Mesko-Rol Z 175-1 Troubleshooting guide

1

CONTENTS:

1.

EU DECLARATION OF CONFORMABILITY ……………………………………….

2

2.

INTRODUCTION ………………………………………………………………………...

3

3.

APPROPRIATE USE OF THE MACHINE …………………………………………….

3

4.

SAFETY OF USE …………..……………………………………………………………..

4

4.1. General safety principles ……………………………………………………….

4.2. Detailed safety principles ………………………………………………………

4

5

4.2.1. Preparation for work …………………………………………………….

4.2.2. Transporting ……………………………………………………………..

4.2.3. Working …………………………………………………………………

4.2.4. Disconnecting the mower from the tractor for the stop and storage ……

4.2.5. Technical maintenance ………………………………………………….

4.2.6. Safety signs ………………..…………………………………………….

5

6

6

7

7

8

5.

MOWER OPERATING …………………………………………………………………..

10

5.1. General characteristics and description of the mower ………………………….

5.2. Preparation for transport and transporting ……………………………………...

10

11

5.2.1. Linking mower and tractor into a working unit ………………………...

5.2.2. Assembling a PTO driver shaft …………………………………………

5.2.3. Transporting the mower mounted on the tractor ……………………….

11

12

12

5.3. Setting the mower in working position …..……………………………………..

5.4. Mowing .………………………………………………………………………...

5.5. Preparation for the stop and disconnecting the mower from the tractor ………..

13

14

15

6.

TECHNICAL MAINTENANCE …………………………………………………...........

15

6.1. Routine technical maintenance …………………………………………………

6.2. Lubrication ………………………………………………………………...........

6.3. Preservation and storage ….…………………………………………………….

16

17

17

7.

TECHNICAL CHARACTERISTICS .…………………………………………………..

17

8.

PARTS LIST ………………………………………………………………………………

19

2

1. EU DECLARATION OF CONFORMABILITY FOR MACHINES:

We, the company “MESKO-ROL” Sp. z o.o.

26-111 Skarżysko-Kamienna, ul. I.Mościckiego 51, Poland

declare with full responsibility that machine

SUSPENDED ROTARY MOWER Z 175-1

№ …………………………

which this declaration refers to, complies with requirements of:

Directive 98/37/EC –Machinery changed with a Directive No. 98/79/EC

Decree of Minister of Economy of 20.12.2005. (Dz.U. No. 259, pos. 2170 of 28.12.2005.)

harmonized standards:

PN-EN 292-1 - Basic notions, general principles of projecting

PN-EN 292-2 - Basic notions, general principles of projecting

PN-EN 294 - Safety distances preventing from reaching dangerous areas with upper

limbs.

PN-EN 745 - Agricultural machinery. Rotary and swingle mowers. Requirements

regarding safety.

PN-EN 1553 - Agricultural machinery. Agricultural self-propelling, suspended, half-

suspended and attached machines. Common requirements regarding safety.

non-harmonized standards:

PN-ISO 11684:1998. Tractors, agricultural and forest machines, motor tools. Safety signs

and warning pictograms. General principles.

Skarżysko-Kamienna, 01.07.2008.

Jacek Kowalski

President of Board of “MESKO-ROL”

3

2. INTRODUCTION

Considering the importance of the information, this service manual constitutes an inseparable

part of the mower.

Compliance with all recommendations of this manual will let you optimally exploit the machine.

Careful reading will ensure safe and effective work with the mower.

The mower is made according to the safety standards’requirements. Compliance with the

warnings and instructions of this manual guarantees the safety of the user.

To use the machine failure-free for many years we recommend usage of only original spare parts

produced by “MESKO-ROL” Ltd.

If you have any questions after reading the manual please contact the salesman or

Sale&Marketing Department of “MESKO-ROL” Ltd.:

tel.: 0048 41 2534121

fax. 0048 41 2533309

webpage: www.mesko-rol.com.pl

„MESKO-ROL“ Ltd. constantly tries to improve its products. We reserve ourselves the right to

introduce any changes and improvements which we consider necessary. We have no obligation

for modernizing already sold machines.

