5

Operating Instructions

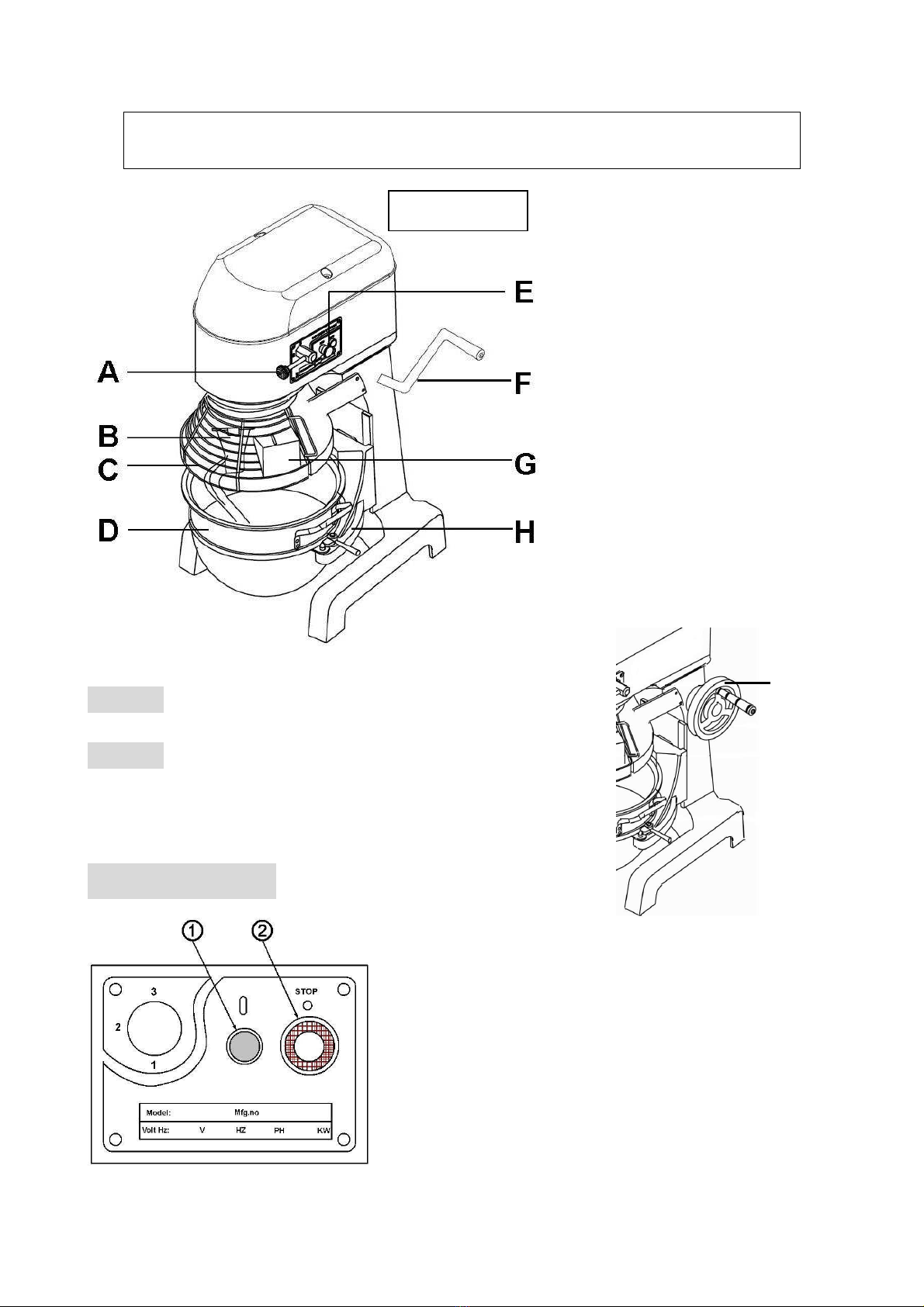

CORRECT USE OF THE MIXER

-It is the responsibility of the operators to use the mixer correctly within the recommended

limitations. Always follow the instructions on the side of the machine when changing gear.

If the motor labors, please stop the machine and reduce the size of the mix immediately.

Damage resulting from improper use is will void the warranty.

-For operator safety, the machine is fitted with a bowl guard which is electrically interloc er

to ensure that the mixer cannot operate unless the guard is correctly positioned and the

bowl is raised. Excessive force used to open and close the bowl guard may damage the

electrically interloc er, and will void the warranty.

-For additional safety, the mixer has a no volt release feature which means that in the event

of a power failure, the machine will only restart after the control button has been pressed

again. This arrangement ensures that when the supply is restored, the machine cannot

restart on its own.

-Careful handling of bagged products by minimizing the height above the bowl base from

which they are poured.

-Careful slitting of bags in the lower part of the bowl to allow dust free discharge of flour as

flour as possible.

-Use temporary bowl covers to minimize openings through which flour many escape.

