Metal Fab TEMP GUAR 14TG User manual

*Combustible material is dened as material made of, or surfaced with, wood, compressed paper, plant bers,

plastic, or other material that will ignite and burn, whether ame proofed or not, or whether plastered or unplastered.

The Metal-Fab Temp/Guard Chimney is intended for use on any residential and building heating appliance burning gas, liquid or solid

fuels such as replace stoves, furnaces, ranges, room heaters, or as dened in columns I and II, Table 2-2.1, NFPA 211. Contact Local

Building or Fire Ofcials about restrictions and Installation Inspection in your area.

WARNING: Metal-Fab Temp/Guard Chimney is not designed for use on products that operate at continuous temperatures in

excess of 1,000°F.

1700°TEMP/GUARD CHIMNEY

SIZES 14” - 16” - 18”

TEMP/GUARD®

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

This symbol on the nameplate

means this product is listed by

Underwriters Laboratories Inc.

Listing No. MH 8251

Tested to 103

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS FAILURE TO

MAINTAIN REQUIRED CLEARANCES (AIR SPACES) TO COMBUSTIBLE

MATERIAL.* MINIMUM CLEARANCE FOR 14”, 16” & 18” TEMP/GUARD IS

TWO (2) INCHES. IT IS OF UTMOST IMPORTANCE THAT THIS CHIMNEY

IS INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

IMPORTANT: FOR OIL OR COAL BURNING APPLIANCES, OUTSIDE THE ENVELOPE OF THE BUILDING, USE ONLY PIPE WITH

STAINLESS STEEL CASING, ALSO USE FLASHING OR STORM COLLARS CONSTRUCTED OF STAINLESS STEEL OR ALUMINUM.

OPERATIONAL PRECAUTIONS

• Maintain 2” minimum clearance to combustibles for 14”, 16” & 18” diameters. (Refer to WARNING above). Use only U.L. Listed

products and INSTALL ONLY IN ACCORDANCE WITH MANUFACTURER’S INSTRUCTIONS.

• Formation of Creosote and Soot and the need for removal.

When wood is burned slowly, it produces tar and other organic vapors, which combine with expelled moisture to create

creosote. The creosote vapors condense in the relatively cool chimney ue of the slow burning re. As a result, creosote

residue accumulates on the ue lining. When ignited, this creosote makes an extremely hot re. The chimney should be

inspected at least once every two (2) months during the heating season to determine if a creosote or soot buildup has

occurred. If creosote or soot has accumulated, it should be removed to reduce the risk of chimney re.

• Do not use replace for food grill. Grease from foods can collect in chimney causing replace to become a potential re

hazard.

• On airtight stoves, open dampers and let equipment burn hot for 15 to 20 minutes. This should be done every time fuel is added.

This lessens the chance of creosote buildup.

• Some chemical chimney cleaners can be harmful to the chimney. These cause accelerated oxidation or corrosion. If chemical

cleaners are used, they must be non-corrosive in nature. If brush is used, it must be of proper size with plastic bristles.

• The 14TG, 16TG and 18TG chimney system is to be installed through a chase and not intended to pass through attic areas that

require insulation shields.

• Except for installation in one- and two-family dwellings, a factory-built chimney that extends through any zone above that on

which the connected appliance is located is to be provided with an enclosure having a re resistance rating equal to or greater

than that of the oor or roof assemblies through which it passes.

• Enclose exterior mounted chimneys below the roof line in geographical areas experiencing sustained low ambient temperatures

to help reduce or limit condensation, creosote and poor draft.

2

ANCHOR

EMBEDDED

IN MORTAR

L944 FIG15A

NOTE:

ANCHOR PLATE MOUNTED

AT MASONRY FIREPLACE

FLUE OPENING AREA

WITH, BOLT, NUTS, AND

WASHERS

ANCHOR PLATE

(CAT. NO. TGAP)

