Metasys UNT Series User manual

Application Specific Controllers Technical Manual 636.3

UNT Controller Section

Technical Bulletin

Issue Date 0398

© 1998 Johnson Controls, Inc. 1

Code No. LIT-6363081 www.johnsoncontrols.com

Introduction Page 5

•

Description 5

•

Standards Compliance 6

Configuring the Controller 7

•

Using HVAC PRO for Windows Configuration Tool 7

•

Defining a UNT Control Device Object *7

•

Defining a UNT Control Device in Companion Software 9

Installation Procedures 11

•

Design Considerations *11

•

Tools Needed *11

•

Environmental Information 12

•

Mounting the Controller *12

•

Power Line Wiring Transient Noise Precautions *16

•

I/O and Communications Wiring Transient Noise Precautions 18

Wiring Details 19

•

Power Source and Loads *19

•

Wiring Precautions 21

•

Grounding and Isolation UNT110/111, 120/121, 140/141 22

•

Grounding and Isolation UNT110/111, UNT120/121,

and UNT140/141 with Separate Load Transformer *23

Unitary Controller (UNT)

* Indicates those sections where changes have occurred since the last printing.

2 UNT Controller—Unitary Controller (UNT)

•

Terminal Designations

Page

25

•

Analog Inputs *30

•

Binary Inputs 31

•

Binary Outputs (Triac Jumper Information) *31

•

Analog Outputs 32

•

Zone Bus 32

•

Wiring to Unit Mounted Controls--UNT110/111 and UNT120/121 *33

•

Wiring to RLY050/002 Relays *35

•

Wiring Sensors and Actuators *37

Networking the Controller 45

•

N2 Bus Overview *45

•

Installing the N2 Bus *46

•

Zone Bus Communications *48

Application Examples 51

•

Fan Coil Applications 51

•

Unit Vent Applications *53

•

Packaged Rooftop Applications *55

•

Heat Pump Applications 57

Downloading/Commissioning 59

•

Commissioning Procedures 59

•

Via Zone Bus 59

•

Via N2 Bus 59

* Indicates those sections where changes have occurred since the last printing.

UNT Controller—Unitary Controller (UNT) 3

Troubleshooting Page 61

•

Hardware Installation Inspection 61

•

Tools Needed for Troubleshooting 61

•

Installation Checkout *61

•

Troubleshooting the UNT Controller with HVAC PRO for Windows *67

•

Troubleshooting the N2 Bus 69

•

Zone Bus Troubleshooting--HVAC PRO for Windows 70

Ordering Information 71

•

Johnson Controls Code Numbers 71

•

Vendor Code Numbers *73

Specifications 77

Appendix A: Precautions for Rooftop Installations 79

•

Environmental Information 79

•

Installation Requirements *79

•

Electrical Noise in Rooftop Units *81

•

Nuisance Resets in Rooftop Units *82

•

Considerations for Gas Ignition *84

•

Considerations for Specific Rooftop Units *88

Appendix B: UNT100/101 91

•

What’s Different About the UNT100/101 91

•

UNT100/101 Terminal Designations 91

•

Grounding and Isolation UNT100/101 93

•

Binary Inputs *94

•

Binary Outputs 94

* Indicates those sections where changes have occurred since the last printing.

4 UNT Controller—Unitary Controller (UNT)

UNT Controller—Unitary Controller (UNT) 5

Introduction

The Unitary Controller (UNT) is an electronic device for digital control of

packaged air handling units, unit ventilators, fan coils, heat pumps, and

other terminal units serving a single zone or room. It also can be

configured as a generic Input/Output (I/O) device for basic point

monitoring applications when used within a Metasys® Network.

You can easily configure point inputs and outputs, and software features to

control a wide variety of Heating, Ventilation, and Air Conditioning

(HVAC) equipment applications. The UNT may be used as a standalone

controller or connected to the Metasys Network through a Network

Control Module (NCM) or Companion.

When connected to the Metasys Network, the UNT provides all point

control information to the rest of the network. The devices communicate

through an N2 Bus. For a smaller facility, the UNT can function as a

standalone controller. Figure 1 illustrates the UNT.

