Meteo Control COMFORT User manual

WEB'log Comfort 110621 - en

WEB'log

COMFORT

Operating Instructions

2/53 WEB'log Comfort 110621 - en

Spicherer Str. 48

D-86157 Augsburg

Tel.: +49 (0) 821 / 3 46 66-0

Web: www.meteocontrol.com

Technical Support:

Tel.: +49 (0) 821 / 3 46 66-88

Fax: +49 (0) 821 / 3 46 66-11

© 2011 meteocontrol GmbH

All rights reserved.

All information in these operating instructions has been compiled and

checked with the greatest care and diligence. Nevertheless, the possibility of

errors cannot be entirely excluded. meteocontrol GmbH therefore cannot

accept any liability for errors or any circumstances resulting from errors.

Subject to technical alterations.

WEB'log Comfort 110621 - en 3/53

Contents

1Notes on using the Operating Instructions ..............................4

2Safety instructions...................................................................4

3Overview of the device............................................................5

3.1 Front view ...............................................................................5

3.2 Operator control elements ......................................................6

3.3 Status LED............................................................................12

3.4 Standard scope of supply .....................................................19

3.5 Rating plate...........................................................................19

3.6 Assignment of connections ...................................................20

3.6.1 RS485 / RS422 interfaces ....................................................20

3.6.2 Other interfaces ....................................................................20

3.7 Default settings .....................................................................22

4Installation.............................................................................23

4.1 Safety instructions for installation .........................................23

4.2 Cables and wiring .................................................................24

4.3 Installation.............................................................................25

4.4 Removal................................................................................25

4.5 Interfaces ..............................................................................26

4.5.1 Analog input..........................................................................27

4.5.2 Digital input ...........................................................................27

4.6 Bus communication...............................................................28

4.6.1 General connection diagram.................................................29

4.6.2 Danfoss inverter....................................................................30

4.6.3 Delta inverter ........................................................................31

4.6.4 Diehl AKO Platinum inverter .................................................32

4.6.5 Fronius inverter.....................................................................34

4.6.6 Ingeteam inverter ..................................................................35

4.6.7 Jema inverter ........................................................................36

4.6.8 Kaco inverter.........................................................................36

4.6.9 Mastervolt inverter ................................................................37

4.6.10 Power One inverter ...............................................................38

4.6.11 Refusol inverter.....................................................................39

4.6.12 Riello inverter........................................................................39

4.6.13 Siemens PVM inverter ..........................................................40

4/53 WEB'log Comfort 110621 - en

4.6.14 SMA inverter......................................................................... 41

4.6.15 Sputnik inverter..................................................................... 43

4.6.16 Steca inverter ....................................................................... 45

4.6.17 Sunways inverter .................................................................. 46

4.6.18 Xantrex inverter .................................................................... 47

5Start-up, configuration .......................................................... 48

5.1 Preconditions........................................................................ 48

5.2 Starting up the WEB'log Comfort.......................................... 48

5.3 Configuring the WEB'log Comfort......................................... 48

5.3.1 Local configuration on the touch screen ............................... 48

5.4 Setting the network parameters............................................ 49

5.4.1 Static addressing in the LAN ................................................ 49

5.4.2 Dynamic addressing in the LAN ........................................... 50

5.4.3 Using the analog modem...................................................... 50

5.4.4 Performing a portal connection test...................................... 50

5.4.5 Guided configuration via web browser.................................. 51

5.4.6 Expert configuration via web browser................................... 51

5.4.7 Registering the WEB’log Comfort on the “safer sun” portal .. 51

6Operation.............................................................................. 55

7Own Consumption ................................................................ 56

8Troubleshooting.................................................................... 57

9Technical data ...................................................................... 58

10 Appendix .............................................................................. 59

11 Declarations of Conformity ................................................... 61

WEB'log Comfort 110621 - en 5/53

1Notes on using the Operating Instructions

These Operating Instructions are intended for end customers and provide

the basis for safe operation of the WEB'log.

The personnel must have access to the Operating Instructions at all times.

The current version of the Quick Reference Guide is given on the

manufacturer’s website.

The personnel responsible for installation, operation and maintenance must

have read and understood these Operating Instructions.

meteocontrol GmbH accepts no liability for personal injury, damage to

property, or malfunctions and their consequences, insofar as these result

from non-observance of these Operating Instructions.

2Safety instructions

Safety instructions for operation

The device must not be opened (except for the cover over the

connections)

The device must not be modified in any way

Damaged devices must be taken out of operation immediately and

checked by a qualified electrician

The local regulations must be observed when using the device

The safety of the device and the operator cannot be guaranteed if the

device is operated in contravention of the described safety instructions

6/53 WEB'log Comfort 110621 - en

3Overview of the device

3.1 Front view

1

2

3

45

6789

10

11

12

13

Fig. 1: Overview of the device (cover over the connections opened)

(1) Status LED

(2) Touch screen

(3) RS485 interface, RJ12 socket

(4) RS485 interface, screw-clamp terminals

(5) RS485 / 422 combined interface, RJ12 socket

(6) RS485 / 422 changeover switch for combined interface

(7) RS485 / 422 combined interface, screw-clamp terminals

(8) Digital output, screw-clamp terminals

(9) Analog inputs, screw-clamp terminals

(10) Digital inputs, screw-clamp terminals

(11) Ethernet, RJ45 socket

(12) Telephone (PSTN), RJ12 socket

(13) Power supply, socket for plug-in power supply unit

For further information about LEDs and touch screen →Chapter 3.3.

