Metkon ECOPRESS 52 Administrator Guide

1

metkon.com

OPERATION & INSTRUCTION MANUAL

AUTOMATIC MOUNTING PRESS

2

EC Declaration of Conformity

Manufacturer : Metkon Instruments Inc.

Address : Demirtas Dumlupinar Organize Sanayi Bolgesi

Ali Osman Sonmez Cd. No: 14 Bursa / TURKEY

Model No : ECOPRESS 52/102/202

Herewith declares that;

Hot Mounting Press,

is in conformity with the provisions of the Machinery Directive (directive 2006/42/EEC), as amended, and with national

implementing legislation;

is in conformity with the provisions of the Low Voltage Directive (directive 2014/35/EU), as amended, and with national

implementing legislation;

is in conformity with the provisions of the EMC Directive (directive 2014/30/EU), as amended, and with national

implementing legislation;

And furthermore declares that

the following (parts/clauses of) standards have been applied

EN ISO 12100:2010, TS EN 60204-1, TS EN IEC 61000-6-2, TS EN 61000-6-4

Authorized Person: ERCIN SENAY

Position: Manager of Research and Development Department

Year: 2019

Bursa / Turkey

3

Index

DESCRIPTION ............................................................................................................................ 4

Design .....................................................................................................................................................................................4

Technical Data ........................................................................................................................................................................5

Warranty .................................................................................................................................................................................6

Safety Precautions ..................................................................................................................................................................6

INSTALLATION & SET UP........................................................................................................... 7

Unpacking & Checking Contents of Package ...........................................................................................................................7

Step by Step Unpacking...........................................................................................................................................................7

Installation and Set-Up ...........................................................................................................................................................8

CONTROL PANEL (ECOPRESS 52).............................................................................................14

Control Button Functions ...................................................................................................................................................... 14

TOUCH SECREEN CONTROL PANEL (ECOPRESS 102/202).......................................................15

Control Button Functions ...................................................................................................................................................... 15

Password List........................................................................................................................................................................ 16

Operation Parameter Ranges ................................................................................................................................................ 16

Recommended Parameters ................................................................................................................................................... 16

OPERATION ..............................................................................................................................17

Making a Mould .......................................................................................................................17

Setting Parameters (for ECOPRESS 52) ...................................................................................18

Setting Parameters (for ECOPRESS 102/202)..........................................................................19

SERVICE AND MAINTENANCE ..................................................................................................21

Maintenance ......................................................................................................................................................................... 21

Troubleshooting....................................................................................................................................................................22

ACCESSORIES AND CONSUMABLES........................................................................................ 24

Mould Assemblies & Accessories ..........................................................................................................................................24

Consumables.........................................................................................................................................................................25

TECHNICAL DOCUMENTATION ............................................................................................... 26

Customer Service ..................................................................................................................................................................26

Hydraulic Wiring Diagrams....................................................................................................................................................26

4

DESCRIPTION

Design

All ECOPRESS models have electrohydraulic operation, which

do not require air. The sample is ejected fast and very

smoothly. All hydraulic components are housed in an ABS

cabinet, which is ergonomically designed.

ECOPRESS 52 is a cost effective automatic digital mounting

press with hydraulic pressure (requires no air). It is fully

automatic and suitable for all current hot mounting materials

used in materialography. User-friendly and modern-looking

control panel for mounting parameters provides high

productivity with last parameter settings being retained in the

memory. The control panel is specially designed to maximize

operator comfort and operation versatility. It is possible to set

mounting parameters in seconds.

ECOPRESS 52 is an easy to use mounting press. All button

controls, direct reading pressure gauge and valve are on the

front panel. Simply place the sample and the mounting media

in the cylinder and close the mold closure. Set the “Molding

Temperature”, “Heating Time”, “Cooling Time” and “Pressure”

then press the “Start” key. Pressure, heating and cooling are

automatically controlled and the total cycle time for a

complete cool mount takes 8 to 10 minutes. The actual

heating temperature and the heating time are digitally

displayed throughout the moulding cycle. The last parameter

settings are always retained in the memory. An audible signal

notifies the operator when the process is completed.

ECOPRESS 102/202 are high capacity, state of the art

automatic mounting presses having advanced software with

programmable colored HMI touch screen controls. Robust

bayonet closure allows for quick and safe operation. Wide

selection of mould assemblies from 25 to 50 mm in diameter

are available. Two mounts can be produced simultaneously

with the use of an intermediate ram. ECOPRESS 202, available

with dual cylinder can produce four mounts at a time offering

a perfect solution for labs with high specimen throughput.

ECOPRESS 102/202 have preprogrammed moulding

sequences built-in (factory set) from which you can choose

according to your own applications. You only need to place

the sample in the mould, select the program number for your

specific application and depress the “Start” button. That is it!

ECOPRESS does the rest for you! After pressing the start key,

the fully automatic program sequence is executed with the

preselected parameters. The pressure, heating and cooling

are automatically controlled and the total cycle time of a

complete cool mount takes 8 to 10 minutes. The parameters

can be changed and adjusted during the mounting process.

ECOPRESS 102/202 has additional capacity to store up to 99

operator-created programs. User-friendly program data and

instructions are displayed on a large touch screen LCD.