BED

OF MORTAR

FIG. 1

FIG. 2

CHIMNEY ASSEMBLY

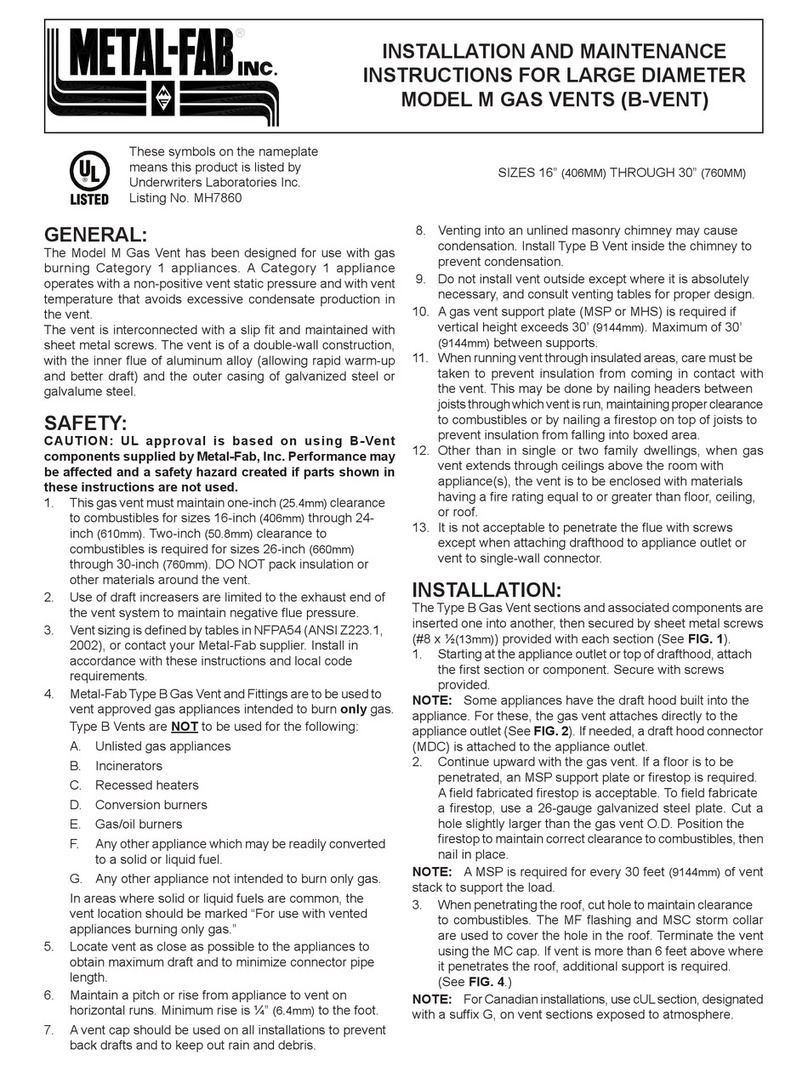

The 14TG, 16TG and 18TG chimney system is designed for

quick and easy installation. The ue and casing assemble at

each joint using a male to female slip t. Each joint is secured

together with four (4) each sheet metal screws at the casing

(See FIG. 1).

MASONARY FIREPLACE CHIMNEY,

AND CHIMNEY EXTENSION

An anchor plate (TGAP) is used to attach Metal-Fab 1700°F

Chimney to a masonry replace or chimney. Maximum

support height of 50 ft.

1. Where the transition is to be made, apply a bed of mortar

approximately 3/4 inches deep and approximately one

(1) inch larger than the anchor plate. (See TG Chimney

Catalog for anchor plate dimensions).

2. Insert four (4) 1/4-20 x 2” anchor bolts, head down into the

mortar bed. J-style anchor bolts are preferred. An alternate

method would be to allow the mortar bed to cure. Then, drill

four (4) holes, matching the holes in the anchor plate and

insert four (4) each 1/4-20 metal anchors. The anchor plate

would then be attached by four (4) each 1/4-20 bolts.

3. Before the mortar sets, place the anchor plate over the bolts

and press down into the mortar. Loosely secure using a

washer and nut on each bolt.

4. Use a level to check the installation, assuring that the TG

chimney connection (TGAP) is level.

5. When the mortar has set up, tighten the nuts onto the bolts.

Proceed to stack Metal-Fab chimney pipe (TG) on the

anchor plate (See FIG. 2 and TABLE 1 for framing

dimensions).

6. See “Flashing Instructions” and “Termination” sections.

NOTE: Existing masonry ues may be extended with TG pipe

by using an anchor plate, following steps 1 through 6 above,

provided that (See FIG. 3):

a) The existing masonry chimney is structurally sound,

and;

b) The ue extension is properly sized so that the

appliance attached to the ue drafts properly.

