. Use a screwdriver or equivalent tool to

pry the pull pawl at least 1/32-inch (0.8 mm) to disengage the

teeth.

앫If the slack adjuster has a conventional pawl: Remove

the pawl.

2. Use a wrench to turn the adjusting nut COUNTERCLOCKWISE

until the brake shoes contact the drum. Figure 6.1. Then back

off the adjusting nut 1/2 turn in the opposite direction.

Figure 6.1

3. Measure the distance from the center of the large clevis pin to

the bottom of the air chamber while the brake is released. The

measurement you obtain is X in Figure 6.2.

Figure 6.2

4. Use a pry bar to move the slack adjuster and position the

linings against the drum, brakes applied. Measure the same

distance again while the brakes are applied. The measurement

you obtain is Y in Figure 6.2.

Figure 6.1

Figure 6.2

Disengage pawl.

4000371e

MEASURE FREE STROKE

“Y”

“X”

FREE STROKE = Y MINUS X

Drum brake free stroke must be

0.5-0.625" (12.7-15.9 mm).

Disc brake free stroke must be

0.75-0.875" (19.1-22.2 mm).

4000372a

6 Adjustment

13

Meritor Maintenance Manual MM-0440 (Issued 09-04)

CAUTION

Do not set free stroke shorter than 0.5-0.625-inch

(12.7-15.9 mm) for drum brakes. If the measurement is too

short, linings can drag. Damage to components can result.

5. Subtract X from Y to obtain the in-service free stroke. The

measurement must be 0.5-0.625-inch (12.7-15.9 mm) for

drum brakes. Figure 6.2.

앫If the free stroke measurement is not within

specification: Turn the adjusting nut to adjust free stroke.

Figure 6.3. Follow the steps above to check free stroke

again, until the measurement is within specification.

Figure 6.3

6. Re-engage the pull pawl by removing the screwdriver or

equivalent tool. The pull pawl will re-engage automatically.

앫If the slack adjuster has a conventional pawl: Install the

pawl assembly into the housing. Tighten the capscrew to

12-17 lb-ft (16-23 N폷m). @

7. If the brakes have spring chambers, carefully release the

springs. Test the vehicle before you return it to service.

Commercial Vehicle Safety Alliance (CVSA)

Guidelines

Measure Push Rod Travel or Adjusted Chamber

Stroke

Use the following procedure to check in-service push rod travel or

adjusted chamber stroke on truck and tractor brakes.

NOTE: Hold the ruler parallel to the push rod and measure as

carefully as possible. A measurement error can affect CVSA

re-adjustment limits. CVSA states that “any brake 1/4-inch or more

past the re-adjustment limit, or any two brakes less than 1/4-inch

beyond the re-adjustment limit, will be cause for rejection.”

1. The engine must be OFF. If the brake has a spring chamber,

follow the manufacturer’s instructions to release the spring.

Verify that no air pressure remains in the service section of the

chamber.

2. Verify that pressure is 100 psi (689 kPa) in the air tanks.

Determine the size and type of brake chambers on the vehicle.

3. With the brakes released, mark the push rod where it exits the

chamber. Measure and record the distance. Have another

person apply and hold the brakes on full application.

Figure 6.4.

Figure 6.4

Figure 6.3

SHORTEN

STROKE

Disengage

pull pawl

or remove

conventional

pawl.

LENGTHEN

STROKE

4000373a

Figure 6.4

• Spring brakes

released

• Service brakes

not applied

• Spring brakes

released

• Service brakes

applied

90-100 psi (620-690 kPa)

in air tank — engine OFF

Mark push rod here

to measure stroke.

STROKE

4000374b

Step 2

Step 1

Step 3

6 Adjustment

14 Meritor Maintenance Manual MM-0440 (Issued 09-04)

4. Measure the push rod travel or adjusted chamber stroke from

where the push rod exits the brake chamber to your mark on

the push rod. Measure and record the distance. Figure 6.4.