ECOPRESS 52

ECOPRESS 102

ECOPRESS 202

5

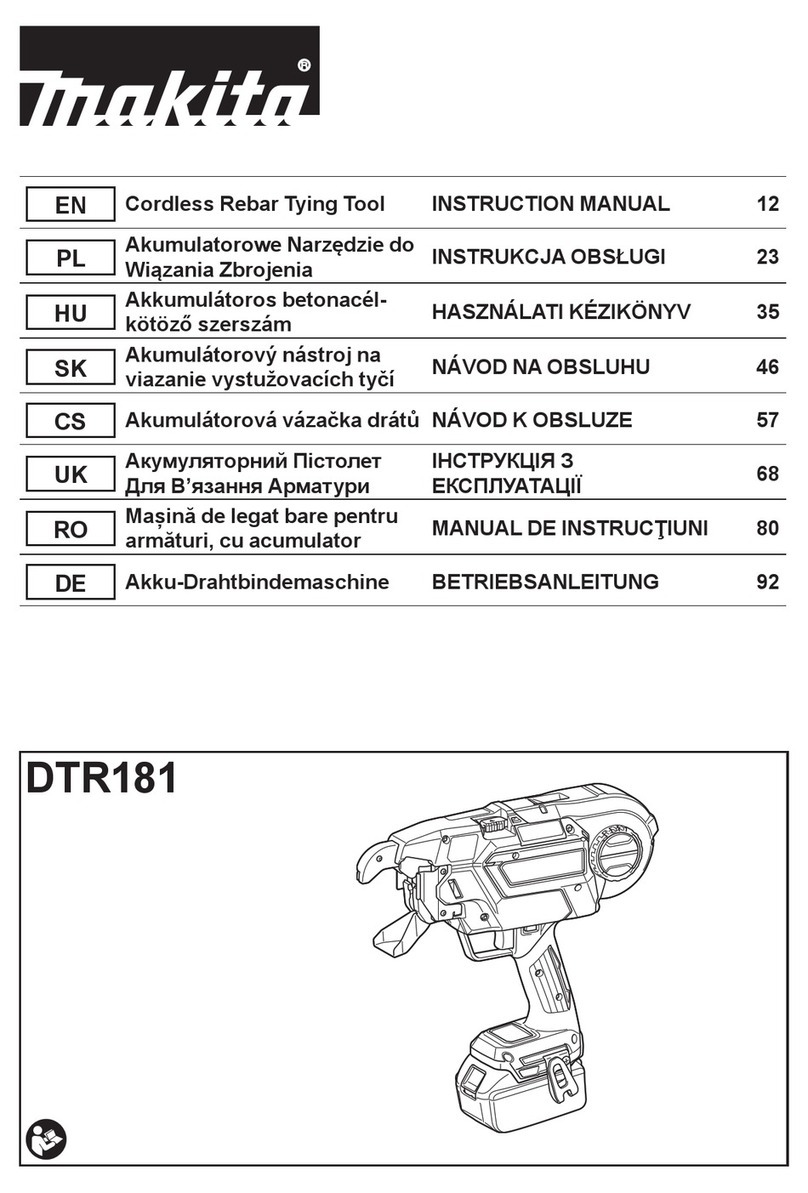

Technical Data

Model

Order No

ECOPRESS 52

25 10

ECOPRESS 102

25 11

ECOPRESS 202

25 12

Number of Moulds

1

1

2

Maximum Pressure, bar

300 bars

300 bars

300 bars

Maximum Temperature, °C

200 °C

200 °C

200 °C

Heating Power, Watt

1650 W

1650 W

2 x 1650 W

Fast Cooling

Yes

Yes

Yes

Slow Cooling

Yes

Yes

Yes

Operation

Automatic

Programmable

Automatic

Programmable

Automatic

Display

Digital Display

7” Colored

Touch Screen LCD

7” Colored

Touch Screen LCD

Mould Assembly, mm

25-50 mm

25-50 mm

25-50 mm

Dimensions, mm, WxDxH

360 x 560 x 470

360 x 560 x 470

470 x 560 x 470

Weight, kgs

37 kgs

38 kgs

54 kgs

6

Warranty

The ECOPRESS is guaranteed against defective material or

workmanship defects for a period of 12 months from the date

of receipt by the customer or latest 18 months after the

shipping date. The warranty is not valid if inspection shows

evidence of misuse or unauthorized repair. Warranty covers

only replacement of defective materials. If this unit need to be

returned to our factory for service, please contact your

distributor for authorization and include the following details:

Serial Number of the unit, Invoice number and date. Transport

costs belong to the customer.

NOTE

The equipment is designed to be used with

METKON accessories and consumables. In case of

misuse of equipment, improper installation,

alteration, use of different source parts, improper

repair, METKON will accept NO responsibility for any

damages to the operator or the equipment. Disassembling of

any part should always be performed by a qualified

technician

Safety Precautions

Read the below instructions carefully before use.

Place the machine on a sturdy and safe platform.

The equipment must be installed in compliance with

local safety regulations.

Only use approved METKON accessories and

consumables to achieve maximum safety and lifetime.

Follow the instructions and safety regulations when

lifting and carrying the equipment.

Be sure that the water connections are assembled

properly without any water leakage.

Be sure that the water outlet hose is safely assembled to

the outlet connection.

Be sure that the mould assembly is properly installed on

the mounting press before starting the process.

Be sure that the top closure and the upper ram is

correctly mounted before starting the process.

Do not operate the mounting press with a higher

force/pressure than the parameters recommended for

the actual cylinder diameter.

In case of mounting powder swallow, please contact to

your doctor.

Do not operate the unit without installing the mould

assembly.

Do not operate the unit without mounting powder.

Disconnect the electrical connection before servicing the

equipment.

Follow the periodically maintenance.

NOTE

METKON Instruments Inc. can make any changes

without notice on the equipment, accessories,

consumables and miscellaneous products.

Consequently; visual or written information on

the instruction manuals, technical materials, catalogues,

website, product videos and other marketing materials may

show inconsistencies and may be different from the product.

7

INSTALLATION & SET UP

Unpacking & Checking Contents of Package

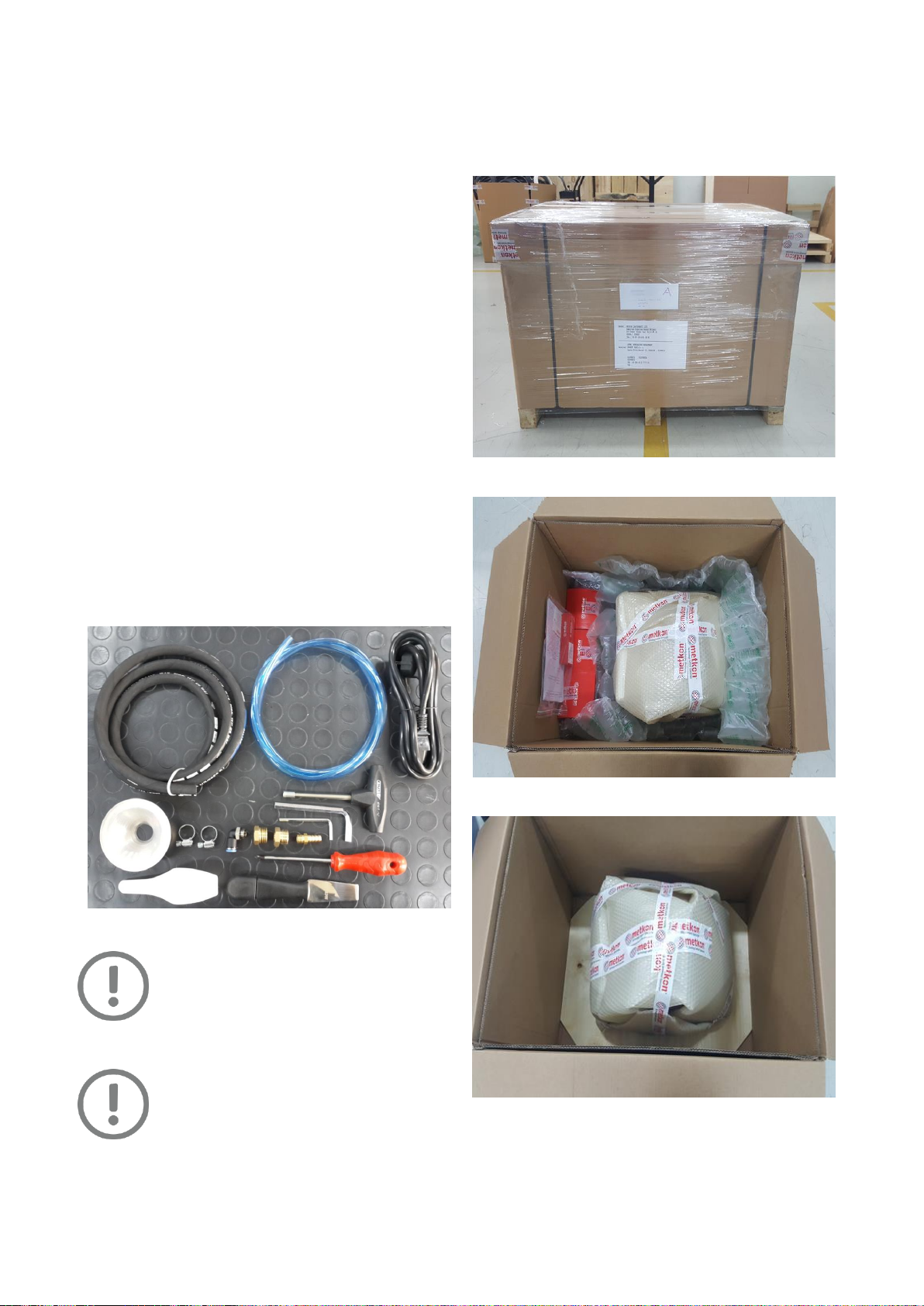

Carefully unpack and check contents of the package. If any

components are missing or damaged, save the packing list

and materials and advise your distributor and the carrier of

the discrepancy.

Carefully unpack and check that the following items have

been received:

Drain Hose for Hot Water, 1.5 m, 1 piece

Water Inlet Hose, 1.5 m, 1 piece

Power Cable, 1.8 m, 1 piece

Aluminium Funnel, 2 pieces

Hose Clamp, Ø10 –Ø16 mm, 2 pieces

Pneumatic Fitting, 8 mm to ¼”, 1 piece

Brass adapter, ¼”to ½”, 2 pieces

Nozzle, ¼”to 10 mm, 1 piece

Magnetic Bits Holder, T-type, 6.3 x 100 mm, 1 piece

Screwdriver, 6 x 100 mm, 1 piece

Hex Key, 8 mm, 1 piece

Hex Key, 4 mm, 1 piece

Scale, 1 piece

Spatula, 1 piece

WARNING

Please consider the weight of equipment and

be sure that there are enough people (at least

2) or lifting equipment to lift safely for

transportation. It is recommended to wear

safety shoes during transportation.

ATTENTION

ECOPRESS is bolted to a wood base for

protection during shipping. Remove the bolt

securing the unit to the wood base.

Step by Step Unpacking

Carefully remove the outer stretch wrap, cut the strips

and remove the cover.

Open the box and remove filling materials inside the box.

Remove the consumables first.

8

Remove the equipment from the box by holding the

bottom. Be careful not to damage ABS cover when lifting.

Please consider weight of equipment when lifting it. Lift

the equipment by considering the center of gravity.

Carefully remove the protective bubble wrap. Be carefull

not to damage equipment while using a knife.

Remove the protective foam on the touch screen

(ECOPRESS 102/202).

Installation and Set-Up

CAUTION

Follow approved procedures and take all

necessary preventive safety measures when

lifting and installing this equipment. Improper

lifting can result equipment damage.

ECOPRESS is available either as bench top or with

cabinet.

ECOPRESS should be placed on a sturdy and safe

platform. Please be sure that the platform is large enough

and can stand its weight.

In order to work with equipment comfortably, it is

recommended to leave at least 30 cm space from all side

of the equipment.

You can see the dimensions and weights of ECOPRESS

series:

ECOPRESS 52

Dimensions

W

D

H

36 cm

56 cm

47 cm

Weight

Approx. 37 kgs

ECOPRESS 102

Dimensions

W

D

H

36 cm

56 cm

47 cm

Weight

Approx. 38 kgs

ECOPRESS 202

Dimensions

W

D

H

47 cm

56 cm

47 cm

Weight

Approx. 54 kgs

ATTENTION

IN ORDER TO PREVENT OIL LEAKAGE FROM

THE RESERVOIR, DO NOT TILT THE

EQUIPMENT.

9

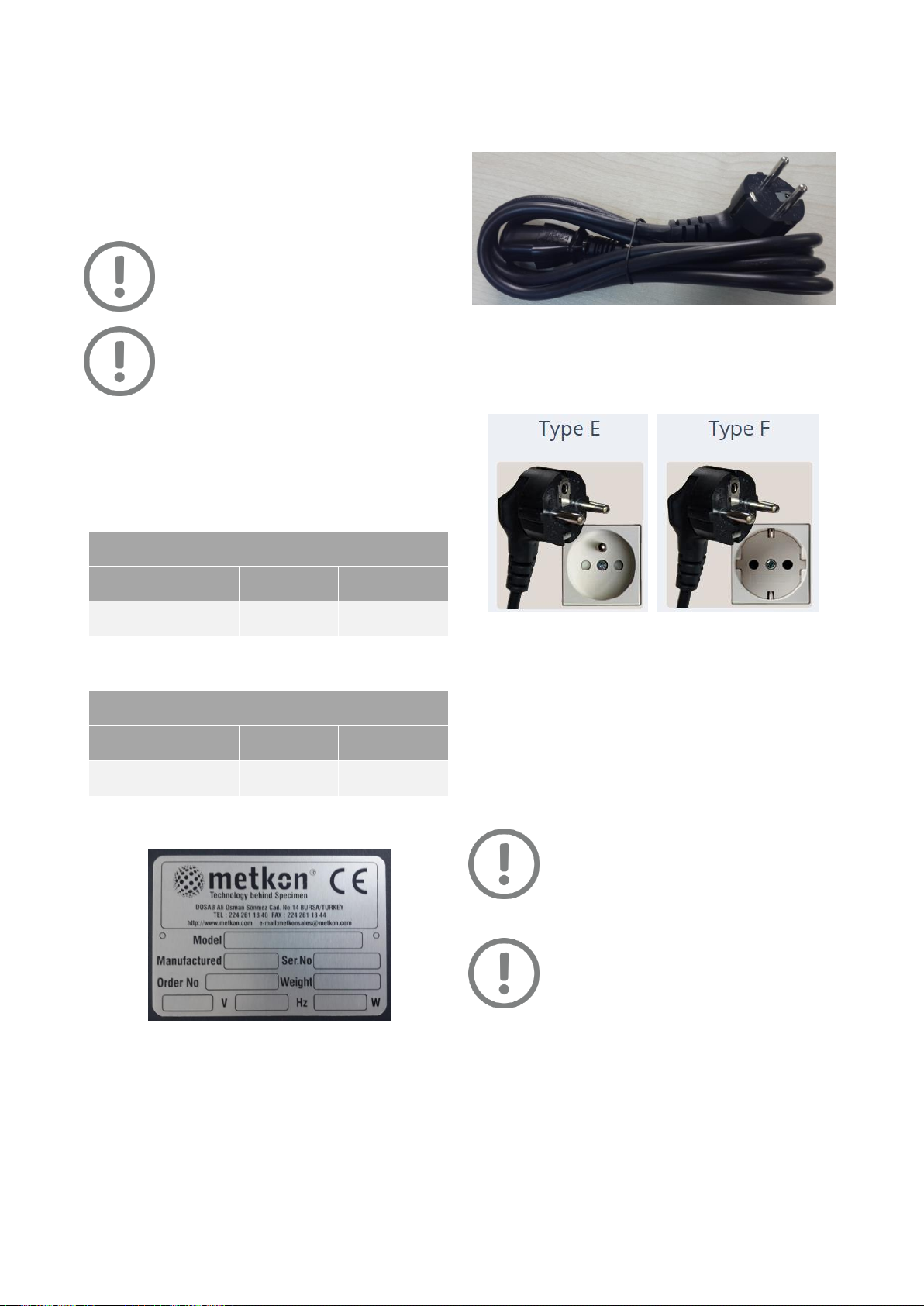

Electrical Installation

Before making electrical connections, check that the voltage

and frequency stated on the specification plate correspond to

the local voltage and frequency. Check that the values for

mono-phase voltage if it is compatible with the intended

electrical supply before installation.

ATTENTION

Connect the unit to the grounded mains

voltage.

WARNING

Electrical Shock Hazard. A qualified electrical

technician should perform all hard wiring and

electrical maintenance.

Disconnect the power supply before making any

electrical adjustments.

Make sure that the supply voltage and frequency is

correct. Check the values from the machine identification

plate located at the rear of the machine:

ECOPRESS 52/102

Voltage / Frequency

Operational

Power Range

Fuse Rating

230 V, 50/60 Hz. 1 ph.

200 - 250 V

10A (C Type)

115 V, 50/60 Hz. 1 ph.

100 - 125 V

20A (C Type)

ECOPRESS 202

Voltage / Frequency

Operational

Power Range

Fuse Rating

230 V, 50/60 Hz. 1 ph.

200 - 250 V

20A (C Type)

115 V, 50/60 Hz. 1 ph.

100 - 125 V

32A (C Type)

Identification Plate

Connect the equipment to the grounded mains voltage.

Power cord will be supplied with the equipment.

Length of power cable is 1.8 meters.

Power Cable

You can see suitable power sockets as below. If you have

not suitable power socket, in this case you should supply

a suitable power cord.

Water & Cable Connections

ECOPRESS requires water supply with a minimum of 2

liters/min flow rate.

Maximum water pressure must not exceed 3 bars. Well

water or hard water must not be used.

Lower water flow rate and pressure will not affect the

operation of the ECOPRESS but longer cooling times may

be needed.