WEB'log Comfort 110621 - en 7/53

3.2 Operator control elements

The data logger is equipped with a touch-sensitive screen (touch screen).

Fig. 2: Touch screen

Symbol Meaning

Go to Diagrams menu

Go to Time selection (Day, Month, Year) menu

Go to Settings menu

Go to System settings menu

Go to Inverter menu

Go to Internet menu

Operator mode display: Administrator

Go to Overview menu

Local alarm active (red background)

Messages (blue background)

8/53 WEB'log Comfort 110621 - en

Delete messages

Go to Provider overview menu

Cursor left or time window minus 1 hour

Cursor right or time window plus 1 hour

Data recording stopped

Data recording started

Increase time scale

Reduce time scale

Reject operator input, return to higher-level menu

Confirm operator input, return to higher-level menu

Option selected (green)

Option not selected (gray)

WEB'log Comfort 110621 - en 9/53

3.3 Status LED

Text LED Meaning

Green: Device is powered

Green: Device is in the start phase

power

Off: Power supply fault

Green: System loaded successfully, normal operation

status

Off: System booting

Yellow: Connection established

Yellow: Attempting to establish a connection

connect

Off: No connection to PSTN modem

Red: Alarm signal at configured output DO1

Red: Fault detected *

alarm

Off: Normal operation

* The Alarm LED flashes in the following cases:

System alarm, measured value alarm, status alarm

Inverter alarm state detected

Inverter Ini file missing

Inverter failure

10/53 WEB'log Comfort 110621 - en

3.4 Standard scope of supply

WEB’log Comfort data logger

24 V DC plug-in power supply unit

Ethernet patch cable

Telephone connecting cable (analog)

Operating Instructions

Drilling template

CD

Drivers (on CF card in device)

Touch pen

Mounting kit (plugs, screws)

