Metallisation ARC150-2310D User manual

Page 1of 48

ssue: 21/11-11

Page 2of 48

Issue: 15-09-2015

This operating manual must be read and understood before any

attempt is made to operate the equipment described herein. In

particular, refer to the Safety Warnings / Risk Assessments in

Section 1.

Under no circumstances should any modifications be made to

the equipment without prior written approval from Metallisation.

MAN-ARC150-OP

For Pistols: ARC150-CG23

ARC150-CG25

For Energiser: S500-PLC

Related Manuals:

Pistol Maintenance Manual:

MAN-ARC150-MA

Energiser Maintenance Manual:

MAN-ENE-S500(150)

Page 3of 48

SPECIFICATIONS

The Metallisation ARC150/S500-PLC Arc Spray System is designed for anti-corrosion coatings and will

give consistent throughputs with high coating quality.

The following specification covers the standard range of ARC150 Pistol with S500-PLC (ARC150)

Energiser with closed loop current control.

The Pistol Pistol Rating - Max Current: 500 Amps

Dimensions:

WEIGHT

LENGTH

HEIGHT

WIDTH

STAND ALONE

INC. CABLE &

HOSES @ 1.2M

275mm (10.8”)

240mm (9.4”)

102mm (4”)

2.1kg (4.65lb)

5.1kg (11.24lb)

The Energiser (S500-PLC)

Dimensions:

LENGTH

HEIGHT

WIDTH

WEIGHT

900mm (35.4”)

800mm (31.5”)

875mm (34.5”) To Handle

485mm (19.1”)

670mm (26.4”) Wheel to Wheel

291.6kg (644lb)

S500-PLC Energiser Specification:

DESCRIPTION

CHARACTERISTICS

Input Power Requirements

380/415/460 Vac 50-60Hz 3 Phase

Optional Input Power

220V 50-60Hz 3 Phase

Fusing Required

37A @ 460 Vac

40A @ 415 Vac

44A @ 380 Vac

76A @ 220 Vac

84A @ 200 Vac

Max Power Consumption

29 KVA (46Vdc/500A output)

Typical Power Consumption

16 KVA (Zinc 26Vdc/500A output)

22 KVA (Aluminium 35Vdc/500A output)

Duty

0-500 AMPS @ 100% Duty Cycle

Output Voltage

0-49 Vdc Switched High/Low & 1 –5

(Nominal Spray Voltage 19 to 44Vdc)

Air Requirements

1.5m³ /min @ 5 bar (53cfm @ 72.5 psi)

Power Factor

0.85 Lag

Auxiliary Circuits

110Vac and 24Vdc

Pressure Switch Setting

30 psi (2.0 bar)

Page 4of 48

CONTENTS

SECTION 1

SAFETY PRECAUTIONS & RISK ASSESSMENTS................................................................................6

1.1 Safety Precautions......................................................................................................................................7

1.1.1 Equipment Dos and Don’ts.......................................................................................................................7

1.1.2 Handling of the Energiser.........................................................................................................................7

1.1.3 The Energiser Mains Supply ....................................................................................................................7

1.2 Risk Assessment........................................................................................................................................8

1.3 Key Hazards...............................................................................................................................................9

1.3.1 Noise........................................................................................................................................................9

1.3.2 Radiant Energy ........................................................................................................................................9

1.3.3 Fume & Dust..........................................................................................................................................10

1.3.4 Mechanical Hazards............................................................................................................................... 12

1.3.5 Electrical Hazards ..................................................................................................................................12

1.3.6 OZONE..................................................................................................................................................12

1.3.7 Material Handling ...................................................................................................................................13

1.3.8 The Pistol...............................................................................................................................................13

1.3.9 Summary................................................................................................................................................13

SECTION 2

THE EQUIPMENT ..................................................................................................................................14

2.1 System Configurations..............................................................................................................................15

SECTION 3

OPERATING THE EQUIPMENT ............................................................................................................17

3.1 Connecting the System.............................................................................................................................18

3.2 Connecting using a Powered Extension Trolley ........................................................................................20

3.3 Preparing to Spray....................................................................................................................................22

3.4 Spraying ...................................................................................................................................................24

3.5 Shutting Down ..........................................................................................................................................26

3.6 Remote Pendant.......................................................................................................................................26

3.7 Using Optional Arc Extension ...................................................................................................................27

3.8 Closed Loop and Open Loop Modes.........................................................................................................27

SECTION 4

BASIC MAINTENANCE..........................................................................................................................28

4.1 Routine Maintenance................................................................................................................................29

4.2 CG Spray Head –Checking Contact Tips................................................................................................. 30

4.3 CG Spray Head –Complete Disassembly ................................................................................................32

4.4 CG Spray Head Reassembly....................................................................................................................34

4.5 Tension Adjustment of Rollers..................................................................................................................36

4.6 Roller Guide Assembly Maintenance ........................................................................................................37

Page 5of 48

4.7 Rear Wire Guides - Checking ...................................................................................................................38

4.8 Supplies & Manifold Maintenance.............................................................................................................39

4.9 Wire Condition..........................................................................................................................................40

SECTION 5

FAULT FINDING.....................................................................................................................................41

5.1 Operational Troubleshooting.....................................................................................................................42

SECTION 6

ILLUSTRATED PARTS LIST .................................................................................................................43

6.1 Main Components.....................................................................................................................................44

6.2 CG Spray Head.........................................................................................................................................45

SECTION 7

INFORMATION TABLES .......................................................................................................................46

7.1 Typical Performance Figures ....................................................................................................................47

Page 6of 48

SECTION 1

SAFETY PRECAUTIONS & RISK ASSESSMENTS

1.1 Safety Precautions

1.1.1 Equipment Dos & Don’ts

1.1.2 Handling of the Energiser

1.1.3 The Energiser Mains Supply

1.2 Risk Assessment

1.3 Key Hazards

1.3.1 Noise

1.3.2 Radiant Energy

1.3.3 Fume & Dust

1.3.4 Mechanical Hazards

1.3.5 Electrical Hazards

1.3.6 OZONE

1.3.7 Material Handling

1.3.8 The Pistol

1.3.9 Summary

Page 7of 48

1.1 Safety Precautions

Provided that the equipment is properly set up, regularly maintained and used correctly, metal

spraying does not present any great danger. However, like most industrial processes, misuse

and careless practices can create hazards for personnel and damage to the equipment.