3. APPROPRIATE USE OF THE MACHINE

The mower is assigned only for agricultural works - mowing the grass and low-stem green

forage on even fields and meadows. Using this machine for other purpose will be understood as

an inappropriate.

Fulfillment of the manufacturer’s requirements regarding usage of the mower, servicing and

repairs as well as thorough compliance with these requirements is a condition of appropriate

usage.

The mower should be used and repaired only by a person who is acquainted with its

characteristics and rules of behaving due to safety principles.

Rules relating to accident prevention as well as all basic rules of the safety and occupational

medicine, and also the traffic rules should be always complied with.

Changes made by an unauthorized person can relieve the producer from the responsibility for

possible harms and damages.

4

4. SAFETY OF USE

IMPORTANT INFORMATION FOR A USER

THE WARNING SYMBOL

This warning symbol points important information referring danger to body or life of people and

animals, which is showed in the service manual. If you see the symbol –be aware and read

carefully the given information.

4.1. GENERAL SAFETY PRINCIPLES

BE CAREFUL –THOROUGHLY READ THE INSTRUCTIONS IN ORDER NOT TO

EXPOSE YOURSELF AND OTHERS TO A DANGER.

REMEMBER to comply with safety principles and keep the precautionary measures

referring the mower as well as safety of use.

Every user must completely know all the possible dangers and ways of avoiding the harm

or damages.

NEVER let the children or youth under 18 operate the mower.

NEVER let the people unacquainted with maintenance and safety principles operate the

mower.

NEVER let the children play on the mower or nearby, even when it is not working or

stored.

BEFORE starting the mower make sure that there is no people or animals in a 50 m

distance from the mower.

5

4.2. DETAILED SAFETY PRINCIPLES.

4.2.1. PREPARATION FOR WORK

CAREFULLY read the service manual. Be absolutely sure that you are acquainted with all

the safety and mower operating instructions referring the preparation for work, transport and

storage of the machine.

If you do not follow the given instructions the producer do not answer for the possible harms

or damages.

THE USER should have carefully buttoned up, not too loose clothing to avoid catching by

protruding parts or possible driving into rotating parts.

FOR DRIVING the mower use the PTO drive shaft with one-way clutch of the type given in

the manual. Protect shields of the PTO shaft against turning according to the PTO shaft

service manual.

The PTO shaft must have complete shields.

Do not use PTO shaft that is not working properly or has damaged shields.

CONTROL the condition of the mower, tighten the bolts and check the fastening of all the

moving and protecting elements before linking the mower and tractor into a working unit.

WHILE CONNECTING AND DISCONNECTING the mower to and from the tractor be

especially careful.

VERY CAREFULLY approach the mower with the tractor to set the fastening points of the

three-point suspension system and power take-off –power input shafts in a close position.

No person should be between the tractor and the mower at that time.

All the operations of connecting the tractor with the mower should be executed only after

you stop the engine, immobilize the tractor with a handbrake and take the ignition key off.

ALWAYS make sure there is no people or animals near the mower, before lifting.

DO NOT LEAVE the mower in lifted position on the tractor’s three-point suspension

system.

BEFORE YOU LEAVE the tractor ALWAYS lower the mower onto the still and flat

ground, stop the drive of PTO shaft, stop the engine, take the ignition key off.

NEVER USE the mower without protective shields and aprons. Working without shields or

with damaged shields is forbidden because of the danger of throwing stones or other hard

objects by rotating drums.

START the mower after setting all elements in working position. Starting the mower in

transport position is FORBIDDEN.

BEFORE setting the mower in transport position, ALWAYS disconnect the PTO shaft from

the tractor.

NEVER start the mower in closed rooms due to harmful exhaust gases.

6

ALWAYS use front weights, when the front axle of the tractor is too lightened.

YOU CAN APPROACH the mower only when the tractor’s engine and the mower’s drums

are totally still.