Connect cable

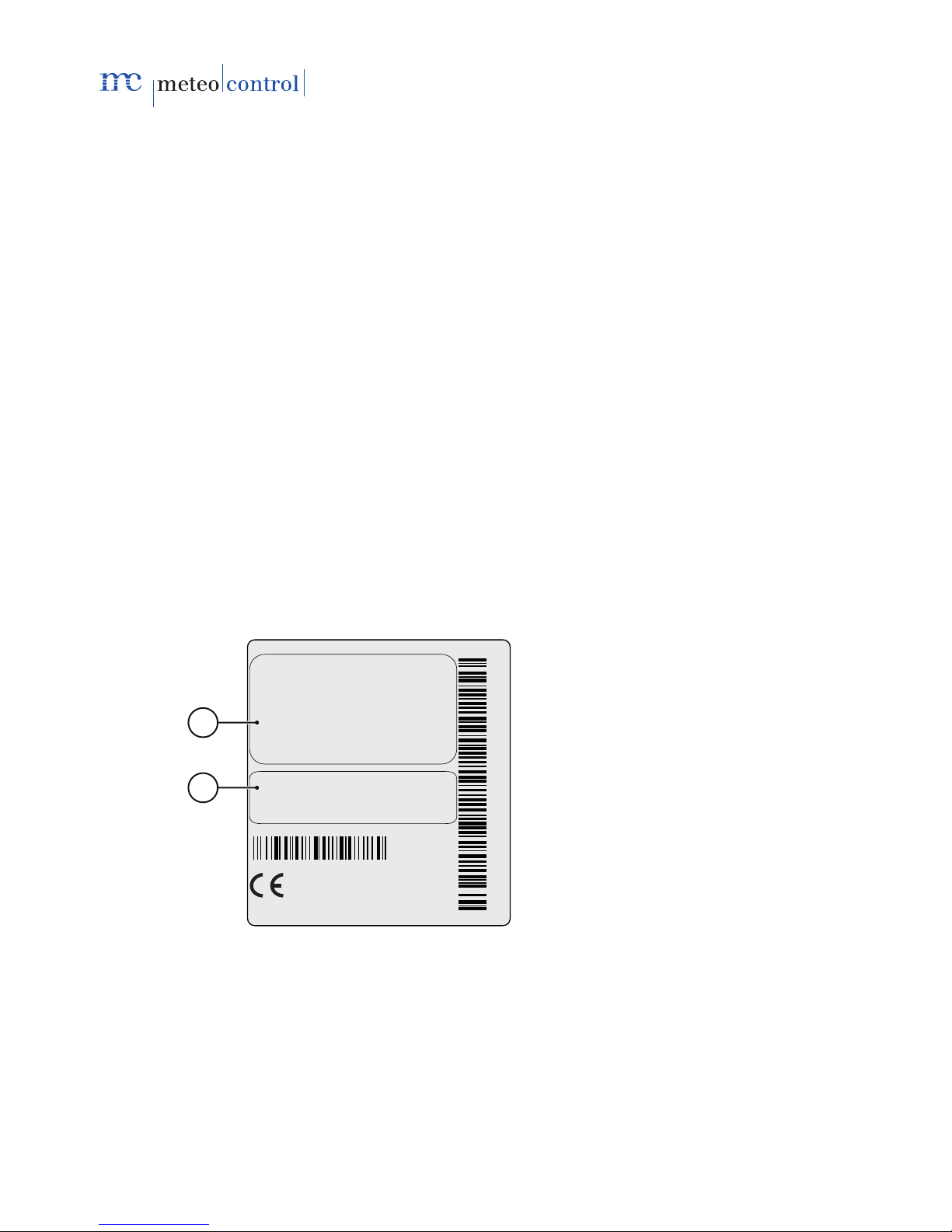

3.5 Rating plate

The rating plate for identification of the device is attached to the back of the

device.

Type

Item No.

YOM

421160 2610 001

Analog

421160 2610 001

2010

Monitoring System

WEB'log Comfort

421.160

MADE IN GERMANY

2

1

Fig. 3: Rating plate

(1) Device type and variant

(2) Modem type, serial number and year of manufacture

Note: Note item number from rating plate for subsequent configuration of

the device.

WEB'log Comfort 110621 - en 11/53

3.6 Assignment of connections

All interfaces are accessible once the plastic cover on the front plate of the

device has been opened.