The equipment detailed in this manual will produce levels of noise, UV light and dust that

require safety measures to be taken by personnel using the equipment. Careful consideration

should be taken when positioning this equipment.

It is the responsibility of the user to ensure that all appropriate measures are in place for safe

operation, before the equipment is used. Metallisation will be pleased to assist and advise as

appropriate.

1.1.1 Equipment Dos and Don’ts

Ensure that all appropriate Risk Assessments are carried out before using this equipment.

Ensure the equipment is properly set up as per Section 3.1 of this Manual.

NEVER point the pistol towards other personnel or combustible material.

NEVER spray onto hoses, cables or instruments.

NEVER operate the pistol without using ear defenders and the appropriate eye protection.

NEVER look into the arc zone, without first ensuring that the power switch is in the "off"

position and the drive motor is switched off.

1.1.2 Handling of the Energiser

The Energiser must only be lifted from the base, under no circumstances should it be lifted by

the handle or by the M12 thread that locates the dispenser spigot.

Care must be taken if attempting to transport the Energiser by fork lift truck not to damage the

underside of the unit.

1.1.3 The Energiser Mains Supply

The mains supply MUST be disconnected before removing any of the outer panels.

Isolate the mains supply.

ALL maintenance or overhaul should be conducted by a fully qualified electrician in

accordance with local regulations.

Page 8of 48

1.2 Risk Assessment

Prior to commencing work with Thermal Spray equipment, a Risk Assessment should be

carried out on the equipment and the way in which that equipment is to be used.

The Risk Assessment should identify the hazards associated with the work and also the

control measures required. This will either eliminate the risk, or reduce it to an acceptable

level to prevent ill health or injury to the persons carrying out, or who could be affected by the

work.

The results of the Risk Assessment and the control measures necessary should be made

known to the persons carrying out, or those affected by the work.

Some control measures are better able to produce the desired result than others.

The safety precedence sequence shows the order of effectiveness of measures.

Hazard Elimination

Use of alternative work methods, design improvements or change of process.

Substitution

Replacement of material/substance with another of less risk.

Use of Barriers

Isolation or segregation.

Use of Documented Procedure

Limiting exposure times, dilution of exposure. Safe systems of work that depend on human

response.

Use of Warning Signs

Signs, instructions, labels that depend on human response.

Use of Personal Protective Equipment (PPE)

Depends on human response, used as a sole measure only when all other options have been

exhausted. PPE is the last resort.

It is the responsibility of the user of the equipment to ensure that all appropriate control

measures identified in the Risk Assessment are in place before using the equipment.

To assist you in carrying out your Risk Assessment we have identified the Key Hazards in the

operation of Thermal Spray Equipment and this information can be found in Section 1.3.

Page 9of 48

1.3 Key Hazards

In this section the key hazards associated with Thermal Spraying are described. It

includes a brief description of the hazards and their possible consequences. In

any Risk Assessment for a Thermal Spray Process, a consideration of all relevant

hazards will need to be included. Ancillary activities that are likely to be undertaken,

such as grinding, grit blasting, solvent cleaning, machining etc. are not included

in this section.

1.3.1 Noise

The two main factors that make noise in the workplace harmful are the loudness of

the noise and the length of time a person is exposed to it each day. Noise destroys the

delicate nerve cells in the inner ear that transmit sound messages to the brain. The nerve cells

are replaced by scar tissue that does not respond to sound. This damage occurs painlessly

and very slowly, but is permanent. There is currently no cure for noise-induced hearing loss,

and it cannot be helped by hearing aids. All spraying processes are noisy and may generate

noise levels in excess of the first action level. Users of thermal spray equipment are

responsible for conducting their own noise assessments, which must be based on the

exposure of the persons in the workplace, and of which a noise survey is only part.

Key Hazards: Stress, difficulty in communication, long term hearing loss, Tinnitus.

NEVER operate the system without adequate hearing protection.

ALWAYS ensure that ALL personnel likely to be exposed are adequately protected, including

those not directly involved in the process.

1.3.2 Radiant Energy

Always wear eye protectors when operating, or watching the arc spray operation.

Inspect the eye protectors frequently. Lenses and over plates, which are scratched, pitted or

damaged, can impair vision and seriously reduce protection. All personnel in eye hazard areas

should wear protective eyewear. This includes employees, visitors, researchers, contractors,

or others passing through an identified eye hazard area. To provide protection for these

personnel, a sufficient quantity of goggles and/or plastic eye protectors should be available. If

personnel wear personal glasses, eye protectors suitable to wear over them should be

provided.

Key Hazards: Cataract, burns, Arc-Eye.

NEVER operate the system without adequate eye protection.

ALWAYS ensure that ALL personnel likely to be exposed are adequately protected, including

those not directly involved in the process.

Page 10 of 48

1.3.3 Fume & Dust

Powdered metals, particularly titanium, aluminium and magnesium give rise to a fire

and explosion risk, depending on the circumstances. Powdered materials can collect in

ducting, on filters, and around the spray booth. If these accumulations are heavy, and they are

disturbed, they can be ignited. An explosion may result from the ignition of a dust cloud,

inside, or outside the equipment. A fire may follow from an explosion and its fireball, or may

result from self-ignition of layers of accumulated dust on hot surfaces, including some

electrical equipment.

