2

Section 1: Introduction

Hazard Definitions

The following terms are used throughout this manual to bring

attention to the presence of potential hazards or to important

information concerning the product.

Indicates an imminently hazardous situation which,

if not avoided, WILL result in death, serious injury or

substantial property damage.

Indicates an imminently hazardous situation which,

if not avoided, COULD result in death, serious injury

or substantial property damage.

Indicates an imminently hazardous situation which,

if not avoided, MAY result in minor injury or property

damage.

Used to notify of special instructions on installation,

operation or maintenance which are important to

equipment, but not related to personal injury hazards.

To reduce the risk of excessive pressures and temperatures in

this water heater, install temperature and pressure protective

equipment required by local codes and no less than a

combination temperature and pressure relief valve certified by a

nationally recognized testing laboratory that maintains periodic

inspection of production of listed equipment or materials, as

meeting the requirements for Relief Valves and Automatic Gas

Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22.

This valve must be marked with a maximum set pressure not

to exceed the marked maximum working pressure of the water

heater. Install the valve into an opening provided and marked for

this purpose in the water heater, and orient it or provide tubing

so that any discharge from the valve exits only within 6 inches

above, or at any distance below, the structural oor, and does

not contact any live electrical part.

The discharge opening must not be blocked or reduced in size

under any circumstances. Hydrogen gas is produced in a hot

water system served by this heater that has not been used for a

long period of time (2 weeks or more). Hydrogen gas is extremely

ammable. When hydrogen is present, there will probably be

an unusual sound such as air escaping through the pipe as the

water begins to ow.

There should be no smoking or open ame near the faucet at

the time it is open. When a water heater is installed in a closed

water-supply system, such as one having a back-ow preventer

in the cold-water supply, means shall be provided to control

thermal expansion. Contact the water supplier or local plumbing

inspector for information regarding the control of this situation.

Model BT26-H, BT40-H & BT80-H

Overview

The Model BT-Series are water tanks suitable for storage of

water and water/glycol mixtures for use in all hydronic systems

for heating, cooling, or a combination of both heating and cooling.

The wide operating range of 32-194°F (0-90°C) allows its use with

chiller/heat-pump, geothermal, fossil fuel or solar systems, or any

combination thereof. The tanks are designed for space conditioning

only. They are not approved for potable or domestic water.

The tank's volume provides thermal storage to retain energy

during period of off cycle or defrosting, and buffering, to extend

boiler or heat pump cycle times, increasing overall system

efficiency and allowing tighter control of supply temperature.

Additionally, each tank is equipped with four circulation ports;

when piped in a primary/secondary arrangement, this ensures

hydraulic separation of the system.

When energized, the two heaters provide 6 kW, or approximately

20,500 BTU/hr of heat to the contents of the buffer tank.

This can be used to achieve three distinct purposes, as controlled

by the Solstice Heat Pump, and configurable through the Carel

μC2 control interface.

1. Standby Freeze Protection. When the chiller is in Standby

(inactive)and the water within the chiller drops below a

predetermined temperature, defined by Parameter A04, the

chiller will engage the circulator immediately, and energize the

electric heaters after an adjustable time delay (0-10 minutes,

adjustable via timer relay, KT, inside the heat pump). The pump

and heaters will continue to operate until the temperature

reaches A04 + A05. The default settings are, A04=36, A05=5

degrees F.

2. Heat Pump Heat Boost. If the water temperature in the circuit

starts below, or falls below, a predetermined temperature,

defined by parameter A08 the chiller will engage the electric

heaters after the adjustable KT time delay. The heaters will

continue to operate until the temperature reaches A08 + A09.

The default settings are, A08=90, A09=5 degrees F.

3. Defrost Operation. If parameter d11 =1 the chiller will engage

the heater during defrost operation after the adjustable KT

time delay,, in order to provide a an additional heat source

to offset heat lost from the system. Setting the parameter to

d11=0 disables this feature. For use with SCM-036, SCM-

060 and LAHP48 heat pumps only.

As with any hydronic heating system, it is HIGHLY recommended

that an oxygen barrier tubing is used throughout the system.

Buffer tanks are to be used in hydronic heating and/or

cooling systems only. All local plumbing codes must

be adhered to. Do not operate beyond specifications

on the rating plate. Failure to comply can result in

property damage, personal injury, or death.

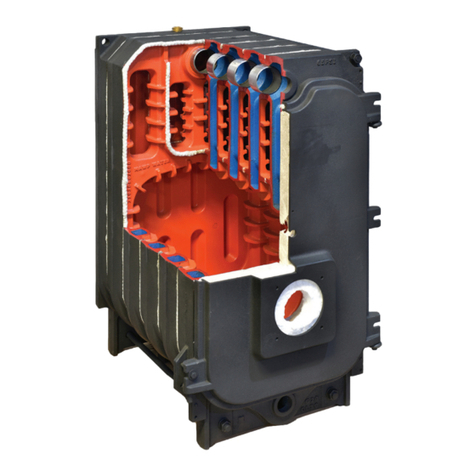

The major components of the BT Series are:

• The BT26-H and BT40-H contain a welded, 18-gauge (.047")

grade 304 stainless steel inner tank with ports for circulation,

air separation & pressure relief, and drain. BT80-H contains a

16-gauge (.059") SSC innner tank.

• 50mm (2") expanded polyurethane insulation for R11 insulating

value.

• Outer shell of .020” powder coated carbon steel.

• ¼" ID temperature sensor well, isolated from the tank interior.

• ½" NPT aquastat well, open to the tank interior.

• Two each 3 kW resistive electric heating elements.

• Electrical junction box for connecting electrical power and

safety circuit wiring for the electric heaters.

DO NOT use for potable water heating. The storage tank and

components are not suitable for the application.

Additional Components Required

• Air Separator and Pressure/Temperature relief valve, to be

located directly in the top of the tank.

• Expansion tank sized for the entire system volume, including

the BT tank, and intended operation mode; heating, cooling, or

combination.