1 2 3 4 5 6

1 2 3 4 5 67 8

BINARY INANALOG INPUTS BINARY OUTPUTS

DSI

1 2 3 4 5 6

ANALOG INPUTS

COMMON

ANALOG INPUTS

1 2 3 4 5 6

BINARY INPUT

1 2 3 4

TO

ZONE

STAT

+15VDC

REF

N2-

N2+

24VAC

COM

ZBUS

Z BUS

24VAC

+15VDC

BINARY OUTPUT

1 2 3 4 5 6

COMMON

COMMON

7 8

COMMON

COMMON

24VAC

24VAC

TRACS

COMMON

5

unt-110

Figure 1: Unitary Controller (UNT)

You may use the UNT for unit ventilator, rooftop, heat pump, or fan coil

applications, or as a generic I/O multiplexer and I/O sideloop control.

Each has a different sequence of operation, all of which are covered in the

HVAC PRO for Windows User’s Manual (FAN 637.5).

The Unitary Controller is available in different hardware sets to suit

different environmental and application needs. Table 1 lists the common

features of the different hardware sets. Table 2 lists the differences by

model.

Description

6 UNT Controller—Unitary Controller (UNT)

Table 1: Unitary Controller Hardware Characteristics--

Similarities

Characteristic Description

6 Analog Inputs RTD temperature elements (1000 ohm nickel, platinum, or silicon)

Adjustable 0 to 2k ohm setpoint potentiometers

0 to 10 VDC or 0 to 2 VDC transmitters

4 Binary Inputs (4) 24 VAC input only (24 VAC provided)

(1) Momentary pushbutton from Zone Sensor for temporary occupancy mode (BI 5)

BI 4 may be used as an accumulator input for frequencies less than 2 Hz.

N2 Bus Isolated

Zone Bus

(see Table 2) Removable screw terminal block, Light-Emitting Diode (LED) Indication, 8-pin phone jack

on controller

24 VAC Power in

Termination Removable screw terminal block

N2 Terminations Removable screw terminal block

Table 2: Unitary Controller Hardware Characteristics--

Differences

Characteristic UNT110-1 UNT111-1 UNT120-1 UNT121-1 UNT140-1 UNT141-1

Operating

Temperature

Rating

0 to 52°C

(32 to 125°F) 0 to 52°C

(32 to 125°F) -40 to 52°C

(-40 to 125°F) -40 to 52°C

(-40 to 125°F) 0 to 52°C

(32 to 125°F) 0 to 52°C

(32 to 125°F)

Analog Outputs:

0 to 10 VDC

@ 10 mA

None 2 None 2 None 2

Binary Outputs:

24 VAC Triacs @

0.5A or 0.8A if

total power is

limited

Low or High side

common

selectable

868686

Zone Bus (see

Table 1) Additional

6-pin Phone

Jack

Additional

6-pin Phone

Jack

I/O Terminations Quick

Connects

(Spade Lugs)

Quick

Connects

(Spade Lugs)

Quick

Connects

(Spade Lugs)

Quick

Connects

(Spade Lugs)

Fixed Screw

Terminal

Block

Fixed Screw

Terminal

Block

Available

Premounted in

EWC10, with

24 VAC, 50 VA

Transformer

UNT110-101 UNT111-101 UNT140-101 UNT141-101

The UNT complies with the following standards:

●FCC Part 15, Subpart B, Class A

●IEEE 472

●IEEE 587 Category A

●UL 916, UL 864

Standards

Compliance

UNT Controller—Unitary Controller (UNT) 7

Configuring the Controller

All UNTxxx-1 models require HVAC PRO for Windows. HVAC PRO for

Windows also works with previously released UNT models. This software

tool configures, commissions, uploads, and downloads the UNT database.

Refer to the HVAC PRO for Windows User’s Manual (FAN 637.5) for

more information on configuring the UNT.

In a Metasys Network System, enter data into the Attribute menu to define

a UNT device object.

1. Go to the Network Map on the Operator Workstation (OWS).

2. Double-click the system name to which the new UNT object is to be

added.

3. On the Item menu, click New.

4. Select Type/N2 devices in the Item New dialog box.

itemnew

OK

CANCEL

Accumulator

Analog data

Analog input

Analog output digital

Analog output setpoint

Binary data

Binary input

Binary output

MS data

MS input

Type MS output

Control system

DL/LR group

LC group

PID loop

Fire Zone

L2 devices

N2 devices

S2 devices

Card Reader

Hardware system name:

Hardware object name:

Copy of (System\Object):

UNT - Item New

Figure 2: Item New Dialog Box

Note: The Hardware System and Hardware Object text fields are not

used for this object type.

