Metrima SVM F4 User manual

SVM F4

Calculator

Manual

2

Calculator F4

manual

1 GENERAL 4

1.1 Installation 4

1.2 Principle of energy measurement 5

1.2.1 Alternative naming 5

1.3 Calculator specifics 5

1.3.1 Monthly values 7

1.3.2 Account days 7

1.3.3 Pulse counter register 1 and 2 8

1.3.4 Placing of flow sensor 8

1.3.5 M-Bus 8

1.3.6 Communication address 8

1.3.7 Power cut 8

2 BUTTONS AND JUMPERS 9

2.1 Push button 9

2.2 Service buttons 9

2.3 Test button 9

2.4 Save data button 9

2.5 2/4-Wire method temperature sensors

jumpers 10

2.6 ON/OFF jumper battery powered

calculators ONLY 10

2.7 Slot jumpers Signal/Power

redirecting 10

2.8 Power ON/OFF 10

3 DISPLAY 11

3.1 Back-light 11

3.2 Display test 11

3.3 Display modes 12

3.3.1 Transport mode 12

3.3.2 Initial mode ( INIT mode) 12

3.3.3. Service Mode 13

3.3.3.1 Service/INIT mode sequence 13

3.3.4 Test mode ( programming mode) 14

3.3.5 Normal mode ( operating mode ) 15

3.3.5.1 Display sequence normal mode 16

3.3.5.2 Display seq. normal mode 2 17

3.3.5.3 Display sequence normal mode

(summary) 17

3.3.5.4 Display sequence normal mode

schematics 18

3.4 Error codes 19

4 SEALS, CALCULATOR

PROTECTION 20

4.1 Volume check 20

5 CONNECTING THE

CALCULATOR / HANDLING 21

5.1 Circuit board F4 21

5.2 Connection terminals 22

5.2.1 Sensors and M-Bus connection 22

5.2.1.1 EN1434 terminal table 22

5.2.2 Pulse input connection 23

5.2.3 Pulse output connection 23

5.2.4 Connection 3V/12V 23

5.2.5 Save data 24

5.2.6 Alarm output connection 24

5.2.7 Option board connection 24

5.2.8 Potential free output 24

3

5.3 Battery and mains connection 25

5.4 Calculator connection 25

5.5 Mains connection and backup

battery 25

5.6 Option board handling 26

5.6.1 Option board installation

procedure 26

5.6.1.1 Installing several option

boards at the same time 26

5.6.2 DIP-Switch setting of option board 27

5.6.3 Installing additional option boards

when one or several option boards

is/are installed 27

5.6.4 Configure the option board 27

5.6.5 Reconfigure option boards 27

5.6.6 Uninstall, removal of option boards or

reconfiguring option boards 27

5.7 Cable fittings 28

5.8 Mounting 28

5.9 Zero sequence current 29

5.9.1 Description of zero sequence

current 29

6 METER MEASURING

6.1 Calculation of flow 30

6.1.1 Momentary flow 30

6.2 Calculation of power 31

6.3 Temperature measurement and

4-wire measurement 31

6.4 Storing values 31

7 TESTING, PROGRAMMING &

SERVICE 32

7.1 Programming the calculator 32

7.2 Display test 32

7.3 Installation test 32

7.4 Service 33

7.4.0 Time 33

7.4.1 Date 33

7.4.2 Pulse value 33

7.4.4 Account days 33

7.4.6 Communication address

(primary address) 33

7.4.7 Resetting stored error time 33

7.4.8 Placement of flow sensor placing33

7.4.9 Recommended date for battery

replacement 33

7.4.A Return to normal mode 33

7.4.10 Clarifications on format 33

7.5 Verifying the calculator 34

8 TECHNICAL DATA 35

8.1 Data output table 35

8.2 Power supply 36

8.3 Temperature sensors 36

8.4 Flow sensors 36

8.5 Temperature ranges 36

8.6 Ambient temperature &

Temperature class 36

8.7 Flow sensor placing 36

8.8 Maximum values for power 36

8.9 Dynamic behaviour 36

8.10 Data output interfaces 36

8.11 Pulse outputs 37

8.12 Pulse inputs 37

8.13 Alarm output 37

4

1 General

1.1 Installation

The calculator is delivered set in “Transport mode”,

but depending on delivery options the calculator

can be delivered in other “display modes”, e.g.

“Transport mode”, see display modes for more

information. Follow this procedure to install the

calculator:

1. Setting of calculator, see “Service, setting

meter” for more information.

2. Install option boards, see “Install option

boards” for more information.

3. To mount the calculator, see “Mounting”.

4. Connecting the calculator, see “Connections”.

5. Check Seal, see “Seals”.

6. Display and function test, see “Display and

function tests”.

7. Set the calculator into normal mode, see

“Different display modes” for more

information.

8. Function test, see “Tests”

5

1.2 Principle of energy

measurement

Energy measurement consists of:

1. Calculator

2. Two paired temperature sensors, resistance

thermometers, PT100 or PT500

3. Flow sensor, that emits pulses

The calculator calculates energy by measuring

temperature difference at each flow pulse emitted

by the flow sensor, or at the sum of several pulses.