NEVER operate the mower while being under alcohol, drugs or medicines that can restrain

the ability of concentration.

4.2.2. TRANSPORTING

REMEMBER that the mower can be transported on the tractor only when set in the

transporting position.

During the transport on public roads the mower should be equipped with cautionary lighting

panels according to obligatory home traffic regulations.

4.2.3. WORKING

BEFORE YOU SETTLE the mower for work, every time stop the engine, take the ignition

key off and immobilize the tractor with a handbrake.

BE ESPECIALLY CAREFUL when recharging the mower from transport to working

position.

CONNECT THE PTO DRIVE SHAFT to the tractor and machine after setting the mower in

working position. Pay close attention to proper fastening the shaft on the splines of tractor’s

drive.

BEFORE YOU START the machine make sure there is no people or animals in a 50 m

distance. The support should be lifted.

NEVER START the mower when it is lifted.

WHEN WORKING pay attention to any alarming vibrations or changes in sounds

of working.

7

4.2.4. DISCONNECTING THE MOWER FROM THE TRACTOR FOR

THE STOP AND STORAGE.

DISCONNECT THE PTO SHAFT only after you put the mower on the ground, stop

the engine, immobilize the tractor and take the ignition key off.

BEFORE YOU DISCONNECT the mower from the tractor lower the support and block

it with a pin.

PLACE the mower for the stop and storage in the room, where other people, children or

animals do not enter.

PROTECT the mower against the reach of children.

DURING STORAGE ALWAYS put the mower on the support.

4.2.5. TECHNICAL MAINTENANCE

MAINTAIN the mower during the stop, before connecting it to the tractor. If you have to

service it when connected to the tractor, proceed as follows:

-put the mower on the ground

-stop the engine, immobilize the tractor with a handbrake, take the ignition key off and

disconnect the PTO shaft

After switching off the drive, drums of the mower rotate with inertial reaction for about

one minute and you must wait until they stop.

EVERYDAY CHECK the condition of the bolt connections and tighten the loosed parts

if necessary, before you start the work.

CONTROL THE LEVEL of possible wear or damage of parts, especially knives and knife

holders, and replace them if necessary early enough with original spare parts offered by the

producer of the mower.