5. Click OK.

Using

HVAC PRO for

Windows

Configuration

Tool

Defining a UNT

Control Device

Object

8 UNT Controller—Unitary Controller (UNT)

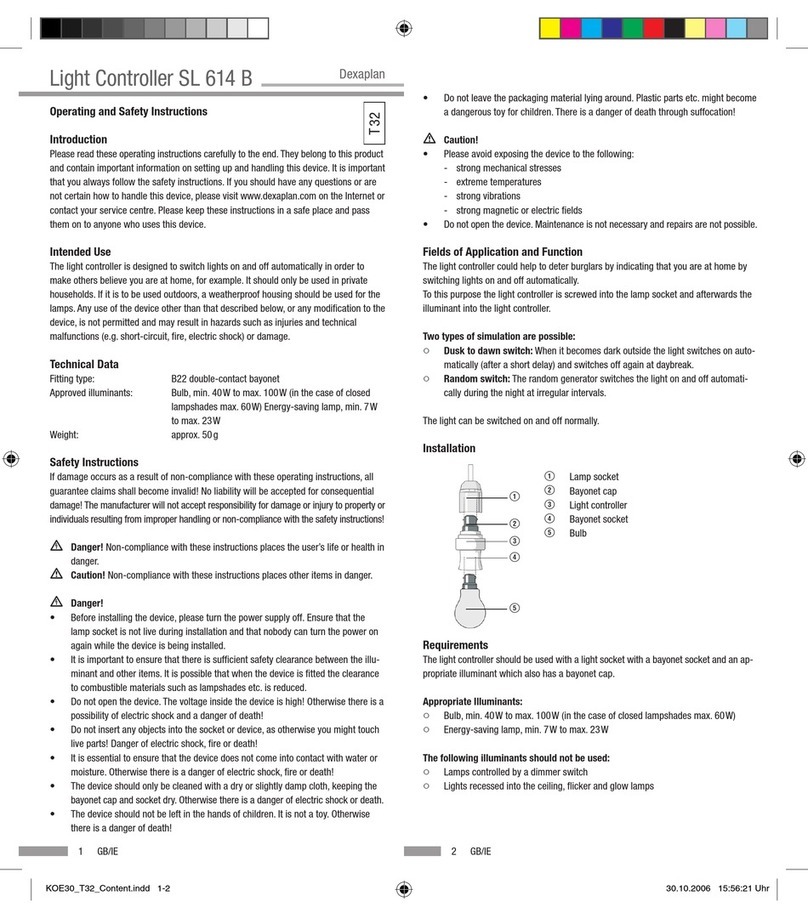

6. Highlight UNT in the Add N2 Device dialog box as shown in Figure 3.

n2dvc

2.

&$1&(/

+DUGZDUH $GG 1 'HYLFH

'HYLFH 7\SH

$+8

'

'&0

'5

';

,)&

/&3

817

Figure 3: Add N2 Device Dialog Box

7. Click OK.

8. Complete the attribute fields in the UNT Definition window

(see Figure 4).

)ORRU

6

\

VWHP 1DPH

2E

M

HFW 1DPH

([SDQGHG ,'

1& 1DPH

*UDSKLF 6

\

PERO

2SHUDWLQ

J

,QVWU

7RZHUB ,

H

elp

I

tem

E

dit

V

iew

A

ction

G

o To A

c

cessory

+DUGZDUH

1 7UXQN 1XPEHU

1 'HYLFH $GGUHVV

3ROO 3ULRULW

\

)OD

J

V

$XWR 'LDORXW

1

&RPP 'LVDEOHG 1

+DUGZDUH

1&

%RRNPDUN

windobj

817 'HILQLWLRQ

Figure 4: UNT Control-Device Object Definition Window

Note: Fill in the blank UNT Definition attribute fields as required.

Specify an N2 Device Address from 1 to 255. Default values in the

remaining attribute fields may be accepted or changed.

UNT Controller—Unitary Controller (UNT) 9

Table 3 explains the blank attribute fields. The Operator Workstation

User’s Manual (FAN 634) describes the general procedures for

entering and modifying data.

Table 3: Blank UNT Object Attributes

Attribute Description Entry Values . . .

Object Name Identifies the object

(i.e., UNT1). The object

name cannot be duplicated

in the system.

1 to 8 alphanumeric

characters

Expanded ID Further identifies the object

(i.e., Garage Level Heater) 0 to 24 alphanumeric

characters

(optional)

9. On the Item menu, select Save to save the new UNT object and add

the object to the NCM database.

10. Upload the NCM to make an archive copy of the new object. Refer to

the Operator Workstation User’s Manual (FAN 634), Uploading from

the NCM.

To define a UNT control device in Companion, refer to the Metasys

Companion Technical Manual (FAN 628.1).

Defining a UNT

Control Device

in Companion

Software

10 UNT Controller—Unitary Controller (UNT)

UNT Controller—Unitary Controller (UNT) 11

Installation Procedures

Instructions for installing the UNT and its accessories are detailed in this

section. The number and types of components (sensors and actuators) used

with the UNT will vary according to application. Analyze the proposed

installation for logical locations to place these devices and draw an

inventory based on that study. Information on available accessory devices

is in the Ordering Information section of this technical bulletin.

Decide how close the UNT can be to the air handling equipment while still

allowing adequate room for installation and maintenance accessibility.

Also take into consideration any existing power sources or communication

lines. The UNT must be secured to a solid wall and not to any vibrating

surface.

IMPORTANT: Do not mount the UNT near high voltage or

electrically noisy devices. Refer to Appendix A:

Precautions for Rooftop Installations.

For a typical installation, you need the following:

•HVAC PRO for Windows software, current release

•IBM® PC-compatible laptop computer

•Microsoft® Windows® (3.xx or 95)

•AS-CBLPRO-2 (for Zone Bus downloading, uploading, and

commissioning) or MM-CVT101-0 (for N2 downloading, uploading,

and commissioning)

•two screwdrivers (1/8 in. and 1/4 in. flat-blade)

•drill

•(optional) AS-ZTU100-1 (Zone Terminal unit)

Note: The AS-ZTU100-1supports both AS-UNTxxx-0 and

AS-UNTxxx-1models. The AS-ZTU100-0supports

AS-UNTxxx-0models only.

Design

Considerations

Tools Needed

12 UNT Controller—Unitary Controller (UNT)

The installation site of the UNT must meet the following environmental

standards:

•The atmosphere must be free of explosive vapors and escaping gases.

•The atmosphere must be free of exposure to corrosive chemical or salt

vapors that might damage electrical equipment.

•For UNT100/101, UNT110/111, and UNT140/141 series

controllers, the temperature must be maintained between

0 and 52°C (32 and 125°F) with relative humidity (non-condensing)

maintained between 10 and 90 percent.

•For UNT120/121 series controllers used with outdoor rooftop

applications, the temperature must be maintained between

-40 and 52°C (-40 and 125°F) with relative humidity maintained

between 10 and 90 percent. Some intermittent condensation is

tolerable. This operating temperature range is possible in the

UNT120/121 series controllers due to the heater, coated circuit board,

and BZ-1000-7 size enclosure.

The UNT is commonly packaged either in an enclosure provided by the

installation contractor, or in an AS-ENC100-0 or EN-EWC10-0 enclosure.

The UNT140/141-101 and UNT110/111-101 come mounted in an EWC10

enclosure with a 50 VA transformer. The controller requires a flat

mounting surface area to match its dimensions.

The UNT controller has the following dimensions:

•165 x 163 x 56 mm (6.5 x 6.4 x 2.2 in.) H x W x D without enclosure

•173 x 185 x 119 mm (6.8 x 7.3 x 4.7 in.) H x W x D with the

AS-ENC100-0 enclosure

•229 x 406 x 191 mm (9.0 x 16.0 x 7.5 in.) H x W x D with the

EWC10 or UNTxxx-101 version

Allow enough room to install the enclosure and conduit for wiring

terminations to the controller.

Environmental

Information

Mounting the

Controller

Physical

Dimensions

UNT Controller—Unitary Controller (UNT) 13

The UNT120/121 low temperature rated controller must be installed in an

enclosure as suggested below, unless it is mounted within the enclosed,

low voltage electrical compartment of the mechanical unit being

controlled. The BZ-1000-7 enclosure is the common package for a

UNT120/121 mounted in the air stream or in the mixed air chamber of a

mechanical unit.

The BZ-1000-7 enclosure is the recommended size for optimum

performance of the UNT120/121. Venting the BZ-1000 enclosure

(possibly removing unused knockouts), using the AS-ENC100-0 or

EN-EWC10-0, or using a larger enclosure is recommended for

environments that regularly exceed 32°C (95°F).

The UNT120/121 series controller has the following dimensions:

•165 x 163 x 56 mm (6.5 x 6.4 x 2.2 in.) H x W x D without enclosure

•259 x 249 x 76 mm (10.2 x 9.8 x 3 in.) H x W x D with the

BZ-1000-7 enclosure

•229 x 406 x 191 mm (9.0 x 16.0 x 7.5 in.) H x W x D with the

EWC10 or UNTxxx-101 version

Before installation, position the controller and enclosure on the proposed

mounting surface to ensure that the calculated mounting area is correct.

Precise distance measurements can be made between controller terminals

and sensor/actuator mounting points on the air handling equipment if the

equipment is in place. Confirm electrical power source and conduit

requirements at this time.

Note: You can install a UNT100/101, UNT110/111, or UNT140/141

series controller in a control panel, or in an AS-ENC100-0 or

EN-EWC10-0 enclosure. You must enclose the UNT120/121

series controller in a BZ-1000-7 enclosure or another enclosure of

comparable dimensions.

Mount the UNT in a convenient location using the predrilled mounting

holes. The controller must be mounted vertically on a wall or panel where

it can be easily wired through the enclosure cover. This also applies to

remote location packages.

Enclosures for

Mounting a

UNT 120/121

Positioning

14 UNT Controller—Unitary Controller (UNT)

4

42

Top / Bottom

Side

UNT Enclosure (Cover)

Do not use this knockout.

Otherwise, controller will

be in the way of wiring.

untencl

5

3

UNT

1

Figure 5: Installing the UNT Controller in ENC100 Enclosure Kit

To install the UNT in an ENC100 enclosure kit (see Figure 5), use the

following procedure:

1. Use a flat-blade screwdriver and pliers to remove the necessary wire

passage knockouts ①.

2. Position the enclosure firmly against the mounting surface and mount

it with the appropriate screws.

3. Secure the UNT ②inside the enclosure kit ③, using the

three mounting tabs ④on the sides of the controller board base.

4. Attach the enclosure cover ⑤after installing the wiring.

Installing the UNT

in a ENC100

Enclosure Kit

UNT Controller—Unitary Controller (UNT) 15

The UNT can be directly mounted into an EWC10 enclosure. You may

also purchase the UNT110/111 or UNT140/141 premounted in an EWC10

enclosure with a 24 VAC 50 VA transformer. When the UNT is

premounted in an EWC10 enclosure with a 50 VA transformer, the model

number will be UNTxxx-101 rather than UNTxxx-1. For instructions on

mounting the enclosure to a wall, see the Application Specific Controllers

Technical Manual (FAN 636.3), the Accessories tab, the Universal

Packaging Module Technical Bulletin (LIT-6363070).

untpwer2

Low Voltage

Wiring Trough

Figure 6: UNT Premounted in EWC10, with

50 VA Transformer (UNTxxx-101)

To mount the UNT in the EWC10, use the following procedure:

1. Position the terminals of the UNT toward the low voltage wiring

trough located on the left side of the enclosure (see Figure 6).

2. Align the three mounting holes in the base of the controller with the

holes in the backbone of the enclosure. On the side with

four mounting holes, use the two outside holes for mounting in the

EWC.

3. Secure the controller with three No. 8 x 1 in. screws. For best results,

use a plastite type thread. A thread forming or sheet metal type thread

may also be used.

UNTxxx-101

Mounting a UNT

in a EWC10

16 UNT Controller—Unitary Controller (UNT)

The standard UNT, when powered by any typical separate isolation

transformer or stepdown transformer, operates reliably in an electrical

environment defined as Location Category A by the IEEE 587 Standard;

that is, when installed more than 30 feet from electrical distribution

panels or major bus and feeder systems in industrial plants.

IEEE 587 Location Category A power line surge/noise level is specified at

6 kV, 500 A (Normal Mode Ringwave).

The UNT exceeds the Category A specification by meeting these surge

levels as well:

IEEE-587 style Common Mode Pulse 3 kV

IEEE-587 style Normal Mode Pulse 1.5 kV

IEEE-472 style Common Mode Ringwave 1.5 kV

IEEE-472 style Normal Mode Ringwave 500 V

When the controller is installed within 9 m (30 ft) of electrical distribution

panels or major bus and feeder systems in industrial plants, you must take

further precautions to prevent unwanted binary output cycling, resetting,

or other possible controller malfunctions. This electrical environment is

defined as Location Category B by the IEEE 587 Standard.

You can use the following method to prevent electrical noise from

adversely affecting the controller:

•Connect an MOV (Metal Oxide Varistor) across the UNT supply

transformer primary. The MOV must be rated appropriately for the

line voltage. Use the list in Table 4 to select the correct MOV sold

through your electronics parts distributor.

The UNT meets the following power line surge/noise standards when you

correctly apply the MOV as described.

IEEE-587 Common Mode Pulse 1.5 kV

Normal Mode Pulse 6 kV

Normal Mode Ringwave 6 kV

IEEE-472 Common Mode Ringwave 1.5 kV

Normal Mode Ringwave 500 V

Note: The 50 VA split bobbin transformer in the EWC15 or -101 model

UNT provides additional surge/noise immunity.

For more information, refer to Appendix A: Precautions for Rooftop

Installations in this technical bulletin.

Power Line

Wiring

Transient Noise

Precautions

Surge Levels

UNT Controller—Unitary Controller (UNT) 17

Table 4: MOV Selection Table

Power Transformer Primary Voltage

120 VAC 208 to 240 VAC 277 VAC 347 VAC

Minimum

Continuous

Voltage Rating

130 to 135 VRMS 250 to 280 VRMS

Only 250V types listed 300 to 320 VRMS 385 VRMS

Minimum Energy

Rating 30 Joules 55 Joules 80 Joules 85 Joules

Minimum Peak

Current

(8 x 20 micro

second pulse)

4,000 Amperes 4,000 Amperes 4,000 Amperes 4,000 Amperes

UL Recognized Required Required Required Required

Harris V130LA10A

V130LA20A*

V130LA20B*

V250LA20A

V250LA40A*

V250LA40B*

None None

Iskra V130K14

V130K20* V250K14

V250K20* V300K14

V300K20* V385K14

V385K20*

Malda D6321ZOV131RA15*

D6521ZOV131RA20*

D6921ZOV131RA09

D6321ZOV251RA90*

D6521ZOV251RA130*

D6921ZOV251RA72

D6321ZOV301RA105*

D6521ZOV301RA150*

D6921ZOV301RA80

None

MalloryVSAC14DK201U

VSAC20DK201U* VSAC14DK391U

VSAC20DK391U* VSAC14DK471U

VSAC20DK471U* VSAC14DK621U

VSAC20DK621U*

Marcon TNR15G211KM

TNR23G201KM*

TNR23G211KM*

TNR15G391KM

TNR23G391JM*

TNR23G391KM*

TNR15G471K

TNR23G471K* None

Oneida(CKE) OZ130LA10A

OZ130LA20A*

OZ130LA20B*

OZ21L221

0216NR14-3

0216NR20-4*

OZ250LA20A

OZ250LA40A*

OZ250LA40B*

OZ21L471 None

Panasonic ERZ-C14DK201U

ERZ-C20DK201U* ERZ-C14DK391U

ERZ-C20DK391U* ERZ-C14DK471U

ERZ-C20DK471U* ERZ-C14DK621U

ERZ-C20DK621U*

Phillips 2322-595-51316 2322-595-52516 2322-595-53016 2322-595-53816

Siemens S14K130

S20K130* S14K250

S20K250* S14K300

S20K300* S14K385

S20K385*

Stetron 0216NR14-3

0216NR20-4*

0216NR20DB*

0390NR14-3

0390NR20-4*

0416NR14-3

0416NR20-4*

0620NR14-3

0620NR20-4* 0620NR14-3

0620NR20-4*

Thomson VE17M00131K

VD24M00131K VE17M00251K

VD24M00251K VE17M00301K

VD24M00301K None

* Indicates the preferred model if several are listed.