ATTENTION

A Hydrophore generates much higher water

pressure than city water. This causes input

hose to blow out and solenoid valve to be

damaged. Maximum water pressure must not exceed 3 bars.

ATTENTION

Well water or hard water causes solenoid valve

to be clogged up and broke down due to dirt

and lime.

10

If the equipment used with well water, hydrophore or

very hard water; a water filtering and pressure regulator

system must be used. Please contact Metkon Service

representative if you need water filtering and pressure

regulator system.

Water Filtering and Pressure Regulator System

Water inlet and drain hoses will be sent together with the

equipment. (See: Installation Kit)

See diameters of hoses as below:

Drain Hose:

Interior diameter: 5/16”

Outer diameter: 14 mm

Water Hose:

Interior diameter: 5 mm

Outer diameter: 8 mm (5/16”)

Please be sure that there are enough space or holes for

hoses at the backside of the equipment.

Below fittings will be sent for water hose connection

together with the equipment :

Connect the line water to the unit with the plastic tube

supplied.

Fix the copper tube to the water outlet of the unit to the

drain.

Connections

CAUTION

After making the connection of line water and

drains please check if any leaks are occurred or

not, before any electrical connection.

ATTENTION

There is a small blue plug at the backside of the

equipment, which is used for transport. This

plug is used to prevent oil leakages during the

transport. Please take the plug out before using the

equipment and do not use it anymore unless you will

transport it somewhere.

NOTE: If for any reason the ECOPRESS has to be moved, close

the small blue plug before moving and open before

operating.

Optional Recirculating Cooling System

The GR 1363 Recirculating Cooling System is composed of 40

liters stainless steel cooling tank, 24V recirculating pump and

connection hoses, etc.

Recirculating Cooling System

Follow below steps to make recirculating cooling system

ready for operation:

Position the recirculating cooling tank below level of

ECOPRESS.

Fit the blue inlet pipe to the ECOPRESS

Fit the black hose to the drain outlet on the ECOPRESS.

Fill the tank with fresh water.

Mains Cable

Connection

Drain Water

Outlet

Water Inlet

Transport

Plug

11

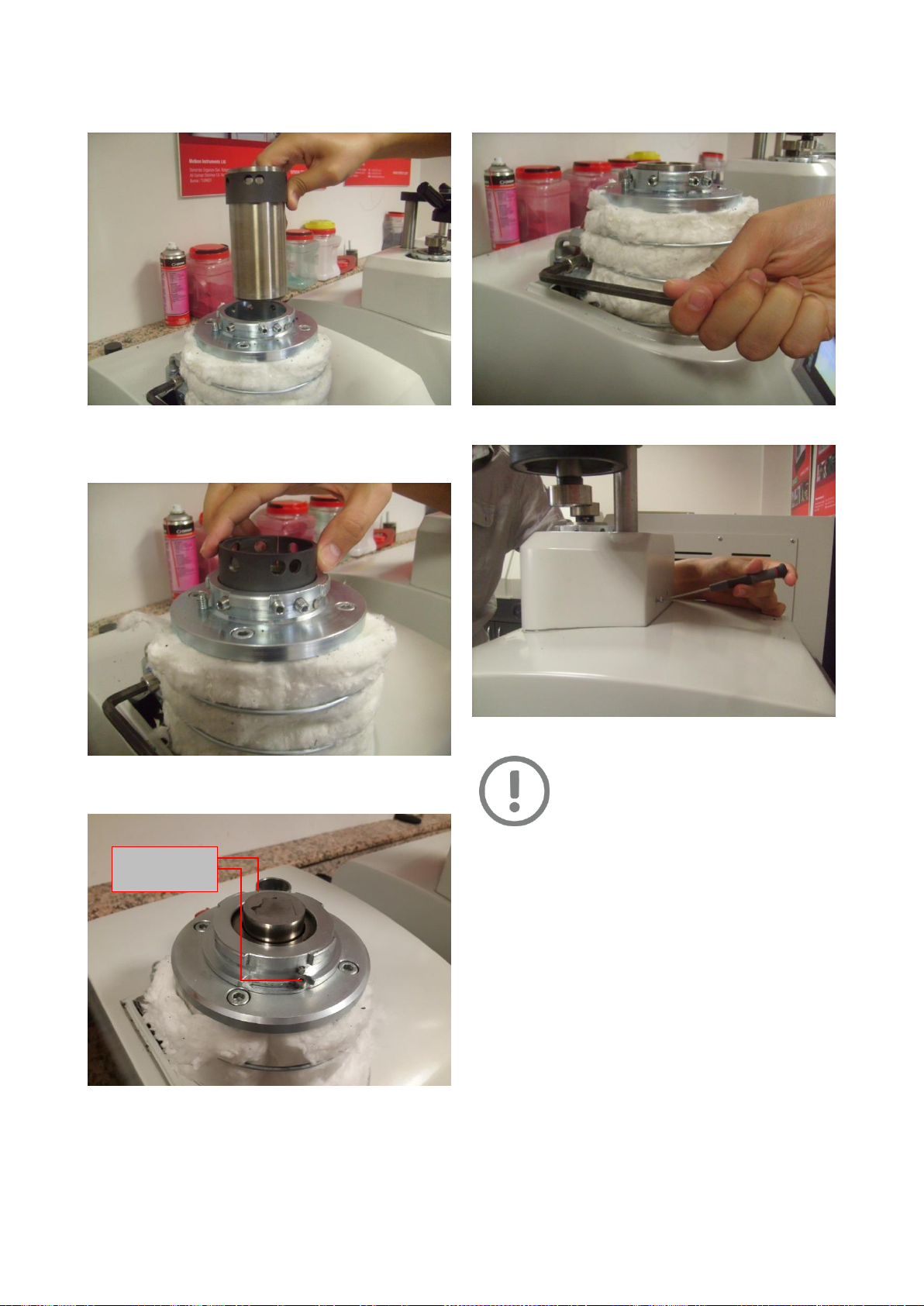

Mounting Mould Assembly

ECOPRESS is shipped as completely assembled. However if

you need to change the mould or assemble it later for any

reason, follow the below steps to assemble the mould:

Take out the mould closure completely.

Remove the two fixing screws from back of the ABS

cover of the mould chamber then, remove the upper ABS

cover.

Take out the bottom ram then, lower the ramrod to the

bottom.

Disassemble the screws and take out the upper part

metal thread of the mould.

Tighten (clockwise) the Cylinder Lock screw.

Take out the mould assembly as shown in below photo:

Remove

these screws

12

Replace your mould assembly. Insert the mould assembly

until it sits level with the mould closure.

Insert the Mould Cylinder Insulator Ring into the Mould

Closure. Align the holes of the Insulator Ring with the

screws.

Assemble the upper part metal thread of the mould cover

and tighten the screws.

Loosen (counterclockwise) the Cylinder Lock screw

shown on below photo:

Close the upper cover and assemble the screws.

IMPORTANT!

You should order the mould assembly

according to dimensions and shape of your

sample. Big samples, which touch the inner

wall of moulds, can scratch the mould assembly. In addition,

using less hot mounting powders than the required can

scratch the mould assembly. Please keep in mind that this

kind of damages due to operator fault are not covered by

warranty.

