Metallisation MK 73 User manual

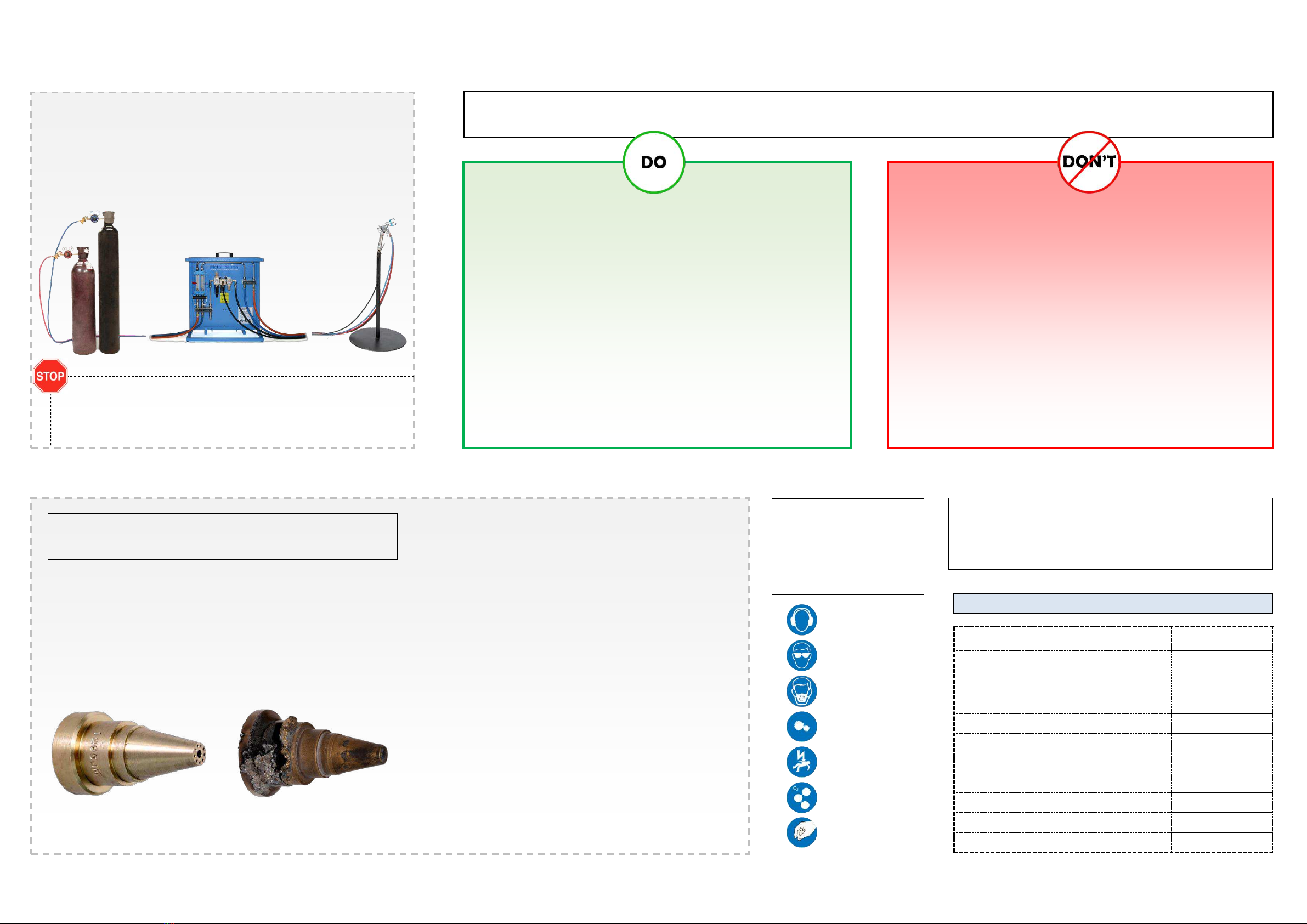

HAZARD

RATING

Compressed Gases

*

Highly Flammable / Extremely flammable

gases. Hydrogen, Propane, Acetylene, LPG

and/or Oxygen (fire and explosion risk

***

Noise

**

Fine Dusts, fume and powders (explosion risk)

***

Potentially toxic consumables

***

Water borne disease (water curtain fitted)

*

Mechanical Hazard (automated equipment)

*

Burns

***

Stab Risk

*

If hose protection and flashback arrestors are fitted, the risk of flames

reaching the fuel gas and oxygen supplies is virtually eliminated.