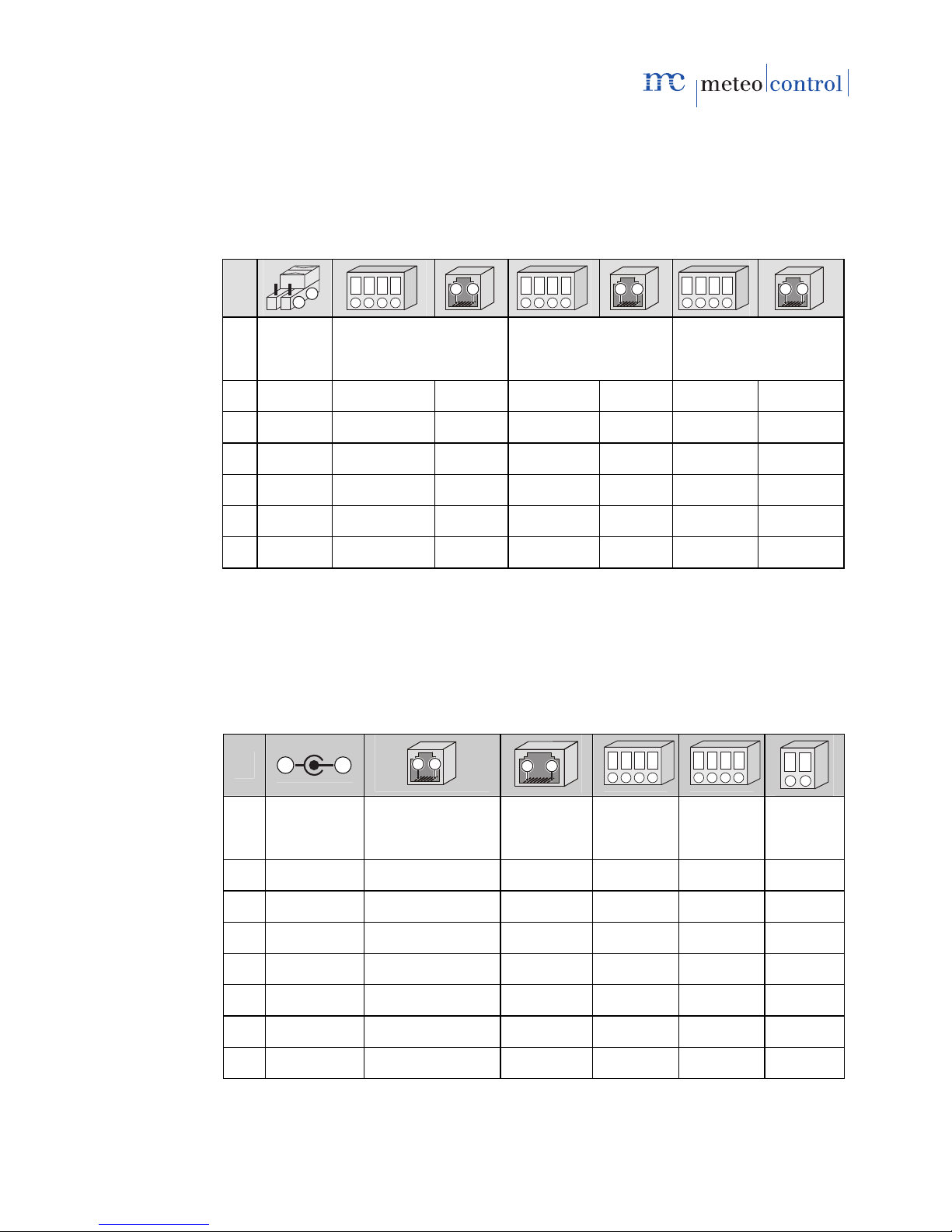

3.6.1 RS485 / RS422 interfaces

Pin

1

2

1 2 3 4

6 1

1 2 3 4

6 1

1 2 3 4

6 1

Change-

over

switch

Combined interface,

RS485 mode

Combined interface,

RS422 mode

Interface RS485

1 RS485* -- -- RX+ -- +24 V DC +24 V DC

2 RS422 -- RS485 A RX- TX+ RS485 A RS485 A

3 -- RS485 A -- TX+ RX+ RS485 B --

4 -- RS485 B RS485 B TX- TX- GND RS485 B

5 -- -- -- -- RX- -- --

6 -- -- GND -- GND -- GND

Note: The combined interface is not suitable for supplying power to

devices via the RS485 bus (e.g. RS485 hub).

For RS485, always use right-hand interface.

* Factory setting

3.6.2 Other interfaces

Pin

2

1

6 1

81

1 2 3 4 1 2 3 4

12

Plug-in

power

supply unit

PSTN (internal

analog modem)