Data stored in calculator can be read on the display

or through an external communication. M-Bus is

the standard communication protocol. Other

communication protocols are available on option

boards.

1.2.1 Alternative naming

The nomenclature for the energy industries are not

unified, different words are used to explain the

same things. The words recommended are under-

lined.

Calculator,Heat meter or meter

Flow sensor:

Supply, forward, hot and high.

Return, cold, low

1.2.2 Medium

The F4 calculator algorithm is only for measuring

energy in water.

When using water mixtures another algorithm is

required then the calculator MF4, a calculator for

mixtures is required.

Fig. 1.1, Principle of energy measurement

ABB

F4

1

Supply

2

Return

3

2

SVM

6

1.2.3 Operating conditions

All electronics have limitations like response time,

in memory capacity and so on. In order for the

battery consumption and for trouble free usage of

the calculator following limitations apply for the

F4, see below.

1.2.3.1 Normal operating conditions

for battery supplied calculators

The usage of the calculator is different. In order for

the battery life expectancy to be valid, following

definition of normal operating condition, limits

where one can use the calculator:

M-Bus telegram reading (all protocols) maximum

once per day. High frequency usage of M-Bus

reading reduces battery life.

Only one option board can be installed in the

calculator. When more boards are required and

installed the battery life expectancy will be

reduced. E.g. one option board 10 years, two option

boards 6 years. Note: Not every option board can

be used in a battery supplied calculator, see the

option board documentation for more information.

Flow sensor pulses emitted at the average rate of

maximum 1,5 p/min and with the maximum

temperature difference at 50 degrees K. The

average shall be based on the whole lifetime of the

battery. The calculator shall also have standard

decimal setting, see standard decimal setting

Appendix, A1.

Configuration by using the “FlexServ program”

wrongly can seriously reduce battery life

expectancy on the calculator. Use factory settings

when possible, the settings in which the calculator

was delivered from factory.

Calculator must be set in normal mode (sequence

“10” on display) when using the calculator for

measuring, see also 3.3.5 normal mode. Service-

/Init-/Test-mode reduces battery lifetime expect-

ancy when the calculator is set in these modes for

longer periods of time.

1.2.3.2 Limitations mains supplied

The M-Bus reading frequency must not exceed

once every 20 min. When the reading frequency

exceed this interval the calculator must be equipped

with “galvanic separation board” (FCR2-M1A, for

slot A).

7

1.3 Calculator specifics

The calculator also stores additional data, besides

recorded and calculated values. The calculator

specifics are explained below.

1.3.1 Monthly values

The calculator has up to 37 monthly registers. In

these registers monthly values are stored at then

end of each month. The monthly value is a snap

shot of values at the end of the month. The values

are: oWhen values are stored

oAccumulated energy

oVolume, according to flow sensor

oVolume, according to energy calculation

oEnergy

oAccumulated volume form pulse 1

oAccumulated volume from pulse 2

oPossible error code, at the time of storage

When the maximum number of monthly values is

reached normally 37 values, the calculator replaces

the “oldest” value with a new.

The monthly values can be read in the display and

over the M-Bus the calculator. The order of

presentation is the “newest” value first and then the

previously stored value will be presented and so on.

The number of monthly values can be changed by

using the “FlexServ version 2”. Note: Only by

authorized personnel from Metrima AB.

See also 3.3.5.1 table 3.2 for more information on

sequence 40.

1.3.2 Account days

Some utility companies prefer to read all their

meters at the same time twice a year, at two

predicated days (specific dates) also called account

days.

The F4 has the possibility to store two account

days. The user can specify when these dates are

using service mode or the “FlexServ program”.

Values stored in the account days register are the

same set of values as for monthly register, see

monthly values 1.3.1. Account day is default set to:

Account day 1: 1 January (0101)

Account day 2: 1 July (0701)

The values for the account day will be stored at the

day shift. E.g. Calculator will store the account day

values at 00:00, 1:st of January and at 00:00, .1:st

of July each year.

The “newest” value will be presented first and then

the previously stored value and so on. The “old”

account day values will be replaced when “new

ones” are to be stored. See also 3.3.5.1 table 3.2 for

more information on sequence 30.

Account days can only be changed by the

“FlexServ program version 2”. Note: Only by

authorized personnel from Metrima AB.

8

1.3.3 Pulse counter register 1 and 2

The calculator has two (2) pulse inputs that acts as

volume accumulators in [m³]. To set the volume

accumulators to pulse counters the pulse weight in

calculator must be set to:

1000 [l/p], 0 decimals

Example: 1000 [l/p], 0 decimals -1 m³ per pulse

(One pulse one increment of display). See also

3.3.5.1 table 3.2 for more information on sequence

13 and 14.

1.3.4 Placing of flow sensor

The calculator uses different algorithms to calculate

the energy depending on which pipe (hot or cold)

the flow sensor is placed. Always set the flow

sensor placing correctly in the calculator.

Recommended flow sensor placing is in the return

(cold) pipes, see also fig 1.1, 1.2 principle of energy

measurement, as this side normally is the “cooler

side” for the flow sensor.

The flow sensor placing can be set in the “service

mode”, see Service 7.4 or by using the “FlexServ

program” version 2 or higher.