However, if flashback is sustained, it can seriously damage the nozzle

assembly.

Flashbacks can be caused mainly as a result of poor maintenance,

missing or damaged seals, blocked or damaged nozzle parts.

Flashback

Immediately close the pistol valve.

Shut off the oxygen supply valve.

Shut off the fuel gas supply valve.

If fitted, operate the safety shut-off handle on the flowmeter.

Re-open the pistol valve and allow air to flush the nozzle

assembly for approximately 30 seconds to cool the nozzle

parts.

Open the oxygen and fuel gas supplies and check the gas

flows on the flow meter.

If the flows appear to be ok re-light the pistol.

If the flows are out of specification or if there is a repeat

flashback close the pistol down as above.

Remove and inspect the nozzle assembly as per

maintenance instructions.

If flashback occurs, the following procedure should always

be carried out:

FIG 1. A good working

Nozzle.

FIG 2. A nozzle having

Incurred a flashback.

Approximate rating of the hazards in typical circumstances.

Hazard ratings may change in individual circumstances

Key

Hazards

Noise

Radiant Energy

Fume & Dust

Mehanical Hazards

Electrical Hazards

Ozone

Material Handling

Equipment Dos and Don’ts

IMPORTANT

SAFETY

PRECAUTIONS

All appropriate safety precautions and risk assessments

MUST be carried out prior to and during use of the system.

These can be viewed in full in the complete MK61 / MK73

System Manual.

DO Check all hoses regularly. Damaged hoses must be replaced

immediately.

DO Ensure that all hose connections are properly tightened and do

not leak.

DO Ensure that proper extraction is available and is turned on

before the gas supplies are tuned on and turned off after the

gas supplies are turned off.

NEVER Point the pistol towards other personnel or combustible

material.

NEVER Spray onto hoses, regulators or flowmeters.

NEVER Operate the pistol without using ear defenders and the

appropriate eye protection.

NEVER Apply grease to any thread or connection which

is to carry oxygen.

NEVER Operate the pistol without using regulators

fitted with flashback arrestors.

NEVER Release gases into an un-extracted area.