Ethernet Digital

inputs

Analog

inputs

Digital

output

1 GND -- TX+ DI 1 AI 1 DO Pos

2 +24 V DC a2 (out) TX- GND GND DO Neg

3 -- a1 (in) RX+ DI 2 AI 2

4 -- b1 (in) -- GND GND

5 -- b2 (out) -- -- --

6 -- -- RX- -- --

7,8 -- -- -- -- --

12/53 WEB'log Comfort 110621 - en

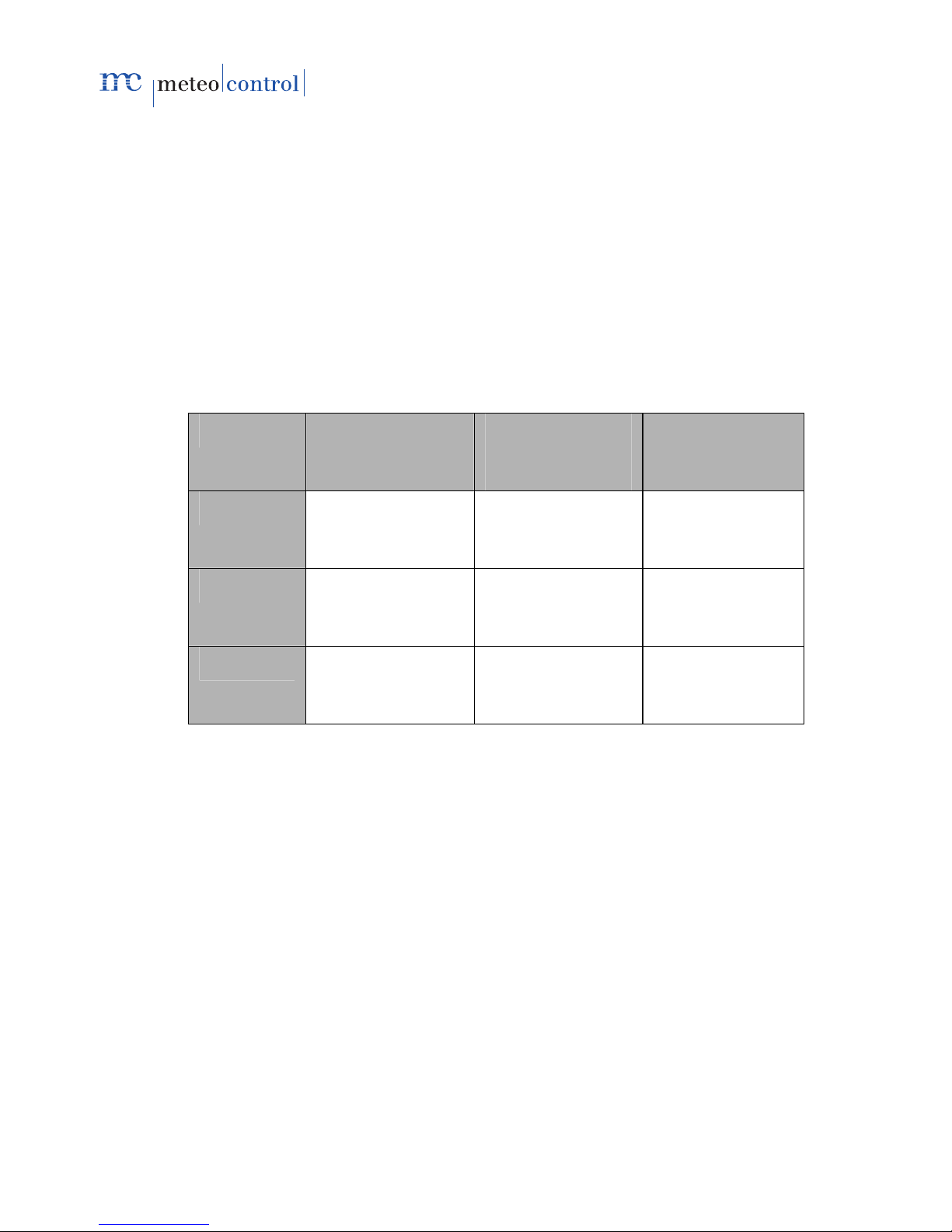

3.7 Default settings

Default setting for the Ethernet connection: DHCP

A manual network configuration is only necessary if no DHCP server is

present.

IP address 192.168.30.40

Subnet mask 255.255.255.0

Gateway 0.0.0.0

Default setting for the modem connection:

IP address 192.168.200.1

Remote IP 192.168.200.51

Subnet mask 255.255.255.255

Direct portal

communication

Sending alarm

messages, daily

files

Time

synchronization

Protocol http smtp (e-mail) SNTP

or

TIME

Port 80,

alternatively 8572

25 SNTP: 123

or

TIME: 37

IP address 213.179.128.168

and

213.179.128.183

213.179.128.176 TIME:

132.163.4.102

WEB'log Comfort 110621 - en 13/53

4Installation

4.1 Safety instructions for installation

Note

Damage due to incorrectly connected cables!

If cables are connected incorrectly, this can damage or destroy the

measuring inputs and the device.

–Connect cables only to the correct locations.

–Ensure the correct polarity of the cables being connected.

Note

Damage due to overvoltage!

Overvoltage or voltage peaks can damage or destroy the device.

–Protect the power supply against overvoltage.

Note

Damage due to overvoltage!

If voltages of more than 10 V DC are applied to the analog inputs, or if

currents of more than 20 mA flow, this can destroy the affected

measuring inputs.

–Ensure that only voltages of up to 10 V DC are applied and only

currents of up to 20 mA flow.

Note

Damage due to incorrect supply voltage!

If there is a voltage higher or lower than 24 V DC at the input for the

supply voltage, the device may be damaged or destroyed.

–Only use the original plug-in power supply unit.

–Only supply the plug-in power supply unit with voltage from the

public grid (no isolated operation).

14/53 WEB'log Comfort 110621 - en

4.2 Cables and wiring

Cable types

Bus cabling (inverters)

Data cable RS485,

twisted and shielded: Li2YCYv (TP) 2×2×0.5 mm21)

Network cable: CAT 7

Sensors (irradiance sensor, temperature sensor)

Sensor cable: LiYCY 2×2×0.5 mm2

Meters (energy meters)

Telephone cable: J-Y(ST)Y 2×0.6 mm2

Ethernet network

Network cable: CAT 5e / CAT 6 / CAT 7

Maximum permissible cable lengths:

Bus cabling (data cable RS485) 1200 m 2) 3)

Sensors 100 m

Meters 200 m

Ethernet network 100 m

3)

“Connect cable” option

We offer a pre-assembled data cable (Connect cable) for connecting the

WEB'log and the first device (inverter).

1) We recommend using the cable type UNITRONIC®Li2YCYv (TP)

manufactured by Lapp Kabel, or an equivalent cable type.

This cable is suitable for direct installation in soil.

2) For longer cable lengths, repeaters must be used.

3) A hub is necessary if a number of separate cables of this length are used.

WEB'log Comfort 110621 - en 15/53

4.3 Installation

The device is intended for wall mounting.

1. Note the ITEM number from the rating plate on the rear for subsequent

configuration.

2. Remove cover over the connections (1).

3. Insert two screws (6) 164 mm apart into the wall (use drilling template

supplied).

4. Mount the device so that the heads of the screws are located in the slots.

5. Push the device down a short way and check that it is seated correctly.

6. Tighten the two screws until the device is securely seated.

1

2

3

4

6

5

Fig. 4: Wall mounting, side view

(1) Remove cover (4) Lift device off

(2) Device (5) Wall

(3) Mount device (6) Fastening screws

4.4 Removal

1. Loosen the two fastening screws.

2. Push device upwards and remove from the screws.

16/53 WEB'log Comfort 110621 - en

4.5 Interfaces

PSTN connection

1. Test the PSTN telephone connection for outgoing and incoming calls (e.g.

provider number; if necessary, include external call prefix and ensure

there are no dialing restrictions). Set the telephone system as described

in the manufacturer’s instructions.

2. Connect the device and the telephone connection with the supplied cable.

If the cable needs to be extended, ensure secure contact and correct

polarity.