8

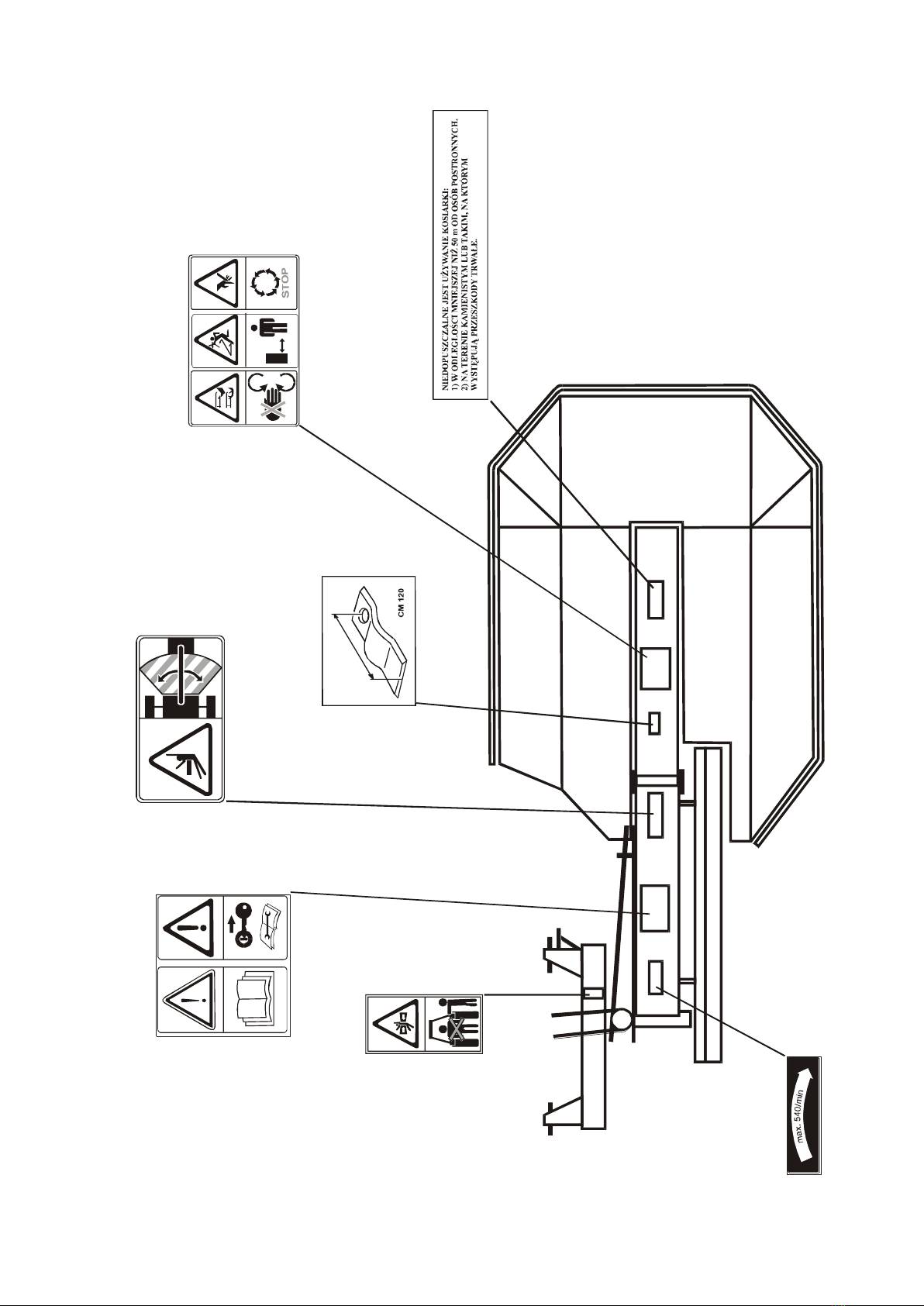

4.2.6. SAFETY SIGNS

The warning and information labels are put on the mower in places showed at Fig.1.

Warnings and information are given as pictograms that show clear instructions where to put

especial attention to work safely with the mower.

Carefully watch every label and thoroughly check the meaning in this chapter of the service

manual.

Keep the labels clear and readable while using the mower.

If any label is damaged, illegible or lost replace it with a new one.

New assembles and parts which are replaced during repairs should be marked with all necessary

labels shown in this manual.

You can purchase new labels at producer or dealer. While ordering, please advise catalogue

number of the label ( given at Fig.1.)

List of the warning and information labels placed on the mower.

GENERAL WARNINGS. During operating the mower comply with all warnings and

safety principles marked with this sign.

CAREFULLY READ the service manual before you start to work with the machine.

STOP THE TRACTOR’S ENGINE and take the ignition key off before any service or

repair.

DO NOT TOUCH moving parts of the machine until they are absolutely still.

MIND THE SPINNING KNIFE. Stay away from the spinning knives while mower is

working.

DO NOT USE THE MOWER:

1. closer than 50 m from people or animals

2. on a stony ground or ground with constant obstacles.

DO NOT STAY within the bend of the unit while tractor’s engine is working.

DO NOT STAY OR MAINTAIN THE MOWER WITHIN THE LIFTED MACHINE.

9

91,5mm

Label TR 338/A

Label TRA 5

Label KR 852

Label KR 853

Label KP 00.00.12

Label TR 1011

Label

TR 46 B

Fig.1. Placing the warning and information labels on the mower.

10

5. MOWER OPERATING.

You can use and operate the mower after reading carefully the service manual.

5.1. GENERAL CHARACTERISTICS AND DESCRIPTION

OF THE MOWER.

The Z 175-1 rotary mower cooperates with an over 23 kW tractor of II category. It is assigned

for mowing grass and low-stem green forage on even and sloped up to 12° fields and meadows.