See also 3.3.5.1 and table 3.2 for more information

on sequence 64, flow sensor placing.

1.3.5 M-Bus

The F2/3/4 calculator is equipped with M-Bus

communication. The M-Bus in the calculator is

according to M-Bus standard and the recommen-

dation according to M-Bus user group.

Battery powered calculators are sensitive and may

not be connected into loops with more than 250 M-

Bus nodes with maximum one M-Bus read once a

day, otherwise the battery life expectancy in the

calculator will be affected.

Extreme M-Bus communication, when the

calculator is flooded by the M-Bus, the calculator

will prioritize the M-Bus over the display. This

flooding will result in strange calculator display

behaviour.

Flooding of the M-Bus communication will not

affect the calculator readings.

1.3.6 Communication address

The calculator has two (2) communication add-

resses in M-Bus.

Primary address, this is a value from 1-250. The

primary address can be changed in the “service

mode”, see also service 7.4 or by using the

“FlexServ program” version 2 or higher.

When two or more meters within a M-Bus loop use

the same primary address a communication coll-

ision will occur. The primary address must be

unique for each calculator in the M-Bus loop.

“Secondary address”, is normally set to F4 serial

number (S/N).

When two or more calculators in an M-Bus loop

use the same primary address a communication

collision will occur. This is why secondary

addressing is recommended when no calculator has

the same secondary address from factory.

In most M-Bus reading programs the user can

choose to address the calculator by the primary or

secondary address. The transfer and communication

speed for the calculator will not be affected by

choosing the primary or the secondary addressing

in M-Bus.

1.3.7 Power cut

Mains powered

When the mains power is cut the calculator will run

following sequence:

1. Automatically switch over to the backup

battery.

2. Store calculator data to an EEProm.

3. Generate an error code “0000080” on display

sequence 15. See also Error Codes, 3.4 (Only

when selected in the calculator programming).

The F4 calculator has a backup battery (both mains

and battery driven calculators). This battery will

supply the calculator with power when main power

is cut. The backup battery will last up to 10 years at

normal usage of calculator, maximum one M-Bus

reading per day and normal energy values.

When power fails, the calculator stores all data to

the EEProm at dayshift. When power is cut from

both mains and backup battery and the calculator

looses all recorded data in temporary memory,

there are two (2) cases:

1. All data stored after dayshift will be lost, see

also storing values, 6.4

2. All data stored after the save by short circuit

the “Save data button” will be lost, see also 2.4

Save data button. Only when the “save data

button” is short circuit after a dayshift.

9

2.3b, Error code displayed when data is saved.

Fig 2.3, Test key

2 Buttons and jumpers

2.1 Push button

The calculator is equipped with a “Push button”.

With the “Push button” the user can toggle between

different values on the display at the display

sequence the calculator is in at the moment. The

user can also use the button to in enter different

display sequences by holding the button until the

calculator shift sequence. There are two ways to use

the “Push button”,

1. Push, e.g. press (and release) to toggle

between different values in the display seq-

uence, see “Display” for more information.

2. Hold, e.g. hold Push button and hold it pressed

until the display changes display sequence, see

“Display” for more information.

2.2 Service button

The service button is used in combination with

holding the “Push button” to enter service mode,

see also “Service mode 3.3.3”.

Tool: Screwdriver or any other suitable dull object.

To enter (or exit) service mode, hold the service

button (carefully) pressed using a small screwdriver

and then hold the “Push button” pressed a few

seconds (5s), then release the “Push button” and

then release the screwdriver. The display sequence

changes to “01” (or back to “10”). For more

information, see “Display 3” for more information.

2.3 Test button

This button is used in combination with holding the

“Push button” to set calculator into test mode.

Tool: Test key

(Rubber key with a leading top)

Enter test mode, hold test button

using “Test key” and then hold

the “Push button” pressed in for

approximately five (5) seconds

then release the “Push button”

and then release the rubber key.

A flash will appear on the display

to indicate the test mode.

Exit test mode, by using the same procedure as

entering the “test mode”, see above, the flash will

disappear after exiting the test mode.

Note: only to be used by authorized personnel

2.4 Save data button

The save data button is used when saving data is

necessary, when changing batteries or when

installing option boards.

When the “Save data button” is short circuited, the

calculator makes readings and saves all data from

temporary memory to the calculator EEPROM.

Note: Data from option boards will not be saved.

Tool:Test key

(Rubber key with a leading

top to short circuit buttons.)

To save, use the “Test key”

and short circuit the “Save

data button” the calculator

will store all temporary data

to the EEPROM.

Check “save data” procedure:

The calculator will display an error code when data

is properly saved. Prior to “save” change the

display sequence to number 15. Then short circuit

the “Save data button” using a “Test key”, the code

“0000080” will be displayed and confirm data

storage, see also Error codes 3.4.

Service button

Test button

Fig 2.2, Location of service and test buttons

Fig 2.4, Save data button

Pu

sh button

Fig 2.1, Push button

10

Fig 2.5, 2/4

-

Wire jum

p

ers

Fig. 2.6, ON/OFF jumper,

OFF, no jumper

2.5 Jumpers 2/4-Wire method

for temperature sensors

The F4 is by default configured for 2-wire

measuring method connection for temperature

sensors. The calculator allows 4-wire measuring

method, by removal of jumpers, see fig 2.5.