Ethernet connection

Direct connection from data logger and PC / laptop via crossed network

cable (crossover).

DC

PSTN

Ether DI AI DA

RS485 RS485 RS485

RS422 RS485

RS422

3

2

1

Fig. 5: Crossed network cable

(1) Data logger (3) Computer / laptop

(2) Crossed network cable

Note: The crossed network cable is not part of the scope of supply.

Connection to a switch / hub via an uncrossed network cable.

DC

PSTN

Ether DI AI DA

RS485 RS485 RS485

RS422 RS485

RS422

3

2

1

2

4 4

Fig. 6: Uncrossed network cable

(1) Data logger (3) Hub / switch

(2) Uncrossed network cable (4) Computer / laptop

Note: The hub/switch is not part of the scope of supply.

WEB'log Comfort 110621 - en 17/53

4.5.1 Analog input

The analog inputs can be configured as:

- Voltage input (DC): 0...10 V

- Current input 0...20 mA

- Resistance measurement input for a PT1000 two-wire measurement

DC

PSTN

Ether DI AI DA

RS485 RS485 RS485

RS422 RS485

RS422

3 4

2

1

1

Si-12TC

+24 V

GND

Fig. 7: Example of irradiance sensor Si-12TC

(1) Irradiance (orange) (3) GND (black)

(2) + 24 V DC (red) (4) PE shield (black)

4.5.2 Digital input

The digital inputs are pulse inputs according to DIN43864 (S0) and can be

configured as:

- Counter input

- Status input

DC

PSTN

Ether DI AI DA

RS485 RS485 RS485

RS422 RS485

RS422

2121

1234

21 20

+

-

21 20

+

-

Fig. 8: Example of energy meter

(1) S0 interface, minus (21) (2) S0 interface, plus (20)

Note: For further information about configuration, see Appendix.

18/53 WEB'log Comfort 110621 - en

Power supply

For power supply, use the plug-in power supply unit supplied.

DC

PSTN

Ether DI AI DA

RS485 RS485 RS485

RS422 RS485

RS422

2

1

12

Fig. 9: Power supply

(1) Flexible connecting cable (2) 24V DC plug-in power

supply unit

Note: Only supply the plug-in power supply unit with voltage from the

230 V public grid. Do not power from inverter in isolated operation!

4.6 Bus communication

For communication with inverters, the WEB’log must be equipped with the

appropriate driver.

Note: The required driver is installed by the manufacturer before shipment.

For inverters, only the information required for connection is given.

For further information →Inverter documentation.

Observe the maximum permissible number of devices

Connect the WEB'log to the first device with the data cable or Connect

cable

The order of the bus devices is unimportant

The use of a repeater is necessary for long cable lengths.

As a rule, no operating voltage may be connected to the communication

interfaces of inverters.

The shield of the bus cable must be grounded at one end of the

connection only.

When routing the bus cabling, ensure as great a distance as possible

from AC cables.

To prevent reflections, the bus must always be terminated with a parallel

terminator.