Many of the materials that are routinely sprayed have the potential to be hazardous to health

due to their intrinsic properties. Even the least toxic materials, if present in the air in sufficient

quantities, can be hazardous to health. Dust produced by the process produce airborne

particulate matter, in size ranges that can be inhaled. Both inhalable and respirable matter

may be produced. Respirable particles are more dangerous because they can be breathed

deeply into the lungs. The user must therefore identify the hazards, assess the risks, and

prevent or, where not reasonably practicable, adequately control them. The assessment must

take into account all occasions where exposure may occur –which include spraying, cleaning,

disposal and maintenance.

Several commonly sprayed substances are subject to statutory exposure limits. The

assessment must take into account these exposure limits. When a substance or preparation

has an occupational exposure standard, control of exposure is adequate if levels are

maintained below that standard. Below are the most commonly sprayed materials. However,

other materials may also be toxic. It is essential that users consult the MSDS (Material Safety

Data Sheets) that arrive with their consumables (manufacturers must supply these), so that

they can take into account the health effects, any exposure limits, and any properties such as

explosion hazard, when conducting their risk assessments.

Key Hazards: Fire & explosion, toxic effects by inhalation, toxic effects by skin contact.

The information that follows highlights the most commonly sprayed materials and their

potential effects.

Commonly sprayed materials

Aluminium

Long term inhalation of aluminium powder or aluminium oxide may cause scarring of the

lungs. Aluminium powder can form explosive mixtures with air.

Chromium

Prolonged exposure to Chromium metal dust may give rise to lung fibrosis. It is highly toxic.

Chromium oxide and chrome carbide feedstock are both Chromium (III), the less toxic form of

Chromium. However spraying may convert Chromium (III) compounds to Chromium (IV)

compounds, which are suspected human carcinogens. Exposure to Chromium (IV)

compounds must be kept as far below the maximum exposure limit (MEL) as is reasonably

practicable.

= May react with water to form hydrogen

= Fire / Explosion Hazard

Page 11 of 48

Cobalt

Cobalt is moderately toxic. It may cause sensitisation by inhalation and skin contact, resulting

in occupational asthma and allergis dermatitis. Exposure must be kept as far below the

maximum exposure limit (MEL) as is reasonably practicable.

Copper

Copper fume may give rise to metal fume fever. Inhalation may cause muscle weakness and

headache. Some compounds of copper are highly toxic and may cause long term effects.

Iron

Inhalation of iron oxides over a long period may cause scarring of the lungs without

physiological symptoms.

Molybdenum

Occupational ill-health from exposure to Molybdenum is unlikely.

Nickel

Nickel is harmful. Repeated skin contact may cause allergis contact dermatitis. It is a suspect

human carcinogen, and exposure must be kept as far below the maximum exposure limit

(MEL) as is reasonably practicable.

Tin

Tin powder may cause irritation. Inhalation over a long period may cause scarring of the lungs

without physiological symptoms.

Titanium

Occupational ill-health from exposure to titanium is unlikely.

Tungsten

Ingestion of soluble tungsten compounds may cause illness, but occupational ingestion of

tungsten, other than in hard-metal alloy is not known to cause long term ill health.

Zinc

Zinc can cause metal fume fever, but is otherwise only moderately toxic.

NOTE: In certain concentrations, a mixture of aluminium dust and iron oxide (rust) can

cause a thermitic reaction, resulting in a spontaneous combustion. This is very rare but

efforts should be made to minimise cross contamination of aluminium dust and iron oxide.

Page 12 of 48

1.3.4 Mechanical Hazards

If equipment has been installed to manipulate the component and/or spray gun, it is

important that it is designed to protect the operator from mechanical hazards. It is possible for

the operator to be struck by a moving table or manipulator, to be crushed against the wall of

the booth, or to become entangled in rotating machinery. Serious injury could occur. Trailing

cables and other obstructions present a tripping hazard, and because of the relatively confined

area of a spray booth, and the close proximity to machinery, the consequences may be

serious.

Key Hazards: Entanglement, being struck by machinery, trips and falls.

1.3.5 Electrical Hazards

Electricity can give rise to electric shock, fire, explosion and burns. It can also lead

to falls and muscular injury. The risk of death from electric shock is related to the current that

passes through the body, and the path it takes.

Voltages below 50Vac or 120Vdc are considered safe, except in conducting environments. A

typical spray booth is a conducting environment. However, the power supply for the equipment

will usually be fed from a higher voltage supply, typically 240V or 415V, which must always be

considered hazardous.

Other related causes of electrical accidents include poor placement of cables. These may

become trapped on booth doors, or damaged whilst on the floor, leading to exposure of the

live conductors. Electrical apparatus can also be the source of sparks, and like electrostatic

discharges can ignite explosive mixtures; additionally they can cause a fire, which, with gases

present, could be dangerous.

Key Hazards: Electric shock, explosion, fire, burns.

1.3.6 OZONE

Arc systems with much brighter arc intensity operate between 280 and 220 nm,

also called the UV-C region. Arc systems operating in this range also generate ozone. Ozone

is formed from dioxygen by the action of ultraviolet light and also atmospheric electrical

discharges.

It is a colourless gas with a sharp characteristic odour; it can be smelled at concentrations

below the permissible exposure level. The odour is generally detectable by the human nose at

concentrations of 0.02 and 0.05 ppm. It has a density of 1.244 g/l, around 1.6 times heavier

than air.

Ozone affects the body by being inhaled or by irritating the eyes, nose and throat. When a

person is exposed to very low concentrations of ozone, the person may notice a sharp

irritating odour. As the concentration increases, the ability to smell it may decrease. Irritation of

the eyes, dryness of the nose and throat, and cough may be experienced. If the Ozone

concentration continues to rise, more severe symptoms may develop. These may include

headache, upset stomach or vomiting, pain or tightness in the chest, shortness of breath or

tiredness, which may last for several days to weeks. Finally, with higher levels of exposure, the

lungs may be damaged and death may occur.

The following limits are widely accepted (USA, Sweden, UK and other parts of Europe):

- 8 hour per day/5 days per week (occupational exposure limit) - 0.1 ppm

- 15 minutes (short term exposure limit) - 0.3 ppm

Key Hazards: Irritation, headache, vomiting, lung damage, death.

Page 13 of 48

1.3.7 Material Handling

The wire is supplied in either drums, coils or MIG reels. It is important to assess any

manual lift before carrying out the lift, and if necessary, use a crane or suitable lifting device to

prevent injury. Always lift the drums as indicated on the drums info label. Do not attempt to

manually handle the drums, or to roll them, as this will render them useless.

1.3.8 The Pistol

The ARC150 Pistol is designed for handheld or automated use, where it can be attached to a

manipulator / robot. Under these circumstances the Pistol should be installed in a manner

where it cannot cause harm to the operator or the surrounding environment.

In the case of the automated operation, it is the responsibility of the client to risk assess the

automatic installation and ensure all safety criteria are met.

1.3.9 Summary

Below is an approximate rating of the hazards in typical circumstances while using the

ARC150 Arc Spray System. It must be stressed that the hazard ratings may change in

individual circumstances. An example of this would be the rating for toxic consumables. This

would relate directly to the consumable in use.

Compressed Gases

Asphyxiant Gases

Noise

UV Radiation

Fine Dusts, fume and

powders (explosion risk)

Potentially toxic consumables

Water borne disease (water curtain fitted)

Mechanical Hazard (automated equipment)

Electric Shock

Burns

Stab Risk

OZONE

Lower level of hazard

Medium level of hazard

Very high level of hazard

Page 14 of 48

SECTION 2

THE EQUIPMENT

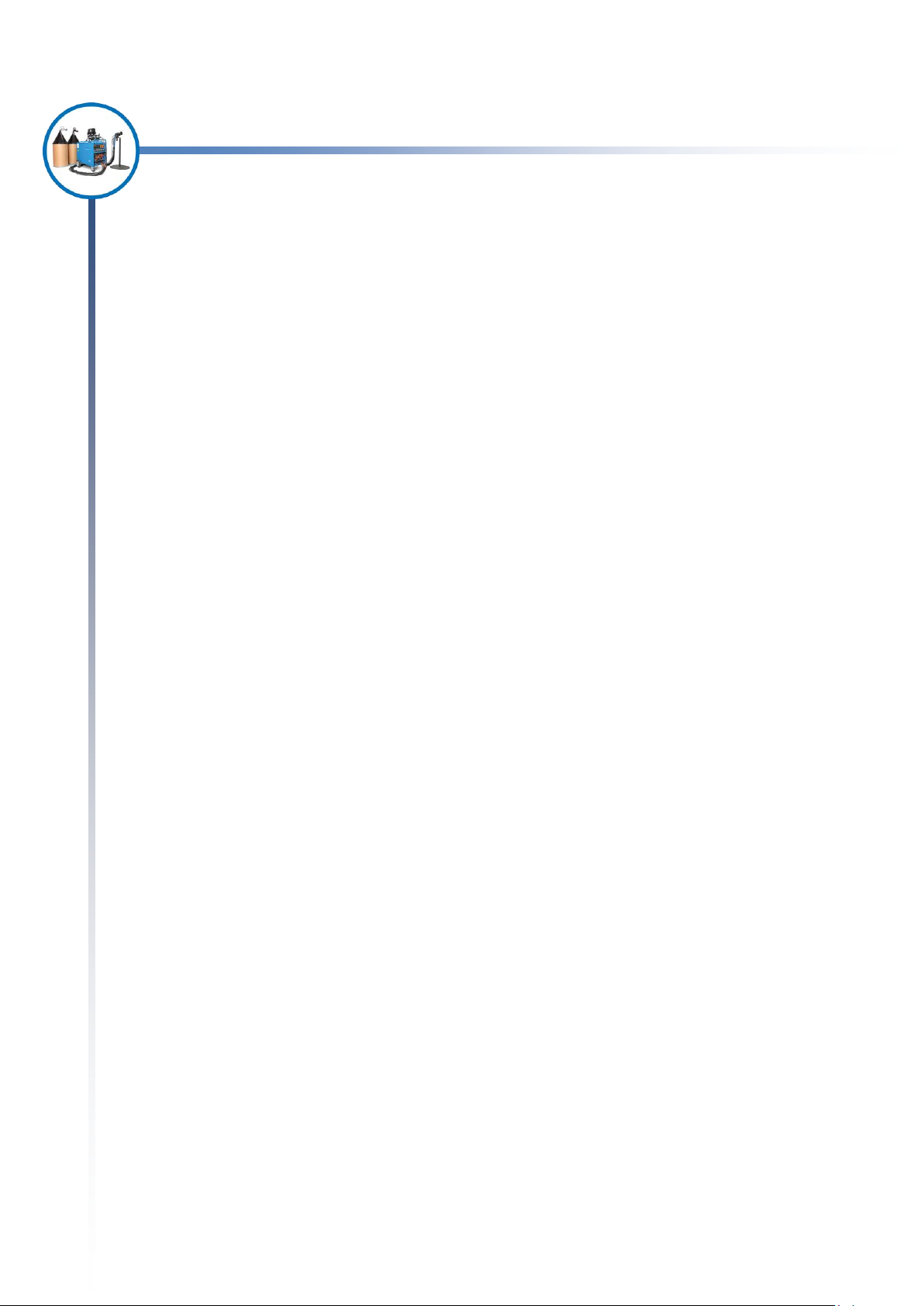

2.1 System Configurations

Page 15 of 48

2.1 System Configurations

Variations of the below standard configurations may be possible. Contact Metallisation to

discuss your specific application requirements.