NOTE: The TG ue size for a height less than 15 feet should be

at least 1/8 the area of the replace opening. The TG ue size

for a height over 15 feet should be at least 1/10 the area of the

replace opening. (For sizing of TG ue, See Metal-Fab literature

L1372.)

FIG. 3

TABLE 1

14", 16" & 18" DIAMETER FRAMING DIMENSIONS

FOR FLOOR, CEILING & ROOF OPENINGS

14" 21"x 21"

16" 23" x 23"

18" 25" x 25"

3

L944 FIG17

C

B

A

FIG. 5

FIG. 4

L944 FIG18

NAILNAIL

SUPPORT BAND/

PLUMBERS

STRAP

4’ MAX.

4’ MAX.

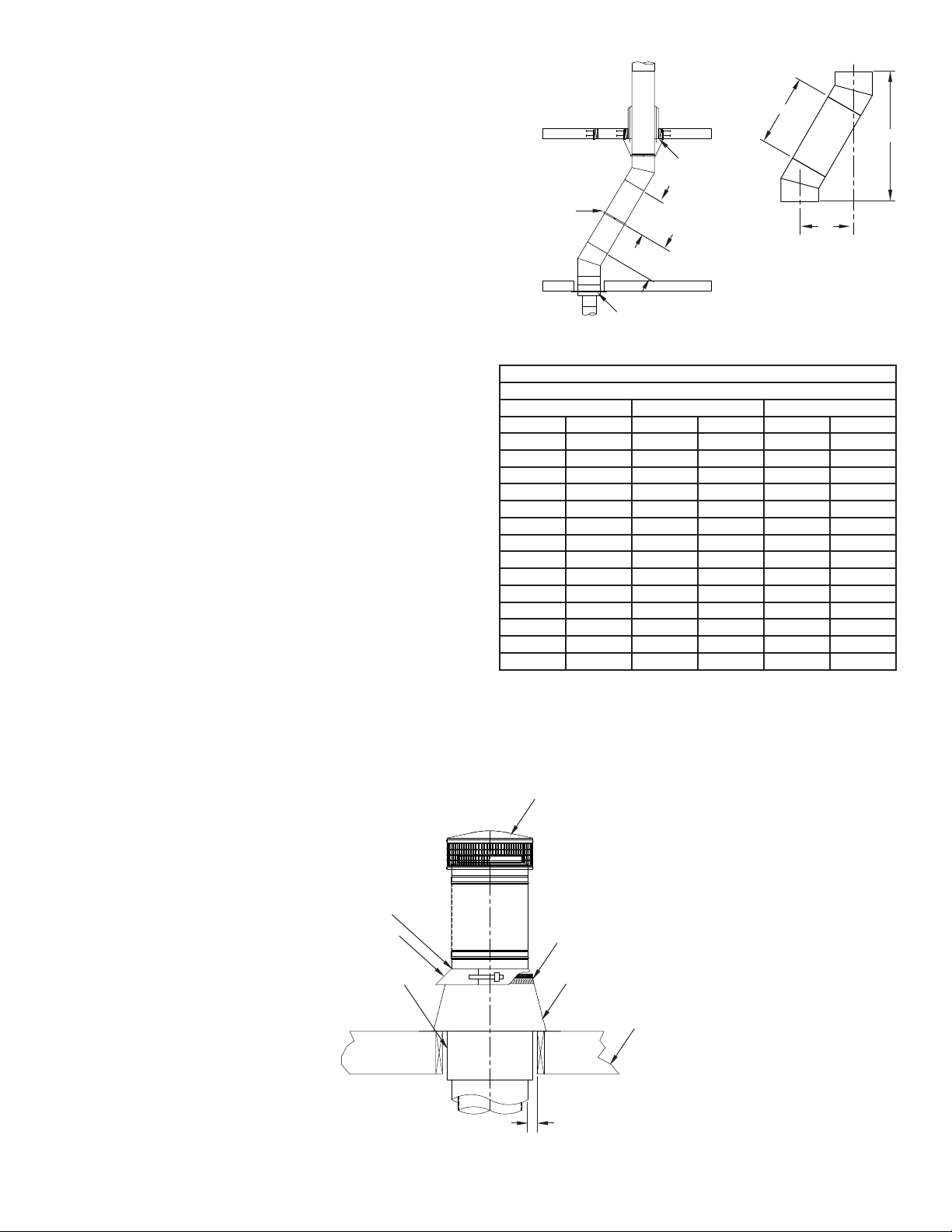

ELBOW INSTALLATION

1. 15° (TGA15) and 30° (TGA30) elbows are provided to allow

chimneys to avoid framing member or roof peaks. A

maximum of 30° from the vertical is allowed, and a total of

four elbows (two pair) for each chimney installation Maintain

2” clearance to combustibles for 14”, 16” and 18” diameters.

