Metal Fab Model M User manual

INSTALLATION AND MAINTENANCE

INSTRUCTIONS FOR LARGE DIAMETER

MODEL M GAS VENTS (B-VENT)

GENERAL:

The Model M Gas Vent has been designed for use with gas

burning Category 1 appliances. A Category 1 appliance

operates with a non-positive vent static pressure and with vent

temperature that avoids excessive condensate production in

the vent.

The vent is interconnected with a slip t and maintained with

sheet metal screws. The vent is of a double-wall construction,

with the inner ue of aluminum alloy (allowing rapid warm-up

and better draft) and the outer casing of galvanized steel or

galvalume steel.

SAFETY:

CAUTION: UL approval is based on using B-Vent

components supplied by Metal-Fab, Inc. Performance may

be affected and a safety hazard created if parts shown in

these instructions are not used.

1. This gas vent must maintain one-inch (25.4mm) clearance

to combustibles for sizes 16-inch (406mm) through 24-

inch (610mm). Two-inch (50.8mm) clearance to

combustibles is required for sizes 26-inch (660mm)

through 30-inch (760mm). DO NOT pack insulation or

other materials around the vent.

2. Use of draft increasers are limited to the exhaust end of

the vent system to maintain negative ue pressure.

3. Vent sizing is dened by tables in NFPA54 (ANSI Z223.1,

2002), or contact your Metal-Fab supplier. Install in

accordance with these instructions and local code

requirements.

4. Metal-Fab Type B Gas Vent and Fittings are to be used to

vent approved gas appliances intended to burn only gas.

Type B Vents are NOT to be used for the following:

A. Unlisted gas appliances

B. Incinerators

C. Recessed heaters

D. Conversion burners

E. Gas/oil burners

F. Any other appliance which may be readily converted

to a solid or liquid fuel.

G. Any other appliance not intended to burn only gas.

In areas where solid or liquid fuels are common, the

vent location should be marked “For use with vented

appliances burning only gas.”

5. Locate vent as close as possible to the appliances to

obtain maximum draft and to minimize connector pipe

length.

6. Maintain a pitch or rise from appliance to vent on

horizontal runs. Minimum rise is ¼” (6.4mm) to the foot.

7. A vent cap should be used on all installations to prevent

back drafts and to keep out rain and debris.

8. Venting into an unlined masonry chimney may cause

condensation. Install Type B Vent inside the chimney to

prevent condensation.

9. Do not install vent outside except where it is absolutely

necessary, and consult venting tables for proper design.

10. A gas vent support plate (MSP or MHS) is required if

vertical height exceeds 30’ (9144mm). Maximum of 30’

(9144mm) between supports.

11. When running vent through insulated areas, care must be

taken to prevent insulation from coming in contact with

the vent. This may be done by nailing headers between

joists through which vent is run, maintaining proper clearance

to combustibles or by nailing a restop on top of joists to

prevent insulation from falling into boxed area.

12. Other than in single or two family dwellings, when gas

vent extends through ceilings above the room with

appliance(s), the vent is to be enclosed with materials

having a re rating equal to or greater than oor, ceiling,

or roof.

13. It is not acceptable to penetrate the ue with screws

except when attaching drafthood to appliance outlet or

vent to single-wall connector.

INSTALLATION:

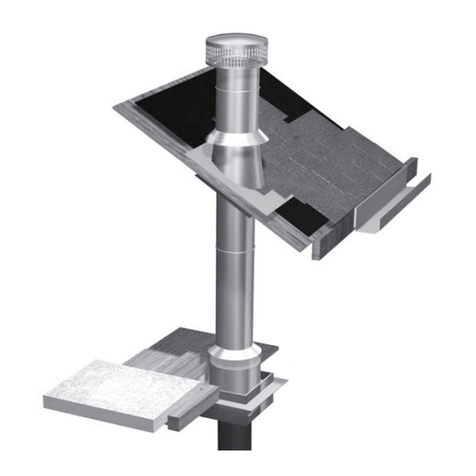

The Type B Gas Vent sections and associated components are

inserted one into another, then secured by sheet metal screws

(#8 x ½(13mm)) provided with each section (See FIG. 1).

1. Starting at the appliance outlet or top of drafthood, attach

the rst section or component. Secure with screws

provided.

NOTE: Some appliances have the draft hood built into the

appliance. For these, the gas vent attaches directly to the

appliance outlet (See FIG. 2). If needed, a draft hood connector

(MDC) is attached to the appliance outlet.

2. Continue upward with the gas vent. If a oor is to be

penetrated, an MSP support plate or restop is required.