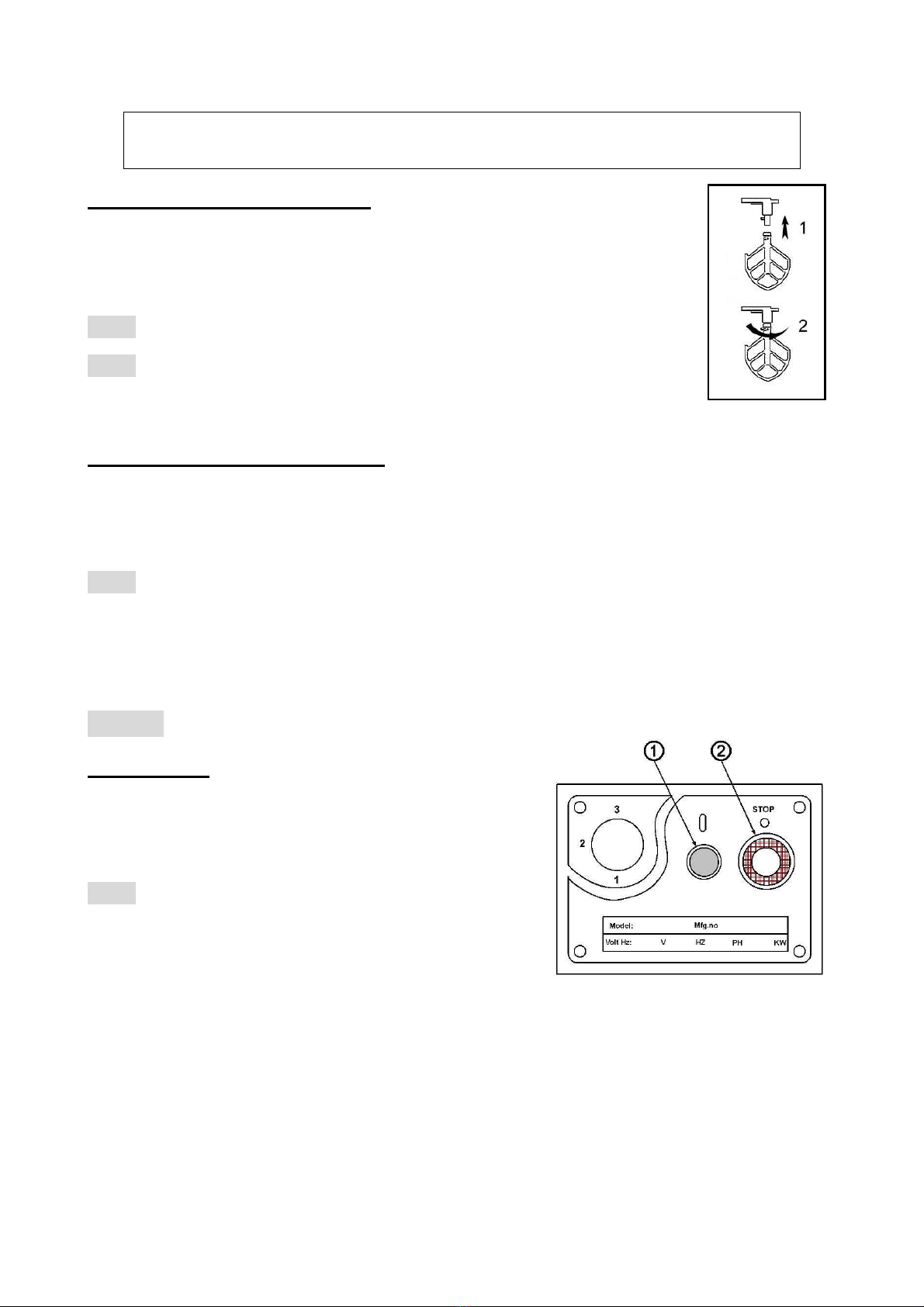

TOOL SELECTION

The beater, whis and spiral dough hoo are

tools for the wor implied by their names. Do not

use the beater for dough ma ing or the whis for

anything other than whis ing, aerating or mixing

light mixtures.

The Table 1 shows the typical uses for each

of the tools.

NOTE: Always wash agitator with mild soap and

apply light quantity of mineral oil to planetary

shaft after cleaning.

FITTING THE BOWL

With the bowl cradle lowered, place the chosen mixing tool in

the bowl and position the bowl on the cradle. There are three

location points when fitting the bowl. Please refer to Figure :

(1) The loc ing pin at the rear of the bowl should locate in the hole

of the cradle.

(2) The two holes in the bowl handles must engage on the pins

located on the cradle.

(3) Please ensure that the bowl is seated correctly on the cradle

before securing the bowl loc ing latches prior to use.

Beater: Firm mixes such as light

pastry, ca es biscuits, icings

fillings and mashed vegetables.

Spiral Dough Hook: Heavy mixes

such as dough, pie pastry. .

Whisk: Light mixes such as

whipped cream, mayonnaise,

egg whites, panca es and

Table 1

Figure