Meritor RideSentry MPA Series User manual

Maintenance Manual 14R

RideSentry™ MPA Series Sliding Tandem

Trailer Air Suspension System

Revised 12-18

Service Notes

Information contained in this publication was in effect at the time the publication was

approved for printing and is subject to change without notice or liability. Meritor Heavy

Vehicle Systems, LLC, reserves the right to revise the information presented or to

discontinue the production of parts described at any time.

Meritor Maintenance Manual 14R (Revised 12-18)

About This Manual

This manual provides the correct lubrication, service and installation

procedures for the Meritor RideSentry™ MPA Series sliding tandem

trailer air suspension system.

Before You Begin

1. Read and understand all instructions and procedures before

you begin to service components.

2. Read and observe all Warning and Caution hazard alert

messages in this publication. They provide information that can

help prevent serious personal injury, damage to components,

or both.

3. Follow your company’s maintenance and service, installation,

and diagnostics guidelines.

4. Use special tools when required to help avoid serious personal

injury and damage to components.

Hazard Alert Messages and Torque

Symbols

WARNING

A Warning alerts you to an instruction or procedure that you

must follow exactly to avoid serious personal injury and

damage to components.

CAUTION

A Caution alerts you to an instruction or procedure that you

must follow exactly to avoid damage to components.

@This symbol alerts you to tighten fasteners to a specified torque

value.

How to Obtain Additional Maintenance,

Service and Product Information

Visit Literature on Demand at meritor.com to access and order

additional information.

Contact the Meritor OnTrac™ Customer Call Center at

866-668-7221 (United States and Canada); 001-800-889-1834

(Mexico); or email OnTrac@meritor.com.

If Tools and Supplies are Specified in

This Manual

Contact Meritor’s Commercial Vehicle Aftermarket at

888-725-9355.

pg. pg.

Contents

1Section 1: Exploded View

RideSentry™ MPA Series Sliding Tandem Trailer Air

Suspension System

2Section 2: Introduction

Description

3 Components

Features

4 Identification

5Section 3: Inspection and Maintenance

Inspection

7 Maintenance

Slider

8 Trailer Air Suspension

Inspection

Height Control Valve

9 Axle Inspection and Maintenance

Lubrication

10 Section 4: Component Removal, Installation

and Adjustment

Removal and Installation

Height Control Valve (HCV)