Tighten these

screws

13

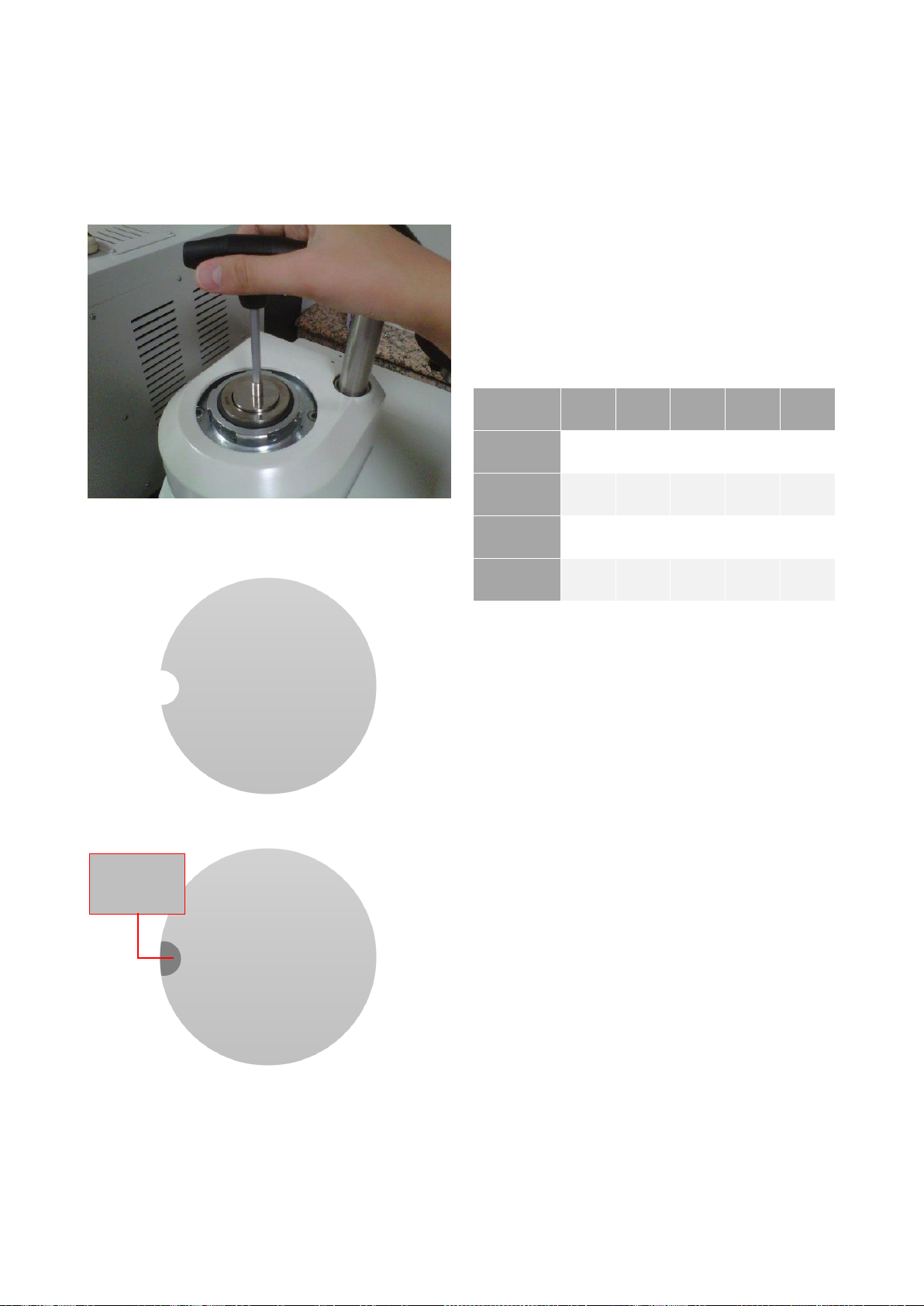

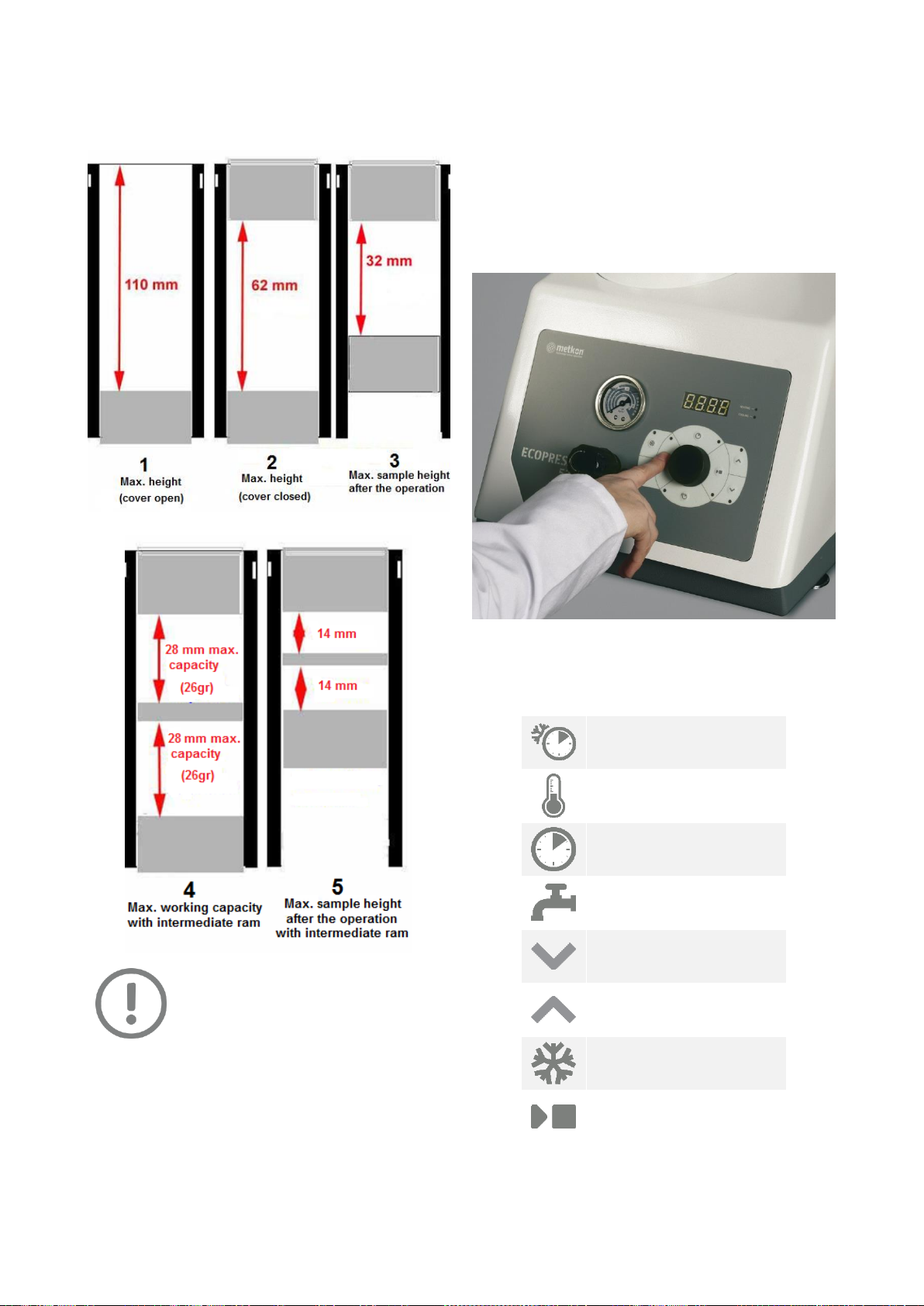

Using Intermediate Ram

You can get double mounts in one cycle by using

intermediate ram. After placing your first sample and

mounting compound, insert the intermediate ram with the

help of the magnetic ram holder. Then put your second

sample and mounting compound.

Please clean the material accumulated at the groove of the

intermediate ram as shown below before each operation for

safety.

Intermediate Ram before Operation

Intermediate Ram after Operation

Be sure that the resin that you put on the sample exceeds

the sample height enough.

Maximum height of the samples should be 10 mm.

If the put resin is not enough, the sample may touch to

the upper ram or to the intermediate ram. This will distort

the intermediate ram and the inner surface of the mold

assembly.

Do not put your specimen close the edge of mould.

Otherwise, the sample may scratch the mould.