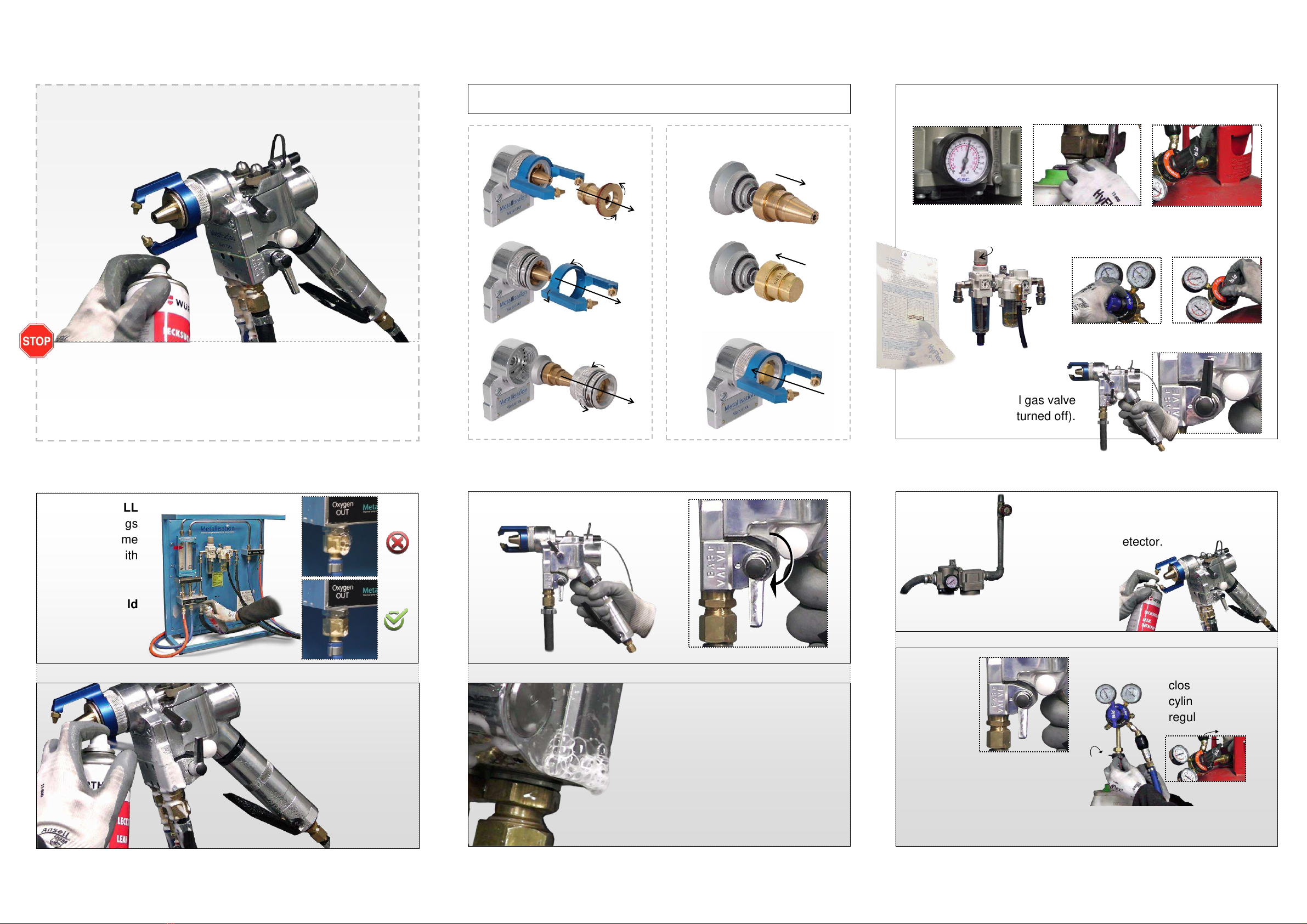

Unpack and check all parts are present and undamaged.

Ensure that all hoses, fittings and components are clean and free

from damage.

1

2

Fit the fuel gas and oxygen regulators to their respective supply

lines or cylinders.

Fit the flashback arrestors to the fuel gas and oxygen regulators.

Ensure that all connections are properly made and gas tight.

If not using the board as a freestanding unit, fix the mounting panel

to a suitable vertical surface.

6

7

Fit the other ends of the hoses to the appropriate connections on

the pistol.

Supplies

MK73 Propene Hose shown

MK61 requires Acetylene hose (Red)

CONNECTING

THE

SYSTEM

All appropriate safety precautions and risk assessments

MUST be carried out prior to and during use of the system.

These can be viewed in full in the complete MK61 / MK73

System Manual.

Flowboard

Regulators &

arrestors

Pistol &

Toolkit

The pistol may be

provided with or

without the

spreader

Fit the oxygen and

fuel gas hoses to their

respective arrestors.

NB: The indents on

the fuel gas hose

indicate a left turning

thread.

Fit all hoses to their appropriate connections on the flowboard.

Some installations require in-line flashback arrestors to be fitted to

the outlet connections to the pistol.

4

3

5

TO

PISTOL

TO

REGULATORS

For easier access, fit the

the middle hose first (left

thread).

If fitted connect the oxygen hose to the

panel mount regulator instead of directly

into the manifold under the flowmeter.

Connect the inlet air hose to the

manifold

Fit leak test nozzle to the pistol.

2

Open air, oxygen and fuel gas valves

3

Spray ALL

unions / fittings

on the flame

spray board with

leak detector.

No leaks should

be visible.

Open the pistol gas valve (turned on).

5

7

Isolate the

air supply.

LEAK TEST PROCEDURE

Spray ALL unions / fittings &

cam spindle housing /

diaphragm housing / mixing

Ensure the pistol gas valve

is closed (turned off).