A eld fabricated restop is acceptable. To eld fabricate

a restop, use a 26-gauge galvanized steel plate. Cut a

hole slightly larger than the gas vent O.D. Position the

restop to maintain correct clearance to combustibles, then

nail in place.

NOTE: A MSP is required for every 30 feet (9144mm) of vent

stack to support the load.

3. When penetrating the roof, cut hole to maintain clearance

to combustibles. The MF ashing and MSC storm collar

are used to cover the hole in the roof. Terminate the vent

using the MC cap. If vent is more than 6 feet above where

it penetrates the roof, additional support is required.

(See FIG. 4.)

NOTE: For Canadian installations, use cUL section, designated

with a sufx G, on vent sections exposed to atmosphere.

These symbols on the nameplate

means this product is listed by

Underwriters Laboratories Inc.

Listing No. MH7860

SIZES 16” (406MM) THROUGH 30” (760MM)

2

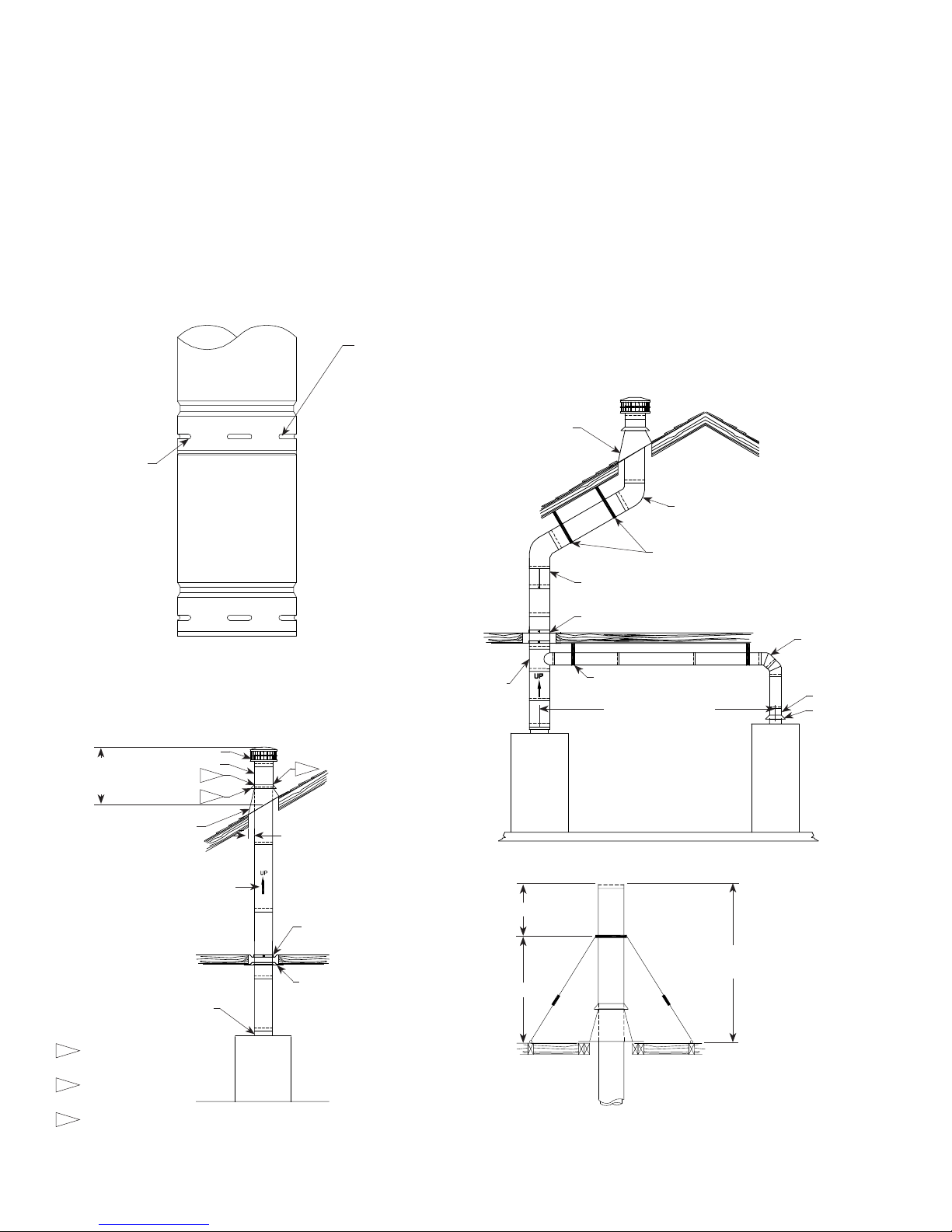

4. If the installation requires offsets, elbows are available. The

inclined run (distance between elbows) must be

supported every 5 feet (1542mm). Plumbers straps are

acceptable. Total lateral and horizontal length shall not

exceed 75 percent of total vertical height (See FIG. 3).