WEB'log Comfort 110621 - en 19/53

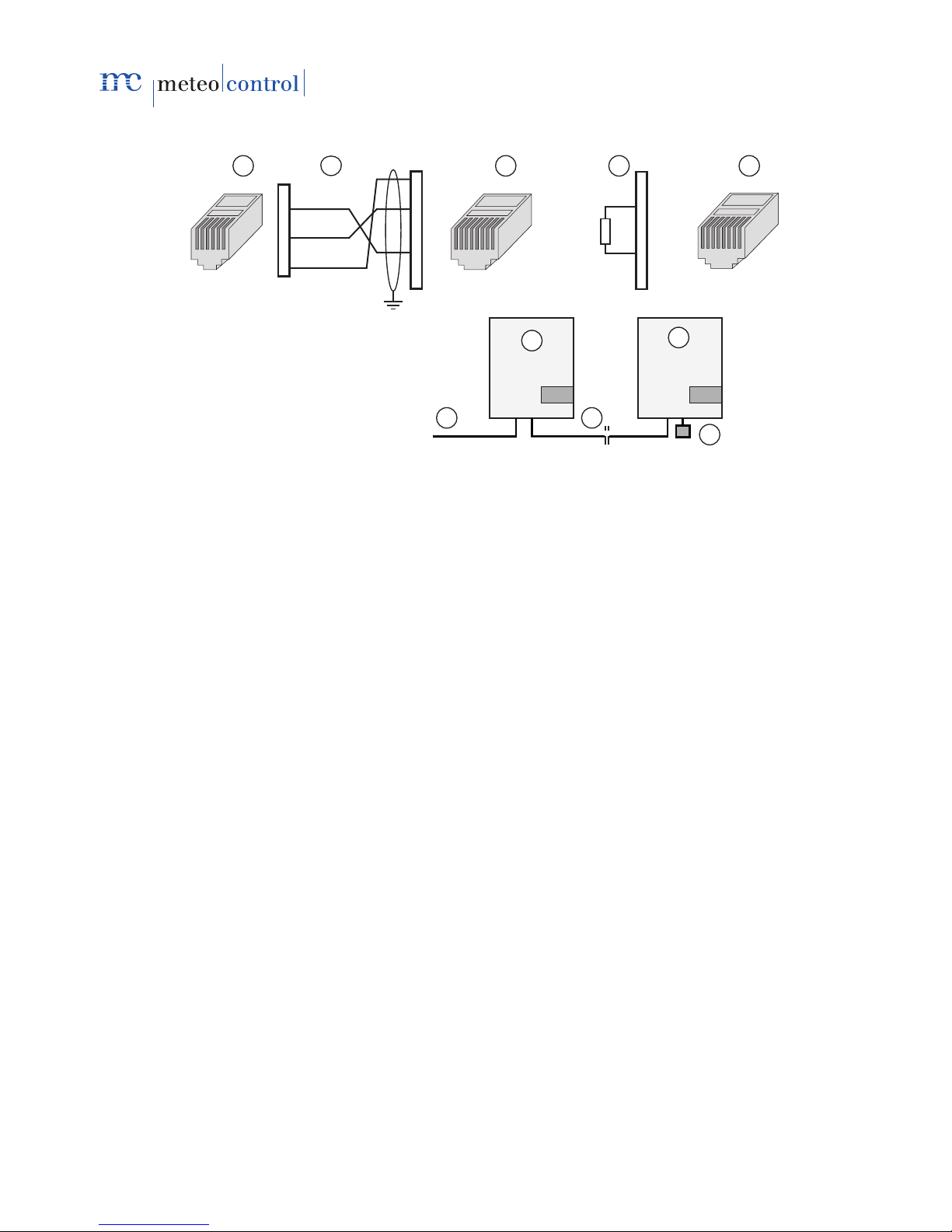

4.6.1 General connection diagram

If the connection of the applicable inverter type is not described in the

following sections, then the general connection diagram must be used.

Observe any additional information in the manufacturer’s documentation!

12

RS485 A

RS485 B

RS485 B

RS485 A

1

2

3

4

5

6

GND

+24V

654321

RS485 A

RS485 +

+TR

T+

RS485 B

RS485 -

-TR

T-

3

4

5

Fig. 10: General connection diagram

(1) RJ12 connector (WEB'log), RS485 (4) Inverter

(2) Signal names (5) Possible connection names

(3) Bus cable to the WEB'log

Signal wires RS485 A and RS485 B must not be interchanged

A twisted and shielded wire pair must be used for the bus cable

Terminate the RS485 bus after the last device

(using a resistor, switch, jumper, etc., depending on type of device)

20/53 WEB'log Comfort 110621 - en

4.6.2 Danfoss inverter

654321 543876 21

RS485 A

RS485 B

GND

1

2

3

4

5

6

1

2

3

4

5

6

7

8

543876 21

1

2

3

4

5

6

7

8

123

9

10

4 5

67

8

120 Ω

Fig. 11: Danfoss inverter with Connect Danfoss

(1) RJ12 connector (WEB'log), RS485 (6) First and subsequent inverters

(2) PIN assignment (Connect cable) (7) Last inverter

(3) RJ45 connector (inverter) (8) Connect Danfoss

(4) Pin assignment, terminator (9) Ethernet patch cable

(5) RJ45 terminator (10) Terminator for last inverter

Maximum of 10 inverters per device.

Connect the cable shield to the ground terminal at the WEB'log end

Set the inverter bus address (see inverter documentation)