4-wire

connection,

remove jumpers

J1, J2, J3 and J4.

2-wire

connection, place

jumpers J1, J2, J3

and J4.

Note: the jumpers

must be placed

according to fig 2.5.

Note: Wrongly placed jumpers can damage the

calculator.

2.6 ON/OFF jumper battery

powered calculators

ONLY

Some F4 is equipped with an ON/OFF jumper this

jumper should be used for battery powered

calculators only.

Note: When cutting the power to the calculator, e.g.

setting calculator “Power OFF” remove the “K2”

then “K3”. See also Power ON/OFF 2.8 below.

Note: ON/OFF jumper only applicable on calculat-

ors powered with batteries. To cut power from

mains supplied calculator see fig 5.1, Circuit board

5.1 and Power ON/OFF.

Power off, no jumper

Power on, jumper on

To cut power from

mains supplied

calculator see fig. 5.1,

Circuit board 5.1 or

2.8 Power ON/OFF.

WARNING: The ON/OFF jumper will not set a

mains powered calculator into “pow-

er OFF” mode. When installing opti-

on boards in a “mains powered” cal-

culator this operation (ON/OFF jum-

per) will only damage the option

board and the calculator.

2.7 Slot jumpers

Signal/Power redirecting

On the slots “C” and “D” there are jumpers for

redirecting power and bus signals. When these are

removed without placing a correct option board in

to the slot, the signals from the calculator can be

disturbed and the calculator’s pulse output and

alarm output can be disabled depending on which

jumper that is wrongly removed.

2.8 Power ON/OFF

For power off cut the power to the calculator by

removing the 4-pole connector “K2” and then

“K3”. Recommended procedure:

Power OFF:

1. Save data, short circuit

“Save data button” (avoid

loosing any data).

2. Remove K2 (main)

3. Remove K3 (backup)

Power ON:

1. Connect K3 (backup)

2. Connect K2 (main)

Fig 2.7, Slot jumpers on slot C and slot D

Fig. 2.7, Power off

11

3 Display

The F2/3/4 calculators are equipped with a LCD

(Liquid crystal display). The units on display label

and decimal placing is different depending on

calculator configuration. See also clarification of

display fig. 3.1:

1. Display sequence, in this case “10”, default

position, (the position the calculator returns to

after 60 seconds of “push-button” inactivity).

The digit “1” displays the sequence and the “0”

displays the order in the sequence. The digits

together form the display sequence “10”, see

also fig. 3.1b (below).

2. Sensor pulse indicator square, indicates a flow

pulse emitted from flow sensor. The square can

also indicate that an error has been detected.

At error (revers to normal); the square will

appear as long as the calculator do not receive

pulse, and disapear when receiving a pulse.

At High frequency (2Hz or more); The square

will appear steadily and disappear on error.

3. Value, max. seven (7) digits

4. Value unit indicator arrow, the triangle points

on the correct unit on the display label for the

unit. (Only when the calculator is correctly

set).

5. Different units on display label, depends on

ordering configuration of calculator.

6. Decimal placing.

Note: the digits after the decimalplacing

“blinks” only in sequence “10” in accordance

with EN1434, according to the standard the

decimals on the display must be clearly

marked.

3.1 Back-light

The calculator display can be equipped with a

“back-light” function. The “back-light” will light

up the display each time the “Push button” is

pressed, and will be turned off one minute after

“Push button” inactivity.

In the display modes Service/INIT/Test mode the

light will light steadily. Avoid setting a calculator

equipped with “back-light” in these modes for

longer periods (10min.). Do not set the calculator

into these modes during transport otherwise the

backup battery life span will seriously be reduced.

During transport and temporarily storage of the

calculator the “Transport mode” mode is to prefer,

in this mode the “back-light” is off. See display

modes, 3.3 for information about display modes.

Note: The “back-light” function consumes more

energy than a calculator without “back-

light” function. Battery powered calcul-

ators (powered with only batteries) should

not be equipped with the “back-light”

function.

3.2 Display test

In accordance with EN1434 all calculators must

have display test. For F2/3/4 the display test is on

sequence 12.

mC

m/h

kW

MWh

3 3

10

1

2

5

4

3

6

Fig 3.1, Display, m

3

, C…

Fig 3.1b, sequence number, value

number together form display

sequence.

Sequence number

Value number

Fig. 3.2, Display test

12

3.3 Display modes

The calculator can be set in different display modes

depending on what data that shall be accessed in the

calculator. To enter the different modes the seals

must be broken and a recommended tool should be

used, see below. The calculator is normally

delivered in “Transport mode”. Depending on

programming the calculator can be delivered in

other display modes as well.

The sequences in the different display modes can

vary depending on different programming of the

calculator. The display modes are:

1. Transport mode

2. Initiation-mode (INIT-mode) programming

by using “Push button”, see service mode.

3. Service mode, programming by only using

the “Push button”

4. Test mode (test and programming mode), by

using the “service program” version 2 or

higher the calculator can be programmed.

5. Normal mode, operating mode, working

mode.