4

1

Regulate to recommended full system pressure (as per manual).

Spray unions / fittings & cam spindle

housing / diaphragm housing /

mixing block with leak detector.

AIR WILL BLEED through the cam

spindle housing & potentially

between the cam spindle housing /

diaphragm housing.

block with leak

detector.

No leaks

should be

visible.

6

Spray unions / fittings & cam spindle

housing / diaphragm housing / mixing

block with a leak detector.

No leaks

should be

visible.

8

Ensure the

pistol gas

valve is still

open

(turned on).

Isolate/

close

cylinder

regulators.

Observe regulators for pressure drop over 2 minutes - no pressure

drop should be seen if there is no gas leak.

The full leak test procedure must be carried out every 6 months as per routine maintenance,

after any maintenance before the pistol is lit and every time gas cylinders are changed.

Additionally, before every shift it is also best practice to leak test from the cylinders to the gun

using a leak detector spray.

NB: Before leak testing ensure all hoses are connected correctly and all gauges are in good

working order. Leak test information is based on the assumption that all pressure gauges are in

good working order, with any visible defects having already been rectified e.g. damaged hoses,

broken flowmeters etc.

Check the

ARF.

A

NB: 90% of coating failures are a result of poor substrate preparation. These

general rules should be followed prior to spraying:

1

A. Check that the ARF filter bowl is empty and clean. If not remove and clean.

B. Check the ARF lubricator bowl. Top up lubrication oil if low, clean out and

refill if oil is contaminated.

NB: Should be set to 1 drop per 20 to 30 seconds.

2

B

6

Turn on the extraction system and ensure it is operating correctly.

Open the Drive Rollers and feed wire into the gun until it protrudes

from the Air Nipple.

4

Ensure the pistol gas valve is fully open.

5

Set the regulator pressures as per the parameter settings for

the size of wire being sprayed. See full operation manual for

more details.

Check the flow meters and adjust

the oxygen regulator if the flows

are slightly out of specification.

DO NOT adjust fuel gas.

For extended supplies adjust using

the board mounted regulator.

Flow differentials are important. If

the errors are excessive inspect

the nozzle assembly.

OPERATING THE SYSTEM

PART 1

Pull down

and twist to

remove

bowl

Before attempting to spray, leak test the system. Also, every time the system is

assembled and/or at least once per week.

• Workpieces must be prepared in accordance with the customers requirements.

• All surfaces to be sprayed should be degreased using a suitable degreaser.

• All surfaces should be GRIT blasted to the specification required by the customer.

Pull

down

and twist

Close the Drive Rollers.

3

Turn on compressed air, fuel gas and oxygen.

The pistol gas valve

can now be closed in

preparation for the

spraying process.

7

Draw the wire back until it is flush with the front of the nozzle

1

Note: Air nipple removed for clarity

End flush with nozzle

Cone shoulder flush with nozzle

OPERATING THE SYSTEM

PART 2

• Workpieces must be prepared in accordance with the

requirements.

• All surfaces to be sprayed should be degreased using

a suitable degreaser.

• All surfaces should be GRIT blasted to the

specification required by the customer.

NB: 90% of coating failures are a result of poor substrate

preparation. These general rules should be followed prior

to spraying:

It is important that the valve lever is turned to the

fully open position. Also a steady action is important

- Opening too slowly will burn out the Air Nipple. Too

fast will blow out the flame.

If the flame is not burning correctly adjust the

oxygen flow at the supply regulator (DO NOT adjust

fuel gas). For a long hose system (i.e. 3/8” hoses)

adjust the oxygen flow at the board.

When the pistol is alight, the flowmeter floats will

change position. This is normal DO NOT try to re-

adjust parameters to get the flowmeter floats to the

‘before lighting’ settings.

Horizontal

fan

Vertical

fan

Aligned with groove

= narrow round spray

Counter

clockwise

to increase

speed

Poor spray angle:

Wastes material

Poor adhesion

Good spray angle:

Good adhesion

Maximum deposits

To extinguish turn the pistol valve to the

OFF position (180° anti-clockwise in a

single smooth movement) but hold the wire

feed trigger for approximately 1 second

longer. NOTE: Turning the valve too slow

can cause damage to the pistol.