2. Attach the elbow to the chimney pipe or other support part.

Using the offset chart, add chimney sections between

elbows. A support band or plumbers strap is required every

4 foot interval between elbows to support the load as

shown in FIG. 4. Attach the upper elbow to bring chimney

back to vertical. See Table 2 and FIG. 5 for offset

combinations.

FLASHING INSTALLATION

1. Continue the TG chimney to the roof. Cut the roof opening,

centered over the chimney. A 2” airspace around

the chimney is required as it penetrates the roof

(See FIG. 6 and TABLE 1 for construction and framing

dimensions).

2. Install the next TG chimney section through the roof and

install the ashing (TGF) around the chimney and centered

over the roof penetration opening.

NOTE: If your roof is already shingled, be sure to slide the upper

edge under the shingles to prevent leakage.

3. Install a radiation shield (TGRSH) over the chimney

section and center the radiation shield within the joist area.

Bend straps of radiation shield over the top edge of ashing

to position in place. Apply a bead of caulk around the pipe at

the top edge of the ashing screen. Wrap the Storm Collar

around the pipe and imbed the edge of caulk to prevent

leakage around pipe. Bend the ashing strap around the tab

to tighten around the chimney (See FIG. 6).

4. Continue to install pipe sections until proper termination

height is reached. See termination section.

TABLE 2

14", 16" AND 18" DIAMETER OFFSET TABLE

A15 Angle 30 Angle

Length No. Pcs BCBC

0" 0 20-1/4" 2-1/2" 23-1/8" 5-7/8"

12" 1 30-1/2" 5-1/4" 32-1/4" 11-1/8"

18" 1 36-3/8" 6-3/4" 37-1/2" 14-1/8"

24" 1 42-1/8" 8-3/8" 42-5/8" 17-1/8"

30" 2 46-1/2" 6-1/2" 46-5/8" 19-3/8"

36" 1 53-3/4" 11-1/2" 53" 23-1/8"

42" 2 58-1/4" 12-5/8" 57" 25-3/8"

48" 2 64" 14-1/4" 62-1/4" 28-3/8"

54" 2 69-3/4" 15-3/4" 67-3/8" 31-3/8"

60" 2 75-5/8" 17-1/4" 72-5/8" 34-3/8"

72" 2 87-1/8" 20-3/8" 83" 40-3/8"

84" 3 97-3/8" 23-1/8" 92-1/4" 45-3/4"

90" 3 103-1/4" 24-3/4" 97-3/8" 48-3/4"

96" 3 109" 26-1/4" 102-5/8" 51-3/4"

FIRESTOP W/ INTEGRAL

RADIATION SHIELD

FIRESTOP

ROOF JOISTS

FLASHING (TGF)

FLASHING VENTS AND

SCREEN STAND OFF

TERMINATION CAP (TGC)

RADIATION SHIELD

BEND STRAPS OVER

FLASHING (TGRSH)

STORM COLLAR (SC)