Note: Avoid setting the calculator into “service/

initial mode” or “testing mode” for longer

time periods (1 hour) otherwise the battery

life length expectancy will be effected.

3.3.1 Transport mode

The calculator normally is delivered in transport

mode. In transport mode the calculator “sleeps”, no

measurements and no communication from or to

the calculator will be preformed. In transport mode

only the system clock and (if any) option board will

be supported with minimum power requirements.

The calculator’s “operating time” (display sequence

50) will be in a stand still.

To exit “Transport mode”, hold “Push button”

pressed (approximately 5 seconds) until the “no”

sign disappears. The display sequence changes to

“00” or “10” depending on calculator settings. In

most settings the calculator enters the INIT-mode.

The INIT-mode is indicated by display sequence

“00” see also initiation mode 3.3.2 for further

information.

Using the “service program” version 2.0 or higher

the calculator can be set in “Transport mode”, only

to be used by authorized personnel.

3.3.2 Initial mode ( INIT mode)

The calculator enters the INIT mode after exiting

the transport mode (this can vary depending on

setting of the calculator). The INIT mode is

indicated by display sequence “00”, see also fig 3.5

above. In the INIT mode some calculators setting

can be altered using the “Push button” prior to an

installation without braking any calculator seals.

See Service/INIT mode display sequence 3.3.3.1.

The calculator’s INIT mode can be identical to its

service mode. In some calculators a few sequences

are missing compared to the service mode

depending on calculator setting. For service/INIT

mode sequence, service mode sequence 3.3.3.1.

In INIT-mode the value digit to be changed will

blink and the display sequence will indicate unit for

the value, see service mode 3.3.3 for more

information.

To change value digit, push “Push button” until

correct value is acquired, see fig 3.5 below.

To change digit “to be changed”, hold “Push

button” until the next value digit starts to blink, see

fig 3.5.

To exit INIT mode without braking any seals

when in INIT mode:

1. Hold “Push button” until display sequence

“0A” appears.

2. Release the “Push button”

3. Press “Push button” once to change the

value digit to “1” (exit INIT mode).

4. Hold “Push button” to exit the INIT mode,

the display sequence should read “10”,

normal mode.

Fig. 3.3, Sequence transport mode

Fig. 3.5, Sequence service or INIT mode

Sequence

Service /

INIT

mode

“Blinking” value digit,

digit to be changed.

Hold “push button” for next

digit to be changed.

Push “push button” to change

the value digit.

13

3.3.3 Service Mode

In service mode the settings of the calculator can be

altered using the “Push button”. The service mode

is indicated by “00” (or “0x”) in the display

sequence. See also service 7.4 for more information

on each service sequence and INIT mode 3.3.2 for

initial mode.

To enter “service mode”, hold the “Service

button” pressed with and screwdriver (or another

dull object) at the same time hold “Push button”

pressed in 1-2 seconds. Then release the “Push

button” and the display sequence will change to

service mode, display sequence “00” (also remove

the screwdriver), see also service buttons 2.2.

To exit “service mode”, the same procedure as

when entering the service mode, see above.

To change value digit, push “Push button” until

correct value digit is acquired.

To change value digit “to be changed”, hold

“Push button” pressed until required value digit

starts to blink. Note: The changed value digit is

changed, only when the next value digit is selected

and starts to blink. E.g. do not exit service mode

when the changed value digit is still blinking.

Ensure that the change has been carried out by the

calculator, by first reaching the next service

sequence (example from “01” to “02”) before

exiting the service mode.

To enter next sequence, hold the “Push button”

until next service sequence appears on display, see

also fig. 3.1b.

To exit Service mode in service sequence “0A”:

1. Hold “Push button” until display sequence

“0A” appears.

2. Release the “Push button”

3. Press “Push button” once to change the

value digit to “1” (exit INIT mode).

4. Hold “Push button” to exit the INIT mode,

the display sequence should read “10”,

normal mode.

3.3.3.1 Service/INIT mode

sequence

Sequence Description, format

00 Time, HHMM

01 Date, YYMMDD

02 Pulse value, 0000-9999

e.g. 2.5l/p is displayed with 2500

03 Pulse value decimal places, 0-4

04 Account days 1, MMDD

05 Account days 2, MMDD

06 Primary communication address set

with three (3) digits,

e.g. “5” is set to “0005”

07 Resetting stored error time,

0 = Reset stored error time (default)

1 = Do not reset error time

08 Flow sensor placing,

0 = installed at low temp.(default)

1 = installed at high temperature

09 Replacement of battery date, YYMMDD

Do not change without consulting

Metrima AB

0A Exit service sequence,

1 = Exit

0 = Return to sequence “00”

Table 3.1, Service display sequence,

HH–Hour, mm-Minutes,

YY-Years, MM-months, DD-Days.

See, “Testing…., Service” for additional information

Note: Values in the service mode may only

be altered by trained professionals.

Note: The display sequences in service mode

may vary depending on calculator

configuration.

Warning: Altering the values in the service mode

can seriously effect on the calculator

performance and can result in wrong

measuring.

Fig. 3.5, Sequence service or INIT mode

Sequence

service /

INIT

mode

“Blinking” value digit,

digit to be changed.

Hold “Push button” for next

digit to be changed.