HCV Installation Options

11 Adjustment

Verify Ride Height

Maintain the Correct Ride Height When You Change an

HCV

12 Removal and Installation

Air Spring

14 Upper Control Arm

17 Lower Control Arm

Axle Replacement Procedure

19 Axle Alignment

Before You Align the Axle

Front Axle

Rear Axle

20 Auto-Dump Configuration

To Auto-Dump from No-Dump

No-Dump Configuration

To No-Dump from Auto-Dump

21 Section 5: Welding

Check Welding Procedures Before You Weld to

Suspension Components

Axle

Suspension

Slider

22 Section 6: Slider Removal, Installation and

Adjustment

Check Body Rail Specifications

Installation

Slider-to-Trailer Retrofit

24 Slider Repositioning

25 Section 7: Diagnostics

Troubleshooting

27 Section 8: Specifications

Torque Specifications

28 Section 9: Special Tools

Tool Drawing

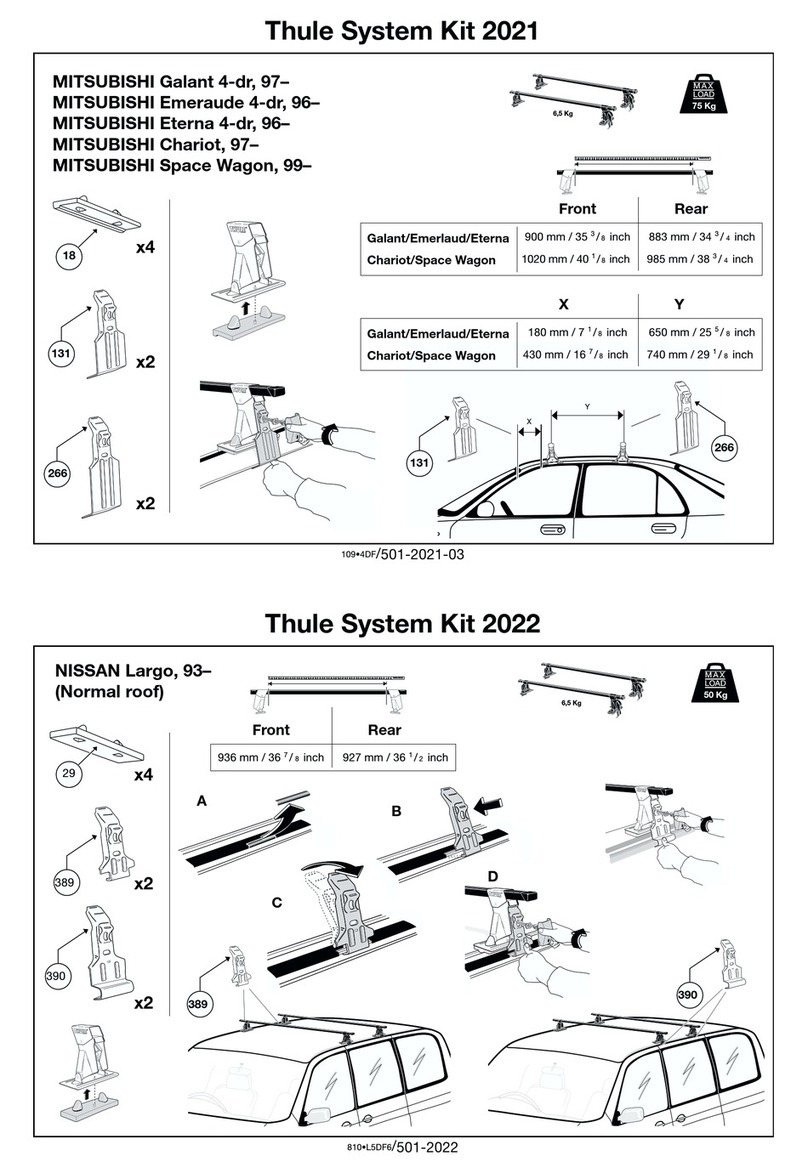

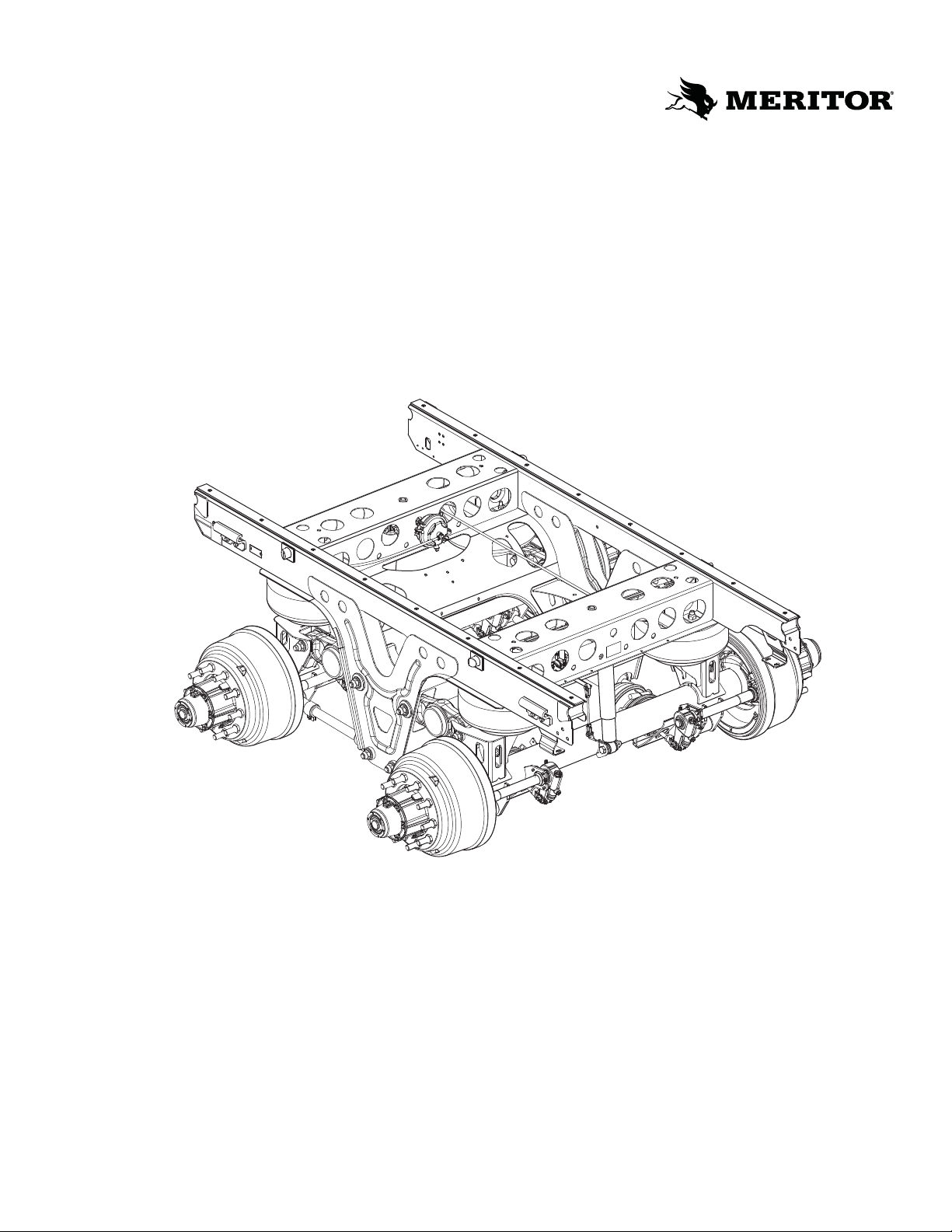

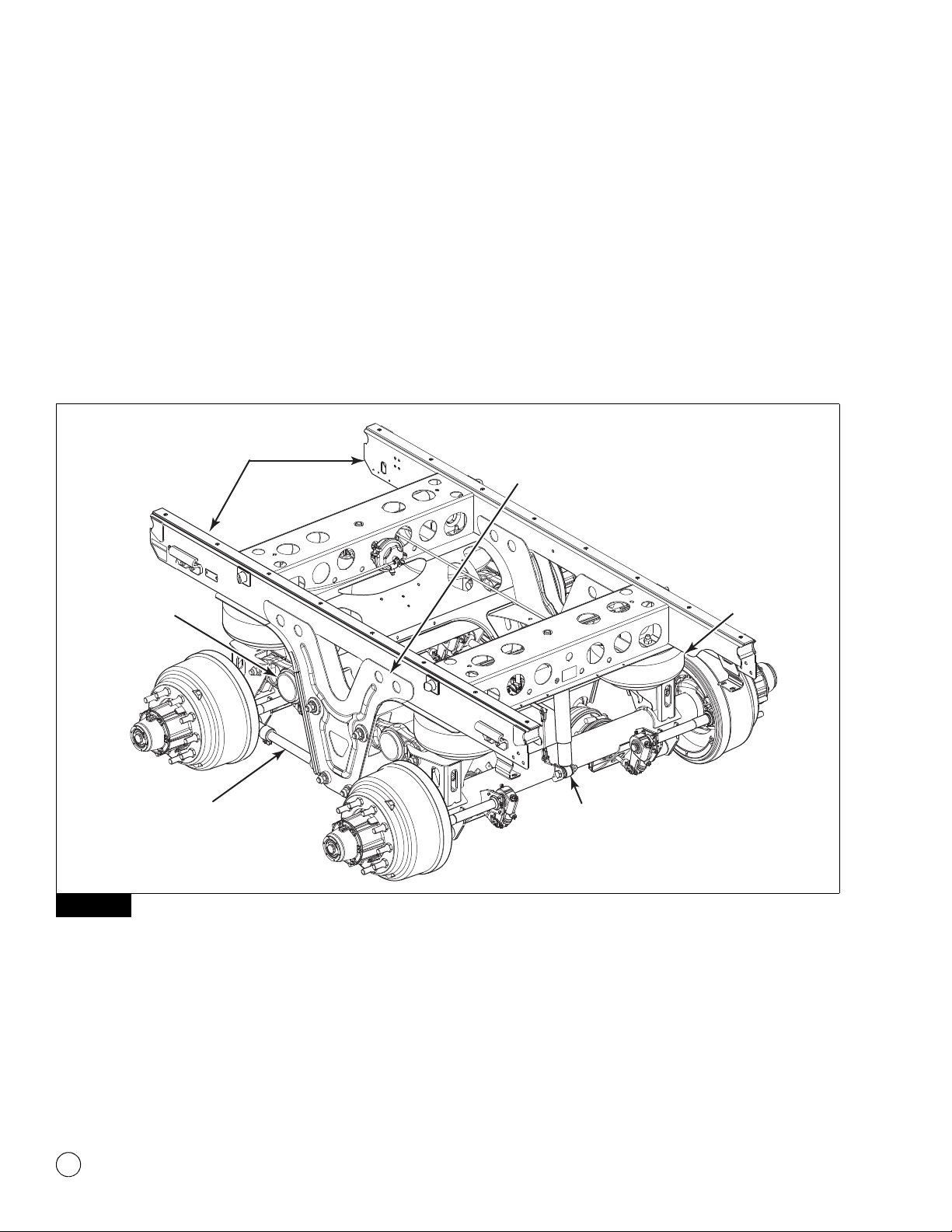

1 Exploded View

1

Meritor Maintenance Manual 14R (Revised 12-18)

1 Exploded View

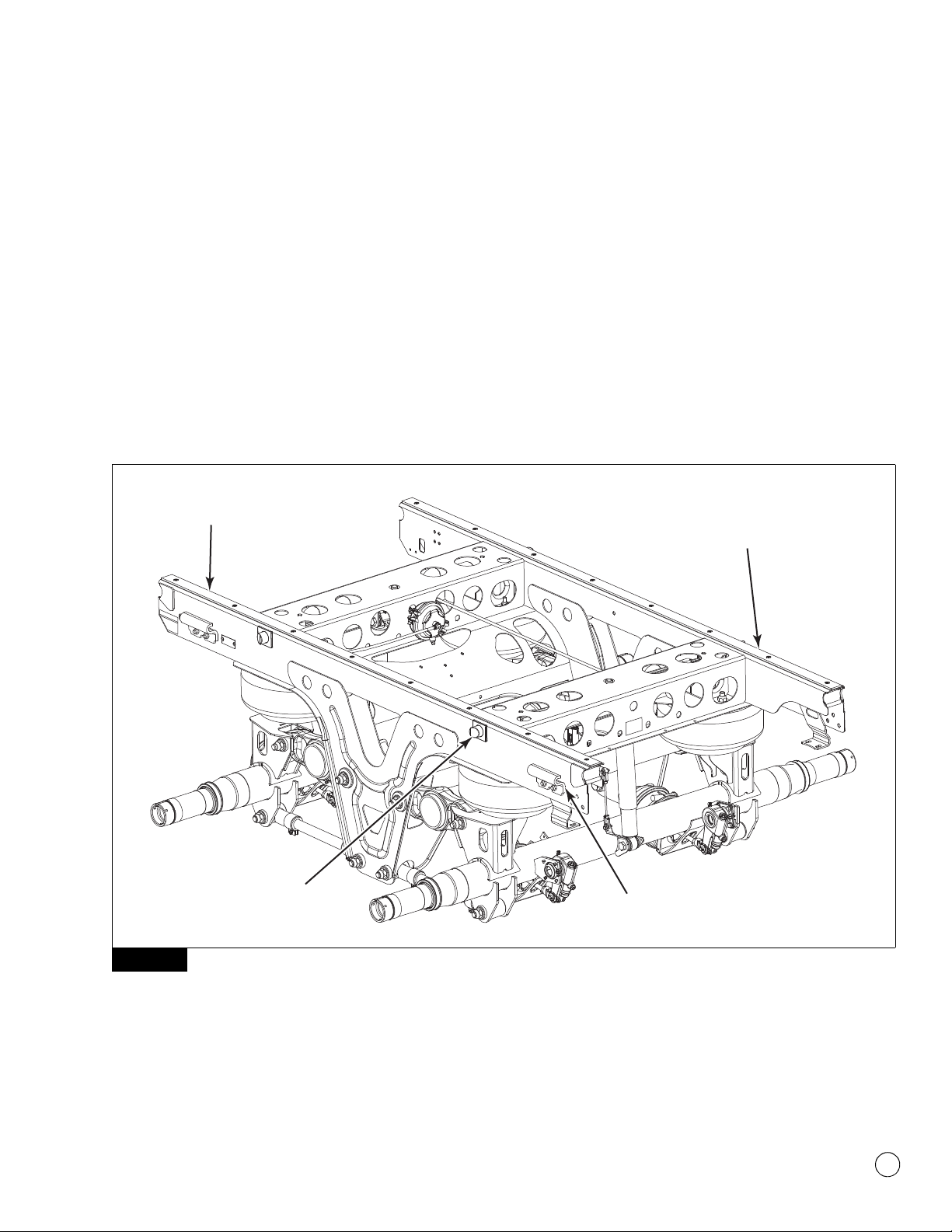

RideSentry™ MPA Series Sliding Tandem Trailer Air Suspension System

Figure 1.1

4006703a

14

13

20

6

4

5

5

19

19

7

18

17

15

21

23

24

10

9

16

8

8

2

22

3

2

1

1

10

12

11

7

9

Item Description

1Slider Wear Pad

2Slider Cross Member

3Meritor PinLoc™ System

4Slider Side Rail, Curbside

5Air Spring

6Lower Control Arm, Fixed

7Lower Bushing

8Lower Inner Sleeve, Bushing Inner Metal

9Upper Axle Seat

10 Upper Control Arm

11 Lower Axle Seat

12 Upper Bushing

13 Clevis, Shock

14 Axle Assembly, Rear

15 Height Control Linkage

16 Lower Shock Mounting Bracket

17 Shock Absorber

18 Height Control Air Valve (Hadley 1500

Series)

19 Lower Control Arm, Adjustable

20 Axle Assembly, Front

21 Suspension Tag

22 Slider Slide Rail, Roadside

23 Hold Down Clip

24 Lock Pin Operation Label

Item Description

2 Introduction

2Meritor Maintenance Manual 14R (Revised 12-18)

2 Introduction

Description

The Meritor RideSentry™ MPA Series sliding tandem trailer air

suspension system centers around a stabilized parallelogram design

that incorporates a single unified frame bracket. The upper and

lower control arms are parallel to each other. The air springs mount

directly over the axle. Figure 2.1.

Ride height and mounting height are important measurements for

overall vehicle height. Measure ride height from the centerline of the

axle to the bottom of the slider frame. Measure mounting height

from the centerline of the axle to the bottom of the trailer frame.

Figure 2.2.

Figure 2.1

Figure 2.1

4006704a

FRAME

BRACKET

AIR

SPRING

SHOCK

ABSORBER

UPPER

CONTROL

ARM

LOWER

CONTROL

ARM

SLIDER

ASSEMBLY

CURBSIDE

ROADSIDE

2 Introduction

3

Meritor Maintenance Manual 14R (Revised 12-18)

Figure 2.2

Refer to the trailer manufacturer’s specifications for the correct ride

height. Note that the nominal ride height, also referred to as the

design height, refers to the designed ride height and may not be the

same as the actual ride height. To determine the nominal ride height

of the RideSentry™ suspension, the following indicators apply.

앫16.5-inch ride height has the air spring mounted directly to the

upper axle seat.

앫17.5-inch ride height has a 1.0-inch spacer under the air spring.

앫18.5-inch ride height has two 1.0-inch spacers under the air

spring.

Components

앫Frame brackets and slider assembly

앫Upper and lower control arms

앫Axle assemblies

앫Air springs

앫Shock absorbers

Features

앫A compact 38,000 and 40,000 lb (17 237 and 18 144 kg)

capacity tandem trailer air suspension and slider system

designed for sliding tandems.

앫Nominal ride heights of 16.5-inches (41.9 cm), 17.5-inches

(44.5 cm) and 18.5-inches (47.0 cm) are offered with eight

inches (20.3 cm) of total travel for the 16.5- and 17.5-inch ride

heights. The 18.5-inch ride height has seven inches of total

travel.

앫A mounting height of 24.5-26.5-inches (62.2-67.3 cm).

Figure 2.2

4006705a

LOCKING PIN

SLIDER

RIDE

HEIGHT

MOUNTING

HEIGHT

ROADSIDE

AXLE

2 Introduction

4Meritor Maintenance Manual 14R (Revised 12-18)

Identification

The identification tag is located on the roadside of the suspension

near the front of the slider side rail. Figure 2.3.

Figure 2.3

The model number on the identification tag provides suspension and

axle information. Figure 2.4.