Each mounting compound has different melting and cooling

properties. Therefore, the working capacity and amount of

powder would be change for each powder. Below table

shows general dimensions according to different compounds

in Ø40 mm mould assembly.

No

1

2

3

4

5

Phenolic

110 mm

62 mm

32 mm

28 mm

(26 gr)

14 mm

Epoxy

110 mm

62 mm

33 mm

28 mm

(38 gr)

15 mm

Acrylic

110 mm

62 mm

40 mm

28 mm

(25 gr)

17 mm

Diallyphtalat

110 mm

62 mm

27 mm

28 mm

(28 gr)

12 mm

Above-mentioned information has been given as a reference

for Ø 40 mm to give an idea about the mounting compound

transformation.

Accumulated

Material Must

be Cleaned

14

Below table shows capacity of the moulds in different stages

while using phenolic mounting powder in Ø40 mm mould

assembly.

ATTENTION

All mould jamming and scratching problems

caused by operator fault are out of warranty!

Noise Level

Approx. 60 dB is measured at idle running at a distance of 1 m

from the machine.

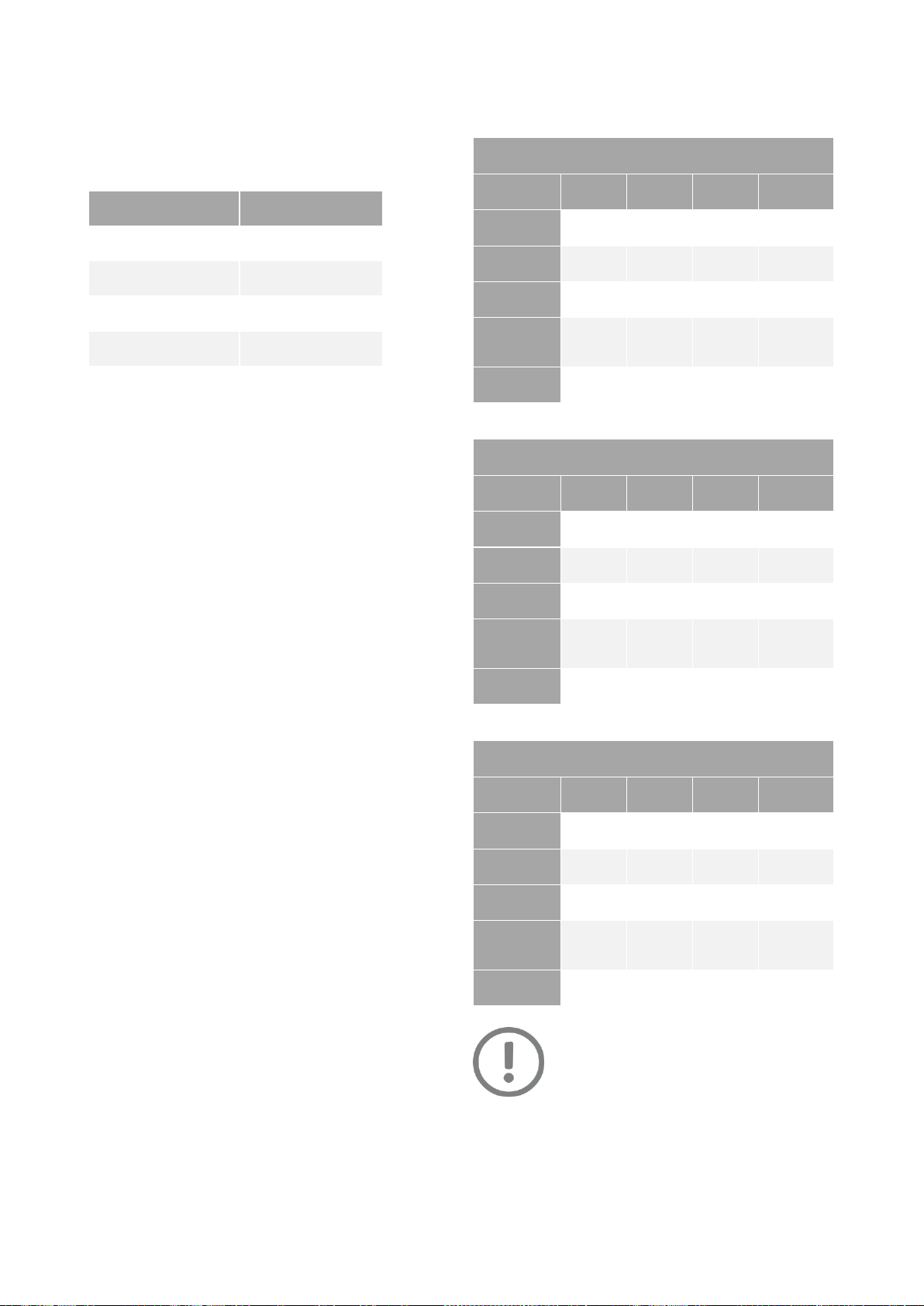

CONTROL PANEL (ECOPRESS 52)

ECOPRESS 52 has a modern looking and easy to use operator

panel with buttons and knob. It has specially designed to

increase operator comfort and maximize productivity. All

mounting parameters can be set easily and quickly. A

multipurpose digital display allows you to observe all

parameters.