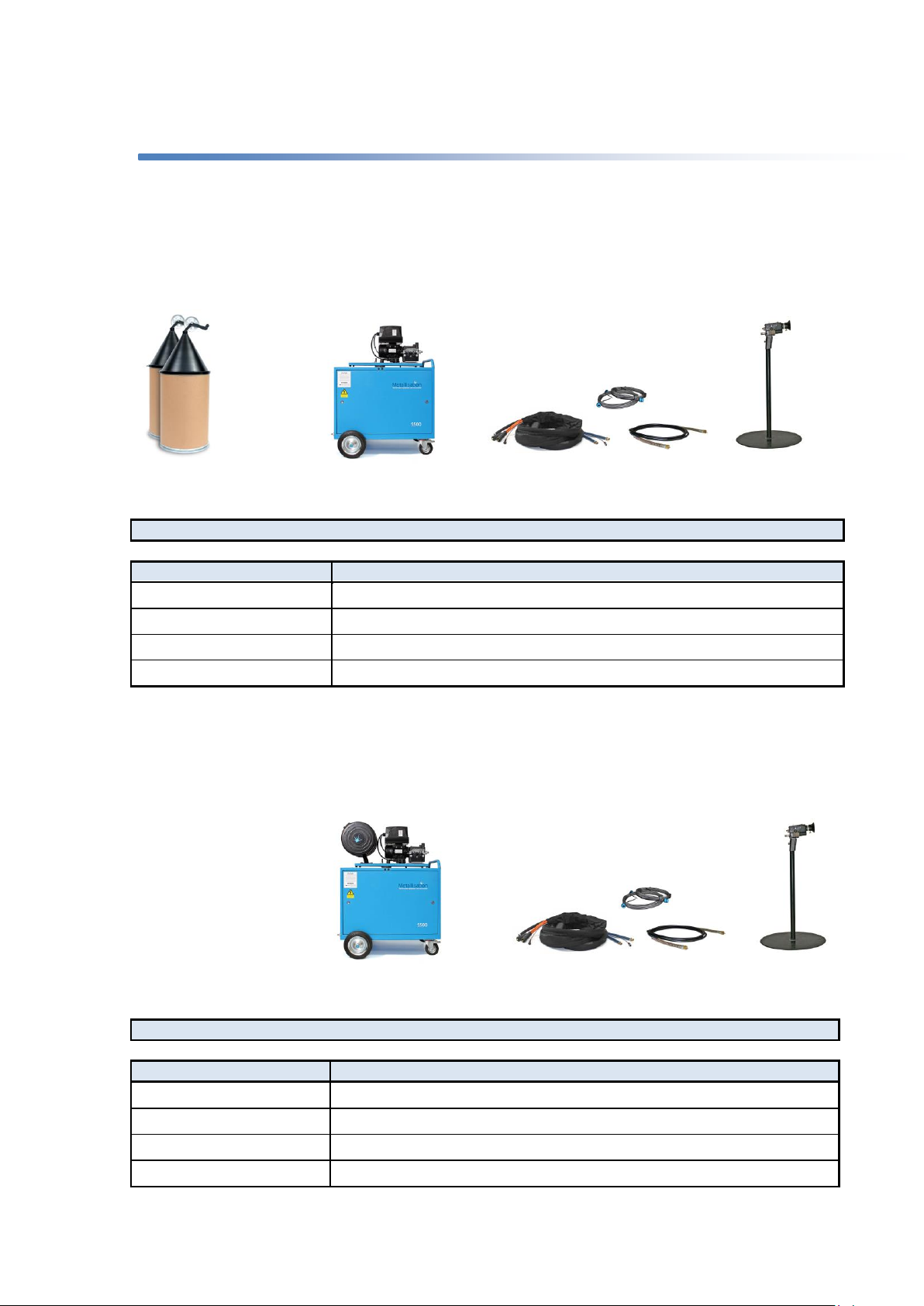

Standard Configuration –Push/Pull with wire in Drums

Most commonly used for in-house anti-corrosion applications where drums can easily be handled.