Figure 2.4

Figure 2.3

Figure 2.4

STAMPED INFORMATION

Suspension Capacity

Nominal Ride Height

Model Number

Serial Number

FOR SUSPENSION NOMINAL RIDE HEIGHT

(NRH), REFERTOTHE NRH VALUE INDICATED

ONTHIS LABEL. FORTHE ACTUAL RIDE

HEIGHT VALUE, REFERTOTHE VEHICLE/

TRAILER MANUFACTURER'S SPECIFICATION

SUSP. CAP.

MODEL SERIAL NO.

LB. IN.

NRH

C

A

B

C

D

AB

D

4006707a

ROADSIDE

IDENTIFICATION

TAG

MPA XX S XX XX XXXX

Suspension Model

Axle Type

Nominal Ride Height

Sliding Subframe

Suspension Rating x 1000 lbs.

Sequence Number:

Can be cross

referenced to the

Bill of Material.

4006708a

Nominal Ride Height

65 16.5-inches

75 17.5-inches

85 18.5-inches

3 Inspection and Maintenance

5

Meritor Maintenance Manual 14R (Revised 12-18)

3 Inspec tion and Maint enance

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Check fastener torque values, tighten loose fasteners and

replace damaged fasteners. Loose, damaged or missing

fasteners can cause loss of vehicle control, serious personal

injury and damage to components.

Refer to Section 8 for the torque values.

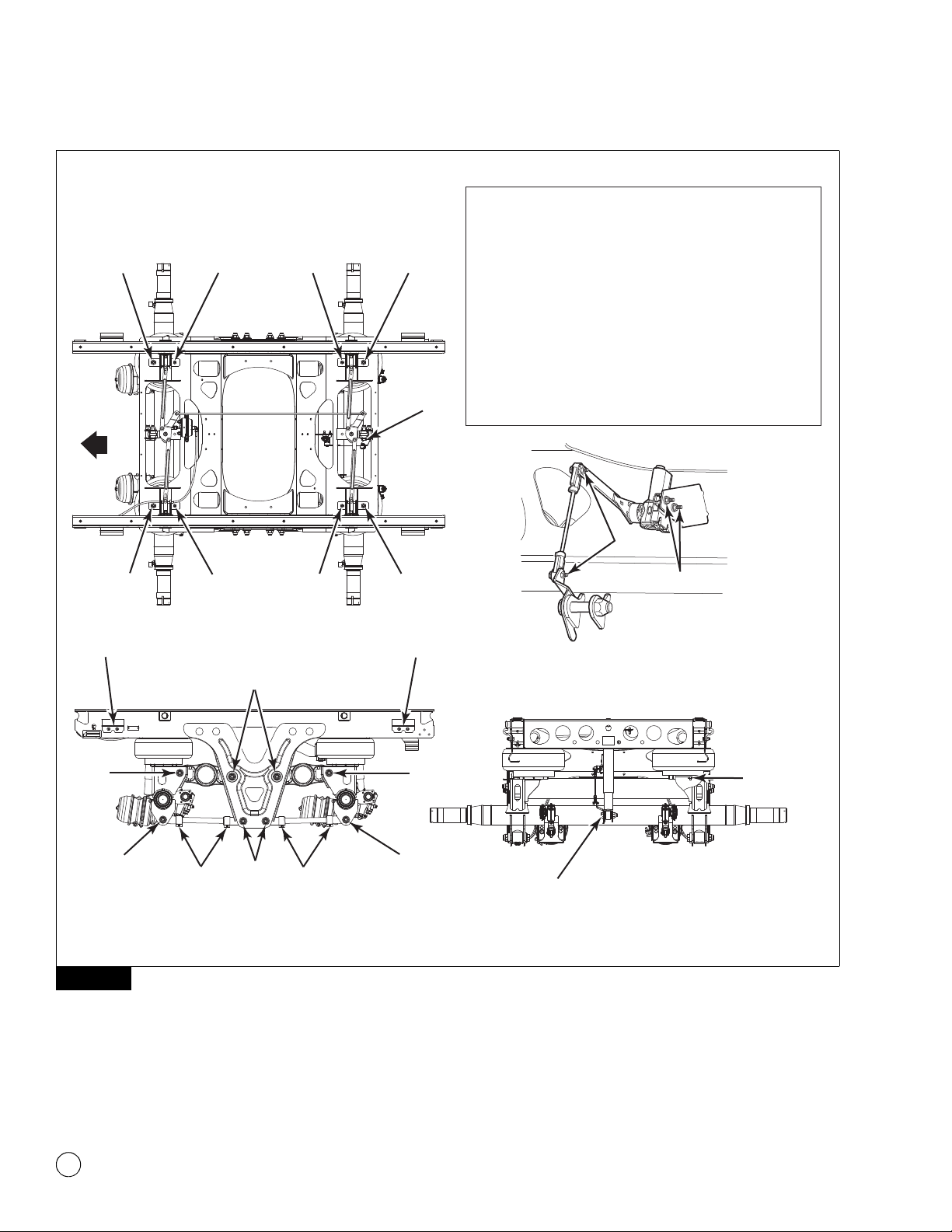

Inspection

Inspect the suspension, air suspension components, height control

valve and axle at regular intervals during normal operation and each

time the trailer is serviced.

앫Before each trip, visually inspect the system. Listen for air leaks.

After 1,000 Miles (1600 km) and Annually Thereafter

1. Visually inspect all fasteners for looseness or movement.

Figure 3.1. Ensure loose fasteners have not caused damage to

any suspension components. Tighten loose fasteners to the

correct torque specified in Section 8.

앫Replace any damaged components and fasteners. Refer to

Section 4 for component removal and installation

procedures.

앫If a loose pivot bolt is at an upper control arm pivot

connection: Disassemble the pivot joint at the loose

fastener location. Refer to “Upper Control Arm” in Section 4

for the procedures.

2. Replace damaged fasteners to maintain the correct torque

specifications to comply with warranty requirements. Refer to

Section 8.

3. Visually inspect the upper control arm bushings for ragged or

loose pieces that can protrude from the pivot connection area.

Damage to components can result.

앫If the upper control arm bushings are ragged or have

loose pieces that protrude from them: Replace the

bushings. Refer to Section 4 for the upper control arm

bushing removal and installation procedures.

3 Inspection and Maintenance

6Meritor Maintenance Manual 14R (Revised 12-18)