In case of problems with the power take-off shaft please contact with a producer of this

particular PTO shaft.

The knife CMA 120 is not under warranty.

WARNING!

For proper work use appropriate type of PTO drive shaft:

Torque –460 Nm, Lmin. –560 mm, Lmax –885 mm.

Producer recommends PTO shafts of SIPMA, Poland –type 45R-502-2-BA-J501

www.lfmr.pl

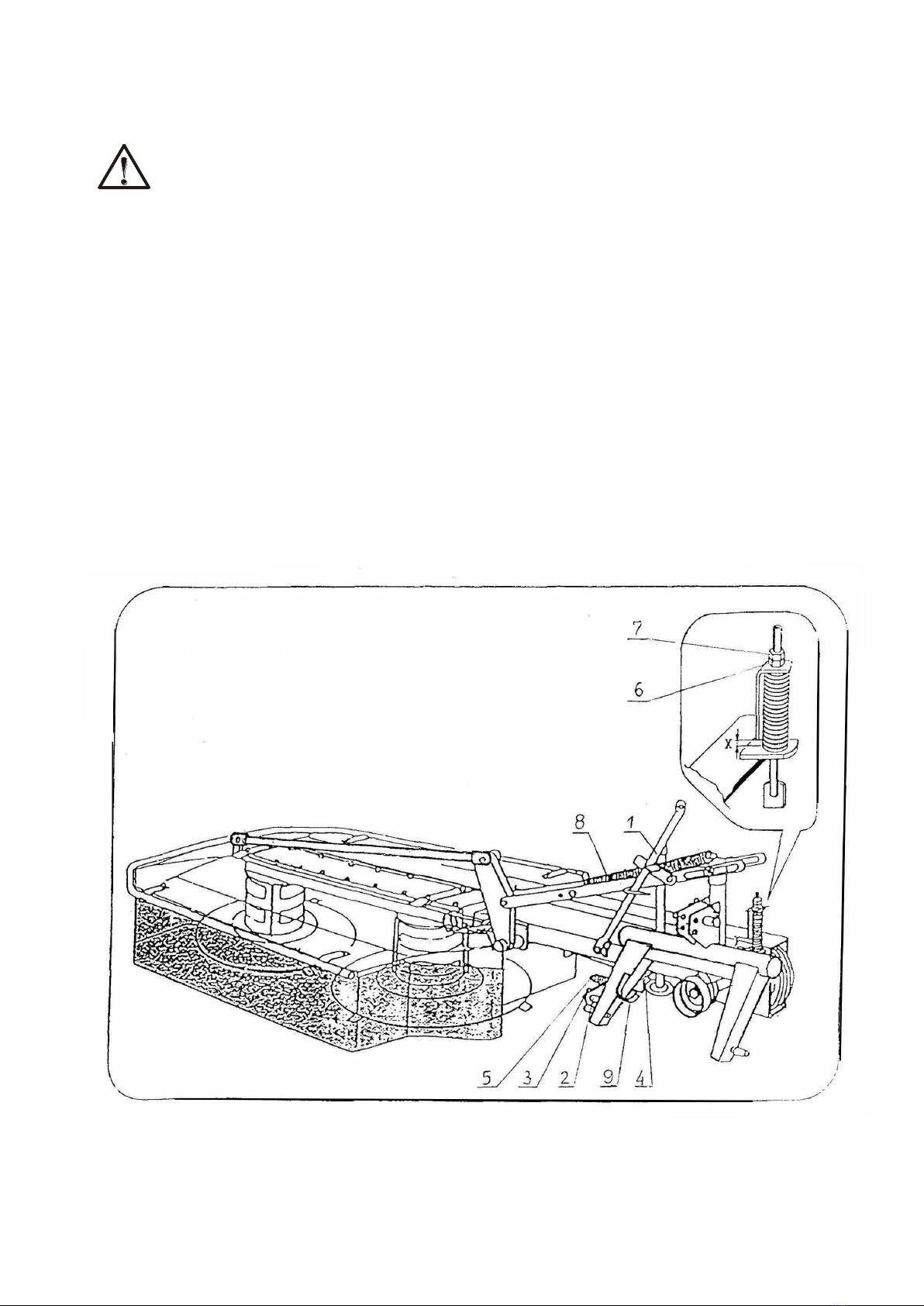

The Z 175-1 rotary mower consists of the following main assemblies (Fig.2.):

-three-point frame (1)

-indirect drive (2)

-main drive (3)

-complete housing (4)

Fig. 2. Z 175-1 suspended rotary mower.