Push “Push button” to change

the value digit.

14

3.3.4 Test mode

(programming mode)

In the test mode all the calculator parameters can be

configured, with the “service program” version 2.0

or higher. Tests can also be performed on the

calculator, see verifying the calculator 7.5. A flash

on the display will indicate this mode, see fig 3.6.

The calculator also activates the optical interface

and emits high frequent pulses corresponding to the

energy increment. See Service 7.4 for more

information. The M-Bus and the display response

in this mode will be slower and in some cases

disturbed.

Setting calculator into test mode by using the

“test key”, a rubber key with an electric leading

head. Hold the “test key” pressed to short circuit

the “test button” (at the same time), hold the “Push

button” pressed (approximately 1-2 seconds), and

then release the “Push button”. The display will

show a “flash” indicating “test mode”, (remove the

“test key”), see also fig 3.6 (below).

Exit test mode, the same procedure as to “set the

calculator into test mode”, see above. The “flash”

will disappear from the display upon exit.

Energy consumption will be higher in “Test

mode” than in calculator normal operating mode.

Avoid setting the calculator into “Test mode” for

longer period than (>1h) or the battery/backup

battery life length will be seriously reduced.

Only Service program version 2.00 (00-10-09) or

later versions may be used to program F4. With the

service program the calculator can be programmed

(configured). This program is backward compatible

e.g. F3/2 can be programmed with the service

program version 2.00 or higher. See also the

Service program manual for further information.

In the service program:

Read type, the calculator programming is read into

the service program.

Change mode, the display mode is changed.

Change type will erase all previously stored

calculator readout data.

Note 1: Avoid to set the calculator into “Service/

Initial mode” or “Testing mode” for

longer time periods (1 hour), when

battery life length will be affected.

Note 2: Calculators delivered with energy unit

“BTU” and flow unit “USG/min” has

fixed decimal setting.

Warning 1: Changing the programming using the

service program version 2.0 or higher

can seriously affect the calculator

behaviour, such as parameters as

battery life length can be seriously

reduced and measuring will be aff-

ected. Do not use the service program

without proper education or

consulting Metrima AB.

Warning 2: When programming the F4 only use

Service program version 2.0 or high-

er, otherwise the calculator will be

seriously damaged!

Warning 3: When programming the F4 only use

Service program version 2.0 or high-

er, otherwise the calculator will be

seriously damaged!

Fig 3.6, Display in test mode, “flash” in display

Flash

15

3.3.5 Normal mode

( operating mode )

Normal mode is the calculators operating mode. In

this mode the calculator accumulates energy,

calculates and makes measurements. The calculator

can also communicate by using M-Bus or SIOX

protocols (SIOX only with an extra option board).

Display sequences

The first digit from left is the sequence number, see

also fig. 3.1b below. This number announces in

which sequence currently is on display (1 to F).

The second digit from left is the value number and

announces which value is displayed in the specific

sequence. The value numbers loops within each

sequence (there are a few exceptions).

See also, display sequence schematics 3.3.5.4 and

display sequence normal mode 3.3.5.1.

Enter next sequence

Hold the “Push button” to enter next sequence,

release when correct display sequence is reached.

Repeat this procedure to enter next sequence. When

exiting the last display sequence F0 the display will

return to the first display sequence 10.

On exiting the display sequence 30 and 40 the

calculator will return to display sequence 10.

Read values

Press “Push button” to toggle to the next display

value. After the last value in the specific sequence

the first value in this sequence will be displayed

and so on.

Default position

When calculator is set in normal mode the display

will return to the default sequence position after

60s, (the return time can be altered by using the

“Service program 2.0” or higher).

Blinking digits

In accordance with EN1434 the digits after the

decimal places blink.

Unit arrow

An arrow will indicate the correct unit for the

value, the display labels varies depending on

calculator.

Example, calculator delivered with different dis-

play labelling depending on kWh, MWh, GJ or

MBTU to be outputted by the calculator.

Note: When calculator is reprogrammed the

“service program” version 2.0 or higher the

label is not “automatically” changed.

Fig 3.7, Display sequence “10” in nor

mal

(seq. 10 default sequence position).

Fig 3.1b, Sequence number and

value number together form display

sequence.

Sequence number

Value number

16

3.3.5.1 Display sequence normal mode

Table 3.2, Display sequence 10 –70, normal mode

Seq Description

10 Accumulated energy (Default position)

11 Accumulated volume according to flow sensor1

12 Display test, see fig.3.2

13 Accumulated volume for pulse input 1, [m3]

14 Accumulated volume for pulse input 2, [m3]

15 Error code, see Error code

16 Error time, [Minutes]

20 Momentary power

21 Momentary flow

22 High temperature, 0 decimals

23 Low temperature, 0 decimals

24 Temperature difference, 1 decimals

30 Account days2, when values are stored, [YYMMDD]

31 Account days2, Accumulated energy

32 Account days2, Accumulated volume according to flow sensor.

33 Account days2, Accumulated volume according to energy calculation

34 Account days2, Accumulated volume pulse input 1, [m3]

35

Account days2, Accumulated volume pulse input 2, [m3]

36 Possible error code, at time of storage of account days

37 Possible accumulated error time, at the time of storage account days, [Minutes]

3x Following account days registers (loop back)