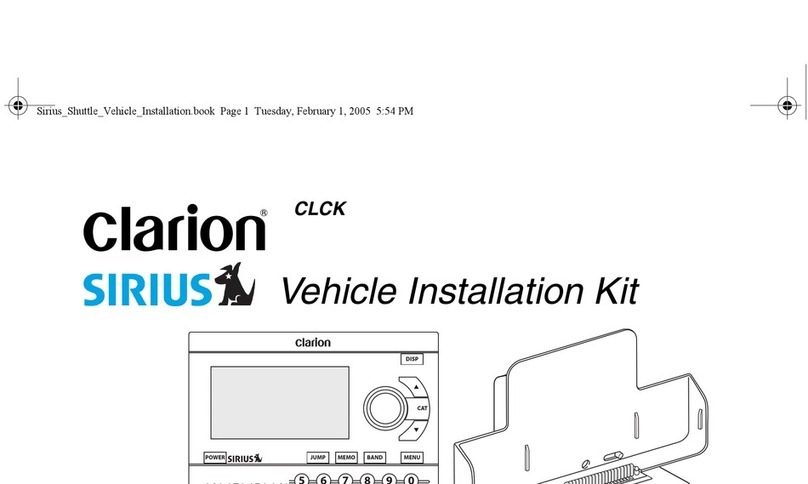

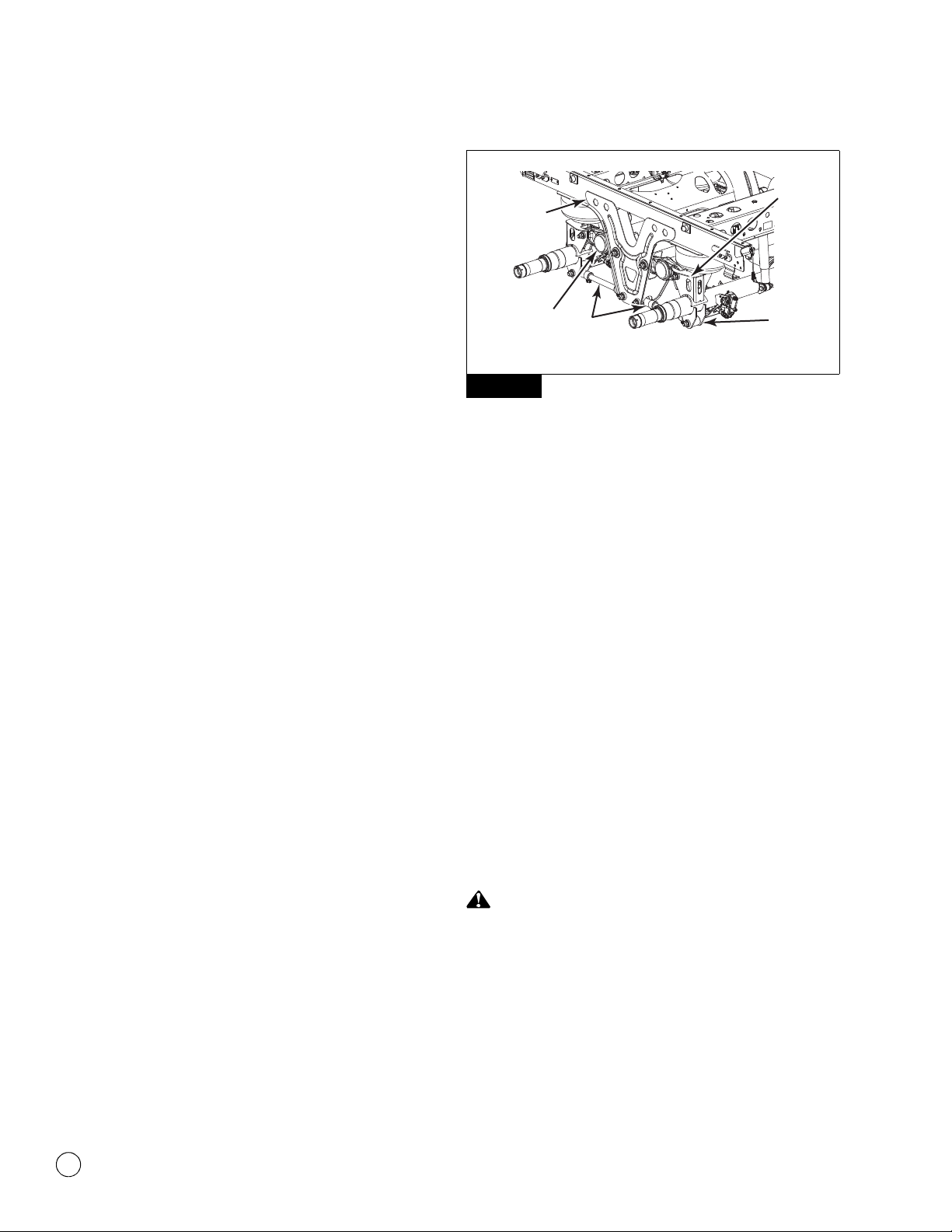

Figure 3.1

Figure 3.1

1. Upper Control Arm, Axle End

2. Upper Control Arm, Frame Bracket End — Roadside

3. Upper Control Arm, Frame Bracket End — Curbside

4. Lower Control Arm — Fixed, Axle End

5. Lower Control Arm — Fixed, Frame Bracket End

6. Lower Control Arm — Adjustable, Axle End

7. Lower Control Arm — Adjustable, Frame Bracket End

8. Lower Control Arm — Adjustable, Clamp Bolt

9. Upper Air Spring Nut, 3/4-16 NF

10. Upper Air Spring Nut, 1/2-13 NC

11. Lower Air Spring Nut

12. Shock Absorber — Upper and Lower

13. Height Control Linkage — Upper and Lower

14. Height Control Valve Mounting Bolt

15. Slider Hold Down Clip

ROADSIDE

BOLT KITS

ROADSIDE

910 109

91010 9

14

13

11

12

6/4

8

7/5*

8

6/4

15

2/3*

1

1

15

12

*CURBSIDE SIMILAR

4006709a

CURBSIDE

FRONT

3 Inspection and Maintenance

7

Meritor Maintenance Manual 14R (Revised 12-18)

Maintenance

Slider

1. Inspect for loose, broken or missing fasteners. Repair or

replace as needed. Refer to Section 8 for the correct torque

specifications.

2. Check the slider locking pins and slider wear pads for signs of

excessive wear or binding. Figure 3.2. Repair or replace as

needed.

3. Inspect the structure of the slider box and crossmembers for

damage. Repair as needed.

4. Inspect the front and rear hold down clips to ensure that they

are secured correctly around the body rails.

Figure 3.2

Figure 3.2

4006710a

WEAR PAD

WEAR PAD

HOLD DOWN

CLIP

LOCKING

PIN

3 Inspection and Maintenance

8Meritor Maintenance Manual 14R (Revised 12-18)

Trailer Air Suspension

1. Inspect for loose, broken or missing fasteners. Repair or

replace as needed. Refer to Section 8 for the correct torque

specifications.

2. Inspect the welds for cracks at the axle, frame bracket and

upper control arm crosstube.

3. Inspect the bushings for ragged or loose pieces that can

protrude from the connection area.

앫If the condition exists: Contact the Meritor OnTrac™

Customer Call Center at 866-668-7221.

4. Inspect the flex member of the air springs for cuts and

abrasions. Replace the air spring if it is cut or damaged.

5. Check for obstructions or interference to the air spring surface

that can damage the air spring. Relocate and secure items,

such as air hoses, that can contact the air spring.

6. Check for leaks in the air lines at the air spring bead plate,

piston and mounting studs. Replace air lines, fittings or air

springs that leak. Refer to Section 4.

7. Inspect the shock absorbers for worn bushings, oil leaks and

dents. Check that the mounting holes have not enlarged.

8. After normal operation, check the shock absorbers for heat.

앫Warm shock absorbers most likely indicate that the shock

absorbers are operating correctly.

앫Cold shock absorbers can indicate that the shock absorbers

are not operating correctly and must be replaced. Replace

the shock absorbers as necessary.

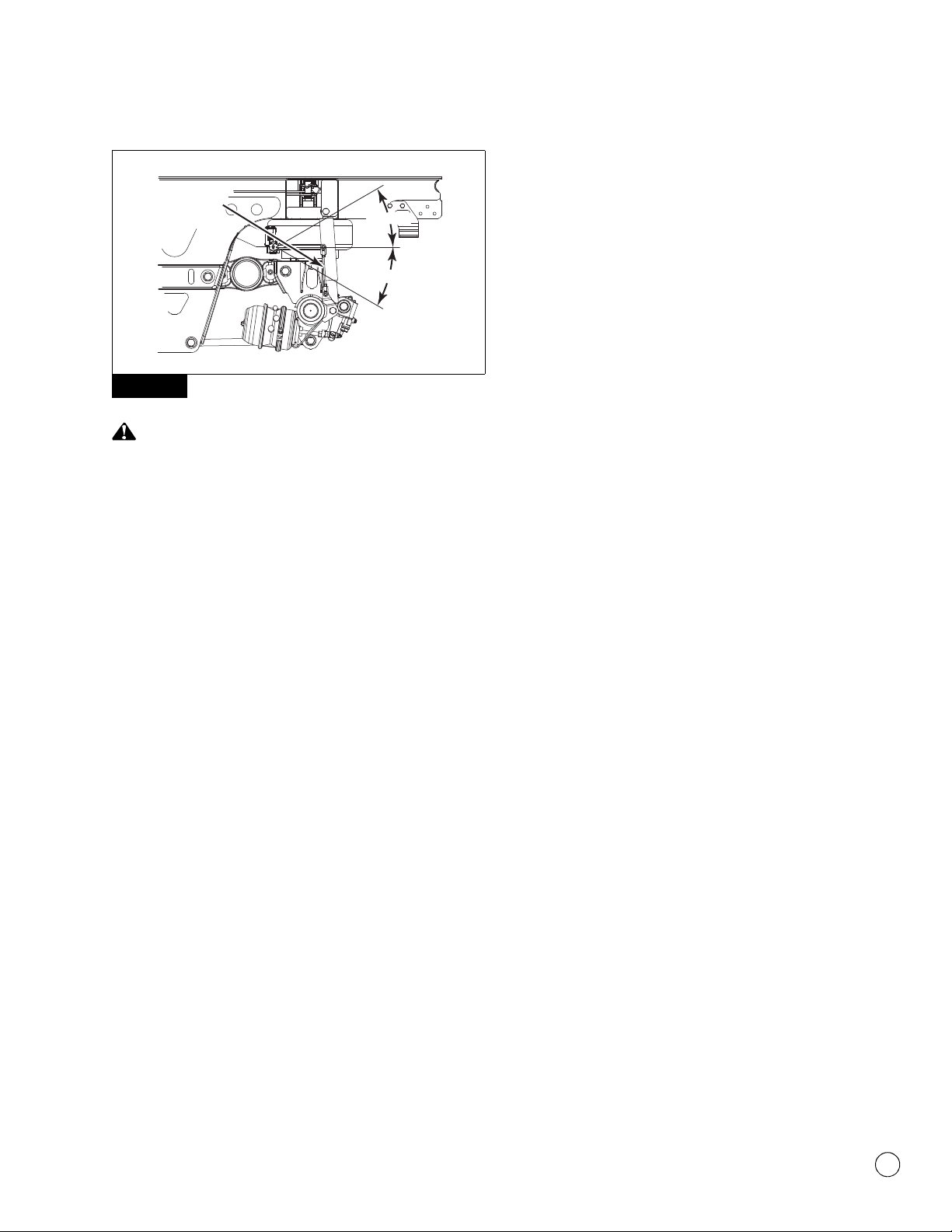

9. Inspect the structure of the suspension. Figure 3.3. Inspect the

following items.

앫Upper axle seats

앫Upper control arms

앫Lower axle seats

앫Lower control arms

앫Axle welds

앫Brake interference, cam or chamber

앫Frame brackets

앫Shock absorber brackets

Figure 3.3

Inspection

Height Control Valve

There are three basic configurations for plumbing the height control

valve (HCV) into the air suspension system.

앫No-dump

The no-dump configuration is standard equipment. In the

no-dump configuration, the valve maintains air pressure and

enables the trailer to maintain ride height during loading and

unloading, if it is attached to an air supply.

앫Auto-dump

The auto-dump configuration will exhaust the air springs when

the trailer parking brakes are set. This lowers the trailer deck

height three-inches providing a stable platform for loading and

unloading. The trailer will return to the ride height when the

parking brakes are released.

앫Manual-dump/auto-reset

The manual-dump/auto-reset configuration offers the same

feature as auto-dump, except at the operator’s discretion.

WARNING

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury and

damage to components can result.

1. Park the unloaded vehicle on a level surface. Block the wheels

to prevent the vehicle from moving.

2. Disconnect the height control linkage. Figure 3.4.

Figure 3.3

4006711a

UPPER

AXLE

SEAT

LOWER

AXLE

SEAT

LOWER

CONTROL

ARMS

UPPER

CONTROL

ARM

FRAME

BRACKET

3 Inspection and Maintenance

9

Meritor Maintenance Manual 14R (Revised 12-18)