1- three-point frame, 2 –indirect drive, 3 –main drive, 4 –complete housing,

5 –drum, 6 –lock, 7 –PTO shaft housing, 8 –spring, 9 –tightening pin.

11

The mower is supplied partly disassembled. Assemble the machine in accordance with Fig. 12.,

13. and 16. of the parts list.

The three-point frame 1. is attended for mounting the mower on tractor.

The power is transmitted to the power take-off shaft through the jointed shaft, belt transmission

(indirect drive 2.) to the main drive 3. equipped with two drums 5. Three CMA120 cutting

knives are rotationally mounted in each drum and they deviate when they hit an obstacle, e.g. a

stone, which protects them from getting damaged. The knives have two cutting edges. When one

edge wears out, the cutting tools can be installed in the other drum, which rotates in the opposite

direction, thus they preserve dual life.

Each drum has replaceable transport strips preventing grass from getting wrapped in the drum

and decreasing the friction and wearing of drums. The drums and cutting knives whirl in

opposite direction forming the mowed green fodder into a swath roller.

The tightening pin 9. and indicator enables the tightening of the V-belt assembly.

The mower is equipped with a lock 6. which, in case of hitting an obstacle, reacts causing the

machine to move backwards. If that happens you must stop immediately and withdraw a little, so

that the lock is automatically locked up again.

In order to assure operational safety the mower is outfitted with housing 4. and aprons fastened

to them.

The end of power take-off shaft is protected with a special housing 7.

Spring 8. connecting the lift with the three-point frame decreases the pressure of drums to the

base preventing the turf from being devastated and decreasing wearing-out of the drum plates.

When working on uneven ground (max. decrease of pressure to the base) and with lighter

tractors on steep slopes a spring should be fixed in the down hole (best steerability of the tractor

is then achieved).

5.2. PREPARATION FOR TRANSPORT AND TRANSPORTING

CAUTION !

When charging to the working or transport position do not get between the tractor and the

cutting unit, setting the mower in working or transport position should be done closely to

the ground! When charging the mower to transport position, first, with utmost severity,

disconnect the jointed shaft from the tractor.

Before disconnecting the mower from the tractor, place the mower on a support 4. and rest

the jointed shaft on the yoke 5. (Fig. 3.)

5.2.1. LINKING THE MOWER AND THE TRACTOR INTO A WORKING

UNIT

Set up the three-point frame in a transport position –the transport rod 1. should be placed on

mandrel 2. of the three-point frame and secured with a pin 3. (Fig. 3.).

Connect the three-point frame 1. of the mower with the three-point suspension system of the

tractor in accordance with the manual of the tractor.

Lift the support 4., set it on the high position and block with a pin.

12

Fig. 3. Linking of the mower and the tractor into a working unit.

1 –transport rod, 2 –mandrel, 3 –pin, 4 –support, 5 –yoke.

5.2.2. ASSEMBLING A PTO DRIVE SHAFT

For driving the mower use the PTO drive shaft of the type given in the manual.

CAUTION!

Always use shields of the PTO shaft and tractor’s drive shaft. Shields of PTO shaft must be

protected against turning according to the PTO shaft service manual.

5.2.3. TRANSPORTING THE MOWER MOUTED ON A TRACTOR.

CAUTION !

During the transport on public roads the mower should be equipped with cautionary

lighting panels according to obligatory home traffic regulations.

For driving to the workplace, disconnect the jointed shaft of the mower from the PTO shaft of

the tractor and rest it on the yoke 1. During transport the mower should be raised on a hydraulic

lift with the cutting tool turned backwards for safety.

Fig. 4. Mower in transport position.

1 –yoke.

13

5.3. SETTING THE MOWER IN WORK POSITION

CAUTION !

Before releasing the transport rod from the mandrel, position the mower and tractor

horizontally; if necessary, secure the mower against unintended departing.

Lower the mower to the ground, release the transport rod 1., mount the PTO shaft on the yoke

9. and lock the transport rod in the upper position.

Set up mower in the work position, fasten lock 4. on mandrel 2. and secure with pin 3.

Connect the PTO drive shaft with the tractor.

Set up the length of the upper pull rod in such a way that the drums in the work position are

parallel to the base or slightly slopped forward. In order to avoid fodder lost due to dual

cutting, never slope the machine backwards. Set up the bottom balance lever of the tractor in

such a way that the mower is positioned as shown in Fig. 6.

NOTICE:

Depending on the length of the upper pull rod of the tractor, the front as well as rear holes of the

three-point frame can be made use of.

Fig. 5. Mower in work position.

1 –transport rod, 2 –mandrel, 3 –pin, 4 –lock, 5 –securing nut, 6 –nut,

7 –doubling nut, 8 –spring, 9 –yoke.

14

Fig. 6. Correct setting of the mower.

CAUTIONS !

Start the mower only when set in working position.

Before working with the machine read the service manual carefully.

It is inadmissible to lift the mower on a hydraulic lift with power feed on and rotating

drums.

Never use the mower without shields and aprons. Operating the mower without shields

or with damaged shields is inadmissible due to danger of thrown out hard objects.

Before switching on the PTO shaft secure the jointed shaft shields against turning.

It is inadmissible to use the mower at a distance smaller than 50 m from strangers and

on stony ground or ground with constant obstacles. Handle with care especially near

roads and roadways.

In no instance should the speed of PTO shaft be increased above 540 rpm.

In case of excessive unloading of the front axle of the tractor, use front wheel weights in

order to load additionally .

When running on steep slopes the mower should be on the higher side of the slope.

Running the mower at high speeds of drums requires taking watchful attention to all

kind of unbalance causing vibration which can result in serious damage of the mower.

If increased vibration or a changed noise of operating mower is noticed, stop working

immediately. Continue the work with the machine only after you find and remove the

cause.

Conduct operations on the mower only after placing the mower on the ground, turning

off the PTO shaft, stopping the engine and immobilizing the tractor with a handbrake

or placing the wedges under the tractor’s wheels.

Do not start the engine or try to operate the mower indoors due to harmful exhaust

gases.

5.4. MOWING.

Slowly switch on the mower drive until achieving a full number of revolutions before the

mowing starts, that is 540 rpm

Match driving speed to the ground conditions and type of mowed material; avoid uneven and

stony ground.

When mowing on uneven ground or in cooperation with lighter tractors on steep slopes

suspend the spring (pos. 8. Fig.5.) to down hole.

15

5.5. PREPARATION FOR THE STOP AND DISCONNECTING THE

MOWER FROM THE TRACTOR.

To disconnect the mower from the tractor proceed as follows:

Set the mower in the transport position.

Set up the support 4 (Fig. 3.) in position for the stop.

Disconnect the PTO shaft from the tractor and put it on the yoke 5.

Disconnect the tractor’s three-point suspension system from the mower.

6. TECHNICAL MAINTENANCE

CAUTION !

Regularly control the condition of the knife-holder pins. When the pin wears out

halfway absolutely replace the knife-holders (Fig.7.).

When replacing the knives, notice should be taken to the correct mounting; they should

rotate freely on the pins.

Always fasten the knife-holders with original bolts M12x25-8.8 and nuts P M12-8-A,

tighten them with a torque 85 Nm.

Fig. 7. Minimal thickness of the knife-holder pin.

The condition of drums should be regularly checked. If the drum plates show cavities

caused by cutting tools or if they are overworn, proceed as follows:

-unscrew three bolts 7. which are screwed in at the bottom of sliding plate

(Fig. 15.)

-disassemble the sliding plate

-fasten the knife-holders 1. (Fig. 9.) in another place to let the cutting tool

adhere to an unworn surface.

Immediately replace damaged or worn drums.

16

6.1. ROUTINE TECHNICAL MAINTENANCE

Regularly check the condition of knives. Each drum should be equipped with three new or

uniformly worn CMA 120 knives. A suitable wrench is provided for replacing the knives

(Fig. 8.). Correctly settled knife should easily spin on the knife-holder pin. Fig. 8. shows how

to replace the cutting knives.

Systematically check the condition of transport strips. If they are worn to such a degree that

the drum can untimely wear out, replace strips with new ones.

During the season check the functioning of the lock every day (pos. 4. Fig. 5.). If the

mechanism functions while mowing, even though no obstacle has been struck, this means

that the force of the spring is too small and it should be tighten better with a securing nut

(pos. 5. Fig. 5.).

During the first few hours of work carefully watch the behaviour of V-belts, after 0,5 –

4 hours of work under full load –tighten belts. The ‘x’ clearance (Fig. 5) should be

approximately 1 mm. This clearance is adjusted with nuts 6. and 7. Proceeding like this

the initial stretch is considered. After next 24 hours of work check the indicator again

and tighten belts if necessary. Maximum ‘x‘ clearance cannot exceed 3 mm.

Next inspections can be done even after few hundred hours of work.

Notice: If the V-belts are stressed more than the indicator is showing, a damage to ball

bearings can be caused in result of overloading.

After a few working hours of a new or repaired machine check if all the bolts and nuts are

properly tightened, especially the bolts tightening the lift. Repeat the checking in regular

intervals.

If the gasket between the shield and main frame (for example after repairing the machine)

needs to be replaced, use only original gaskets. Stick them on exactly in place of the old one.

Bolts that connect shield with main frame should be tighten with torque 48 Nm.

Fig. 8. Method of replacing the knives.

Fig. 9. Position of knife-holders.

1 –knife-holder.

17

6.2. LUBRICATION.

During the operational use the mower should be lubricated every day (the lubricating points

are shown in Fig.10.)

The main frame filled with grease “Liten EPX 00” ORLEN OIL doesn’t require checking.

If a repair has been conducted, the amount of lubricant should be refilled! The lubricant

should level up to the bottom part of the horizontal shaft (5,5 kg).

Fig. 10. Lubricating points.

6.3. MAINTENANCE AND STORAGE

-Every time after finished work clean the machine of plant remains and dirt and check

the connection of parts and assemblies.

-When the season is over, clean the mower and carry out a technical survey. If any

defects are found, remove them. If paint has come off in some places, they should be

cleaned of rust and repainted. Cover unpainted parts with a thin layer of grease e.g.

STP, vaseline. It is recommended to store the mower indoors to secure it from moisture

and precipitation.

7. TECHNICAL DATA

-working width……………………………………… 1650 mm

-transporting width…………………………….……. 1450 mm

-transporting length……………………………….…2900 mm

-height………………………………………………. 1150 mm

-cutting height………………………………………. 40 mm

-number of drums…………………………………… 2

-number of knives …….…………………………….. 6

-PTO shaft ………………………………………….. 540 rpm

-weight………………………………………………. 380 kg

-power required …………………………………….. 24 kW

-tractor ……………………………………………… II Cat.

18

NOTES

19

PARTS LIST

When ordering parts, please advise the name and number of the part and the year

of production of the mower.

Table of contents

Popular Lawn Mower manuals by other brands

Tar River

Tar River BDR 210 Original user manual

COMPANION

COMPANION 944.362011 owner's manual

Yard force

Yard force Y0LMX22S300 Operator's manual

Columbia

Columbia 100 Series Operator's manual

Hyundai power products

Hyundai power products LM3601E Original operation instructions

MTD

MTD 520 Series Operator's manual