This manual suits for next models

1

Table of contents

Popular Weather Station manuals by other brands

Hyundai

Hyundai WSC 2180 instruction manual

La Crosse Technology

La Crosse Technology WS-9625U-IT instruction manual

Explore Scientific

Explore Scientific WSH5001 instruction manual

La Crosse Technology

La Crosse Technology WS-3512 Operation manual

La Crosse Technology

La Crosse Technology 308-805 Quick manual

La Crosse Technology

La Crosse Technology WS-7136U instruction manual

Ambient Weather

Ambient Weather WS-YG302 user manual

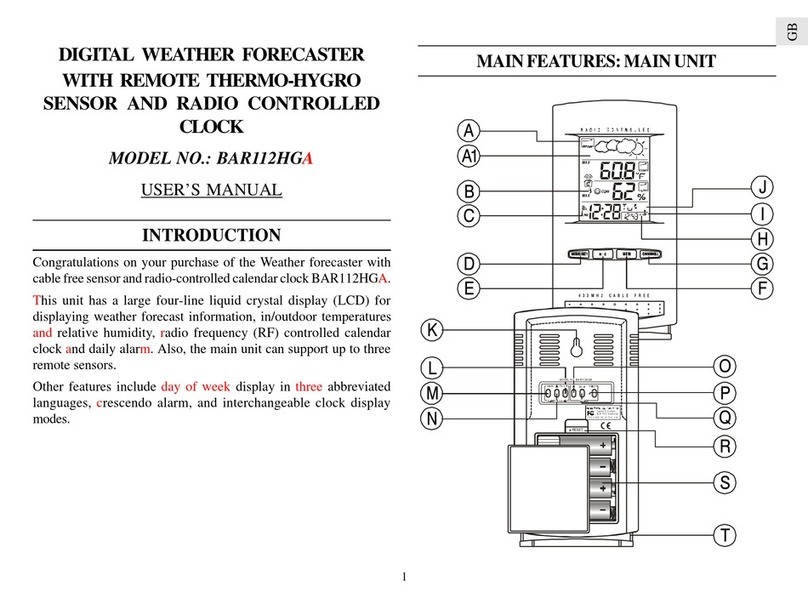

Oregon Scientific

Oregon Scientific BAR112HGLA user manual

FuehlerSysteme

FuehlerSysteme Compact WS3/O Instructions for use

TFA

TFA 35.1133 instruction manual

Ambient Weather

Ambient Weather WS-1500-IP user manual

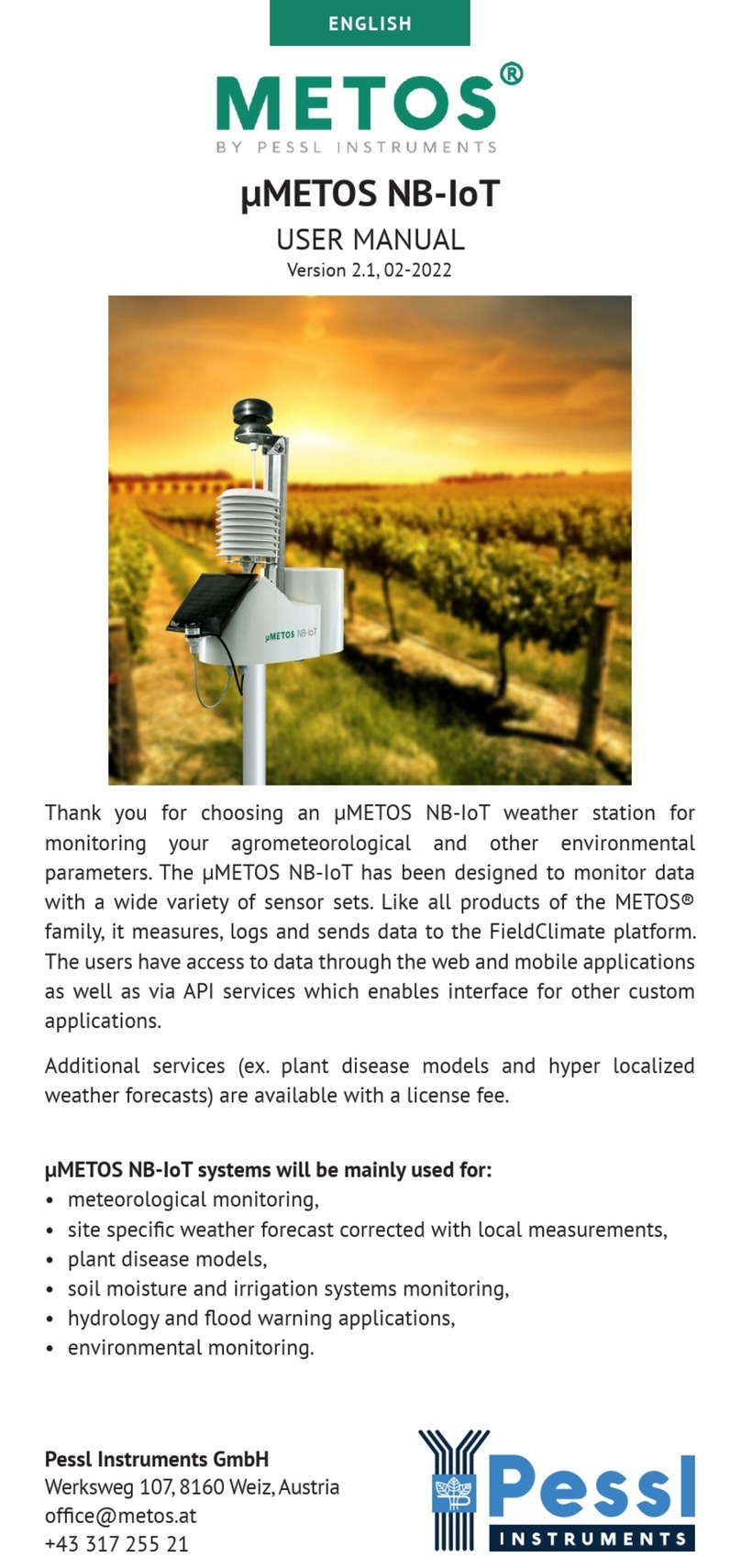

Pessl Instruments

Pessl Instruments uMETOS NB-IoT user manual