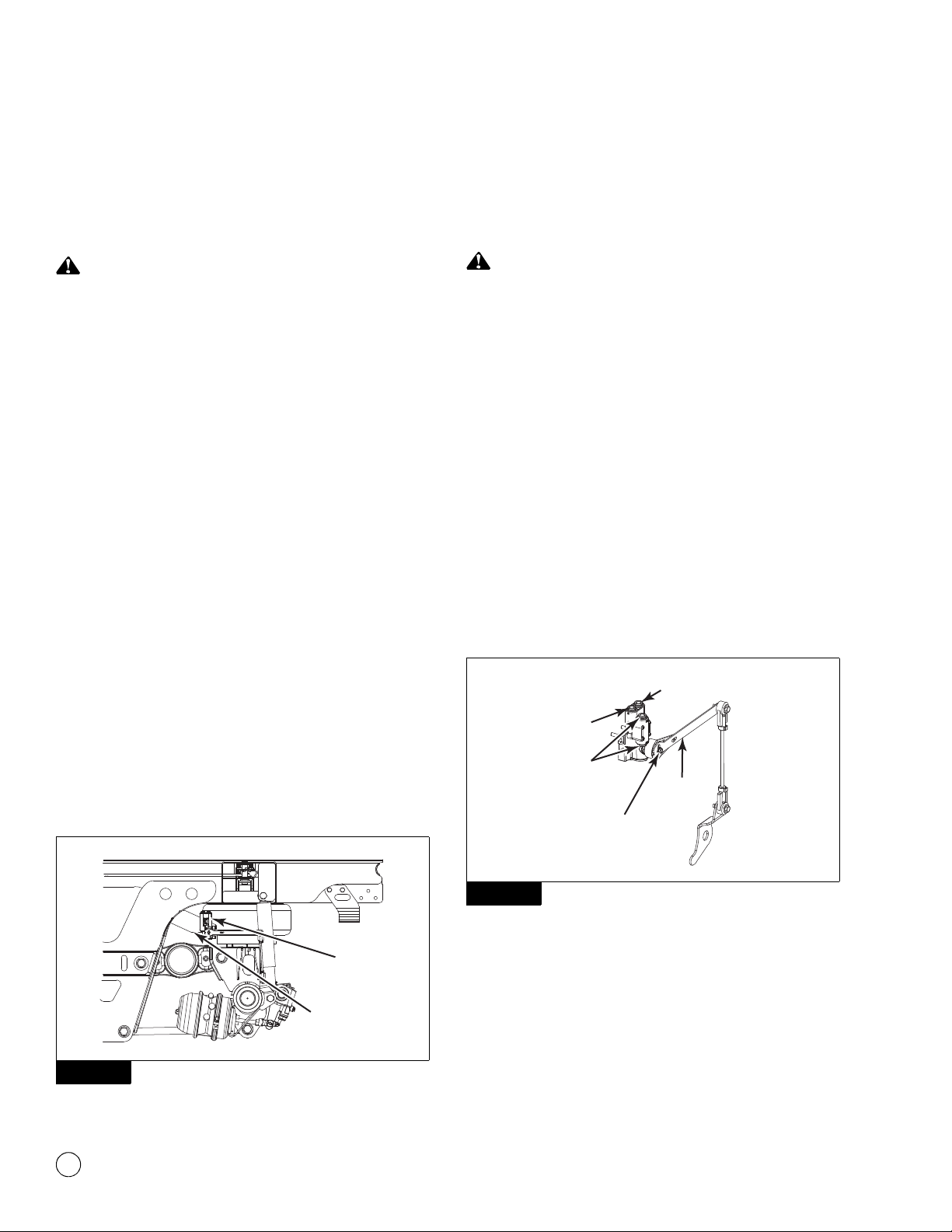

Figure 3.4

WARNING

Verify that all personnel are clear of the trailer before you

inflate or deflate the air springs. The air suspension system

has various pinch points that can cause serious personal

injury.

3. Check the air supply to the height control valve. A minimum of

65 psi (448 kPa) is required to correctly test the height control

valve.

4. Rotate the lever UP 30 to 45 degrees. Air should begin to flow

into the air springs.

5. Rotate the lever to the neutral position. Airflow should stop.

6. Rotate the lever DOWN 30 to 45 degrees. Air should begin to

flow out of the air springs.

7. Rotate the lever to the neutral position. Airflow should stop.

앫If the air does not flow to and from the air springs:

Drain the air from the system. Use compressed air to clean

the screens in the supply and delivery ports.

8. Connect the air lines to the height control valve and repeat the

above steps.

앫If air still does not flow to and from the air springs, or if

the airflow cannot be stopped in the neutral position:

Replace the height control valve.

9. Inspect the height control valve for air leaks and a cracked

lever arm housing.

앫If air leaks or cracks are detected: Replace the height

control valve.

Axle Inspection and Maintenance

For correct inspection and maintenance procedures and intervals,

refer to Maintenance Manual 14, Trailer Axles. To obtain this

publication, refer to the Service Notes page on the front inside cover

of this manual.

Lubrication

The RideSentry™ MPA Series slider box or suspension does not

require lubrication. For lubrication and maintenance requirements

for axles, hubs and brakes, refer to Maintenance Manual 14, Trailer

Axles; and Maintenance Manual 1, Preventive Maintenance and

Lubrication. To obtain these publications, refer to the Service Notes

page on the front inside cover of this manual.

Figure 3.4

4006712a

HEIGHT

CONTROL

LINKAGE 30°-45°

30°-45°

4 Component Removal, Installation and Adjustment

10 Meritor Maintenance Manual 14R (Revised 12-18)

4 Compone nt Removal, Installatio n and Adjustment

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury and

damage to components can result.

Verify that all personnel are clear of the trailer before you

inflate or deflate the air springs. The air suspension system

has various pinch points that can cause serious personal

injury.

Removal and Installation

Height Control Valve (HCV)

1. Park the unloaded vehicle on a level surface. Block the wheels

to prevent the vehicle from moving.

2. Drain all the air from the surge tank and air springs.

3. Remove the air supply and delivery lines from the height

control valve.

4. Disconnect the linkage. Replace bent or damaged linkage.

5. Remove the height control valve from the bracket. Figure 4.1.

Figure 4.1

6. Install the new HCV onto the mounting bracket. Tighten the

mounting bolts to 5 lb-ft (7 N폷m). @

7. Connect the linkage. Tighten the upper and lower linkage bolts

to 5 lb-ft (7 N폷m). @

CAUTION

The Hadley 1500 HCV is equipped with 3/8-inch (9.525 mm)

push-to-connect fittings. Do not use sealant on

push-to-connect fittings. Damage to components can result.

8. Connect the air supply and the delivery lines to the height

control valve.

9. Charge the air system.

10. Use a soapy spray solution to check the entire system for air

leaks.

11. Verify the ride height setting. Refer to the procedures in this

section.

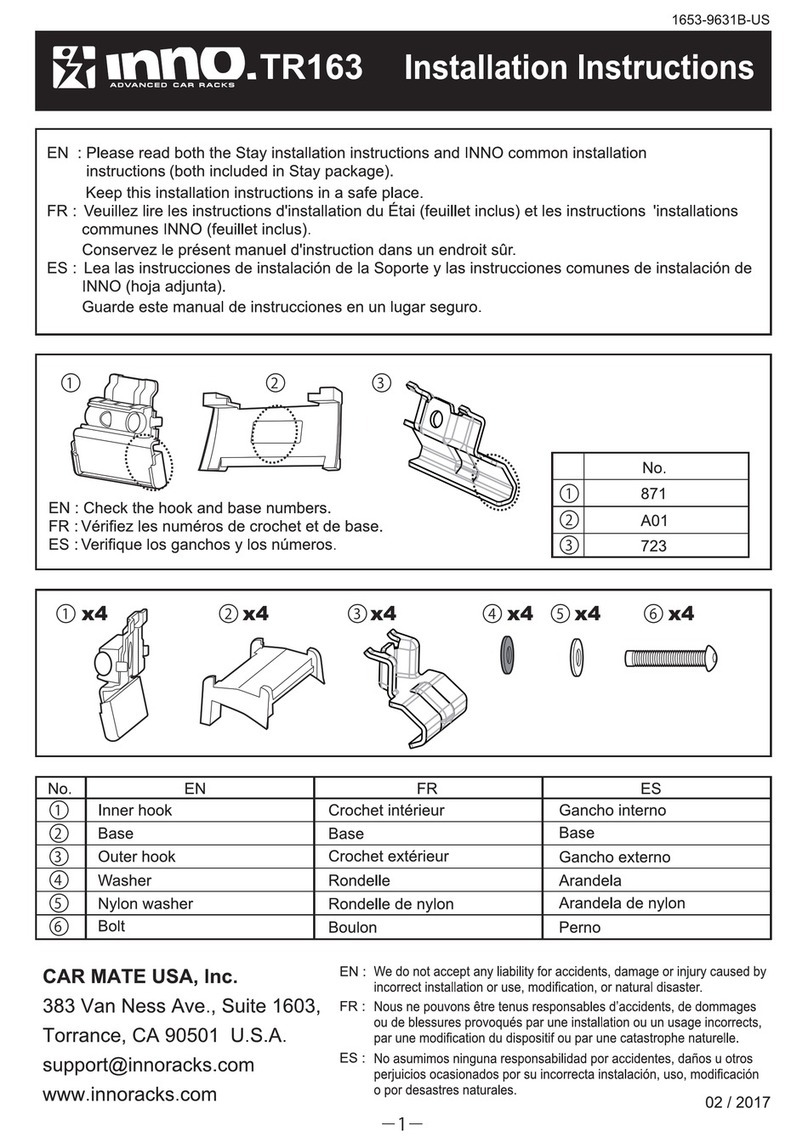

HCV Installation Options

The suspension may be equipped with a 1500 Series auto-dump

configuration or a 1500 Series no-dump configuration. Figure 4.2

and Figure 4.3.

Figure 4.2

Figure 4.1

4006713a

HEIGHT

CONTROL

VALVE

MOUNTING

BRACKET

Figure 4.2

4006714a

LEVER

SUPPLY PORT

DUMP PILOT

PORT

SUSPENSION

PORT

BOLT TORQUE

50-55 LB-IN

(6 N•m)

AUTO-DUMP

4 Component Removal, Installation and Adjustment

11

Meritor Maintenance Manual 14R (Revised 12-18)

Figure 4.3

Adjustment

Verify Ride Height

1. Refer to the trailer manufacturer’s specifications for the correct

ride height.

2. Unload the vehicle before you adjust the height control valve.

Support the trailer king pin at the normal operating height.

3. Verify the correct ride height by measuring the ride height from

the axle centerline to the bottom of the slider frame.

앫If the measured ride height does not meet the trailer

manufacturer’s specifications: Continue to the next step.

앫If the measured ride height does meet the trailer

manufacturer’s specifications: Go to Step 10.

4. Disconnect the height control valve linkage from the lever arm.

Inflate or deflate the air springs by raising or lowering the

height control lever arm 30 to 45 degrees. Hold the lever arm

in the UP position for at least 15 seconds or until the air bags

are correctly inflated. Figure 4.4.

Figure 4.4

5. Check the ride height. Figure 4.5. Repeat the previous step

until the measured ride height matches the trailer

manufacturer’s specified ride height.

Figure 4.5

6. Use a 3/8-inch wrench to loosen the 0.25-inch adjusting screw

located on the lever arm body. Allow the lever arm to swing

free.

7. Align the end of the lever arm to the top opening of the linkage.

Loosely insert the upper linkage bolt.

8. Tighten the 0.25-inch adjusting screw to 50-55 lb-in

(6 N폷m). @

9. Connect the upper linkage bolt. Tighten the bolt to 5 lb-ft

(7 N폷m). @

10. Verify that the overall trailer height does not exceed the local

legal limit.

앫If the ride height is not within the specification: Repeat

the ride height adjustment procedure until the ride height is

correct.

Maintain the Correct Ride Height When You

Change an HCV

You must maintain the correct ride height when you change an HCV.

Refer to the trailer manufacturer’s specifications for the correct ride

height.

Figure 4.3

Figure 4.4

4006715a

LEVER

BOLT TORQUE

50-55 LB-IN

(6 N•m)

NO-DUMP SUPPLY PORT

SUSPENSION

PORT

4006716a

HEIGHT

CONTROL

VALVE

LINKAGE

ADJUSTING

SCREW

Remove

this bolt.

30°-45°

INFLATE

DEFLATE

30°-45°

Figure 4.5

4006717a

MOUNTING

HEIGHT

RIDE

HEIGHT

4 Component Removal, Installation and Adjustment

12 Meritor Maintenance Manual 14R (Revised 12-18)

Removal and Installation

Air Spring

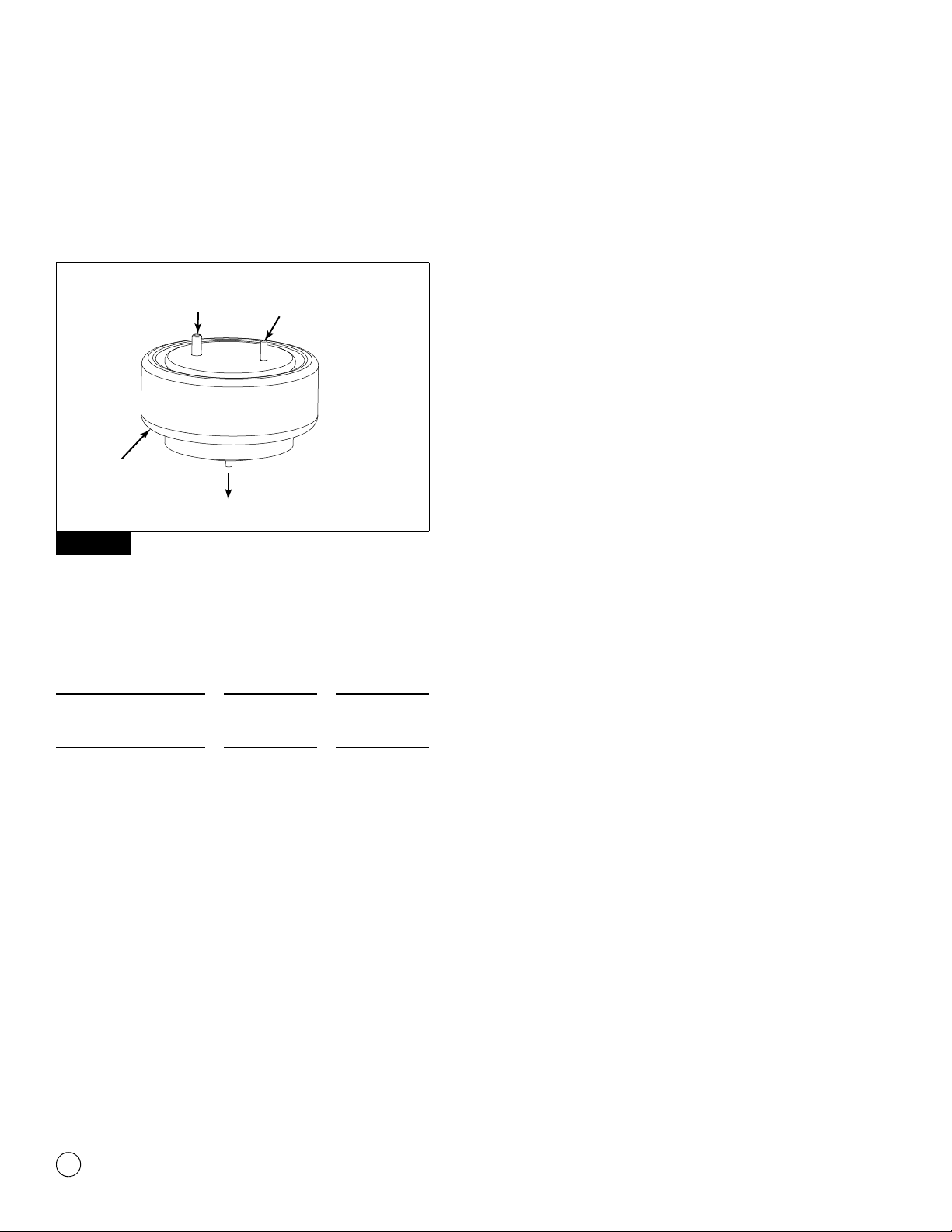

Figure 4.6 shows the standard air spring used on the suspension.

Figure 4.6

The RideSentry™ suspension uses three different air springs based

on the suspension model and ride height. Refer to the following

table for the air spring part numbers.

1. Refer to the preceding table to identify the specific air spring

that is damaged or leaking air.

2. Park the trailer on a level surface. Block the tires to prevent the

trailer from moving.

3. Use an appropriate lifting device to raise the trailer to extend

the air springs, but not enough to raise the tires off the ground.

Support the trailer with safety stands.

4. Verify that all the air has been exhausted from the air system.

5. Remove the air inlet line and fitting from the damaged air

spring. Figure 4.7.

Figure 4.6

Air Spring

Suspension

Model Ride Height

A-2258-F-1410 MPA38/40 16.5

A-2258-W-1531 MPA38/40 17.5

A-2258-X-1532 MPA38/40 18.5

AIR SUPPLY

FITTINGTO SLIDER

FRAME

TO UPPER AXLE SEAT

AIR

SPRING

4002674a

4 Component Removal, Installation and Adjustment

13

Meritor Maintenance Manual 14R (Revised 12-18)

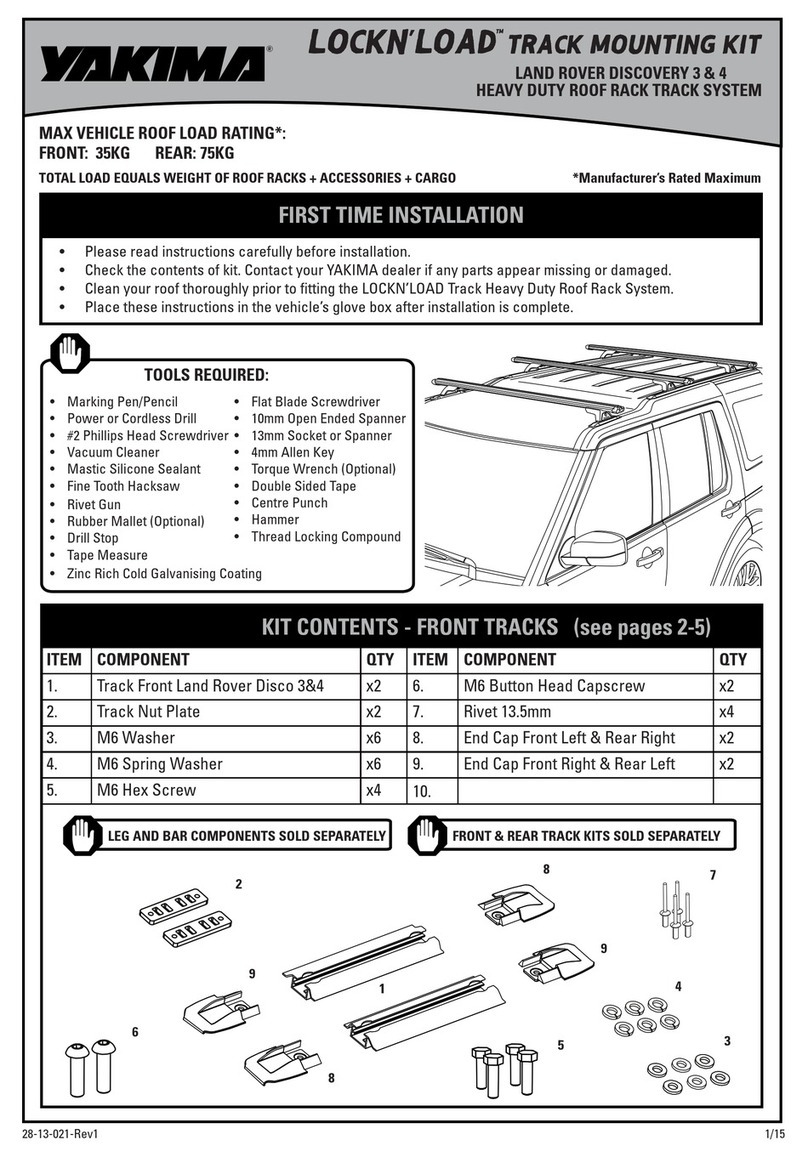

Figure 4.7

6. Remove the nuts from the studs that secure the top of the air

spring.

7. Remove the nut from the bottom of the air spring. You can

reach the nut from inside the front or rear of the upper axle

seat.

8. Compress the air spring. Remove the spring from the

suspension.

9. Compress the new air spring. Slide the spring into the space

between the axle seat and slider frame. Reuse the air spring

spacer(s), if originally supplied.

10. Align the air inlet and mounting stud. Insert them into the holes

in the slider frame.

11. Install the lower nut. Tighten the lower nut to 30-35 lb-ft

(41-47 N폷m). @

12. Install the nuts on the top mounting studs. Tighten the 1/2-13

UNC nut to 20-25 lb-ft (30-35 N폷m). Tighten the 3/4-16 UNF

nut to 45-50 lb-ft (60-70 N폷m). @

13. Install the fitting and inlet air line to the top of the air spring.

Apply a sealant tape.

14. Seat the valve at the bottom of the air tank. Pressurize the air

system.

15. Check that items such as tires, air lines or suspension

components do not interfere with the air spring flex members.

16. Use a soap solution to check the entire system for air leaks.

17. Raise the trailer. Remove the safety stands.

18. Verify that the ride height of the trailer is correct.

앫If the ride height is incorrect: Adjust the height control

lever arm to obtain the correct ride height. Refer to the

trailer manufacturer’s specifications for the correct ride

height.