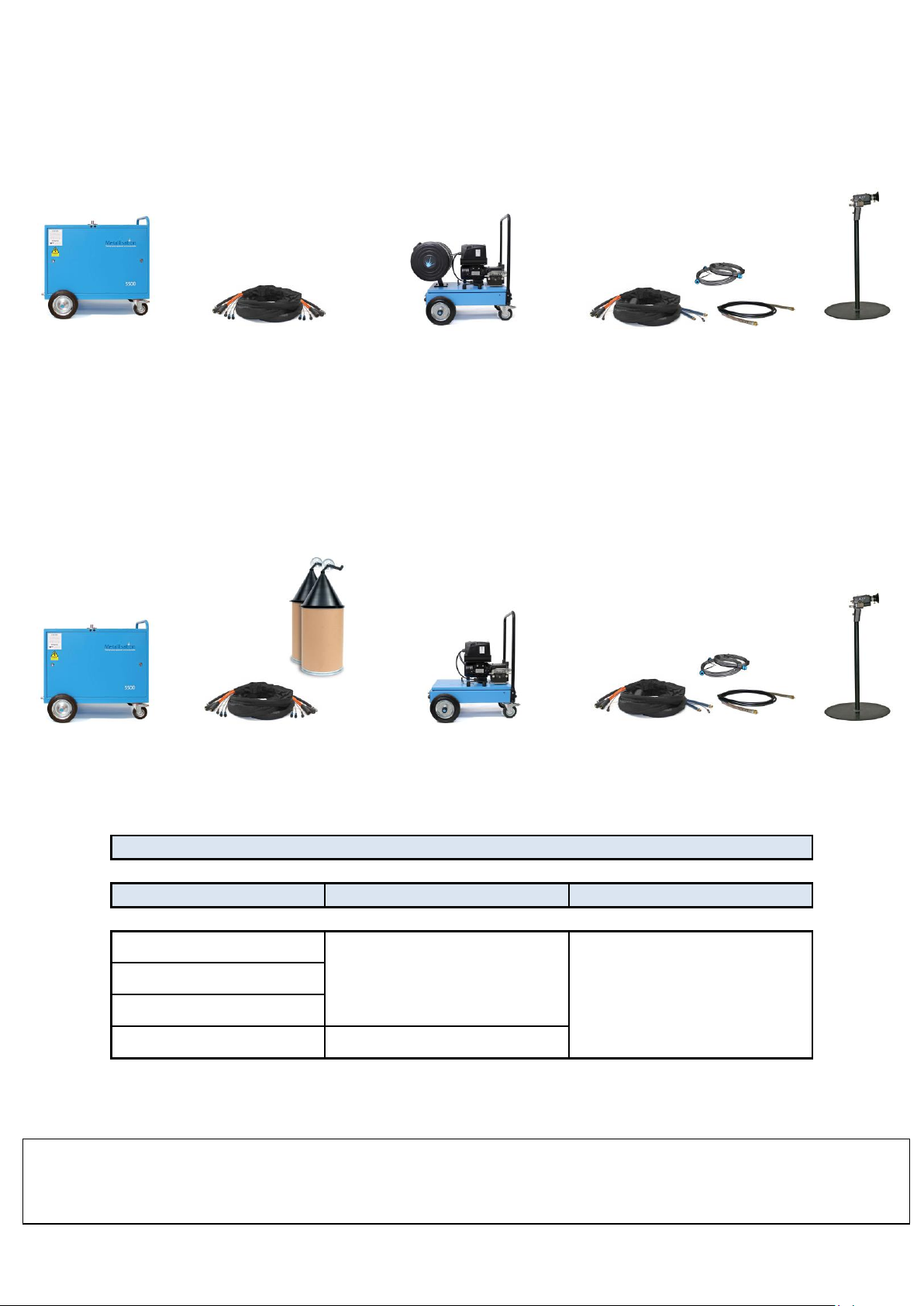

Standard Configuration –Push/Pull with wire on MIG reels

Most commonly used for on-site anti-corrosion applications where loading of the smaller MIG reels is

more feasible than using drum material.

STANDARD DRUM SYSTEM PART NUMBERS

PART NO

DESCRIPTION

ARC150-2310D

ARC150 System, 2.3mm, 10m supplies, drum dispense

ARC150-2320D

ARC150 System, 2.3mm, 20m supplies, drum dispense

ARC150-2510D

ARC150 System, 2.5mm, 10m supplies, drum dispense

ARC150-2520D

ARC150 System, 2.5mm, 20m supplies, drum dispense

STANDARD MIG SYSTEM PART NUMBERS

PART NO

DESCRIPTION

ARC150-2310M

ARC150 System, 2.3mm, 10m supplies, MIG dispense

ARC150-2320M

ARC150 System, 2.3mm, 20m supplies, MIG dispense

ARC150-2510M

ARC150 System, 2.5mm, 10m supplies, MIG dispense

ARC150-2520M

ARC150 System, 2.5mm, 20m supplies, MIG dispense

Energiser and push/pull

drive unit

Energiser and push/pull

drive unit

Pistol

Pistol

10m / 20m supplies from wire

drive to pistol

10m / 20m supplies from wire

drive to pistol

3m max.