5. It is acceptable to use a tee (MT) to multi-vent appliances

into a common vent (See FIG. 3). A support plate (MSP),

or other method, is required to support the gas vent

weight above the tee. The horizontal run of the vent must

be supported every 5 feet (1524mm). If no vent enters the

bottom of the tee, a tee cap (MTC) is required to close the

tee.

FIG. 4

6. Because the available lengths of vents may not meet your

installation needs, an adjustable vent section (M18A)

may be needed. The male end of the adjustable section

engages in the same manner as the vent section, the female

end opens to accept the male end of the vent section, then

must be secured by tightening the clamp of the adjustable

section (See FIG. 3).

7. If the vent system must increase in size due to vent

capacity, use an appropriate increaser (MI). The increaser

is installed the same as any vent section.

This completes your installation. If assistance is required,

contact your Metal-Fab supplier.

MAINTENANCE:

Gas Vent System normally operates trouble free. Conduct a

yearly inspection of the system, and replace any damaged

parts.

NOTE: If extreme weather conditions occur, inspection of all

exposed vent items is necessary. Replace any damaged part.

©2003 Metal-Fab, Inc. Form No. L1258 - 07/18

9817

FIG. 1

NOTE: SEAT MALE END INTO

FEMALE END AND SECURE WITH

SHEET METAL SCREWS PROVIDED.

TYPICAL FOR ALL JOINTS.

CAUTION: IF OTHER SCREWS ARE

USED, MAKE SURE THEY DO NOT

PENETRATE FLUE.

#8X1/2" SCREW

USE PREPUNCHED

SLOTS AS TEMPLATE

TO DRILL HOLES FOR

SCREWS.

FIG. 2

1.

2. 3.

STYLE M VENT

MC CAP

FLASHING

2.0FT. (635MM) MIN.

MIN. OF 2.0FT. (635MM) ABOVE

ROOF OR PARTION OF BUILDING

WITHIN 10FT.

MAINTAIN CLEARANCE TO

COMBUSTIBLE THROUGH JOIST AREA.

ARROW ALWAYS AWAY FROM

APPLIANCE. FOR EACH SECTION.

MSP - REQUIRED FOR EVERY

30FT. OF VENT HEIGHT.

FIRESTOP - 26ga GAL. STL. LOCATE

OVER JOIST TO MAINTAIN CORRECT

CLEARANCE FROM VENT CASING

TO COMBUSTIBLE MATERIAL

[1"(25MM) FOR 16" THRU 24" DIA;

2"(51MM) FOR 26"DIA AND UP.]

MDC (IF REQUIRED)

SEE APPLIANCE

INSTRUCTIONS

1. APPLY CAULKING OR METAL-FAB

MST TAPE WHERE VENT PASSES

THROUGH FLASHING.

APPLY THICK RING OF CAULK-

ING OR METAL-FAB MST TAPE

AROUND VENT AS SHOWN.

SLIDE STORM COLLAR DOWN

INTO CAULKING OR TAPE RING.

2.

3.

FIG. 3

SUPPORT EVERY

5FT(1524MM)

OF LATERAL RUN

M12A OR M18A (USED TO ADJUST FOR VARYING LENGTHS)

MSP [REQ'D ABOVE TEE AND EVERY 30FT. (9144MM)]

SEE FIGURE 2

FOR TERMINATION

M45 QTY. 2

MDC

DRAFT HOOD

M45

KEEP HORIZONTAL LENGTH

SHORT AS POSSIBLE

FOR GOOD DRAFT

SUPPORT EVERY

5FT(1524MM)

OF LATERAL RUN

NOTE: TOTAL OF HORIZONTAL LENGTH

AND INCLINED LENGTH CANNOT

EXCEED 75% OF VERTICAL LENGTH

MT

(MTC IF NO

BOTTOM ENTRY)

2/3

2/3

IF OUTLET EXCEEDS 6FT.

ABOVE ROOF. USE PIPE

BRACING OR CABLE GUYING.

NOTE: MAXIMUM UNSUPPORTED HEIGHT

FOR ALL DIAMETER SIZES IS 6FT.

APPLIANCE

APPLIANCE

#2

APPLIANCE

#1

Other Metal Fab Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual