Metasys TC-9100 Series Service manual

System 91 Manual

TC-9100 Universal Controller

Technical Bulletin

Issue Date 0306

©2006 Johnson Controls, Inc. 1

Order No. MN-9100-2120

TC-9100 Universal Controller

Introduction Page 3

•Controller Hardware Models 4

•Modes of Operation 5

Software Configuration 9

•Analog Input Configuration (AI1 to AI4) 10

•Digital Input Configuration (DI1 and DI2) 13

•Output Module Configuration (OCN1 to OCN7) 14

•Programmable Module Configuration (PM1 to PM6) 24

•External Analog Input Configuration (XAI1 to XAI6) 39

•Low Limit (Anti-freeze) Module Configuration 40

•Summer/Winter Compensation Module 41

•Auto-dial Feature 42

•Supervisory Functions and Configuration 43

•Configuration for a TM-9180 Room Command Module 47

Installation 49

•Mounting 49

•Wiring 50

•Jumper and Switch Selections 56

•Startup 57

•Commissioning 57

Specifications & Technical Data 59

•Ordering Codes 60

2 Technical Bulletin—TC-9100 Universal Controller

Appendix 1: TC-9100 Item Descriptions and Tables 61

•Table 1: Item List 63

•Table 2: Programmable Module Algorithms 77

Appendix 2: Configuration Worksheets 85

•Worksheet 1: Connections 86

•Worksheet 2: Configuration Parameters – Programmable Modules 87

•Worksheet 3: Configuration Parameters – Input/Output and General 88

Technical Bulletin—TC-9100 Universal Controller 3

Introduction

The TC-9100 Universal microprocessor-based DDC Controller provides

room temperature control and is designed for use with HVAC terminal

units having a heating and/or cooling function, with and without fan-

assisted air circulation or flow control by damper positioning.

Applications include fan coil units, hot-water radiators and cold ceilings,

variable air volume (VAV) units, and small air handling units.

The controller is fully configurable to provide a wide range of control

strategies using its four analog inputs to measure temperatures and flow

rates, its two digital inputs to detect environmental conditions such as

space occupancy, window opening or fan failure, and its seven analog or

binary outputs to control heating, cooling and air flow control devices. A

RS-1100 or TM-9180 series room command module provides set point

adjust capabilities and a temporary occupancy override of the

COMFORT, STANDBY and NIGHT operating modes of the controller.

The TM-9180 can also provide local time scheduling of the operating

mode when the controller is not overridden by a supervisory system. The

controller has a low limit temperature protection feature and automatic set

point compensation for the winter and summer seasons.

When connected to a communications bus, the controller provides

operating data to a supervisory system, which also allows a user to

modify control set points and to set the operating mode of the controller

either manually or according to a time schedule.

The TC-9100 controller is part of the System 91 series of controllers and

is fully compatible with the Metasys network system. The compact size

of the controller makes it easy to mount within the terminal unit housing,

above a false ceiling or within a small control cabinet.

2667 2335

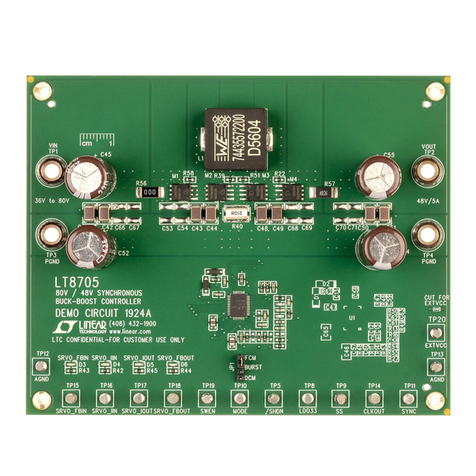

Figure 1: TC-9100 Universal

Controller

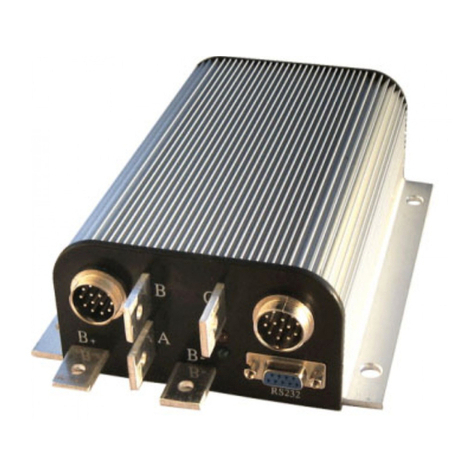

Figure 2: RS-1160 Room

Command Module

4 Technical Bulletin—TC-9100 Universal Controller

2333

Figure 3: TM-9180 Room Command Module

Note: The TM-9180 Room Command Module is only available as a

replacement part from July 2006.

There are two models of the TC-9100 Universal Controller. Each model

is available with fixed terminals or separable terminals.

Table 1: Controller Inputs and Outputs

Inputs/Outputs Qty. Type of Signal Model

Analog Inputs 4 0 - 10 VDC

Digital Input 1

Digital Input 2

1

1

Dry contact or HX-9100-8001

Condensation Sensor

Dry contact

Models 1 and 2

Mode Contact

(Occupancy Button)

1 Dry momentary contact

LED Mode Signal 1 Voltage for LED in RS-1100

Series

Analog Output 1a/b

(Heating/Cooling)

Analog Output 2

2

1

0 - 10 VDC

0 - 10 VDC

Model 1 only

Digital Outputs

(PAT, DAT, 2-Stage

On/Off, and On/Off)

5 Triac rated at 24 VAC

(switched only - no power

supplied)

Digital Outputs

(PAT, DAT, 2-Stage

On/Off, and On/Off)

7 Triac rated at 24 VAC

(switched only - no power

supplied)

Model 2 only

Power Supply 1 24 VAC Models 1 and 2

For detailed information about the physical characteristics of the inputs

and outputs, refer to the Specifications and Technical Data section further

in this document.

For detailed information about the configuration possibilities, refer to the

appropriate Software Configuration section further in this document.

Controller

Hardware

Models

Technical Bulletin—TC-9100 Universal Controller 5

Note 1: Digital inputs 1 and 2 may be used with any sensor that

provides a dry (voltage-free) and isolated contact, suitable for

low-voltage (24 V) switching. Digital Input 1 may also be used

with the Johnson Controls Condensation Sensor, code number

HX-9100-8001. No other condensation sensor may be used

except a sensor which provides a dry contact that is isolated

from all other electrical circuits.

Note 2: The TC-9100 controller is compatible with the RS-1100 series

of room modules for room temperature, remote set point and

temporary occupancy mode change inputs. The controller is

also compatible with the TM-9180 Room Command Module,

which also provides 3-speed fan override and operating mode

override. Only one RS-1150/RS1160 series module with an

occupancy mode button or only one TM-9180 may be

connected to the controller.

The TC-9100 Universal Controller can operate in any of the following

modes:

•Standalone mode

•Alternate mode

•Supervisory mode

•Low Limit (Anti-freeze) mode

•Summer/Winter Compensation mode

•Auto-dial mode

When the TC-9100 Universal Controller is not connected to a supervisory

system via the communications bus, nor to a TM-9180 Room Command

Module with LCD display, it will operate in one of three operating

modes, which are indicated on the RS-1150/RS-1160 Room Command

Module, as follows:

•COMFORT (room occupied): LED on steady

•STANDBY (room unoccupied): LED flashing

•OFF (room not in use): LED off

The Operating mode is determined by the status of the digital inputs when

configured as Window Contact or Occupancy Sensor, and may be

modified by the occupancy button on the RS-1100 series Room

Command Module as shown in Table 2. When not assigned to a digital

input, the Window Contact function is assumed to be Window Closed,

and the Occupancy Sensor function is assumed to be Occupied.

Modes of

Operation

Standalone

Mode

6 Technical Bulletin—TC-9100 Universal Controller

Table 2: Standalone Modes

Input States: Resulting Modes:

Window Contact Occupancy Sensor Operating Mode

Alternate Mode

(Occupancy

Button)

Open No Action OFF No Action

Closed Occupied COMFORT STANDBY

Unoccupied STANDBY COMFORT

Depending on the way that the controller is configured, the COMFORT,

STANDBY, and OFF modes may change the Working Set Point (WSP)

of any control module, and the OFF mode may be configured to override

the output of each control module to close off the heating, cooling, or air

flow devices.

For further details, refer to the subheading Controller Algorithms 1-6 –

General under the Programmable Module Configuration section of this

document.

Controller Digital Output Number 7 may be configured to switch on in

COMFORT mode for auxiliary circuit control, such as individual room

lighting. For further details, refer to the Output Module Configuration

section of this document.

The Alternate mode is activated and reset by a momentary contact

connected to the mode input terminals of the controller. This contact is

provided by the occupancy button of the RS-1150/RS-1160 Room

Command Module.

The occupancy button on the TM-9180 Room Command Module can also

provide this function via the room command module communication

interface instead of the hard-wired contact.

When pressed for approximately one second, the occupancy button

changes the operating mode of the controller to the Alternate mode, or

back to the normal operating mode as shown in tables 2 and 3. The

COMFORT (T) mode is active only for a period of one or two hours

(dependent on the configuration: see the Supervisory Mode Configuration

section), after which the controller automatically resets to the normal

operating mode.

Note: Only one RS-1100 module with an occupancy button or only one

TM-9180 may be connected to the controller.

When connected to a supervisory system via the communications bus, or

to a TM-9180 Room Command Module, the controller may operate in

COMFORT, STANDBY or OFF operating modes, and additionally in

NIGHT mode. These modes are indicated on the TM-9180 or RS-1100 (if

connected), as follows:

•COMFORT (room occupied): LED on steady,

•STANDBY (room unoccupied): LED flashing,

Alternate Mode

Supervisory and

TM-9180 Modes

Technical Bulletin—TC-9100 Universal Controller 7

•NIGHT (scheduled or manually set unoccupied): LED off,

•OFF (room not in use): LED off.

The Operating modes are set by the supervisory system and are modified

by the Window Contact and Occupancy Sensor inputs (if configured),

and by the occupancy button on the room command module, as shown in

Table 3. The Window Contact input always switches the controller to

OFF mode, and a MANUAL mode command from the supervisory

system overrides the action of the Occupancy Sensor and occupancy

button.

Table 3: Supervisory Modes

Input States: Resulting Modes:

Window

Contact

Supervisory Mode Occupancy

Sensor

Operating

Mode

Alternate Mode

(Occupancy

Button)

Open Any Mode No Action OFF No Action

OFF Occupied OFF OFF

Unoccupied OFF OFF

NIGHT Occupied NIGHT COMFORT (T)

Unoccupied NIGHT COMFORT (T)

STANDBY Occupied STANDBY COMFORT

Closed Unoccupied STANDBY COMFORT (T)

COMFORT Occupied COMFORT STANDBY

Unoccupied STANDBY COMFORT

OFF/MANUAL OFF

NIGHT/MANUAL No Action NIGHT No Action

STANDBY/MANUAL STANDBY

COMFORT/MANUAL COMFORT

Depending on the way that the controller is configured, the COMFORT,

STANDBY, NIGHT and OFF modes may change the Working Set Point

(WSP) of any control module, and the OFF mode may be configured to

override the output of each control module to close off the heating,

cooling, or air flow devices.

For further details, refer to the subheading Controller Algorithms 1-6 –

General under the Programmable Module Configuration section of this

document.

Supervisory systems available from Johnson Controls include the

NCM 311/361 in the Metasys Network System, the CS-9105 Control

Station, and the Companion System.

Note: A supervisory system which is setting the operating mode of the

controller will have priority over a locally connected TM-9180

Room Command Module.

8 Technical Bulletin—TC-9100 Universal Controller

The TC-9100 Universal Controller may be configured to set any of the

analog outputs to the maximum level, or switch any of the digital outputs

on, when a low level in an analog input is sensed. This feature is normally

used for low-limit temperature or anti-freeze protection in rooms by

switching on heating devices. The Low Limit mode overrides the OFF

mode of the controller and the manual override of the 3-speed fan

outputs.

Note: As the Low Limit mode is dependent on application and

configuration, the equipment installer is responsible for ensuring

that appropriate additional anti-freeze devices have been installed

to cover all possible low temperature situations which may cause

equipment damage.

For further details, refer to the Low Limit Module Configuration section

of this document.

The working set points in the TC-9100 Universal Controller may be

increased in summer and decreased in winter to provide additional energy

savings when it is possible and appropriate to modify comfort conditions

in the controlled space.

Alternatively, in winter, the set points may be increased to offset the

effect of “cold radiation” from external wall surfaces.

For further details, refer to the Summer/Winter Compensation Module

Configuration section of this document.

The TC-9100 Universal Controller may signal to a supervisory system

that any one or more of the following off-normal conditions has occurred:

•Analog Input High or Low Limit alarm

•Window open

•General alarm

•Low Limit (Anti-freeze) mode is active.

This signal may be used to initiate further actions, such as an automatic

dial connection to a remote monitoring system. The N2 Dial Module

(NDM101) within the Metasys System provides this function. For further

details, refer to the section of this document titled Auto-dial Feature.

Low Limit

(Anti-freeze)

Mode

Summer/Winter

Compensation

Auto-dial Mode

Technical Bulletin—TC-9100 Universal Controller 9

Software Configuration

The software operating system of the TC-9100 Universal Controller

contains a number of modules which can be given operating and

configuration parameters and connected together to perform the desired

control function. Some of the modules condition physical inputs to

provide data to other controlling and calculation modules, and some

modules control the physical outputs, and the behaviour of all modules is

determined by the operating parameters. The modules are shown

graphically in Appendix 2 – Worksheet 1 – Connections, and the

configuration of each type of module is described in detail in the

following sections.

Parameter and connection data are stored in memory locations known as

“Items.” A complete list of all the Items is given in Appendix 1 – Table 1.

All Items have an address (given in hexadecimal and decimal notation)

and a tag for easy identification. Some Items contain analog information

in the form of numbers, some contain logical information in the form of

eight binary states (one byte) or 16 binary states (two bytes), and some

contain an integer number which is the address of another Item and

defines a “connection” between modules. The source of the connection is

the Item address of the analog output of a module and the destination of

the connection is the Item address of an analog input of a module. The

input (or destination) Items are identified by a tag with the “@” character.