18 UNT Controller—Unitary Controller (UNT)

The I/O wiring and N2 Bus must be “clean,” without electrical noise

transients from nearby lighting, heavy equipment switching, or inductive

loads being driven.

For the N2 Bus, the Transient Eliminator, model TE/JC04C12, made by

Advanced Protection Technologies (APT) is recommended. Refer to the

Metasys Network Technical Manual (FAN 636), the N2 Communications

Bus Technical Bulletin (LIT-636018), for more information.

I/O and

Communications

Wiring

Transient Noise

Precautions

UNT Controller—Unitary Controller (UNT) 19

Wiring Details

This section details the special precautions and grounding procedures you

must observe when installing the UNT.

!

WARNING: Possible Equipment Damage or Electrical Shock.

To avoid damaging equipment or suffering electrical

shock, ensure that all power supplies to the system

have been disconnected prior to wiring installation.

The Complementary Metal Oxide Semiconductor

(CMOS) circuits used in the controller are static

sensitive. Use static protection (anti-static) mats

and/or grounding straps when working on or near

internal circuitry.

The power transformer used must comply with:

•CSA 22.2 No. 205

•NEMA ICS 2, Part 2, 230

The power to each UNT must be limited to 3 amperes or less. However, if

you use one low voltage power trunk to power multiple controllers,

follow these precautions:

•Ensure that polarity is maintained at each 24 VAC connection.

•Enclose 24 VAC power trunks with greater than 4 amperes (100 VA)

in conduit as required by the National Electric Code (NEC).

•Do not share a UNT’s power transformer with a Companion Panel or

any other device with a full-wave rectifier in its power supply. (UNTs

use “half-wave” rectification. Half-wave circuitry and full-wave

circuitry must not share the same transformer.)

•Consider all the actual loads as well as the basic load of the controller

when determining the system load.

Notes: Some local electrical codes require that the secondary common of

the stepdown transformer be connected to earth ground (typically

on units which are powered by greater than 150 VAC).

The M100 draws 20 VA if using common power for the controller

and the M100 actuator. It is recommended that each M100 use its

own 24 VAC isolation transformer.

Power Source

and Loads

20 UNT Controller—Unitary Controller (UNT)

IMPORTANT: Any individual binary output (triac) can drive up to

800 mA when you limit the total 24 VAC power

draw. You must limit the power draw of a controller

and its load to avoid heat dissipation problems.

The total 24 VAC power draw of a UNT installed in

an ENC100 or similar size box must be limited to a

maximum of 40 VA.

The total 24 VAC power draw of a UNT mounted in

an open air environment must be limited to a

maximum of 75 VA.

Tables 5 and 6 will assist you in determining the total 24 VAC power

draw of your system.

Table 5: UNT Power and Load Specifications

System Loads Power Draw

UNT with Sensors/Transmitters 10 VA (400 mA)

25 VA for UNT120/121 (due to heater)

BO Load

Relay, Contactor, Solenoid, Incremental Actuator*

Maximum allowable load for any individual binary

output (triac) is 19 VA** (800 mA at 24 VAC).

Minimum required load for each binary output

(triac) used is 1.2 VA (50 mA at 24 VAC).

Relay loads less than 50 mA may cause triac/relay

chattering. If necessary, use a 1k ohm, 2 watt

resistor across the relay coil.

Triac BOs cannot drive loads which use DC

currents, such as a device which has a full-wave

rectifier. Triacs can drive only AC resistive or

inductive loads, i.e., AC relays, contactors, and

actuator motors. If the driving of a DC device is

required, a pilot relay must be used to isolate the

triac.

Refer to specific product

documentation.

AO Load

Actuator

Maximum allowable load for each AO is 10 mA

@ 10 VDC with a minimum load resistance of

1,000 ohms.

See Table 6.

Zone Terminal or CBLPRO 1.2 VA (50 mA)

* Actuator VA requirements found in Table 6.

**With total controller power limited as described previously.

This manual suits for next models

6

Table of contents

Other Metasys Controllers manuals