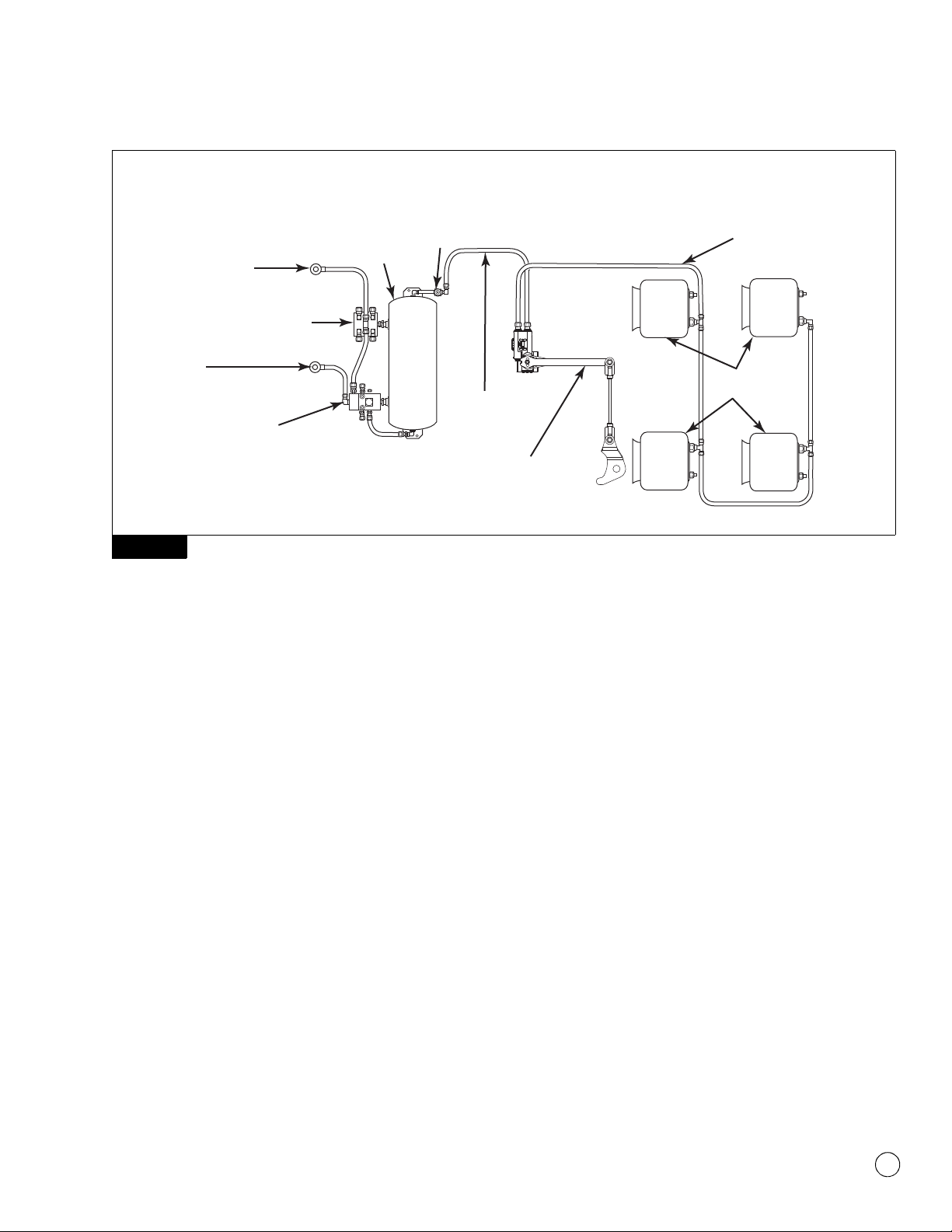

Figure 4.7

BRAKE

PROTECTION

VALVE

PILOT

RELAY

VALVE

4006718a

CURBSIDE

ROADSIDE

TO

AIR SPRINGS

AIR

SPRINGS

TRAILER

SPRING

BRAKE

VALVE

GLAD HAND

SUPPLY

EMERGENCY

PARKING,

RED

GLAD

HAND

CONTROL,

BLUE

AIR

RESERVOIR

FROM BRAKE

PROTECTION

VALVE

HEIGHT CONTROL

VALVE

4 Component Removal, Installation and Adjustment

14 Meritor Maintenance Manual 14R (Revised 12-18)

Upper Control Arm

WARNING

Visually inspect upper control arm fasteners to ensure they are

tightened to the correct specification. Loose fasteners can

damage suspension components. If you find a loose pivot bolt

at the upper control arm pivot connection, disassemble the

pivot joint to check for damaged components. Tighten loose

fasteners. Replace damaged fasteners and components to

prevent serious personal injury and damage to components

during operation.

Visually inspect the upper control arm bushing inner metal ends for

wear. Wear is not permitted between the bushing inner metal and its

mating surfaces. Refer to Figure 4.8.

앫If there is wear between the bushing inner metal and its

mating surface: Replace the upper control arm bushing at the

loose fastener location only.

앫If a loose fastener is at the frame hanger location and

damage is found: Use a roadside or curbside side plate repair

kit.

앫If a loose fastener is at the upper axle seat and damage is

found: Replace the upper axle seat. Contact the Meritor

OnTrac™ Customer Call Center at 866-668-7221 for parts and

kits.

Figure 4.8

1. Lower the landing gear. Use an appropriate lifting device to

raise the trailer frame so that the tires are off the ground.

Support the trailer with safety stands. Set the parking brake.

2. Exhaust the air pressure from the suspension air springs.

Remove the wheels from the axle where you are removing the

bushings to access the pivot bolts.

앫If there is corrosion between the pivot bolts and the

bushing inner metal: Use an impact wrench to spin the

pivot bolt heads at all four connections to disengage the

bolts from the corrosion to the bushing inner metal.

3. Remove only the locknut at the frame bracket on the roadside

and curbside at the upper pivot connections.

4. Record the pivot bolt orientation. Remove the pivot bolts from

the frame brackets. Slide the upper control arm out of the

frame brackets to provide access to the bushings.

5. Remove the bushings. Remove any burrs and clean the inside

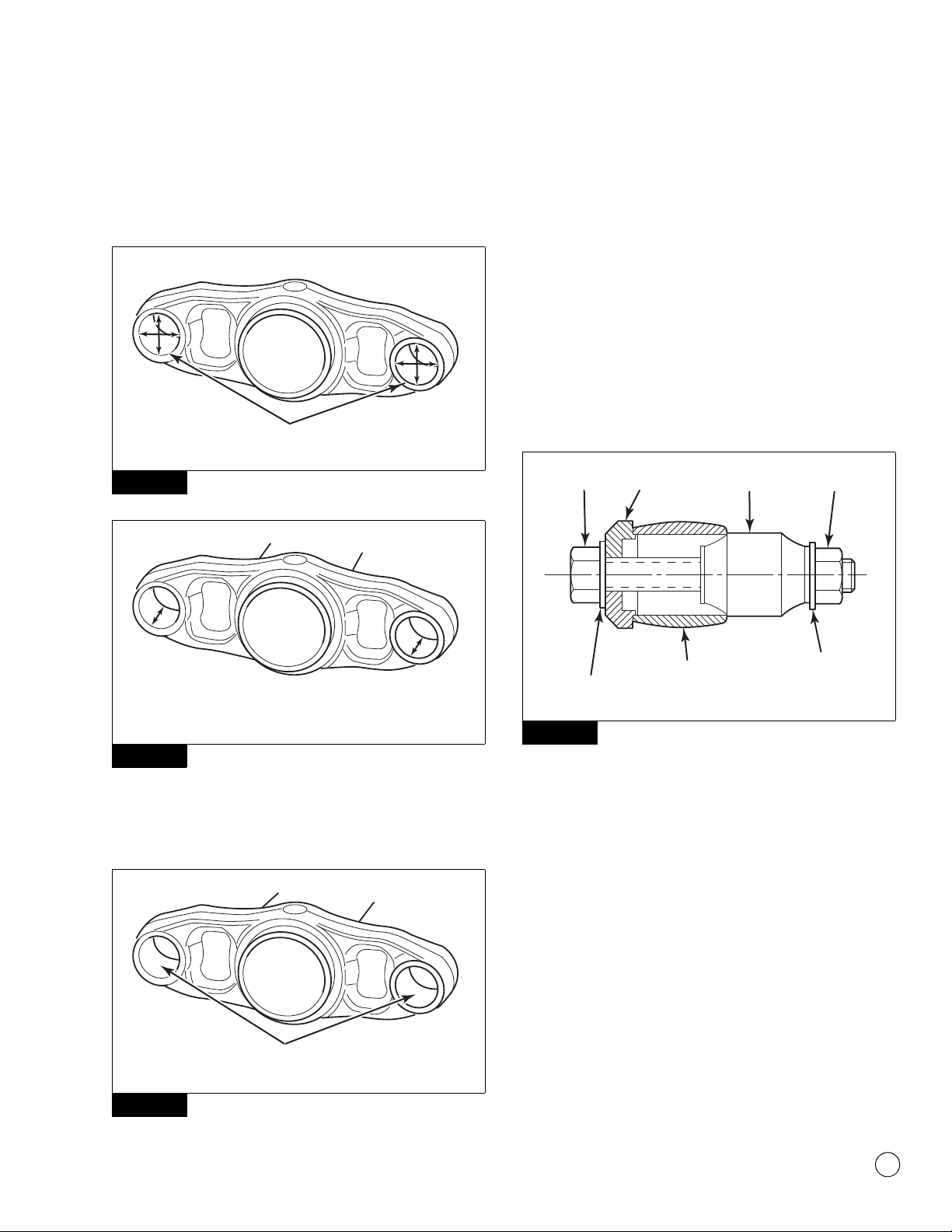

diameter of the upper control arm ends. Figure 4.9.

Figure 4.9

6. Visually inspect the upper control arm bushing tubes, frame

brackets and axle seats.

A. You must measure the bore diameter and bushing tube

length of all four upper control arm bushing tubes before

you install the new bushings. The bore diameter must be

2.240-2.250-inches (56.896-57.150 mm). Figure 4.10.

The bushing tube length must be 2.530-inches

(64.262 mm) or greater. Figure 4.11.

앫If any of the four upper control arm bushing tubes

are not within the specifications: Replace the upper

control arm.

Figure 4.8

No wear is permitted

between the bushing

inner metal and its

mating surfaces.

4005083c

BUSHING

THRUST

WASHER

THRUST

WASHER

BUSHING

INNER

METAL

UPPER CONTROL ARM

BUSHING TUBE

Figure 4.9

4006737a

Inspect and

remove burrs.

4 Component Removal, Installation and Adjustment

15

Meritor Maintenance Manual 14R (Revised 12-18)

B. Inspect the frame brackets and axle seats for wear from

contact with the upper control arm bushing inner metal.

Wear is not permitted between the bushing inner metal

and its mating surfaces.

Figure 4.10

Figure 4.11

7. Using light mineral oil, Meritor specification O-92-B, lightly

lubricate the inside diameter of the upper control arm bushing

tubes. Figure 4.12.

Figure 4.12

8. Refer to Section 9 for a description of the bushing tool part

number A-3256-H-1152.

9. Using light mineral oil, Meritor specification O-92-B, lightly

lubricate the outside diameter of the bonded bushing.