40 Monthly registers3, date when values are stored, [YYMMDD]

41 Monthly registers3, Accumulated energy

42 Monthly registers3, Accumulated volume according to flow sensor

43 Monthly registers3, Accumulated volume according to energy calculation

44 Monthly registers3, Accumulated volume pulse input 1, [m3]

45 Monthly registers3, Accumulated volume pulse input 2, [m3]

46 Possible error code, at time of storage of monthly register

47 Possible accumulated error time, at the time of storage, [Minutes]

4x Following monthly registers (loop back)

50 Operating time, [Hours]

51 Relevant date, [YYMMDD]

52 Relevant time, [HH.MM]

53 Recommended date for battery replacement, [YYMMDD]

60 Communication address, Primary address

A0 Communication address, Secondary address (normally same as meter S/N)

bx Meter S/N5

63 Pulse value [l/p]

64 Placing of flow sensor, [H/L], L = Low

70 Accumulated volume corresponding to accumulated energy

71 Last remote read accumulated energy

72 Time since latest remote read accumulated energy, [Hours]

73 Accumulated error time, [Minutes]

74 Previous error code

75 Time for previous error code, [Minutes]

17

3.3.5.2 Display seq. normal mode 2

For more information on the sequences:

See also for further information, 0calculator specifics.

___________________________________________________________________________

3.3.5.3 Display sequence normal mode (summary)

10 - Readout values 1 (Power, flow)

20 - Readout values 2 (Temperature, momentary values)

30 - Account days values

40 - Monthly registers

50 - Date registers

60 - Communication, settings

70 - Volume check, error listings

90 - Option board status

A0 -F0 Option board sequences

90 ID Option card A

91 Status option card A

92 ID Option card B

93 Status option card B

94 ID Option card C

95 Status option card C

96 ID Option card D

97 Status option card D

98 ID Option card E

99 Status option card E

9A ID Option card F4

9b Status option card F4

A0 Sequence option card A

b0 Sequence option card B

C0 Sequence option card C

d0 Sequence option card D

E0 Sequence option card E

F0 Sequence option card F4

Table 3.2b, Display sequence normal mode

1F2/F3/F4 have two registers for accumulated volume. Value 11, is incremented at the

rate of arrived flow pulses. The other register, value 70 is incremented in

conjunction with energy calculation.

2In order to change to the next account day, keep pushing the button until the date

starts to increment, then release the button. After the display 37, see table above,

the next account day will display. Note: If one hold the “Push button” again the

display reverts to default position (seq. 10).

3To change to another month keep pushing the button until the date starts to

increment. Release at the requisite month. After display 47, see above, the next

stored date will be displayed. Note: If one hold the “Push button” again the display

reverts to default position ( seq. 10).

4This sequence’s slot is only available in the F2, but will also be displayed in the

F4. The F4 has maximum 5 slots.

5The second digit form left in the sequence “bx” (e.g. x) will marke the most

significant digit in the calculator serialnumber. Example: Calculator serialnumber is

“0000 0015” the sequence will display “b0”, and if the seraialnumber is “8000 0015”

the sequece will display “b8”.

18

3.3.5.4 Display sequence normal mode schematics

Fig 3.8, Display schematics for “normal mode”

One (1) Option

board selected

six (6) Option

board selected

10

20

30

40

50

60

70

90

A0

b0

Only when option

board are selected

Loop back to next

monthly register

Loop to next

account day

Default

position

C0

d0

E0

F0*

How to:

To change sequence HOLD the

“Push button” until the display

changes sequence.

To change values within a specific

sequence PUSH “Push button” until

the display changes value.

*

Only in F2. No such option board slot in F4 but will be displayed in

the display sequence.

19

3.4 Error codes

Sometimes an error code will appear in display sequence 15, 37, 47, 74 and on M-Bus.

The error code message can be interpreted using the table below. The error codes consist

of three (3) hexadecimal (Hex) digits, e.g. 0 –15. Each digit can have up to 4 different

error codes in combination. The correct error code can be acquired by combining the

digits, see also example below. The digits shall be read from the right to the left.

Example: 0000005 = 1 + 4 = error 1 and error 4, low temperature sensor disconnected

and high temperature sensors disconnected.

1 Low temp. sensor disconnected

2 Low temp. sensor short circuit

4 High temp. sensor disconnected

Display

digit 1

first

( from

right ) 8 High temp. sensor short circuit

1

Internal bus collision has occurred within

24 hours.

2 I²C error ( internal bus error )

4 Low flow

Display

digit 2

second

( from

right ) 8 Alarm input, low voltage*

1 Battery expire

2 Oscillator error

4 Pulse input too long

Display

digit 3

third

( from

right) 8 Not in use

Table 3.3, Error code numbers

A good help to is use the table below to find out which error the calculator displays

Example: 00000045

First digit 5 from right = Error code 4 + Error code 1 = Temperature sensors (low+high) disconnected

Second digit 4 from right = Error code 4 = Low Flow Error

*“0000080”,can vary depending on setting in the

calculator.

1. No voltage (default value), the calculator will

show this error code when there is no power

supplied from the mains.

