Messana mZone User manual

messana zone

mZone, the controller that conveys comfort and energy where and when needed

Messana mZone delivers a uniform comfort level thorough your living space.

designed in California & made in Italy

4

Programmable zone controller

mZone is a fully programmable zone controller available in two different sizes: 8 and 12 zones.

It is integrated with the Messana climate control platform developed with more then 20 years of experience in

radiant cooling and heating technology. It connects with mBox via Ethernet or, alternatively, via serial bus (RS485

slave) and it interfaces with the Messana web and mobile App.

mZone is powered with a dedicated Emerson programmable I/O module based on a high performance 32-bit ARM9

(200 MHz) microprocessor.

mZone integrates a 24Vdc switching power supply (120-230 Vac with 85W output power for mZone 8 and 120W for

mZone 12) and does not require an external transformer to drive thermal actuators. With a proprietary staggered

activation technology it can drive up to 34 thermal actuators (with mZone 12)

The mZone module connects up to twelve mSense room sensors (mZone 12) or up to eight mSense (mZone 8) in

daisy-chain via serial bus (RS485 master zone bus).

mZone modules are typically installed next to the manifolds to control the flow or the radiant fluid by activating the

thermal actuators installed on the manifold loops or the zone valves.

mZone can also control a local mixing and pumping station with a PID close control loop.

Based on the current supply fluid temperature, mZone adjusts the position of a proportional 3-way mixing valve

and modulate the fluid temperature. Compared to a traditional On/Off control, this technology allows to deliver just

enough heat (or cool, by heat extraction) to avoid temperature swings and oscillations.

With the PID control logic the radiant system always achieves optimized performance in terms of energy efficiency

and comfort maintaining an accurate and uniform indoor temperature.

mZone is designed for 2-pipe as well as for 4-pipe distribution systems for simultaneous heating and cooling

demand. Can also control heating and cooling seasonal changeover (manually or following a schedule) or

automatic changeover based on the internal load and external conditions (adaptive-comfort).

It works also with hybrid radiant/forced-air cooling and heating systems. Can activate fan-coils when supplemental

convective integration is necessary.

One of the features that distinguishes the mZone controller, compared to similar products available on the market,

is the vast range of both analog and digital input/outputs ports to connect with external devices. Most of the I/Os

are fully configurable and are opto-insulated.

As an optional, mZone can be equipped with a graphic display that allows reading of all the parameters (supply

and return temperature, flow and pressure, zone status, zone temperature and humidity) and to perform manual

installation test (pump and zone activations, force zone on or off, mixing valve setup).

5

6

Making control simple and powerful

Controlled by mBox

mZone connects to mBox (via

Ethernet or serial bus RS485).

mBox is the brain of any Messana

climate control platform. It is

based on a Linux embedded

system and it operates advanced

radiant cooling logics.

WAGO CAGE-CLAMP®

WAGO terminal blocks with

CAGE CLAMP® connection

technology.

It makes connections

to the mZone safe, quick and

easy. It requires a small screw

driver to open the clamp and the

wire (strained or solid conductor)

is inserted in the clamp.

Connect with mSense

mZone controls up to 8

(mZone8) or 12 (mZone 12)

different zones. Each zone

is monitored with the new

Messana mSense room comfort

sensor that measures operative

temperature, relative humidity,

and indoor air quality.

Graphic display (optional)

mZone can be equipped with

a graphic display to show I/O

status and allow the operator

to troubleshoot the system and

perform basic tests on thermal

actuator, pumps, mix valve,

actuators etc.

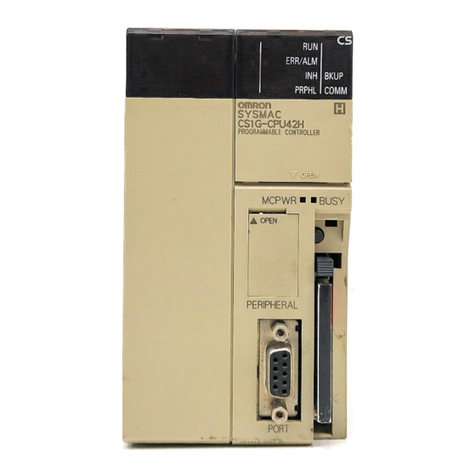

Powered by Emerson

mZone modules are powered

by a dedicated Emerson

programmable I/O controller.

Emerson is the world’s leading

provider of HVAC control

solutions for residential, and

commercial applications.

Opto-insulated I/Os

Opto-isolators provide a safe

interface to protect internal

circuits from excessive or

transient voltage spikes that

could potentially damage the

device.

PID temperature control

mZone can control one or two

mix/pump stations. With a

PID (Proportional Integrative

Derivative) control logic, it

modulates the fluid temperature

to optimize comfort and energy.

Programmable analog I/Os

Programmable I/Os allow to

integrate with different types

of hvac devices. Analog inputs

are configurable as NTC, PTC,

0-20mA, 4-20mA, 0-10V, 0-5V,

0-1V, or DI. Analog outputs can

be set as 0-10V or 4-20mA.

PID

Staggered activation

Messana has developed an

optimization algorithm that

stagger the opening of thermal

actuators to minimize the

maximum current rush. This

technology allows to increase

the number thermal actuators

(up to 34 with mZone 12).

BOX

110/220Vac

50/60Hz

7

PID

Control Logic Rooms Temperature

S

R

Radiant

Panel

Heat

0-10V

T

8

mZone can dynamically modulate the fluid supply temperature when is combined with an hydronic mixing and

pumping station.

The mixing station features a high efficiency recirculating pumps, a motorized 3-way proportional mixing valve

(0-10V or 2-10V) and two temperature probes installed on the supply (S) and return pipes (R). This configuration

allows to a PID (Proportional Integrative Derivative) control loop with temperature feedback mechanism.

PID Control Logic Schematic

Messana PID temperature control logic

Time

Temp

Set-point 72

OFF ON OFF ON OFF ON OFF ON OFF ON

ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF

Legend

PID

ON / OFF Control

OFF ON

71

73

9

The Messana PID control logic evaluates the supply temperature (target ) based on how far is each zone from the

desired set-point (proportional), how long is in that status (integrative) and how quick the radiant terminals reacts

to the fluid temperature change (derivative). This technology allows to deliver just enough heat (or cool, by heat

extraction) to always meet the actual internal loads and maintain the correct room operative temperature within a

0.5F differential.

With the PID control logic the radiant system achieves optimized performance in terms of energy efficiency and

comfort maintaining always an accurate and uniform indoor temperature.

The PID control logic regulates the supply water temperature, and ultimately the room temperature, based on the

three different actions:

Actions Based on

Proportional The actual value of the room temperature

Integral The past values of the room temperature

Derivative The expected variation of the room temperature

Power pick optimization note 1

Time

Power pick is reduced by 40%

Power

7.2W x N/2

6W x N

1W x N/2

Start 2 minutes

Legend

Staggered activation with two groups of actuators each

Normal activation

NIs the total number of thermal actuators

6W x N/2

Power pick (6W x N)

2W x N/2

10

The Messana thermal actuators are based on a PTC resistor-heated elastic element and a return compression

spring. When the elastic element is heated by applying the 24V voltage to the PTC resistor, it expands and moves an

integrated plunger to open the valve. When the PTC resistor stop being energized, the elastic element shrinks and

the return compression spring moves the plunge back and close the valve.

During the activation of the actuator there is an initial phase of about 2 minutes where more heat is necessary to

expand the elastic element. During this initial phase the current spikes up to 6 times the nominal current needed to

hold the actuator activated. This initial high load (6 Watts per actuator) limits the number of thermal actuators that

can be activated simultaneously based on the total available power supply. Once the actuator is open, the elastic

element needs to be maintained hot and this requires only 1 Watt per actuator (nominal power).

When sizing the power supply of zoning module, in order to satisfy the initial rush current needed to open

simultaneously all the actuators, it requires 6W x N (total number of actuators). With the intent of optimizing

the maximum number of actuators that can be driven by one mZone module, Messana has developed a new

technology that staggers the activation of actuators and avoid the initial load pick. It is a group delay mechanism

that prevents to turn on multiple actuators at the same time to prevent power surge. The actuators attached to the

mZone are divided in two groups of N/2 actuators each.

The staggered activation logic activates the first group of actuators (group #1) and wait until they complete the

initial opening phase (about 2 minutes). Once the first group of actuators is partially open, and the power has

dropped close to its nominal value (1W x N/2), the logic starts the activation of the second group of actuators

(group #2).

With an overall delay of 2 minutes, the staggered activation logic can operate two distinct groups of actuators and

reduce the power pick by about 40%. This allows to increase the total number of thermal actuators by 66%

This is particularly useful when controlling radiant floors where typically there are several loops attached to the

same zone.

Staggered activation of the thermal actuators

Notes 1. Staggered activation with 2 groups of thermal actuators. Group #1 is activated fist and Group # 2 is activated with 2 minutes of

delay to minimize the power pick. It turns out that the power pick is reduced by 40%. This allows the mZone controller to drive up

to 66% more thermal actuators.

Group #2 (N/2 thermal actuators)

2 minutes 2 minutes

Warm-upClosed Partially open

Group #1 (N/2 thermal actuators)

2 minutes

Partially openWarm-up

Start

Fully open

11

Model Simultaneous opening

Staggered activation logic with 2 groups

mZone 8

Up to 10 Up to 18

mZone 12

Up to 17 Up to 31

Each digital output (DO) can drive up to 3 thermal actuators

.

12

mZone takes control of hydronic radiant cooling and heating systems

13

14

Below, in a nutshell, are the best 12 reasons to consider mZone for your next radiant cooling project.

1. Messana / Emerson programmable I/O module.

We have based our technology on the new Emerson I/O module custom made and programmed on our

specification.

2. WAGO Terminal Block with CAGE CLAMP® connection technology.

3. Disconnect fuse holder with spare fuse to offer circuit protection. Finger-safe design offers personnel

protection. No fuse pullers or tools required for fuse removal

4. Integrated switching power supply 24Vdc 120W with short circuit, overload and temperature protection.

5. Ethernet adapter to connect to mBox (also used for programing and remote access).

6. Water and dust protected heavy metal enclosure IP65 with powder coating paint.

7. 9/16” (15mm) and 3/4” (19mm) openings for cable pass through with rubber grommets.

8. Additional programmable I/Os with easy accessible plug connectors.

In addition to the most common I/Os pre-wired on the WAGO terminal blocks, there is a set of additional

programmable I/Os that are accessible directly on the Emerson/Messana I/O module.

9. 3/8” cable connector to attach and secure the power cable and provide a strain-relief (supplied separately).

10. Secondary protection fuse to protect the Emerson/Messana I/O module.

11. USB port for service.

12. Adjustable brackets.

3.5” depth allows to enclosure the box in a regular 2x4” wall construction.

12 Reasons to choose mZone

Regardless of the type of conductor, the CAGE CLAMP® has to be opened by pressing it down with a screwdriver. After the

conductor has been inserted into the clamping unit and the spring has been released, the conductor is clamped safely in the

defined contact zone. The predefined clamping force automatically adjusts to the conductor cross section. In contrast to

screw clamp systems, this spring clamp system rules out the possibility that a conductor is inserted into the clamping unit

but not secured.

DO 1 DO 2 DO 3 DO 4 DO 5 DO 6 DO 7 DO 8 DO 9 DO 10 DO 11 DO 12 24V

ZONE BUSZONE THERMAL ACTUATORS (24 VDC) AO MIX AI (NTC) AO DI

0V D+ D- SHD 24V 0V Y SUPPLY RETURN AUX AUX

DO 13 DO 14 DO 15 (PWR)

7

5

12

6

7

4

39

1

2

11

10

8

15

DO 1 DO 2 DO 3 DO 4 DO 5 DO 6 DO 7 DO 8 DO 9 DO 10 DO 11 DO 12

ZONE BUSZONE THERMAL ACTUATORS (24 VDC)

24V

AO MIX AI (NTC) AO DI

0V D+ D- SHD 24V 0V Y SUPPLY RETURN AUX AUX

DO 13 DO 14 DO 15 (PWR)

DO 1 DO 2 DO 3 DO 4 DO 5 DO 10 DO 11 DO 12

ZONE THERMAL ACTUATORS (24 VDC)

ZONE THERMAL ACTUATORS (24VDC POWERED)

24Vdc powered DOs (Digital Outputs) for two-wire zone valves (24Vdc 5 Amps max).

mZone 8: Can control up to 8 Zones (7 zones if the DO8 is used to control) and up to 10

(18) thermal actuators.

mZone 12: Can control up to 12 zones and drive up to 17 (34) thermal actuators. Up to

three thermal actuators can be connected to one digital output.

Messana thermal actuators come with 1.5mt (5ft) of wire.

To extend use two conductor 18 AWG twisted cable, up to 500 feet (150 m).

DOs can also be programmed to control other 24Vdc devices.

24V

ZONE BUS

0V D+ D- SHD

ZONE BUS

RS485 Master bus (Modbus RTU) for mSense temperature/humidity/IAQ sensors.

0V - 24Vdc provides a stable power supply for the zone sensor bus

D+ (positive) D- (negative) are the RS485 signal lines.

SHL is for the cable shield (do not connect to GND).

AO MIX

24V 0V Y

AO MIX

Analog Output (AO) for 3-way motorized mixing/diverting valve

0V - 24Vdc stable power supply (3W max load)

Y is a 0-10Vdc (or 2-10Vdc) to progressively control the valve (40mA max load)

AI (NTC)

SUPPLY RETURN

AI (NTC) SUPPLY AND RETURN

Analog Input for manifold supply and return temperatures.

Use only NTC thermistors 10k@25ºC Beta 3435.

We recommend using Messana pipe mounted strap-on or well mounted temperature probes.

16

I/O’s description

DO 1 DO 2 DO 3 DO 4 DO 5 DO 6 DO 7 DO 8 DO 9 DO 10 DO 11 DO 12

ZONE BUSZONE THERMAL ACTUATORS (24 VDC)

24V

AO MIX AI (NTC) AO DI

0V D+ D- SHD 24V 0V Y SUPPLY RETURN AUX AUX

DO 13 DO 14 DO 15 (PWR)

Extract the fuse holder to disconnect the

mZone from the power line or to replace the

fuse. Additional fuse is placed in the pivoting

extraction door. Fuses are safety pulled out

with fingers. No tools are required.

DISCONNECT FUSE HOLDER WITH SPARE FUSE

Fuse holder offer fuse circuit protection and cylindrical fuse model 8.5x31.5 - 2A

(Fuse Size Imperial: 0.33” x 1.24”).

DRY CONTACT RELAY DIGITAL OUTPUT (SOCKET)

Available on mZone12 only.

It requires 24Vdc Finder 44.52.9.024 miniature industrial relays (not included).

AO DI

AUX AUX

AO (AUX) AND DI (AUX)

Auxiliary Analog Output and Digital Input

Analog Output can be used for any 0-10 or 4-20mA device such as fan coils, servo motors, actuators

and proportional zone valves.

Digital Input can be used for door/window or presence sensors, season changeover switch, alarms

and any on/off communication.

Additional programmable AO and DI are available on the Emerson/Messana I/O device.

17

18

LCD Display

LCD Graphic display with membrane keyboard (optional).

It allows to program the device and to read the status of the device. The mechanical contractor can override

outputs, useful for startup and troubleshooting.

19

20

mZone 8 mZone 12

Inputs note 5 Analog Inputs (AI) note 1

Temperature probes, pressure sensors, flow meters, feedback

Resolution 10-bit A/D converter

NTC 10kΩ@25°C Beta 3435 (for supply and return temp) 2 (S/R) 2 (S/R)

Auxiliary programmable AI 1 (AI AUX) 1 (AI AUX)

Additional programmable AI note 5 3 7

Digital Inputs (DI) note 2

Presence or window sensors, season changeover, alarms, On/Off

Additional programmable DI note 5 11 20

Outputs note 5 Digital Outputs (DO) note 3

Thermal actuators, zone valves, pumps, actuators, air units

24Vdc 5Amp powered (for thermal actuators) 8 (DO1-DO8) 12 (DO1-DO12)

Number of thermal actuators (staggered activation) note 6 up to 10 (18) up to 17 (34)

Auxiliary DO dry contact on relay socket note 7 - 2 (DO13-DO14)

Circulator pump (110/220Vac 50-60Hz) on relay socket note 8 1 (DO8) note 9 1 (DO15relay socket)

Analog Outputs (AO) note 4

Mixing valves, servo motors, actuators, fan-coils

Resolution/Accuracy 8 bit converter (2%)

0-10Vdc with 24V power supply for mix-valve 1 (AO MIX 24V/0V/Y) 1 (AO MIX 24V/0V/Y)

Auxiliary programmable AO – 1 (AO AUX)

Additional programmable AO note 5 3 4

Zone Bus RS485 master with shield and 24Vdc power supply up to 8 mSense up to 12 mSense

(Zone Bus 24Vdc/0V/SHL/D+/D -)

Communication With Messana mBox module Ethernet (Modbus TCP)

RS485 slave (Modbus RTU) note 10

Initial setup and programing via Ethernet through a PC

Power Supply 230/110 Vac - 50-60 Hz (15Amps outlet) 85 W 120 W

Technical specifications

This manual suits for next models

2

Table of contents

Other Messana Controllers manuals