10. Place the draw plate onto the inside surface of the upper

control arm bushing tube. Figure 4.13.

A. Insert the draw bolt with a flat washer, through the draw

plate and bushing tube.

B. Place the bushing over the draw bolt and into the upper

control arm bushing tube.

C. Thread the draw nut and flat washer onto the draw bolt

until it sets against the bushing.

Figure 4.13

11. Snug the draw bolt while ensuring that the bushing and draw

plate rest securely on the upper control arm bushing tube.

12. While holding the draw nut with a wrench, turn the draw bolt

CLOCKWISE using a maximum one-half-inch impact at a

reduced and steady speed. Draw the bonded bushing into the

upper control arm bushing tube.

13. If the bolt stops turning or extreme resistance is present,

reverse the impact and loosen the tool assembly. Inspect all

components of the tool for damage. Reset the draw plate

ensuring that the bonded bushing is correctly seated against

the upper control arm bushing tube. Verify lubrication on the

bushing and control arm tube and repeat the above procedure.

14. Continue rotating the draw bolt until the bolt stops turning and

the bushing is fully inserted. Thread damage to the draw bolt or

draw nut can occur if over tightened.

Figure 4.10

Figure 4.11

Figure 4.12

4006738a

Check both ends

of each tube.

4006739a

4006740a

LUBRICATED

SURFACE

Figure 4.13

4005082b

DRAW

BOLT

FLAT

WASHER

FLAT

WASHER

UPPER CONTROL

ARM BUSHING

TUBE

DRAW

PLATE

DRAW

NUT

BUSHING

4 Component Removal, Installation and Adjustment

16 Meritor Maintenance Manual 14R (Revised 12-18)

15. Ensure that the bushing is centered in the upper control arm

bushing tube from side-to-side. Install the thrust washers onto

the bushings. Figure 4.14.

Figure 4.14

16. Position the upper control arm into the frame brackets. Ensure

that the thrust washers remain in position on the bushings.

Using the recorded pivot bolt orientation, insert a new pivot

bolt, flat washers, alignment washers and nut on the roadside.

Insert a new pivot bolt, flat washers and nut on the curbside.

Figure 4.15.

Figure 4.15

17. Loosely install the roadside and curbside nuts. Do not

completely tighten at this time.

18. Remove only the locknuts at the upper axle seat on the

roadside and curbside upper pivot connections.

19. Remove the pivot bolts from the upper axle seats. Record the

pivot bolt orientation. Slide the upper control arm out of the

upper axle seats to provide access to the bushings.

20. Remove the bushings. Remove any burrs and clean the inside

diameter of the upper control arm ends. Figure 4.9.

21. Repeat Steps 7-15 to install the bushing.

22. Position the upper control arm into the upper axle seats.

Ensure that the thrust washers remain in position on the

bushings. Using the recorded pivot bolt orientation, insert a

new pivot bolt, flat washers and nut on the roadside and

curbside.

23. Loosely install the nuts at the axle seat positions. Do not

completely tighten at this time.

24. Determine the correct suspension ride height. Refer to the

trailer manufacturer’s specifications. The upper control arm

must be at the correct ride height before applying the required

torque to all upper pivot bolts. Figure 4.16.

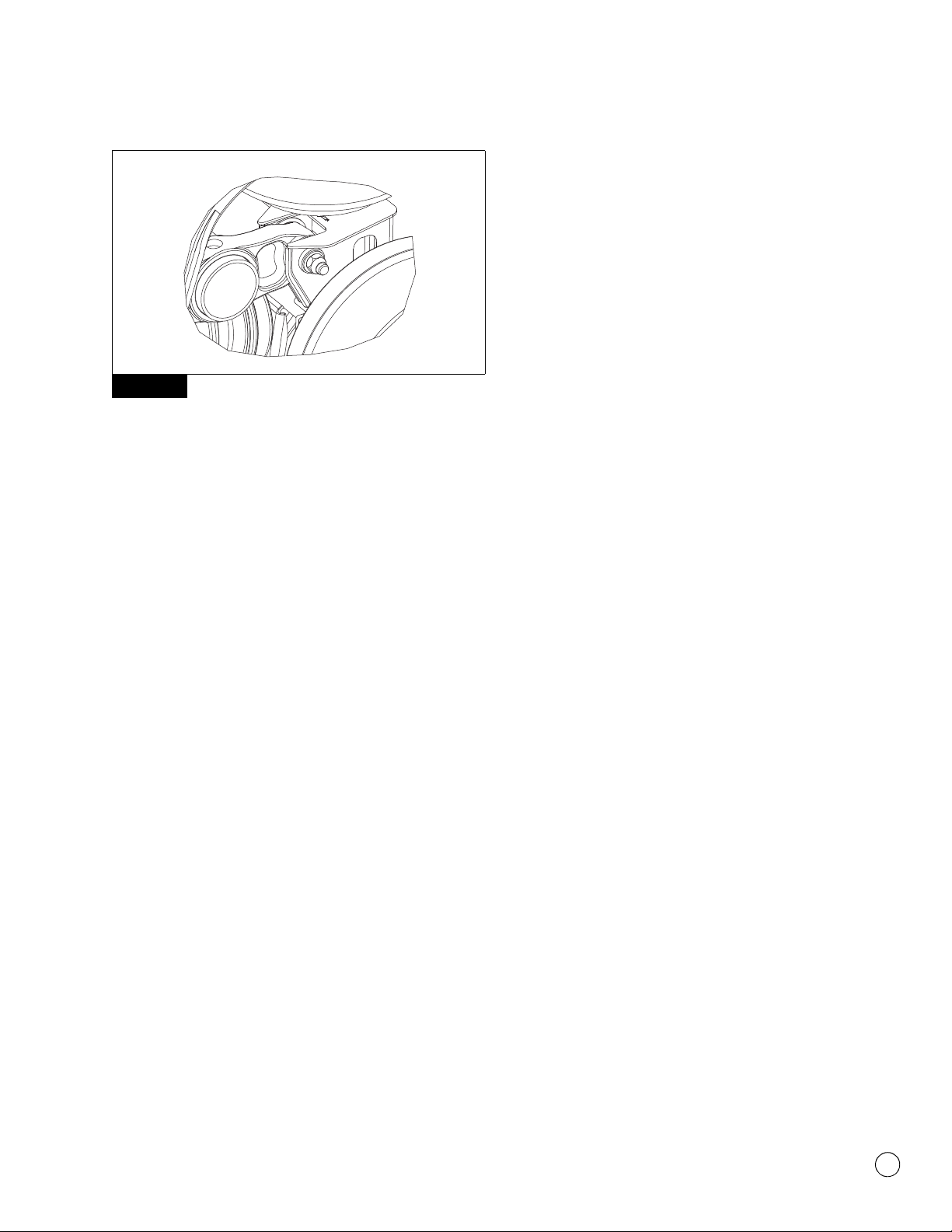

Figure 4.16

25. Install the locknut and tighten to 450-500 lb-ft (611-678 N폷m).

Figure 4.17. @

Figure 4.14

Figure 4.15

4005083b

BUSHING

THRUST

WASHER

THRUST

WASHER

BOTH

DIMENSIONS

SHOULD BE

THE SAME

± 0.010" (0.25 MM)

UPPER CONTROL ARM

BUSHING TUBE

4005084a

PIVOT

NUT

PIVOT

BOLT

FLAT

WASHER

FLAT

WASHER

FRAME

BRACKET/AXLE

SEAT

UPPER CONTROL ARM

BUSHING TUBE

THRUST

WASHERS

Figure 4.16

4006719a

MOUNTING

HEIGHT

RIDE

HEIGHT

AXLE

4 Component Removal, Installation and Adjustment

17

Meritor Maintenance Manual 14R (Revised 12-18)

Figure 4.17

26. Reinstall the wheels and tires. Remove the safety stands at the

rear of the trailer. Slowly lower the trailer back down onto the

suspension.

27. Check the suspension ride height to verify it is correct. If

adjustment is necessary, refer to the ride height adjustment

procedures in this section.

28. Axle realignment is required. Refer to the axle alignment

procedures in this section.

29. Refer to Section 8 for torque specifications.

Lower Control Arm

1. Park the trailer on a level surface.

2. Lower the landing gear. Use an appropriate lifting device to

raise the rear of the trailer frame so that the tires are off the

ground. Support the trailer with safety stands.

3. Exhaust the air pressure from the suspension air springs.

Remove the wheels from the axle to access the pivot bolts.

앫If there is corrosion between the pivot bolts and

bushing inner metal: Use an impact wrench to spin the

pivot bolt heads at all four connections to disengage the

bolts from corrosion to the bushing inner metal.

4. Remove the locknuts from the pivot bolts at the frame bracket

and lower axle seat.

5. Remove the pivot bolts. Remove the lower control arm.

6. Remove the bushings and inner sleeves. Remove any burrs

and clean the inside diameter of the lower control arm ends.

7. Insert new bushings into the lower control arm ends. Insert the

inner sleeve through the bushings. Use light mineral oil, Meritor

specification O-92-B for lubrication. Center the inner sleeve in

the lower control arm ends.

8. Position the lower control arm into the frame bracket and lower

axle seat. Insert a new bolt, flat washers and nut at both pivot

connections.

9. Tighten the nuts to 450-500 lb-ft (611-678 N폷m). @

Axle Replacement Procedure

1. Park the trailer on a level surface. Lower the landing gear.

2. Use a jack to raise the rear of the trailer frame, until the tires on

the axle you will replace just clear the floor. Support the trailer

with safety stands.

3. Exhaust the air pressure from the suspension air springs and

air tank.

4. Remove the drums, tires and wheel ends, preferably all

together.

5. Remove the brake shoes.

6. Disconnect the brake chamber clevis from the automatic slack

adjuster.

7. Disconnect the brake chambers from the axle and secure them

out of the way. It is not necessary to disconnect the brake

hoses.

8. Remove the automatic slack adjusters.

9. Remove the bottom retaining nut from the suspension air

springs.

10. Use a jack to raise the axle up about four inches (101.2 mm).

Stabilize the axle. Remove the bottom bolt from the shock

absorber/axle connection.

앫If you are servicing a rear axle: Move the leveling valve

control rod UP and out of the way.

11. Remove the lower control arm nuts, pivot bolts and washers at

the axle seat. Move the lower control arms DOWN and out of

the way.

12. Remove the upper control arm nuts, bolts and washers at the

axle seat connection on each side.

13. Remove axle from under the trailer.

Figure 4.17

4006720a

Table of contents

Other Meritor Automobile Accessories manuals