2. External alarm set, alarm from an external device.

This error code will also appear when the “Save

data button” is short circuited, see also 2.4, Save

data button.

No.

Hex. Dec. Error

number(s)

0 0 0

1 1 1

2 2 2

3 3 1 + 2

4 4 4

5 5 4 + 1

6 6 4 + 2

7 7 4 + 2 + 1

8 8 8

9 9 8 + 1

A 10 8 + 2

B 11 8 + 2 + 1

C 12 8 + 4

D 13 8 + 4 + 1

E 14 8 + 4 + 2

F 15 8 + 4 + 2 + 1

Table 3.3b, Error hex decoding key

mC

m/h

KW

Mwh

3 3

Fig 3.10, error at display sequence “15”

first digit “5”, second digit “4”

First digit

Second digit

Third digit

20

4 Seals, calculator

protection

The F2/3/4 are tampering protected with seals. To

enter the calculator or to enter “Test mode”,

“Service mode” or to enter the electronics inside

the calculator several seals need to be broken, see

placement of the seals below:

4.1 Volume check

The F2/3/4 have an extra volume check, e.g. the

calculator has two different accumulated volume

registers:

Volume accumulated from flow sensor

(Display sequence 11)

Volume accumulated from energy calcula-

tion, e.g. calculated from increment register.

(Display sequence 70)

This function prevents tampering of flow pulses

programmed in meter and acts as an extra check.

Normally there is a small difference between these

two registers.

Seals

1. Installation seal, installation and tampering

protection.

2. Service seal, to protect the calculator entering

the service mode.

3. Test seal, to protect the calculator entering and

program the calculator.

4. Factory seal, the electronics protection

4.2 Neutral seals

With every delivery of the F2/3/4 four neutral seals

are included. These neutral seals can be used after

installation.

Fig 4.2, Neutral seals can be used after an installation.

4

1

2

3

Fig 4.1, Placement of seals F3/F4

4

3

2

Fig 4.1, F2 Placement of seals

Table of contents

Other Metrima Calculator manuals

Popular Calculator manuals by other brands

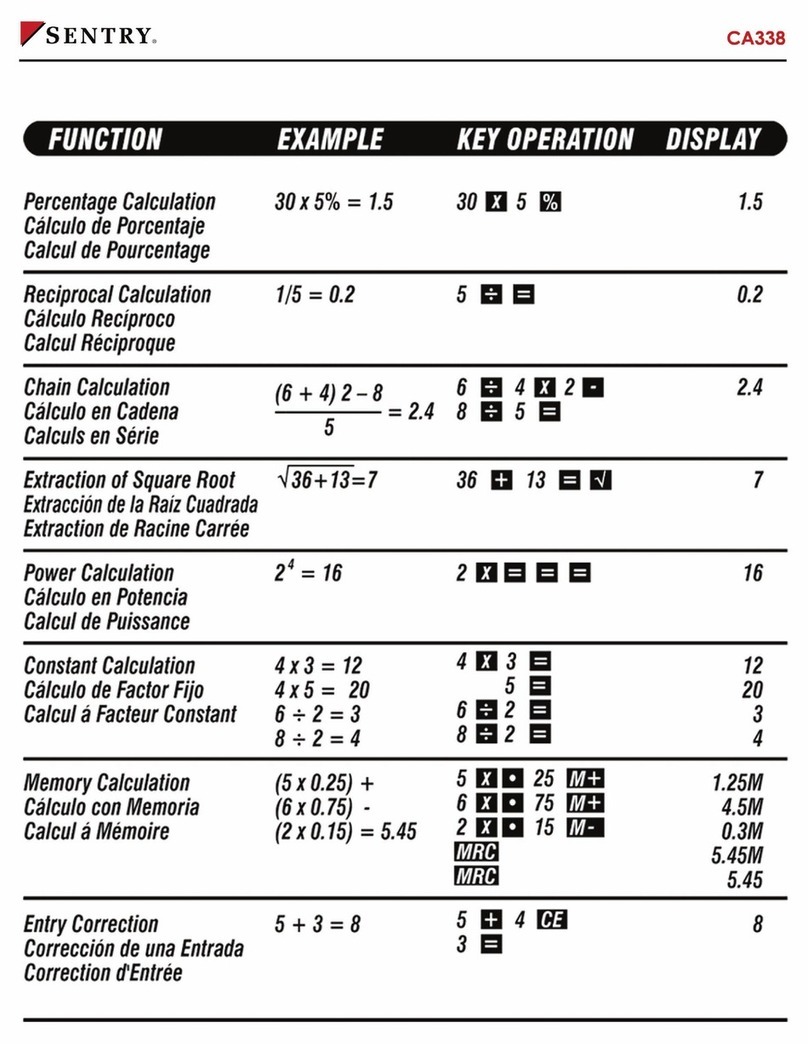

Sentry

Sentry CA338 user guide

Casio

Casio CFX-9850G PLUS Calculations guide

Texas Instruments

Texas Instruments TI36X - Solar Scientific Calculator user guide

Texas Instruments

Texas Instruments TI-83 Plus Silver Edition manual

Citizen

Citizen SDC-9008N instruction manual

Sharp

Sharp Elsi Mate EL-331A Operation manual