ECOPRESS 52 Control Panel

Control Button Functions

Cooling Time

Heating Temperature

Heating Time

Manual Cooling

Ram Down

Ram Up

Slow Cooling

Start/Stop

15

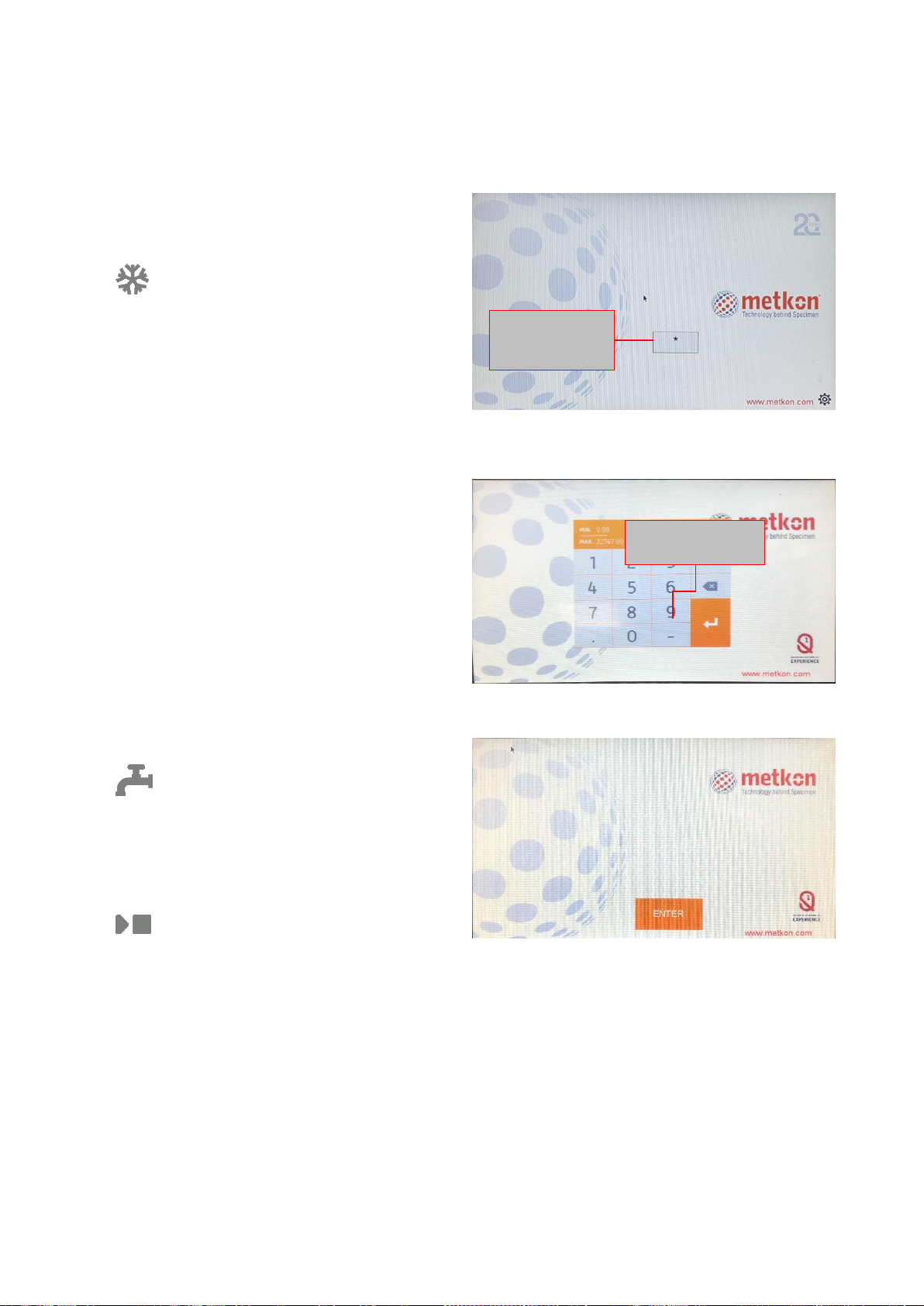

TOUCH SCREEN CONTROL PANEL

(ECOPRESS 102/202)

The operation panel is a 7’’ touch screen LCD. HMI touch

screen controls increasing the productivity, sample

consistency and operator comfort.

ECOPRESS 102/202 HMI Touch Screen

Control Button Functions

Main menu

Metkon contact info

Service and maintenance menu

Information

Language Selection

Bar/PSI Selection

°C/°F Selection

Consumable List

Application Areas

Automatic Mounting Menu

Temperature Parameters

Pressure Parameters

Heating Time Setting

Mould Dimension Selection

Cooling Parameters

Switch to Left Mould

Switch to Right Mould

Ram Up

Ram Down

Manual Cooling

Load Existing Program

Save Parameters

16

Password List

Below are passwords, which are required for operating and

programming the machine. You can use any of them.

Username

Password

Start-up Password

1840

USER1

1234

USER2

123456

USER3

1000

Operation Parameter Ranges

Heating Temperature : 0 –200 °C

Preheating Temperature : 0 –199 °C

Pressure for Ø25-30-40 : 0 –300 Bar

Pressure for Ø50 : 0 –220 Bar

Preload Pressure for Ø25-30-40 : 20 –299 Bar

Preload Pressure for Ø50 : 20 –219 Bar

Heating Time : 0 –35 Mins

Mould Size, mm : Ø25-30-40-50 mm

Mould Size, inch : Ø1”-1 ¼”-1 ½”-2”

Stand-by Temperature : 0 –60 °C

Recommended Parameters

For Ø25 and Ø30 mm Mould Assemblies

Moulding

Resin

BAK/CON

DAP

EPO

NET

Heating

Temperature

170 °C

180 °C

180 °C

150 °C

Pressure

250 bar

210 bar

210 bar

230 bar

Curing Time

3-4 mins

4-5 mins

4-6 mins

3-4 mins

Cooling

Method

Cooling

Based on

Time

Cooling

Based on

Time

Cooling

Based on

Time

Slow

Cooling

Cooling Time

3-4 mins

3-4 mins

3-4 mins

5 sec ON

30 sec OFF

For Ø40 mm Mould Assemblies

Moulding

Resin

BAK/CON

DAP

EPO

NET

Heating

Temperature

170 °C

180 °C

180 °C

150 °C

Pressure

250 bar

210 bar

210 bar

230 bar

Curing Time

2-3 mins

3-4 mins

4-5 mins

3-4 mins

Cooling

Method

Cooling

Based on

Time

Cooling

Based on

Time

Cooling

Based on

Time

Slow

Cooling

Cooling Time

3-4 mins

3-4 mins

3-4 mins

5 sec ON

30 sec OFF

For Ø50 mm Mould Assemblies

Moulding

Resin

BAK/CON

DAP

EPO

NET

Heating

Temperature

170 °C

180 °C

180 °C

150 °C

Pressure for

Ø50 Mould

210 bar

210 bar

210 bar

210 bar

Curing Time

2-3 mins

3-4 mins

4-5 mins

3-4 mins

Cooling

Method

Cooling

Based on

Time

Cooling

Based on

Time

Cooling

Based on

Time

Slow

Cooling

Cooling Time

3-4 mins

3-4 mins

3-4 mins

5 sec ON

30 sec OFF

NOTE

These are the minimum parameters to obtain a

good mount in the shortest time. Higher values

do not cause negative effect on the mount

quality but total cycle time may be increased. Sample shape,

powder amount and temperature of city water may effect

the mount quality. If you cannot obtain good sample with

these parameters, please try different parameters by

following recommendations on the troubleshooting section.

17

OPERATION

Making a Mould

Turn on the equipment from the main switch at the rear

side.

Open the bayonet closure.

Move the ram upmost position by pressing “Ram Up”

button.

Clean the powder residue from the upper and bottom

rams. Brush away any loose mounting material or other

deposits from around the mold area before making a

mold.

Apply Mould Release Spray after every fifth or sixth mold

to prevent buildup of molding powder on the inside of

the mold cylinder and the outside faces of the upper and

lower rams.

Put a specimen on the ram as below.

Move the ram to the bottom position by pressing “Ram

Down” button.

Put enough amount of mounting powder inside the

mould.

Clean the sidewalls of the mould and upper ram.

Otherwise, upper ram cannot go inside the mould and

bayonet closure cannot be closed. Because there is very

small tolerance between the rams and mould.

After cleaning, close the bayonet closure. Be sure that

the closure is closed properly. Hear the click noise to be

sure that it is closed properly. Otherwise, the thread of

the closure may break under pressure.

Set parameters or select a specific program and press

“START” button. The mounting cycle will be completed

automatically. An audio signal will notify the operator

when mounting operation is completed.

After mounting operation is completed, turn the bayonet

closure to unlock it. Do not try to pull it up. Because, the

upper ram is expanded due to temperature and cannot

be moved up easily.

Press “Ram Up” button to move ram up. You can take

your specimen.

18

Setting Parameters (for ECOPRESS 52)

Adjusting Pressure

Follow below steps to adjust pressure:

Put some mounting powder inside the mould and close

the bayonet closure.

Press “START” button.

Wait until bottom ram goes up and apply pressure.

Pull up the pressure regulator to unlock it.

Set the pressure by turning pressure regulator. Observe

the pressure from the gauge.

After desired pressure value is set, push the pressure

regulator to lock it.

Press “STOP” button.

The pressure is set!

Gauge

ATTENTION

The maximum allowable pressure for different

types of moulds are marked on the gauge.

Never increase the pressure into the “DANGER”

zone. This may damage the hydraulic system.

Warranty will not cover the damages due to operator fault.

NOTE

The pressure is already set in the METKON

Factory according to purchased mould

diameter and Bakelite mounting powder (BAK).

However, if you change the mold later with

different diameter, it is required to adjust the pressure. If you

are using different type of mounting powders, you do not

have to change pressure parameter every time. You can use

same pressure parameter for each mounting powders. Just

adjust the pressure parameter for the mounting powder,

which require the highest pressure.

ECOPRESS 52 Control Panel

Moving the Bottom Ram

Press “Ram Down” button to move the ram downwards.

Press the same button again to stop the ram.

Press “Ram Up” button to move the ram upwards. Press

the same button again to stop the ram.

Setting Heating Temperature

Press the “Heating Temperature” button. The LED of this

button will blink and the last parameter will be seen on

the display.

Set heating temperature by turning knob.

Push the knob to save heating temperature.

Heating temperature is set.

