2

1. INTRODUCTION

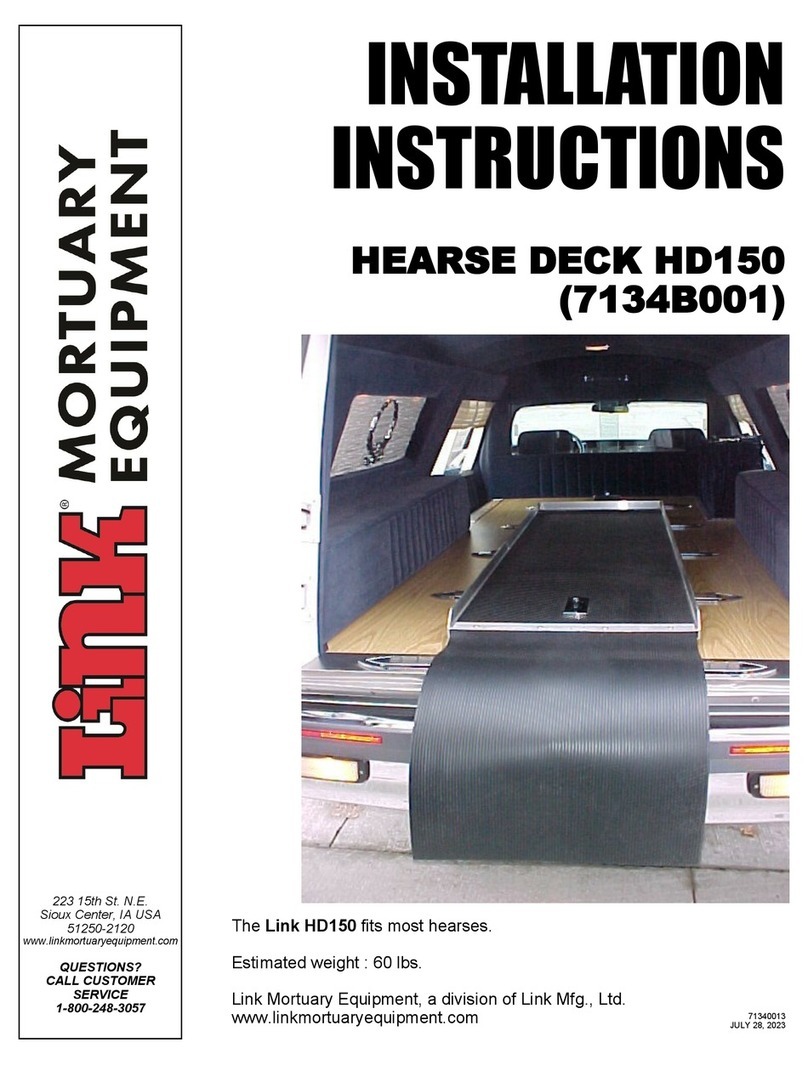

Thank you for choosing a Link Cargo Management

Products (CMP) DD2000-XLC Double Deck

system. We want to help you to get the best results

from the deck and to operate it safely. This manual

contains information to introduce you to the Link

CMP DD2000-XLC and to assist you with its

operation. The manual is intended solely for use

with this product.

All information in this manual is based on the latest

information available at the time of printing. Link

Manufacturing reserves the right to change its

products or manuals at any time without notice.

Contact Link CMP at (800) 248-3057 for

information on recent changes to products.

Damaged components should be returned to Link

with a pre-arranged Returned Goods Authorization

(RGA) number through the Customer Service

Department. The damaged component may then

be replaced if in compliance with warranty

conditions.

2. SAFETY SYMBOLS, TORQUE SYMBOL, and

NOTES

IMPORTANT: IT IS IMPORTANT THAT THE EN-

TIRE OPERATION INSTRUCTIONS BE READ

THOROUGHLY BEFORE USING THIS SYSTEM.

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that follow

this symbol to avoid possible

injury or death.

WARNING

WARNING indicates a

potentially hazardous

situation which, if not

avoided, could result in death

or serious injury.

CAUTION

CAUTION indicates a

potentially hazardous

situation which, if not

avoided, could result in

minor or moderate injury.

The torque symbol alerts you

to tighten fasteners to a

specified torque value.

3. SAFE WORKING PRACTICES:

3.1

3.2

4. OPERATION GUIDELINES

4.1 In order for this deck to operate properly, it must

operate in the parameters specified by Link.

4.2 No alterations of any Link deck component is

permitted without proper authorization from

qualified Link personnel.

Link products must be installed by a trained technician

when being placed into an Electric Vehicle (EV). Electric

Vehicles have higher voltage batteries and cables, and

drilling into Electric Vehicles may cause serious bodily

harm and possible death.

Note: Link is not responsible for optional configurations

or equipment that restrict the installation of the product

in any way. Consult OEM body builder guides for addi-

tional installation guidelines.

WARNING

Practice safe lifting procedures.

The deck weldments are heavy, and can cause in-

jury if lifted improperly or dropped. Consider size,

shape, and weight of objects being moved.

Obtain help or the assistance of a crane when lifting

heavy assemblies. Make certain the path of travel is

clear.

CAUTION