Wire in drums or

coils

Page 16 of 48

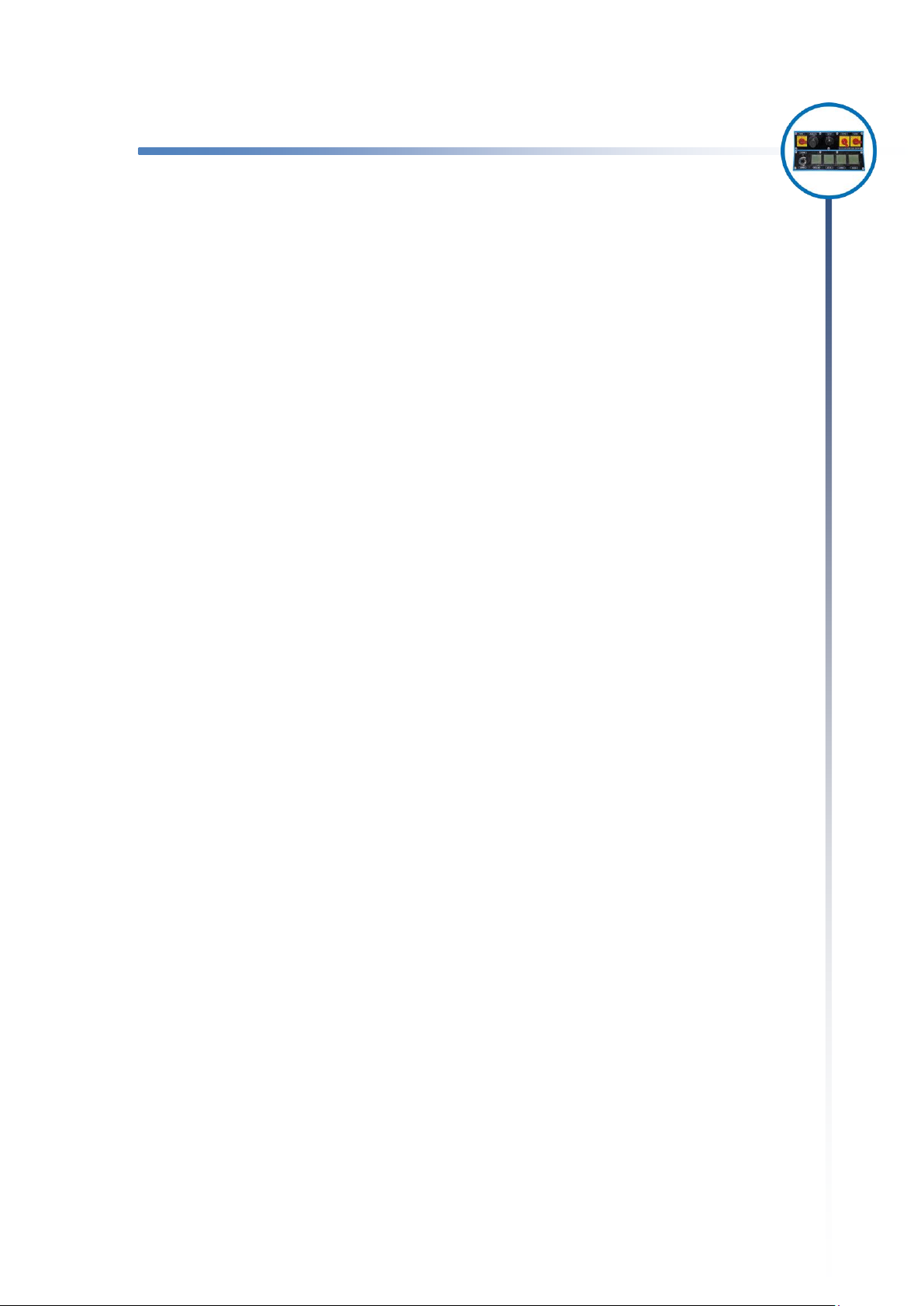

Extended Configuration –Push/Pull with wire on MIG reels

Most commonly used in hard to reach areas such as boilers/vessels where access for the energiser is

limited. Hardboard reel variant can also be offered on the trolley.

Extended Configuration –Push/Pull with wire in Drums

Most commonly used for very long access applications where there is a benefit to remotely site the

energiser away from the spraying area and maintain the benefit of having wire in drums.

NB: Maximum total supplies length is 50M. This can be a combination of 30 + 20 or 40 + 10.

TYPICAL EXTENDED SUPPLIES CONFIGURATION

EXTENDED SUPPLIES

PISTOL SUPPLIES

TOTAL MAX

10M

10/20M

50M

20M

30M

40M

10M

Energiser

Pistol

Extension

Supplies

Pistol

Energiser

Wire in drums

3m max. (2m

std) wire to drive

Extension Supplies

Push/pull drive unit and MIG

reels on power extension

trolley with quick release

connections

Push/pull drive unit on power

extension trolley with quick

release connections

Supplies from wire drive to

pistol

Supplies from wire drive to

pistol

Also available is the Push/Pull with wire on hardboard reels configuration –most commonly used for on-site anti-corrosion

applications where loading of Hardboard reels is more feasible than using drum or MIG material. Hardboard reels are

common in some markets and allow a larger amount of wire to be held on the reel than traditional MIG reels.