If the pistol is not going to be used for a period of time the gas

must be switched off and the hoses drained.

WARNING: The Spreader should always be turned in an anti-clockwise

direction (operator POV). Rotating in a clockwise direction could loosen

the air cover, potentially resulting in damage being caused.

Pull the trigger and adjust the wire speed until an acceptable sharp point of

wire is protruding from the Air Nipple (approx. 3 times the wire diameter).

clockwise to

reduce

speed

If fitted adjust the spreader to give the desired direction of the spread.

Note: There is a position where air to the spreader jet is cut off.

If the spreader is not required, rotate spreader until it shuts off.

Spray perpendicular to the work.

Stand-off distance 4”-8” (100-200mm) travelling at a suitable pace.

Shut off the gas and oxygen at the supply points.

Open the pistol valve to allow the lines to empty.

Shut off the air at the supply point.

ONLY when these steps have been complete

should the extraction system be turned off.

Extinguishing the Pistol

2

3

4

5

Depress the lever and turn to the pilot position.

Turn until it stops (approximately ¼ of a turn).

Light the pistol and

allow the flame to stabilise.

Turn gas control lever to the fully open position using

a smooth steady action.

Pull the wire feed trigger to spray.

Note: the different flame colour when spraying.

General good

spraying practice.

Before attempting to spray, leak test the

system. Also, every time the system is

assembled and/or at least once per week.

GENERAL MAINTENANCE

In order to prevent the ingress of any dirt, ensure that any further disassembly is

carried out in a clean environment and ensure that as a minimum the following

spares are available: Part Number: GAS-SSP -MK61 / MK73 Standard Spares

Pack for Gas Systems.

As part of the routine maintenance, the system should also be leak tested at

least every time the system is assembled and once per week

It is good practice to follow the below maintenance procedure,

after every 8 hours of use:

Clean the outside of the pistol to remove adherent dust.

Remove the air nipple and clean the inside cone, taking

care not to scratch or otherwise blemish the surface.

Instruction on disassembly of the Gas Head is found in the

next section of this guide.

Clean exposed surface of the wire nozzle carefully, again

taking care not to scratch or otherwise blemish the surface.

Check hose connection and hose condition and replace any

connection or hose as necessary.

Drain the ARF and top up / clean the lubricator.

GENERAL ROUTINE MAINTENANCE

AIR MOTOR ROUTINE MAINTENANCE

Daily: Lubrication is vital to reduce wear, friction and corrosion

of internal parts, therefore check the oil lubricator level and fill up

as required.

Note: Dirt particles can cause serious damage. Air should be filtered to

5 micron or less.

Most compressed air systems contain some moisture; if this is allowed

to remain in the motor internal corrosion can cause the motor to seize.

Condensation in the motor is aggravated when the atmosphere is damp

and the working conditions are cold. Since air cools as it expands

within the motor, periods of continuous operation can make the motor

cold and increase the condensation risk, so where this is thought to be

a danger it may be wise to run the motor for several seconds once the

body is no longer cold to the touch, in order to blow through any

droplets.

If the motor is to be left for a few days or stored, put a few drops of light

oil in the air inlet and rotate the motor slowly for a few seconds to

protect the internal parts.

Don’t drop the motor! Internal clearances can be upset by mishandling, and this will cause the motor to run slow

or even stall.

If a motor is tight, usually an injection of WD40 in the air inlet with lever depressed will help. Leave it to soak for 15

minutes before attempting to start the motor. WD40 is not a good lubricant, so once free the motor must be

lubricated.

Use the recommended oil in the oil lubricator unit. Compressor or hydraulic oil is NOT suitable.