5. Subtract the measurement you recorded in Step 3 from the

measurement you recorded in Step 4. The difference is the

push rod travel or adjusted chamber stroke.

6. Refer to Table A or Table B to verify that the stroke length is

correct for the size and type of air chambers on the vehicle.

앫If push rod travel or adjusted chamber stroke is greater

than the maximum stroke shown in Table A or Table B:

Inspect the slack adjuster and replace it, if necessary.

Table A: Standard Stroke Clamp-Type Brake Chamber Data

Table B: Long Stroke Clamp-Type Brake Chamber Data

Alternate Method to Measure Push Rod Travel or

Adjusted Chamber Stroke

Use the CVSA procedure, except in Step 3 and Step 4, measure the

distance from the bottom of the air chamber to the center of the

large clevis pin on each of the brakes.

CVSA North American Out-of-Service Criteria

Reference Tables

Information contained in Table A and Table B is for reference only.

Consult the CVSA’s Out-of-Service Criteria Handbook for North

American Standards, Appendix A. Visit their website at

http://64.35.82.7/ to obtain the handbook.

Type

Outside Diameter

(inches)

Brake

Adjustment Limit

(inches)

6 4-1/2 1-1/4

9 5-1/4 1-3/8

12 5-4/16 1-3/8

16 6-3/8 1-3/4

20 6-25/32 1-3/4

24 7-7/32 1-3/4

30 8-3/32 2

36 9 2-1/4

Type

Outside Diameter

(inches)

Brake

Adjustment Limit

(inches)

16 6-3/8 2.0

20 6-25/32 2.0

24 7-7/32 2.0

24* 7-7/32 2.5

30 8-3/32 2.5

*For 3" maximum stroke type 24 chambers.

7 Reline the Brakes

15

Meritor Maintenance Manual MM-0440 (Issued 09-04)

7 Reline the Brakes

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

ASBESTOS AND NON-ASBESTOS

FIBERS WARNING

Some brake linings contain asbestos fibers, a cancer and lung

disease hazard. Some brake linings contain non-asbestos

fibers, whose long-term effects to health are unknown. You

must use caution when you handle both asbestos and

non-asbestos materials.

Reline the Brakes

CAUTION

Reline the brakes when the lining thickness is 0.25-inch

(6.3 mm) at the thinnest point. The rivets or bolts must not

touch the drum. Damage to components will result.

Use the lining material specified by the vehicle manufacturer. This

will help to ensure that the brakes perform correctly and meet

Department of Transportation (DOT) performance regulations.

Always reline both wheels of a single axle and all four wheels of a

tandem axle at the same time. Always install the same linings and

drums on both wheels of a single axle and all four wheels of a

tandem axle. It is not necessary that the front and rear axles have

the same linings and drums.

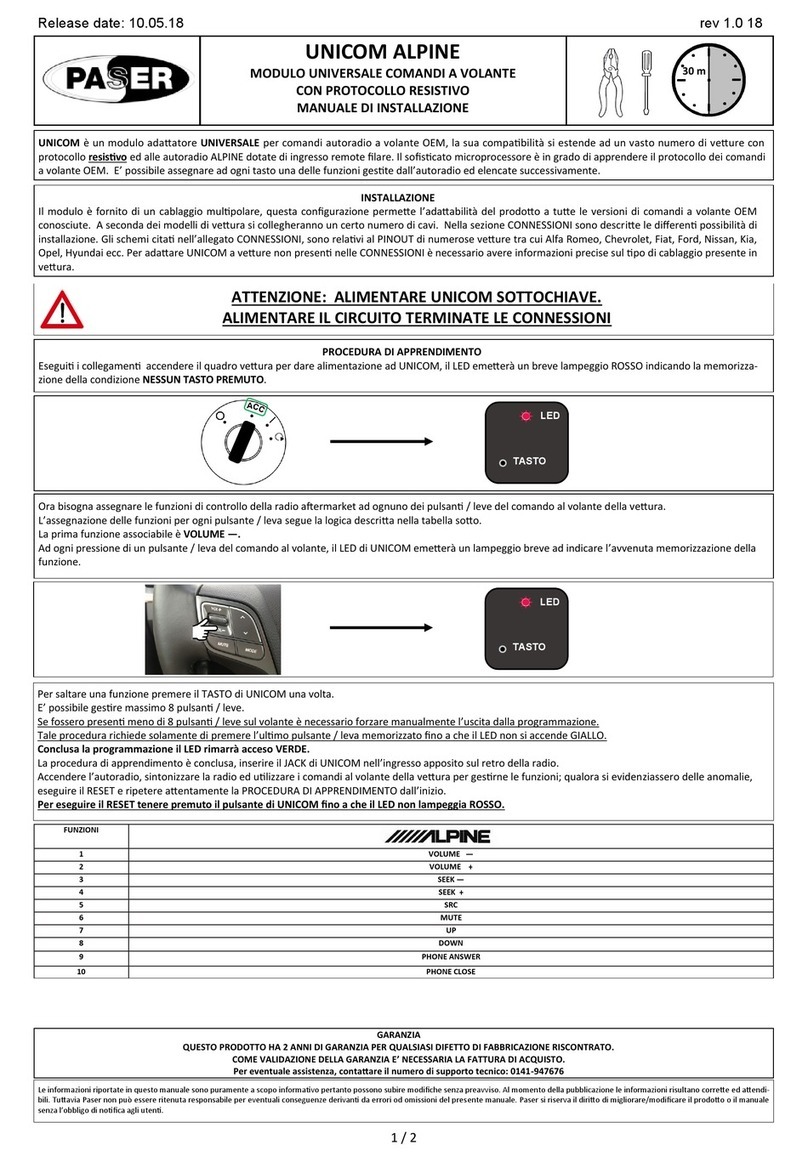

NOTE: The primary linings must be installed onto the primary shoe.

The first shoe past the cam in the direction of wheel rotation is the

primary shoe. Figure 7.1. The primary shoe can be either at the top

or the bottom position, depending on the location of the cam. If the

cam is behind the axle, the top shoe is the primary shoe. If the cam

is in front of the axle, the bottom shoe is the primary shoe.

Figure 7.1

Installing Linings with Rivets

1. Check to ensure that the lining and shoe contact faces are

clean.

2. Align the rivet holes in the lining with the rivet holes in the

shoe.

NOTE: Verify that the rivets are the correct body diameter, head size

and shape, length and material.

3. Install the rivets into the rivet holes following the correct

sequence. Figure 7.2.

Figure 7.1

WHEEL ROTATION WHEEL ROTATION

RIGHT WHEEL ROTATION

CAM IN FRONT OF AXLECAM BEHIND AXLE

LEFT WHEEL ROTATION

WHEEL ROTATION

WHEEL ROTATION

CAM BEHIND AXLECAM IN FRONT OF AXLE

4000375a

7 Reline the Brakes

16 Meritor Maintenance Manual MM-0440 (Issued 09-04)

Figure 7.2

A gap of 0.10-inch (0.25 mm) maximum is acceptable

between the shoe and linings along the side and ends of the

assembly, except between the double web. A 0.025-inch

(0.64 mm) gap is acceptable between the webs. Figure 7.3.

Figure 7.3

Installing Linings with Bolts

NOTE: The same procedures must be followed with bolted linings

as with riveted linings. New lock washers must be used during

installation.

1. Check to ensure that the lining and shoe contact faces are

clean.

2. Align the bolt holes in the lining with the holes in the shoe.

NOTE: Verify that the bolts are the correct body diameter, head size

and shape, length and material.

3. Install the bolts and lock washers into the bolt holes following

the correct sequence. Figure 7.2.

앫Tighten 3/8-inch diameter brass bolts to 220-280 lb-in or

18-23 lb-ft (24.8-31.6 N폷m). @

앫Tighten 1/4-inch diameter brass bolts to 80-100 lb-in or

7-8 lb-ft (9-11.3 N폷m). @

Oversize Drums

CAUTION

Do not operate the vehicle with the brake drum worn or

machined beyond the discard dimension stamped on the

drum. The brake system may not operate correctly if the

drums are worn or machined beyond the discard dimension

and cause serious personal injury or damage.

To compensate for the worn or refaced drums, X (1/16-inch

oversize) and XX (1/8-inch oversize) brake linings are supplied by

the lining manufacturers.

Figure 7.2

Figure 7.3

4004502a

8

9

12

11

9

10

12

8

5

4

1

2

36

7

3

2

1

4

5

6

7

11

10

4004502a

8

9

12

11

9

10

12

8

5

4

1

2

36

7

3

2

1

4

5

6

7

11

10

Table of contents

Other Meritor Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Prorack

Prorack K164 Fitting instructions

Cruz

Cruz 941-401 Assembly instructions

Pilot Communications

Pilot Communications EV Plus+ Quick installation guide

TOP VEHICLE TECH

TOP VEHICLE TECH GR4FORD5 installation manual

Whispbar

Whispbar K708W Fitting instructions

Arkon

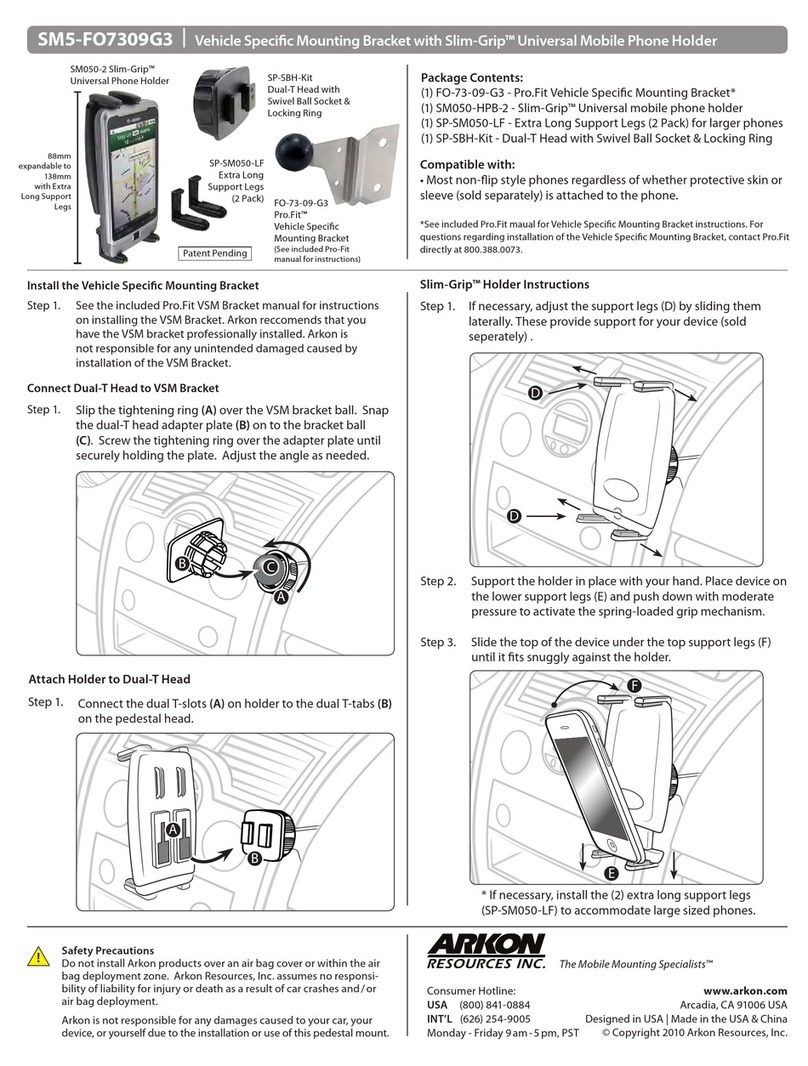

Arkon SLIM-GRIP SM5-FO7309G3 user manual