For example, the output of the module which measures Analog Input

Number 1 is found at Item Address 01, and has the tag name AI1. The

first input of Programmable Module Number 5 is found at Item Address

54 (hex) or 84 (decimal), and has the tag name PM5I1@. By entering the

value 01 in Item Address 54 (hex), a connection is made, whereby the

value of AI1 is transferred to the first input of Programmable Module

Number 5 as shown below:

01

PM5I1@AI1

01

54

Value

Connections to output modules are specified as part of the configuration

parameter item for each module. The first 5 bits contain the Item address

of the source of the connection. For example, when the Item Address 0A

(hex) is entered into the first 5 bits of Item Address 78 (hex) or 120 (dec),

the following connection is defined:

0A

OCN3OCM1

0A

78 Output 3Value

Worksheet 1 in Appendix 2 can be used to develop a control strategy by

making all the required connections graphically. The connection

information can then be entered into the Item address locations in

Worksheets 2 and 3. The parameters and data to define the operation of

the various software modules can also be entered into these worksheets.

Preparing a

Configuration

10 Technical Bulletin—TC-9100 Universal Controller

When the worksheet has been completed, the data can be physically

entered into the controller using the SM-9100 Service Module, which

plugs into the side of the controller (or by connecting a PC to the N2 Bus

serial link and running the M9101 Configuration and Commissioning

Software Package). Using either tool, the data for each Item address is

entered in turn. When complete, the controller operation may be

monitored by displaying the Item addresses that contain the dynamic

parameters of each module of the controller, such as analog input values,

programmable module output values, or the Controller modes of

operation.

Note: It is recommended that the controlled equipment be switched off

when configuration parameters are being changed to avoid any

unexpected control actions.

The TC-9100 Universal Controller has four analog inputs, each accepting

a 0 to 10 VDC input signal. The inputs are conditioned in software using

configuration parameters to provide a numerical value representing the

physical quantity being measured, such as temperature, relative humidity,

or flow rate. The numerical value can be used as an input to a

programmable module (configured as a Control Module or a Calculation

Module), and can be read by a supervisory system. Alarm limit values

may be set in the controller, as fixed configuration parameters or by a

supervisory system, and the high or low alarm status of each analog input

can be read by a supervisory system.

The parameters to be defined for each analog input are listed below.

Refer to Appendix 2 – Worksheet 3, or Appendix 1 – Table 1: Item List,

for the Item addresses. Note that nin the tag names in the table below

stands for the analog input number from 1 to 4.

Table 4: Analog Input Configuration Items

Item Tag Type Description

IOPn 1 Byte

Bit 4

Bits 7,6,5

Bits 8,3,2,1

Analog Input Options that define the conditioning of the

physical signal.

Defines the physical input type and must be set to 0 (zero)

for the voltage input.

000 = Linear Range (0 to 10 V)

010 = Square Root Range (0 to 10 V)

011 = Linear Range (2 to 10 V)

Set to 0 = not used.

HRIn Number

High Range for AIn: value represented by the highest

input signal (10 VDC). (See LRIn for analog value

calculation resulting from High and Low Range values.)

Continued on next page...

Entering a

Configuration

Analog Input

Configuration

(AI1 to AI4)

Configuration

Parameters

Technical Bulletin—TC-9100 Universal Controller 11

Item Tag

(Cont.)

Type Description

LRIn Number

Low Range for AIn: value represented by the lowest input

signal (0 or 2 VDC). This value must be 0 for an input with

the square root option. Use OFSn for zero offset correction.

The analog value is calculated as follows:

Linear:

AI = (PI% + OFS) / 100 x (HRI - LRI) + LRI

Square Root (LRI = 0):

(

)

AI (PI% + OFS) 100 HRI=×

where:

AI = Analog value

PI% = Analog input in % of the physical input range

(10 VDC, or 8 VDC for 2 to 10 V linear)

OFS = Offset Value

OFSn Number

Offset Value for AIn:

value added to the analog input in %

of the physical input range. This parameter is normally

used to offset an input to the square root range from a

differential pressure transducer, for example, where the

output of the transducer is not at “true zero” (0 or 2 VDC)

when the physical differential pressure is zero. (See LRIn

for analog value calculation using OFSn.)

FTCn Number

Filter Time Constant:

(in seconds) to reduce cyclic

instability or rapid changes in the analog input. The effect

of the filter is as follows:

AIt= AIt-1 + [1 / (1 + FTC)] x (AI - AIt-1)

where:

AIt= Filtered analog value at current time

AIt-1 = Filtered analog value at previous poll

AI = Actual analog value at current time

If FTC = 0:

AIt= AI

HIAn Number

High Alarm Value for AIn:

if no high limit is required, enter

a number greater than HRIn.

LOAn Number

Low Alarm Value for AIn:

if no low limit is required, enter

a number lower than LRIn.

If an analog input is configured but not connected to a sensor, install a

wire jumper between the input terminal and the analog common terminal

to keep the analog input at its low range value.

12 Technical Bulletin—TC-9100 Universal Controller

The parameters that are dynamically generated by the controller from the

analog inputs using the configuration parameters are listed below:

Table 5: Analog Input Dynamic Items

Item Tag Item Address

(Hex/Dec)

Description

AI1 01/01 Analog Input 1 Value

AI2 02/02 Analog Input 2 Value

AI3 03/03 Analog Input 3 Value

AI4 04/04 Analog Input 4 Value

AIH1 1E/30, Bit 1 1 = Analog Input 1 High Alarm

0 = No high alarm

AIL1 1E/30, Bit 2 1 = Analog Input 1 Low Alarm

0 = No low alarm

AIH2 1E/30, Bit 3 1 = Analog Input 2 High Alarm

0 = No high alarm

AIL2 1E/30, Bit 4 1 = Analog Input 2 Low Alarm

0 = No low alarm

AIH3 1E/30, Bit 5 1 = Analog Input 3 High Alarm

0 = No high alarm

AIL3 1E/30, Bit 6 1 = Analog Input 3 Low Alarm

0 = No low alarm

AIH4 1E/30, Bit 7 1 = Analog Input 4 High Alarm

0 = No high alarm

AIL4 1E/30, Bit 8 1 = Analog Input 4 Low Alarm

0 = No low alarm

An alarm bit is set when the analog value is equal to the high or low

alarm value, and the alarm bit is cleared when the analog value comes

back into normal range by at least 2% of the range of the analog input,

defined by [HRI - LRI].

Low Alarm Value

2% of rangeNo alarm

Differential =

2% of range

No alarm

Low Alarm

High

Alarm

AI Value

High Alarm Value

Time

Figure 3: High and Low Alarms

When an analog input goes into high or low alarm, the DIAL Item bit is

set. For details, refer to the section titled Auto-dial Feature in this

document.

Dynamic

Parameters

Technical Bulletin—TC-9100 Universal Controller 13

The TC-9100 Universal Controller has two digital inputs, labeled DI1 and

DI2, each connecting to an isolated, voltage-free contact. DI1 may also be

connected to a Condensation Sensor, Order Code HX-9100-8001, which

provides the equivalent of an open contact when the sensor is dry and a

closed contact when water condensation is sensed.

By configuration, the digital inputs are set to provide any two of the

Logic modes in the controller which each have a specific function in the

controller operation. The status of the Logic modes can be read by a

supervisory system.

The parameters to be defined for each digital input are listed below. The

Item TCS2 is included in Worksheet 3 of Appendix 2.

Table 6: Digital Input Configuration Items

Item Tag Type Description

TCS2 2 Bytes

Bits 11,10,9

Controller Options 2

.

Define

Digital Input DI1 Logic mode

, as follows:

000 = Input not used.

001 = Connected to a window contact for “Window

Open” mode.

010 = Connected to an occupancy sensor for

“Occupancy” mode.

011 = Connected to an air quality sensor, condensation

sensor, or other sensor with override function for

“Air Quality / Override” mode.

100 = Connected to a contact to change the action of

one or more control modules for “Reverse Action”

mode.

101 = Connected to a general purpose alarm contact for

“General Alarm” mode. This mode has no effect

on the operation of the controller and is used for

supervisory system purposes only.

Bit 12 Defines the action of the contact connected to DI1.

0 = “Open” contact sets the mode.

1 = “Closed” contact sets the mode.

For example, for a “window” contact that opens when the

window is open, set this bit to 0. For an “occupancy” sensor

contact that closes to indicate occupancy, set this bit to 1.

Bits 15…13

Define

Digital Input DI2 Logic mode

, using the same bit

patterns as shown above for DI1, bits 11, 10, 9.

Bit 16 Defines the action of the contact connected to DI2, the

same as shown above for DI1, Bit 12.

The Logic mode set for DI2 must be different from the Logic mode of

DI1 to avoid interference between the contacts. If an input is not used, set

the Logic mode bits to 000. If a Logic mode is configured but no sensor

contact is connected, install a wire jumper between the digital input

terminals.

Digital Input

Configuration

(DI1 and DI2)

Configuration

Parameters

14 Technical Bulletin—TC-9100 Universal Controller

The Window Open and Occupancy modes are always active, if defined,

and influence the controller operating mode (see tables 2 and 3). The Air

Quality / Override and Reverse Action modes are only active for the

control modules within which they are enabled. Programmable modules

configured as Algorithm 7 to 12 (calculation modules) can be conditioned

by one or both of the configured logic modes, enabling the digital inputs

to be part of the calculation function (see Programmable Modules

Configuration – Calculation Algorithms).

The parameters that are dynamically generated by the controller from the

digital inputs using the configuration parameters are listed below:

Table 7: Digital Input Dynamic Items

Item Tag Item Address

(Hex/Dec)

Description

WIN 20/32, Bit 6 1 = Window open.

0 = Window closed.

OCC 20/32, Bit 7 1 = Occupied status.

0 = Unoccupied status.

AIRQ 20/32, Bit 8 1 = Air quality poor, condensation detected, or other

override condition.

0 = No override condition.

REVL 26/38, Bit 3 1 = Reverse control action of enabled control

modules.

0 = Use configured control action in enabled modules.

ALM 26/38, Bit 5 1 = General purpose alarm or status.

0 = Normal status.

When a Window Open or General Alarm status is detected, the DIAL

Item bit is set. For details, refer to the section titled Auto-dial Feature in

this document.

The TC-9100 Universal Controller has seven output modules. Output

modules OCN1 and OCN2 drive analog outputs or digital outputs,

depending on model number. Output modules OCN3 to OCN7 drive

digital (triac) outputs in both models.

Model TC-9100-x000 has analog outputs, and OCN1 and OCN2 must be

configured for 0-10V analog outputs. (The option for solenoid valve

driver module outputs is no longer used.)

Model TC-9100-x001 has all digital (triac) outputs, and OCN1 and

OCN2 must be configured for one of the digital output options: as a pair

for Position Adjust Type (PAT), or 2-stage on/off output type, or as two

independent on/off outputs. OCN1 may also be configured as a Duration

Adjust Type (DAT) and OCN2 as an on/off type.

Dynamic

Parameters

Output Module

Configuration

(OCN1 to OCN7)

Technical Bulletin—TC-9100 Universal Controller 15

In both models the digital output pairs OCN3/OCN4 and OCN5/OCN6

can be configured as one of the digital (triac) output options mentioned

above for OCN1/OCN2. In addition, the digital outputs

OCN5/OCN6/OCN7 can be configured as a 3-speed fan controller, and

OCN7 has a special option as a “COMFORT” output signal when not

used in the 3-speed fan control option.

The output modules provide the interface between the output of a

programmable module and the hardware output. The status of the digital

(triac) outputs can be read by a supervisory system and can be switched

on and off directly by the supervisory system, overriding the output

module. Digital outputs are normally only controlled by a supervisory

system when not used in the controller configuration and provide a

convenient means of remote switching. Analog outputs cannot be read or

overridden by a supervisory system. However, the output of the

programmable module from which the output module receives its control

value may be read and overridden by a supervisory system (see

Programmable Modules Configuration).

The analog output type is only configurable in output modules OCN1 and

OCN2 must be configured for 0 - 10 VDC. (The option for a solenoid valve

driver module output is no longer used).

The analog hardware output for OCN1 has a special feature. There are in

fact two physical analog outputs that are labeled AO1a and AO1b. Only one

output can be active at one time and the other output will remain with a zero

output. These outputs are typically used in a heating/cooling application

with one controlled (process) variable, such as room temperature. AO1a is

used to control the heating equipment and AO1b is used to control the

cooling equipment, both of which directly influence the temperature

measured by the controlled (process) variable. In order to use this special

feature, the source control signal for OCN1 must come from a pair of

programmable modules configured as Algorithm 4 (heating/cooling PI

controller - single output). AO1a (heating) will be active when the first

module of the pair (loop 1) is active, and AO1b (cooling) will be active

when the second module of the pair (loop 2) is active. (See Programmable

Module Configuration – Algorithm 4 for details.)

If OCN1 is connected to a programmable module configured as an

Algorithm 2 or 6, only output AO1a will be active. If OCN1 is connected

to a programmable module configured as an Algorithm 7 to 13, only

output AO1b will be active.

Analog output OCN2 may be connected to any programmable module.

For all analog outputs, a range of 0 to 100% is assumed, where 0% gives

a zero output and 100% gives the maximum output (10 VDC). OCN1 and

OCN2 are not normally used with the on/off control algorithms 1, 3, and

5, since the output is either 0% or 100% and does not vary between these

two limits.

Analog Output

Type

(0 to 10 VDC)

16 Technical Bulletin—TC-9100 Universal Controller

The DAT output type may be configured in output modules OCN1,

OCN3, and OCN5. The DAT output is a digital output (triac) that is

switched on for a duration within the set heating or cooling valve cycle

time in direct proportion to the controller output from 0 to 100%. To

avoid unnecessary switching of the valve actuator when the output is

between 0 and 5% the digital output (triac) remains off, and when the

output is between 95 and 100% the digital output (triac) remains on. The

cycle time is set as a configuration parameter. DAT output modules may

be connected to any programmable module except those configured as

Algorithm 1, 3, or 5.

30% Output50% Output

OFF

ON

DAT Cycle Time DAT Cycle Time

Figure 4: DAT Output

The PAT output type may be configured in pairs of output modules –

OCN1/OCN2, OCN3/OCN4, and OCN5/OCN6.

The PAT output is a pair of digital outputs (triacs) that are switched on to

open and close an incrementally driven heating or cooling valve. The

duration of switching is directly proportional to the change in the

controller output and related to the full stroke time of the valve such that

a 100% change will completely open or close the valve. At the 0% or

100% position, the duration of switching is increased to ensure that the

valve is completely at its end position and the appropriate digital output is

switched on for the full stroke time every two hours to ensure that the

valve remains at its end position. To prevent unnecessary wear on the

actuator, the digital output will only be switched when the output change

exceeds the PAT dead-band (in % of full stroke) in the same direction as

the previous change, or twice the PAT dead-band if the direction of

change is reversed. The full stroke time and PAT dead-band are set as

configuration parameters. PAT output modules may be connected to any

programmable module except those configured as Algorithm 1, 3, or 5.

Duration Adjust

Type (DAT)

Position Adjust

Type (PAT)

Technical Bulletin—TC-9100 Universal Controller 17

The 2-stage on/off output type may be configured in pairs of output

modules – OCN1/OCN2, OCN3/OCN4, and OCN5/OCN6.

The output is a pair of digital outputs (triacs) that are switched on in

sequence as the controller output increases. The first stage digital output

is switched as soon as the output is above 0% and the second stage digital

output is switched when the output is equal to the set load rating for the

first stage, which is set as a configuration parameter along with the

switching differential.

Note: To ensure that the first stage switches off, the low limit of the

control module to which the 2-stage output module is connected

must be set at the switching differential value as a negative

number. For example, if the differential is set at 5%, then the low

limit of the control module must be set at -5%.

Two-stage output modules may be connected to programmable modules

configured as Algorithm 2, 4, or 6, or as calculation algorithms 7 to 12,

provided that the output range covers the switching differential, as

explained above.

}Differential

}Differential

Stages 1 and 2

Stage 1

Off

0

100

Module

Output

Process Variable

Load Rating

of Stage 1

Figure 5: 2-Stage On/Off Output

An on/off output type may be configured for output modules OCN1 to

OCN6. The output is a single triac that is switched on when its source

signal is greater than 0, and switched off when the source signal is equal

to or less than 0. The on/off output module is normally connected to a

programmable module configured as Algorithm 1, 3, or 5 (an on/off

controller), and the switching differential is provided by the on/off

controller.

2-Stage On/Off

On/Off Output

Type

18 Technical Bulletin—TC-9100 Universal Controller

The 3-speed fan controller output may be configured only in Output

Module OCN5, and it also uses OCN6 and OCN7.

The output is a set of three digital outputs (triacs) that are switched on in

turn at the three fan speed break points, set as configuration parameters.

The switching differential for all break points is also set as a

configuration parameter. The first output switches on at Break Point 1

and off at Break Point 1 less the switching differential. The second output

switches on at Break Point 2 and the first output is switched off. The third

output switches on at Break Point 3 and the second output is switched off.

Only one output is on at one time, and the switching differential is

applied to all on/off transitions.

The 3-speed fan controller output may be connected to any programmable

module except those configured as Algorithm 1, 3, or 5.

}Differential

}Differential

}Differential

Speed 3

Speed 2

Speed 1

Off

0

100

Module

Output

Process Variable

Break Point 1

Break Point 2

Break Point 3

Figure 6: 3-Speed Fan Output

When OCN5 is configured as a 3-speed fan controller, the source control

signal connection to OCN6 defines an analog input that overrides the

controller, as follows:

•Analog input value to OCN6 less than 0 ⇒Automatic mode

(3-speed fan module controlled by source defined in OCN5).

•Analog input value to OCN6 between 0 and 100 ⇒Override mode

(3-speed fan module controlled by analog input value to OCN6).

The output triacs switch at the defined break points and use the defined

switching differential in both Automatic and Manual modes. The

Override feature enables the manual control of fan speed using an analog

input connected, for example, to a switch assembly that generates the

voltage levels to force the appropriate fan speed or allow automatic

operation.

Alternatively, the TM-9180 can be used to override the 3-speed fan

controller. Refer to Configuration for a TM-9180 Room Command

Module, further in this manual, for configuration details.

3-Speed Fan

Controller

Output

3-Speed Fan

Override

Technical Bulletin—TC-9100 Universal Controller 19

Note 1: The Override mode is disabled when the controller is in Low

Limit (Anti-freeze) mode or in OFF mode. In this case, the 3-

speed fan controller operates in Automatic mode and responds

as required by the programmable module to which it is

connected.

Note 2: In controllers with Version 3 or later firmware (Date Code

9714 or later), the Override mode is also disabled in NIGHT

and STANDBY modes. The override is only active in

COMFORT mode.

Note 3: In controllers with Version 3 or later firmware (Date Code

9714 or later), a programmable module with a controller

algorithm (algorithms 1-6) can be configured to set its output to

0 % (or OFF) when the 3-speed fan override sets the fan to

OFF. This interlock is required for applications where heating

or cooling equipment must be switched off when there is no air

flow, such as in fan coil units with electric heating, direct

expansion coils or heat pumps. Refer to Configuration

Parameters for Controller Algorithms (PM Tag PMxTYP Bit

10), further in this manual, for details.

When Output Module OCN7 is not used by Output Module OCN5 as the

third speed of a 3-speed fan controller, the triac may be driven on when

the operating mode of the controller is COMFORT by setting Bit 8 in

Item TCS2 (Address 85 hex, 133 dec) to 1. This output can be used, for

example, for lighting control.

The parameters to be defined for each output module are listed below.

Refer to Appendix 2 – Worksheet 3, or Appendix 1 – Table 1: Item List,

for the Item addresses.

Note: Do not forget to set Item TCS2, Bit 6, according to the power

supply frequency of 50 or 60 Hz.

Table 8: Output Module Configuration Items

Item Tag Type Description

TCS2 Bit 6 Set to 1 if the power supply frequency is 60 Hz, or set to 0

for 50 Hz.

Bit 8 Set to 1 if OCN7 is not used for 3-speed fan control and

DO7 should be on when the controller is in COMFORT

mode.

OCN1 1 Byte

Output Module 1 Configuration

.

Bits 5…1

Source of Module

in binary code:

01010 (0A hex) = Output Module 1 (OCM1).

01011 (0B hex) = Output Module 2 (OCM2).

⇓

01111 (0F hex) = Output Module 6 (OCM6).

Continued on next page...

Output Module

OCN7

Configuration

Parameters

20 Technical Bulletin—TC-9100 Universal Controller

Item Tag

(Cont.)

Type Description

OCN1 Bits 8…6

Output Type

000 = Output not used.

Hardware analog outputs only:

001 = Not used. (Was for solenoid valve driver module.)

010 = 0 to 10 VDC output.

Hardware digital outputs (triac) only:

011 = On/off output.

100 = DAT output.

101 = PAT output (also uses OCN2 – define OCN2 as

“output not used”).

110 = 2-stage output (also uses OCN2 – define OCN2

as “output not used”).

OCO1 Number

Output Module 1 Parameter

.

When OCN1 is PAT = Full stroke time of actuator (sec.).

When OCN1 is DAT = Cycle time of actuator (sec.).

When OCN1 is 2-stage = Load rating of stage 1 (% of

module output).

OCN2 1 Byte

Output Module 2 Configuration

.

Bits 5…1

Source of Module

in binary code:

01010 (0A hex) = Output Module 1 (OCM1).

01011 (0B hex) = Output Module 2 (OCM2).

⇓

01111 (0F hex) = Output Module 6 (OCM6).

Bits 8…6

Output Type

000 = Output not used (or used with PAT or 2-stage

output defined in OCN1).

Hardware analog outputs only:

001 = Not used. (Was for solenoid valve driver module.)

010 = 0 to 10 VDC output.

Hardware digital outputs (triac) only:

011 = On/off output.

OCO2 Number

Output Module 2 Parameter

.

When OCN1 is PAT = PAT dead-band (%).

When OCN1 is 2-stage = Switching differential (%).

OCN3 1 Byte

Output Module 3 Configuration

.

Bits 5…1

Source of Module

in binary code:

01010 (0A hex) = Output Module 1 (OCM1).

01011 (0B hex) = Output Module 2 (OCM2).

⇓

01111 (0F hex) = Output Module 6 (OCM6).

Bits 8…6

Output Type

000 = Output not used.

011 = On/off output.

100 = DAT output.

101 = PAT output (also uses OCN4 – define OCN4 as

“output not used”).

110 = 2-stage output (also uses OCN4 – define OCN4

as “output not used”).

Continued on next page...

This manual suits for next models

4

Table of contents

Other Metasys Controllers manuals

Popular Controllers manuals by other brands

DERUN LIGHTING TECHNOLOGY

DERUN LIGHTING TECHNOLOGY DR-CON-IR20M-3CH-LV user manual

Leslie

Leslie 35 Installation, operating and maintenance instructions

AMX

AMX Tango DAS-T0804-SIG Specifications

Marlec

Marlec HRDi Installation & operation

Omega

Omega Linkr MOBILE Quick install guide

Kelly

Kelly KBL24101X user manual