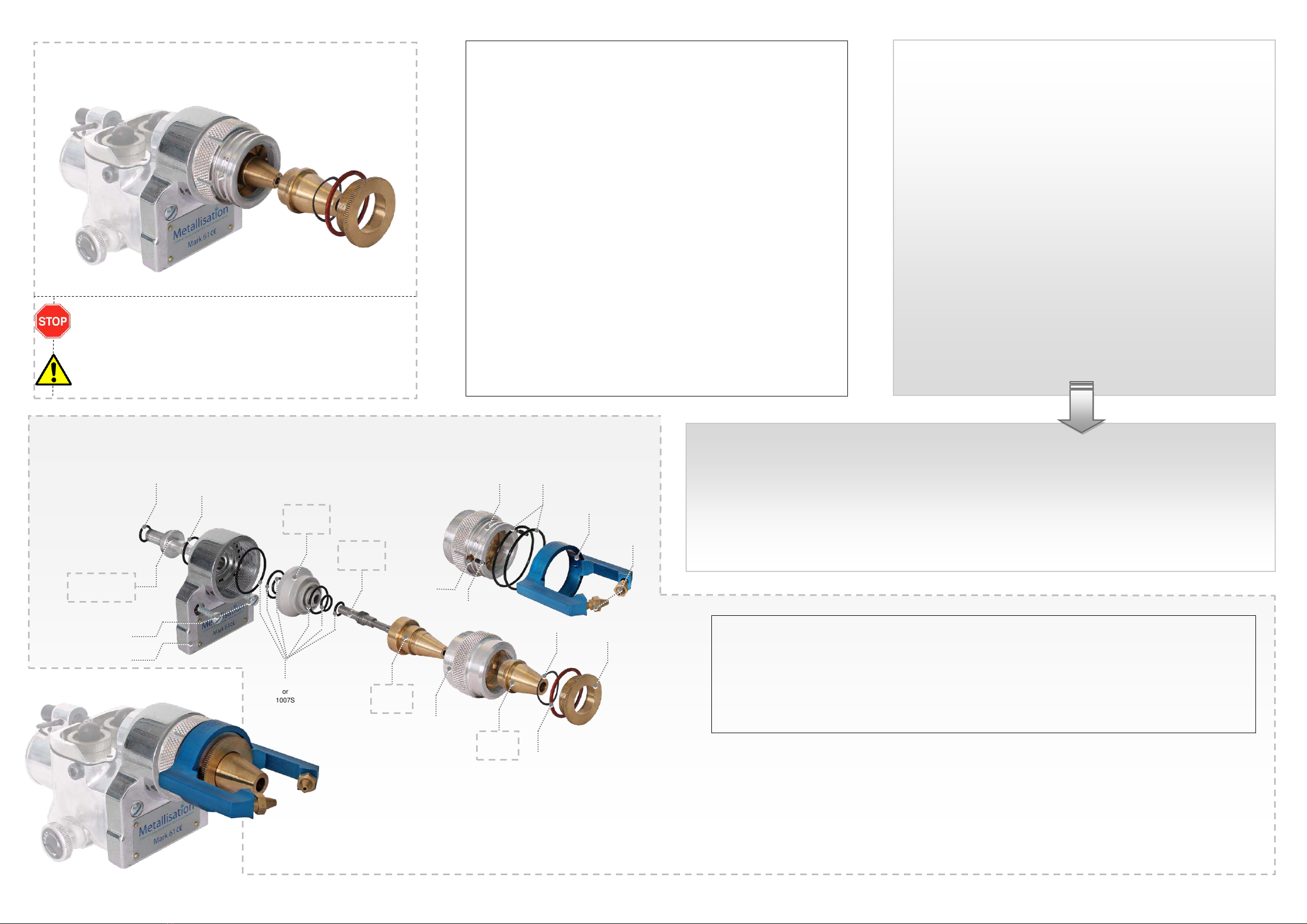

GAS HEAD PARTS & DISCONNECTING THE PISTOL

DISCONNECTING THE PISTOL

Extinguish the pistol.

Ensure that all supplies to the pistol are turned off and that the gas lines have been emptied.

Disconnect all hoses at the pistol. Do not allow the hose ends to fall to the floor or be contaminated with dust.

Coil up the hoses and hang them in a safe place.

Leave the pistol valve open to avoid damaging the internal diaphragms.

The Nozzle Assembly should only be dismantled when it is absolutely necessary. For example:

If it is dirty/worn.

If it is damaged.

When needing to change the Wire Diameter.