CAULK

2” CLEARANCE TO

COMBUSTIBLES

FIG. 6

P.O. Box 1138 • WICHITA, KANSAS 67201

(316) 943-2351 • FAX (316) 943-2717

ECR 8852

L944 FIG22

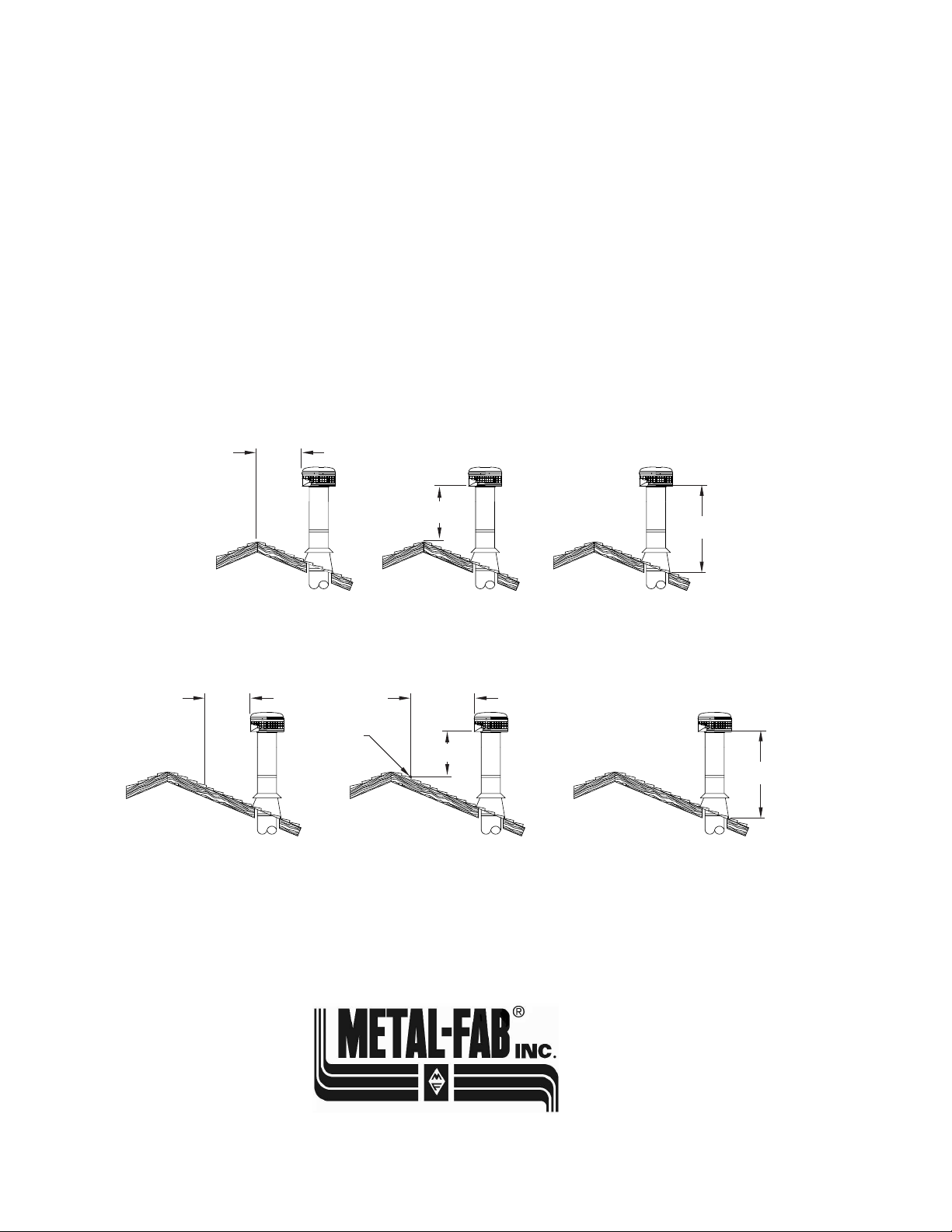

TERMINATION

Major building codes specify a minimum chimney height above

the roof top. These specications are summarized in what is

known as the “Ten Foot Rule”. This rule states:

If the horizontal distance from the side of the chimney to the peak

of the roof is 10 feet or less, the top of the chimney must be at

least 2 feet above the peak of the roof, but never less than 3 feet

in overall height above the highest point where it passes through

the roof (FIG. 7).

If the horizontal distance from the side of the chimney to the peak

of the roof is more than 10 feet, a chimney height reference point

is established on the surface of the roof a distance of 10 feet

from the side of the chimney in a horizontal plane. The top of the

chimney must be at least 2 feet above this reference point, but

never less than 3 feet in height above the highest point where it

passes through the roof (FIG. 8)

FIG. 7

IF 10

FEET OR

LESS

L944 FIG21

THEN BUT

MUST BE AT

LEAST 2 FEET NEVER LESS

THAN 3 FEET

FIG. 8

IF 10

FEET OR

MORE

MUST BE AT

LEAST 2 FEET NEVER LESS

THAN 3 FEET

10 FEET

REFERENCE

POINT

THEN BUT

These chimney heights are necessary in the interest of safety

and do not ensure smoke free operation. Trees, buildings,

adjoining roof lines, adverse wind conditions, etc., may create

need for a taller chimney should smoking occur.

Additional support is required above the roof if the chimney

height exceeds four (4) feet.

This manual suits for next models

2

Other Metal Fab Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual