IGEA LB-BT- Ver. 01

- 11

D811384_01

INSTALLATION MANUAL ENGLISH

Thank you for buying this product. Our company is sure that you will be

more than satisfied with the product’s performance.

Carefully read the “WARNINGS” pamphlet and the “INSTRUCTION

BOOKLET” which are supplied together with this product, since they

provide important information regarding the safety, installation, use and

maintenanceof the product. This product complies with recognised technical

standards and safety regulations. We declare that this product is in

conformity with the following European Directives: 73/23/ EEC, 89/336/

EEC, 98/37/EEC and subsequent amendments.

1) GENERAL SAFETY

WARNING! An incorrect installation or improper use of the product

can cause damage to persons, animals or things.

• The “Warnings” leaflet and “Instruction booklet” supplied with this

product should be read carefully as they provide important information

about safety, installation, use and maintenance.

• Scrap packing materials (plastic, cardboard, polystyrene etc) according

to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children’s reach.

• Keep the instructions together with the technical brochure for future

reference. This product was exclusively designed and manufactured for

the use specified in the present documentation. Any other use not

specified in this documentation could damage the product and be

dangerous.

• The Company declines all responsibility for any consequences resulting

from improper use of the product, or use which is different from that

expected and specified in the present documentation.

• Do not install the product in explosive atmosphere.

• The construction components of this product must comply with the

following European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC

and subsequent amendments. As for all non-EEC countries, the above-

mentioned standards as well as the current national standards should

be respected in order to achieve a good safety level.

• The Company declines all responsibility for any consequences resulting

from failure to observe Good Technical Practice when constructing

closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

• The installation must comply with the provisions set out by the following

European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC and

subsequent amendments.

• Disconnect the electrical power supply before carrying out any work on

the installation. Also disconnect any buffer batteries, if fitted.

• Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3mm.

• Check that a differential switch with a 0.03A threshold is fitted just before

the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with an

earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are

needed to protect the area from any danger caused by squashing,

conveying and shearing, according to and in compliance with the

applicable directives and technical standards.

• Position at least one luminous signal indication device (blinker) where

it can be easily seen, and fix a Warning sign to the structure.

• The Company declines all responsibility with respect to the automation

safety and correct operation when other manufacturers’ components

are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised

by the company.

• Instruct the product user about the control systems provided and the

manual opening operation in case of emergency.

• Donotallowpersonsorchildrentoremainintheautomationoperationarea.

• Keep radio control or other control devices out of children’s reach, in

order to avoid unintentional automation activation.

• The user must avoid any attempt to carry out work or repair on the

automation system, and always request the assistance of qualified

personnel.

• Anything which is not expressly provided for in the present instructions,

is not allowed.

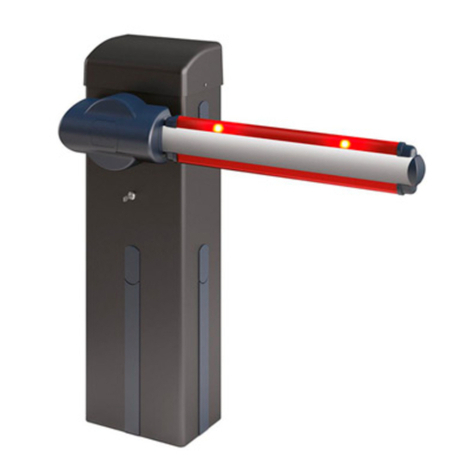

2) GENERAL OUTLINE

The IGEA LB-BT operator is suitable for motorising folding doors with a

maximum of two panels for each controller (fig.1). Two controllers are

needed for two pairs of panels. The non-reversible electro-mechanical

gearmotor maintains the stop during closing and opening.

WARNING! The installation, the maintenance and the repair should be

done by responsible and qualified persons with an updated knowledge of

the current safety standards. It’s strictly forbidden to service the automation

when the power is on.

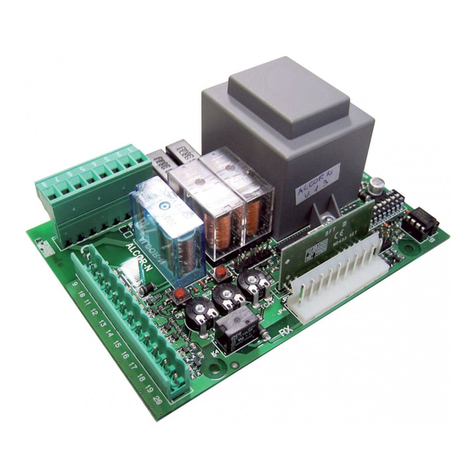

ATTENTION! The IGEA LB-BT model controller is not equipped with

mechanical torque adjustment. It is compulsory to use a control panel of the

same manufacturer, in compliance with the basic safety requirements of

directives 73/23/CEE, 89/336/CEE, 89/37/CEE equipped with appropriate

electric adjusment of the torque.

3) TECHNICAL SPECIFICATIONS

Motor: .............................................................................. 24V 1500 min-1

Power: ..................................................................................................40W

Insulation class: ........................................................................................ F

Lubrication: ................................................................... Permanent grease

Reduction radio: ............................................................................... 1: 812

Output shaft revolutions: ......................................................1.8 min-1 MAX

90°opening time: ................................................................................. 15s

Torque supplied: ............................................................................ 300 Nm

Weight and max leaf length: ........... 2000N (~200kg) for 2.5m leaf length

2500N (~250kg) for 2m leaf length

Impact reaction: ............ Integrated torque limiter on LIBRA control panel

Motion drive: ...............................................................................Lever arm

Stop:.................................................... Incorporated electric limit switches

Manual manoeuvre: ......................... Release knob with personalised key

Number of manoeuvres in 24h: ............................................................ 100

Environmental conditions: ..................................................... -15 to +60°C

Degree of protection: ......................................................................... IP 4X

Operator weight: ................................................................... 160N (~16kg)

Dimensions: ................................................................................ See fig. 1

4) INSTALLATION OF AUTOMATION

Preliminary checks. Check that the leaves move manually for the whole of

their stroke. If a new gate is not being installed, check whether its

components are worn. Repair or replace any worn or damaged parts.

Automation reliability and safety are directly influenced by the condition of

the gate’s structure.

5) POSITIONING

The expected standard position for fixing the IGEA LB-BT controller is

illustrated in fig.1. The controller has to be fixed to the upper part of the

panel hinged to the wall. However, if the overall dimensions do not allow this,

it can be positioned on the panel which is not hinged to the wall (fig.4).

The direction of fitting can be changed by rotating the actuator as shown in

fig. 2 and using the required shaft output.

6) SUPPORT PLATE FIXING (fig.5)

The controller is supplied with a fixing bracket and telescopic arm. Having

identified the panel reinforcing point, weld or fix the anchoring bracket with

screws, respecting the dimensions in fig.5. Fix the gearmotor to the plate

with the 4 screws, in a right or left-handed position (fig.2).

7) TELESCOPIC ARM FIXING

With the door in the opening position (fig.6):

- insert the arm plate through the gearmotor output shaft and lock it using

the grub screw provided.

- Release the controller by operating the release lever in order to allow the

arm to move easily (see paragraph “EMERGENCY MANOEUVRE”).

- Fit the “S” bracket to the “BG” guide arm by means of the “P” pin

and splitpin.

- Insert the “BG” guide arm through the “BM” motor arm, respecting the

measurement in fig.6.

- Bring the “S” pivot bracket of the telescopic arm to its fixing position,

create an anchoring shim for the “S” bracket so that the telescopic arm

becomes level (fig.6).

- The “BM” motor arm must protrude from the “BG” guide arm by the value

shown in fig.6.

- In case of narrow panels, the telescopic arm may need to be shortened.

- Check the door movement by hand.

- With the door closed, check that the “BM” motor arm is inserted far

enough into the “BG” guide arm (at least 70mm).

- Repeat the same operations to install the other controller.

8) ELECTRICAL INSTALLATION SETUP

Lay out the electrical installation with reference to the CEI 64-8 and IEC364

provisions complying with the HD384 and other national standards in force

for electrical installation. Fit a type-approved omnipolar circuit breaker with

at least 3mm contact opening, provided with protection against overloads

and short circuits, suitable for cutting out automation from the mains, either

entirely or by zones. Place, if not al ready installed, a type-approved