Page 17 of 48

SECTION 3

OPERATING THE EQUIPMENT

3.1 Connecting the System

3.2 Connecting using a Powered Extension Trolley

3.3 Preparing to Spray

3.4 Spraying

3.5 Shutting Down

3.6 Remote Pendant

3.7Using Optional Arc Extension

3.8Closed Loop and Open Loop Modes

Page 18 of 48

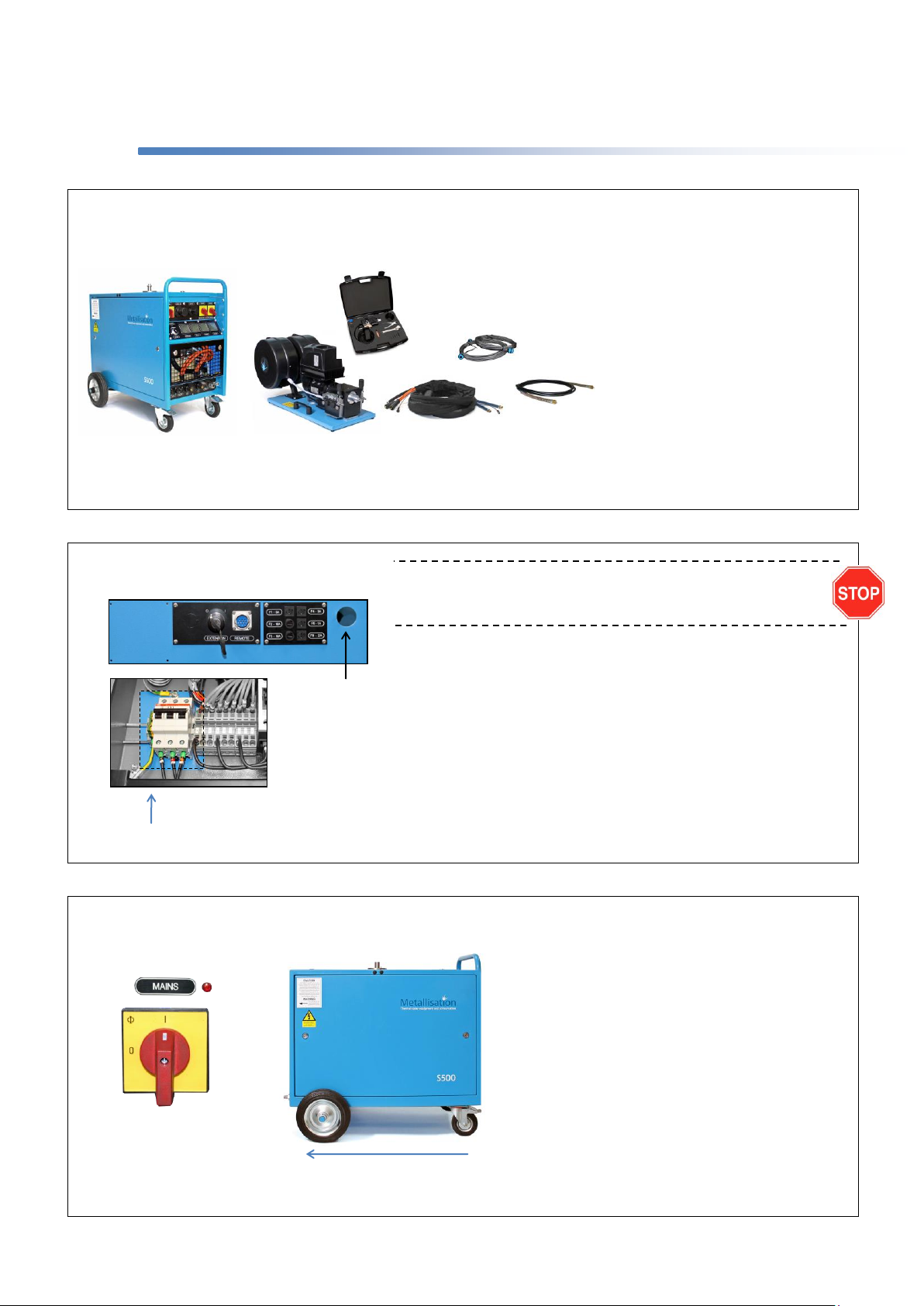

3.1 Connecting the System

1

The Energiser should be connected to an appropriate 3 phase power

supply by a competent qualified electrician in accordance with the

following recommendations:

Position the Energiser to allow unrestricted airflow into / out of the unit and

connect to a mains isolator fuse box ensuring each phase carries suitable

fuses.

Remove the top panel and connect a suitable Power Cable to terminals 1, 2,

3 and Earth.

Check that the input voltage is correct for the unit (Refer to Energiser

Maintenance Manual).

Connect suitable size hose to the air supply. It is strongly recommended that

a filter unit be installed at the mains outlet point. A capacity of 1.5m³ /min @

5 bar (53cfm @ 72.5 psi) is usually adequate.

2

3

Remove any packing materials and ensure that all items are present and the equipment has suffered no damage whilst in transit

(see conditions of sale). NB: if using long supplies with a powered extension trolley also refer to Section 3.2.

A. S500-PLC Energiser.

B. Drive Unit Assembly.

C. Power Cable / Air Hose Assembly.

D. Wire Feed Conduits.

E. Flexible Drive Cable.

F. ARC150 Pistol and Tool Case.

Switch on Power Supply and turn the Mains

Switch on.

Cooling Airflow should pass from front to

back. If air passes from the back to the front

of the Energiser, the fan is running in

reverse.

If this is allowed to continue damage to the

Energiser may occur. Isolate the Power

Supply and reverse two phases of the

input 3 phase.

Once airflow is passing through correctly,

turn the Mains Switch off and refit all panels.

AIRFLOW

Rear of Energiser

A

B

F

E

C

D

Power Terminals

Feed Power

Cable through

opening using a

suitable Gland

Page 19 of 48

Connecting the System continued…

1. Loosen the Pointed Shroud Screw (A) and remove the Shroud (B). Unscrew the Thumb Screw (C) and remove the Hood (D)

from the Pistol.

2. Take one end of the Flexible Drive Cable (E) and carefully position the squared end of the inner into the rear of the Pistol

coupling (F). Apply some grease to the thread on the drive connector and screw home the drive connector ring whilst holding the

Flexible Drive in place. Lightly tighten with the provided spanner. Connect the other end of the Flexible Drive Cable to the DUA

Wire Feed Unit applying grease to the Drive Connector as before.

3. Fit the 2 Cooled Conductors (H) to the Terminal Blocks (G) and firmly tighten. Use one spanner to hold the Terminal Block whilst

tightening the conductor with another to prevent damage to the Terminal Blocks. This joint will carry up to 500 amperes so

ensure they are securely tightened and check periodically.

4. Replace the Hood (D) and Shroud (B).

5. Connect the Control Cable from the supplies pack to the rear of the Pistol (I).

Connect the Control Cables from the DUA Wire Feed Unit (D) to the Energiser.

Ensure that power to the Energiser is isolated.

Connect the Supplies Pack, comprising Power

Cables (A), Motor Drive Cable (B) and Nozzle

Air Hose (C) from the Manifold to the

appropriate connections on the front of the

Energiser.

Polarity of Power Terminals is unimportant

unless spraying pseudo alloys (2 different

materials) - twist power terminals clockwise

firmly to lock.

4

5

‘CLICK’

D

A

A

B

C

D

G

H

C

B

E

F

I

Page 20 of 48

3.2 Connecting using a Powered Extension Trolley

Using a Powered Extension Trolley allows the Energiser to be sited further away from the

spray job whilst still maintaining the power, air and control couplings quick release feature.

PART NO.

DESCRIPTION

ARC150-PET

ARC150 powered extension trolley for ARC150 system

FRONT

BACK

This manual suits for next models

7

Table of contents

Other Metallisation Paint Sprayer manuals