1007

1008

1029

1250

NOZZLE

INSERT

FRONT WIRE

GUIDE

NOZZLE

SHELL

1017

1025

1063

1066

1252

or 1257

1253

1065

6021

AIR

NIPPLE

1254

1024

10073S

or

1007S

MIXING

BLOCK

METALLISATION LIMITED

Pear Tree Lane,

Dudley, West Midlands,

DY2 0XH, UK

Tel: +44 1384 252464

Fax: +44 1384 237196

The information in this manual was correct at the time of publication; Metallisation disclaims liability for any

inaccuracies or omissions that may have occurred. Periodically, changes are made to the information herein, and

Metallisation reserve the right to make improvements and/or changes to the products described in this publication

at any time without prior notice.

Other manuals for MK 73

1

This manual suits for next models

1

Table of contents

Other Metallisation Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Milwaukee

Milwaukee M18 BPFP-CST Original instructions

Worcraft PROFESSIONAL

Worcraft PROFESSIONAL SG06-800 manual

Solo

Solo 424 NOVA Operator's manual & parts list

Birchmeier

Birchmeier Spray-Matic 1.25 P operating manual

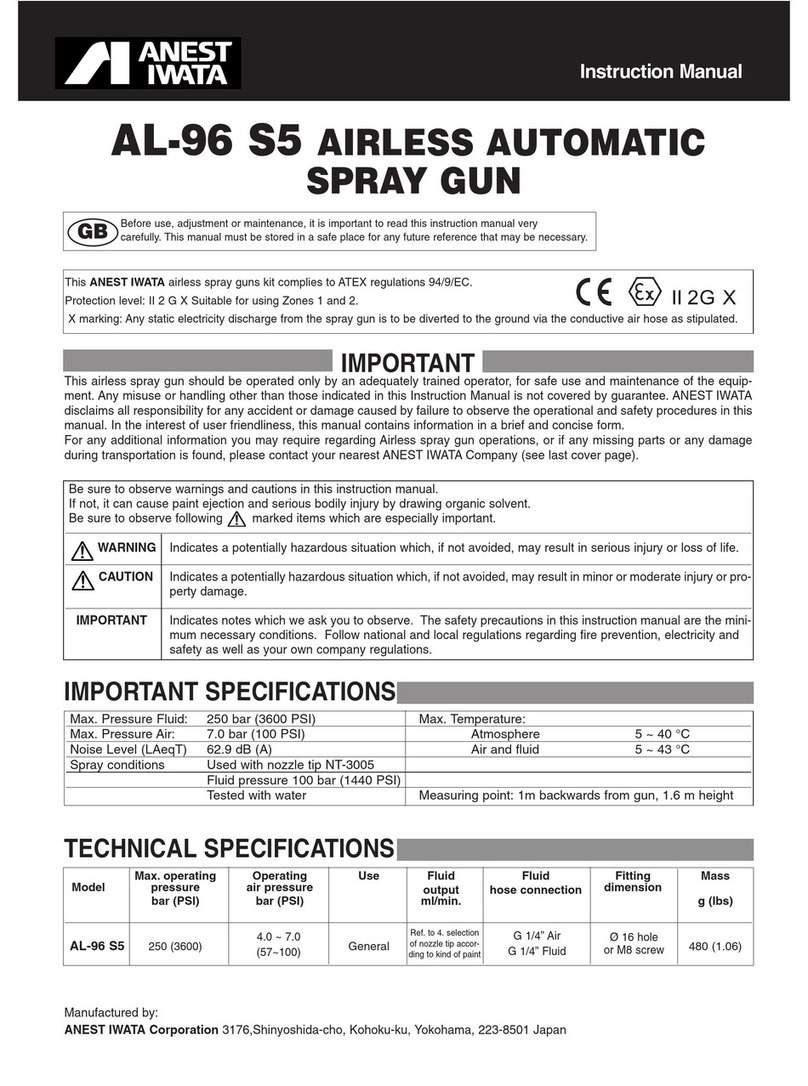

Anest Iwata

Anest Iwata AL-96 S5 instruction manual

Graco

Graco REACTOR 246024 Electrical diagrams