Setting Heating Time

Press the “Heating Time” button. The LED of this button

will blink and the last parameter will be seen on the

display.

Set heating time by turning knob.

Push the knob to save heating time.

Heating time is set.

Setting Cooling Time

Press the “Cooling Time” button. The LED of this button

will blink and the last parameter will be seen on the

display.

Set cooling time by turning knob.

Push the knob to save cooling time.

Cooling time is set.

19

Slow Cooling

Slow cooling feature is used while moulding with

Transparent Acrylic Powder (NET). This mounting powder

will be clear only with the slow cooling.

When you press “Slow Cooling” button, the LED of this

button will be on and slow cooling mode will be

activated. In slow cooling, the cooling water will be on

for 5 second, will be off for 30 seconds. This cycle will

continue until mould temperature reaches to 35 °C.

When slow cooling mode is active, the cooling time

parameter will be deactive.

Press same button again if you want to deactive the slow

cooling mode. The LED of this button will be off and slow

cooling mode will be deactivated.

Changing the Slow Cooling Parameters

Keep pressing the “Slow Cooling” button for 5 seconds.

The final temperature will be seen on the display. Set the

final temperature by turning knob and press on the knob

to save the parameter.

After that, press “Slow Cooling” button. Now, the “water

on time” will be seen on the display and the LED of this

button will blink. Set and save the “water on time” by

knob in same way.

Finally, press again “Slow Cooling” button. Now, the

“water off time” will be seen on the display and the LED

of this button will blink. Set and save the “water off time”

by knob in same way.

Manuel Soğutma

When you press “Manual Cooling” button, the LED of this

button will be on and cooling water will be active. The

water circulation will continue as long as manual cooling

mode is active.

Press the same button again to turn off the cooling water.

Start and Stop

Press the “Start/Stop” button to run or stop the

equipment. The LED of this button will be on when

equipment is running.

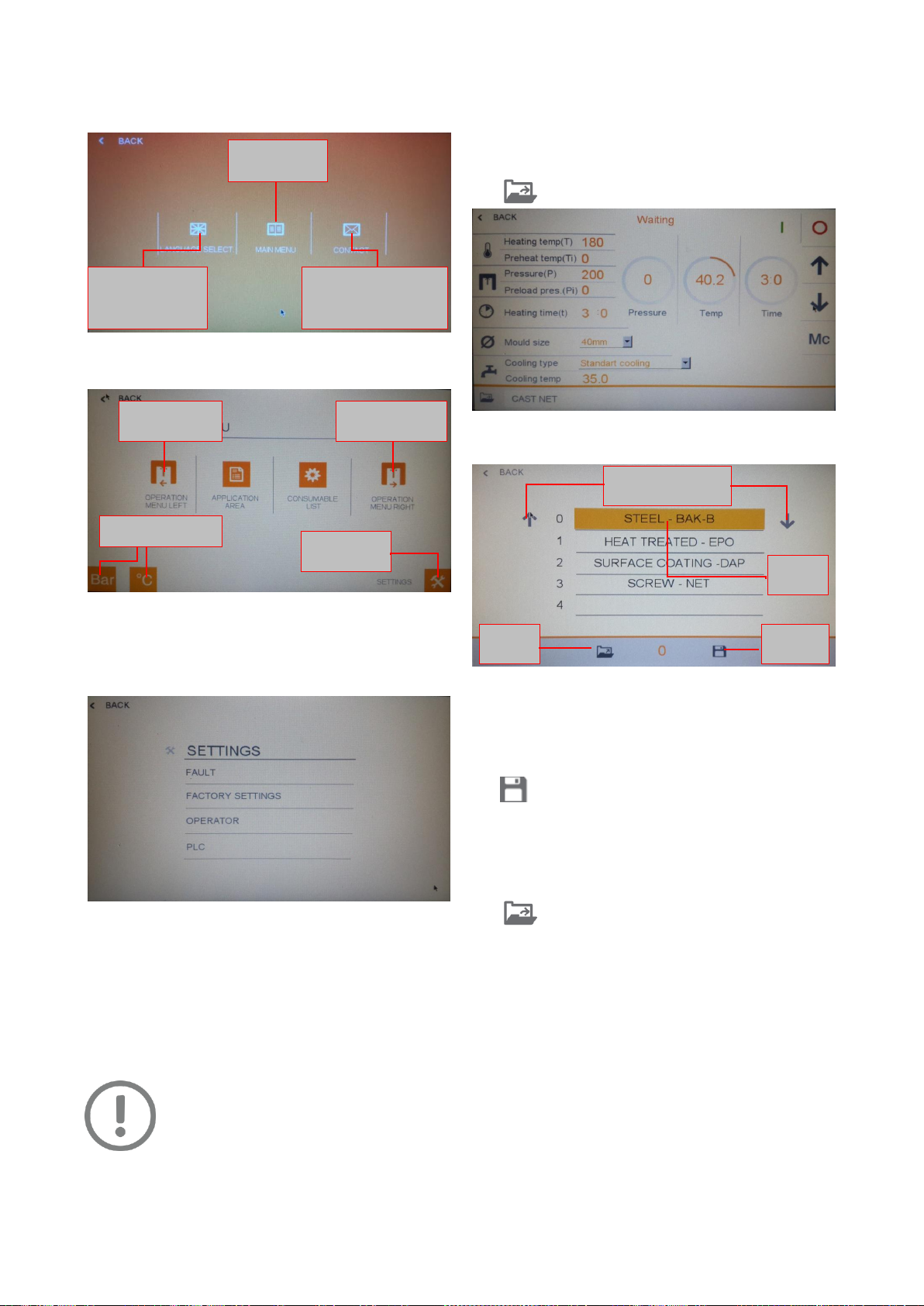

Setting Parameters (for ECOPRESS 102/202)

Turn on the equipment from the main switch at the rear

side. The screen will become light up as below.

Starting Screen

Enter the starting password: 1840

Entering the Starting Password

Press ENTER button to continue.

Starting Screen

Press here to

enter the starting

password.

ENTER the starting

password: 1840

20

The menu will appear as below. Press MAIN MENU

button to continue.

Starting Menu

The MAIN MENU will appear as below:

Main Menu

Service and Maintenance Menu - From this menu, you

can see the lists of possible faults, for periodic

maintenance, and the factory settings.

Service and Maintenance Menu

In order to have Access to the “maintenance” division, you

need to login. The user name is “USER 1” and the password is

“1234”.

You can follow the instructions listed in this menu for

maintenance and monitoring of your equipment. The date and

the time is also set in this menu.

ATTENTION

Every week, month & year you will be advised

of required maintenance procedures via the

machines software. The functions will not

work unless you adhere to the maintenance

menu.

Creating and Saving Mounting Parameters

Set all the parameters from the touch screen and depress

“Load” button.

Operation Menu

Program Save/Load menu will appear as below:

Save Program

Select an empty area by the help of up/down arrows.

Touch the naming area.

Type a specific program name.

Press save button.

NOTE: The parameters can be changed and adjusted

during the mounting process.

To load an existing program, select an existing program

by the help of up/down arrows and then press the “Load”

icon.

You can change

the language

from this menu

Enters the

MAIN MENU

You can see the

contact information

of METKON.

Mould Selection

(Left)

Mould Selection

(Right)

Metric / Imperial

Service &

Maintenance

Move up & down for

program numbers

Program

Save

Program

Load

Naming

Area

This manual suits for next models

5

Table of contents

Popular Power Tools manuals by other brands

Würth

Würth 1952 004 530 Translation of the original operating instructions

Makita

Makita HM1810 instruction manual

Powerfix Profi

Powerfix Profi PKRS 1.5 A1 operating instructions

Chicago Electric

Chicago Electric 66001 Set up and operating instructions

Berner

Berner BACHG Original instructions

Grizzly

Grizzly G9859 instruction manual