Autolab/Electronic load combination

4 | Page

1 – Choice of the electronic load....................................................................... 5

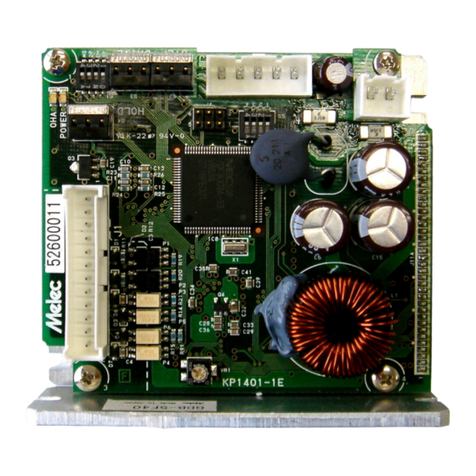

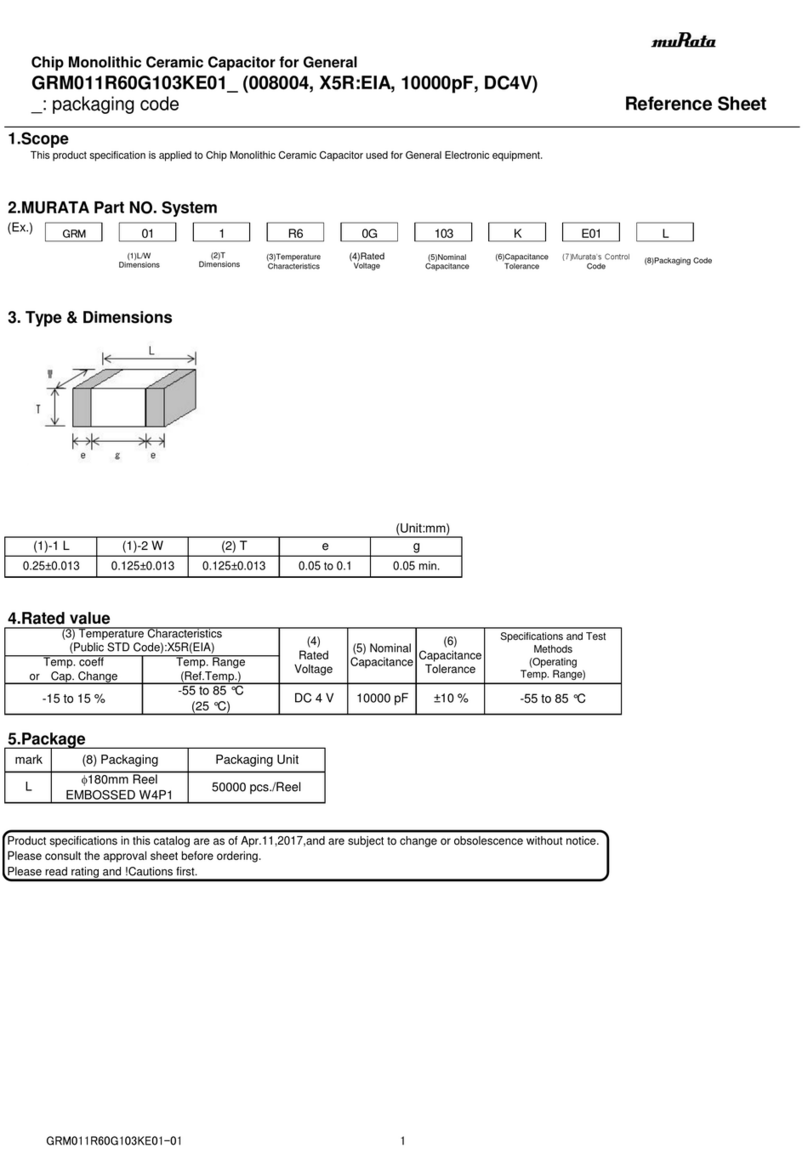

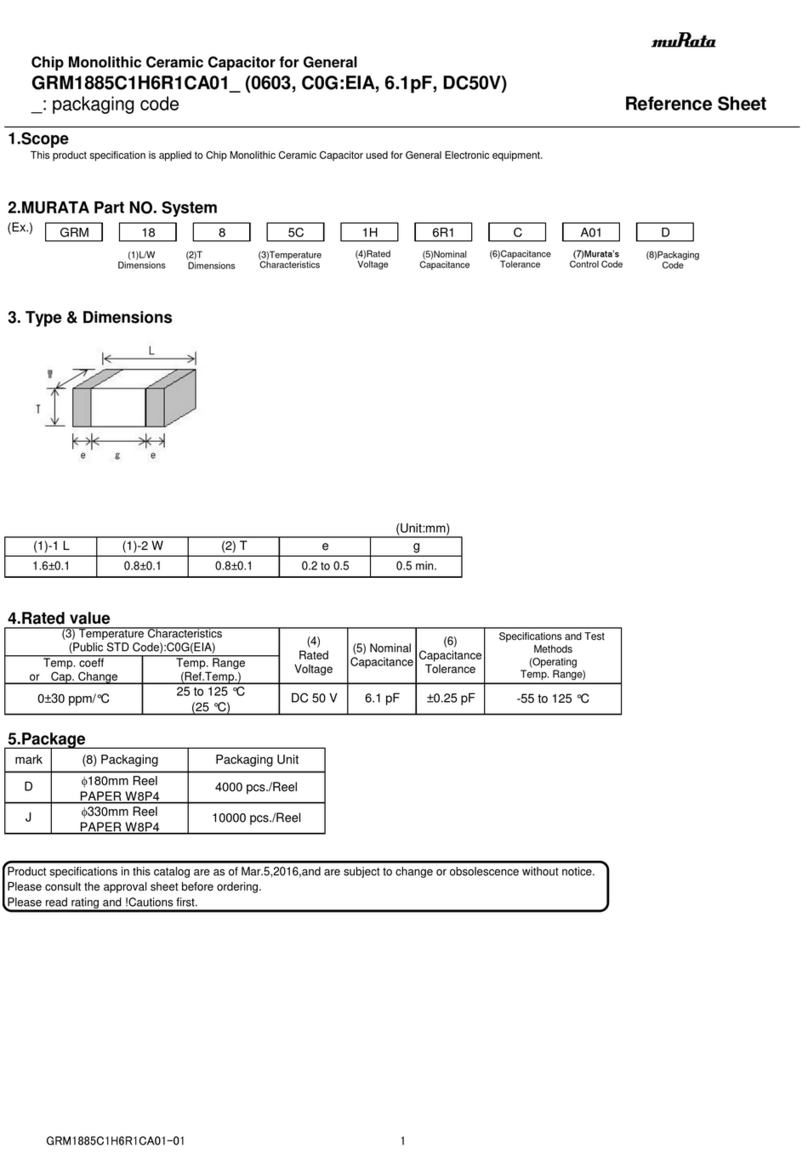

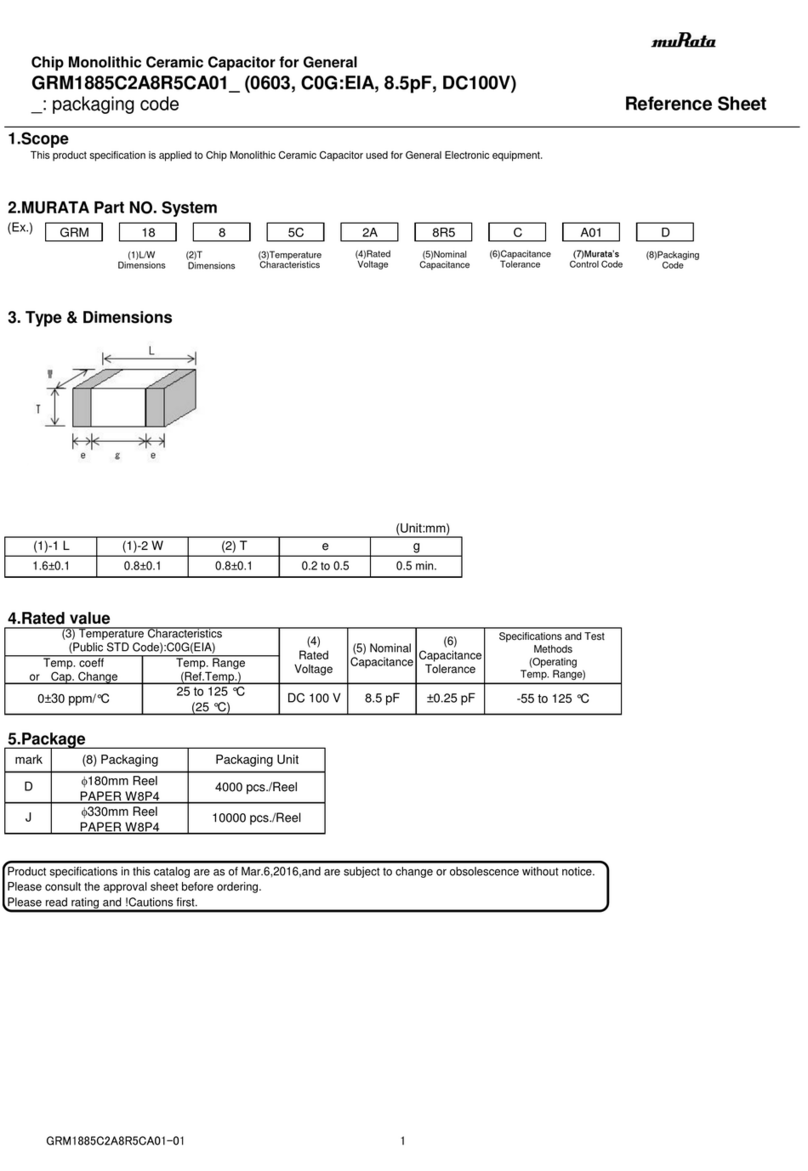

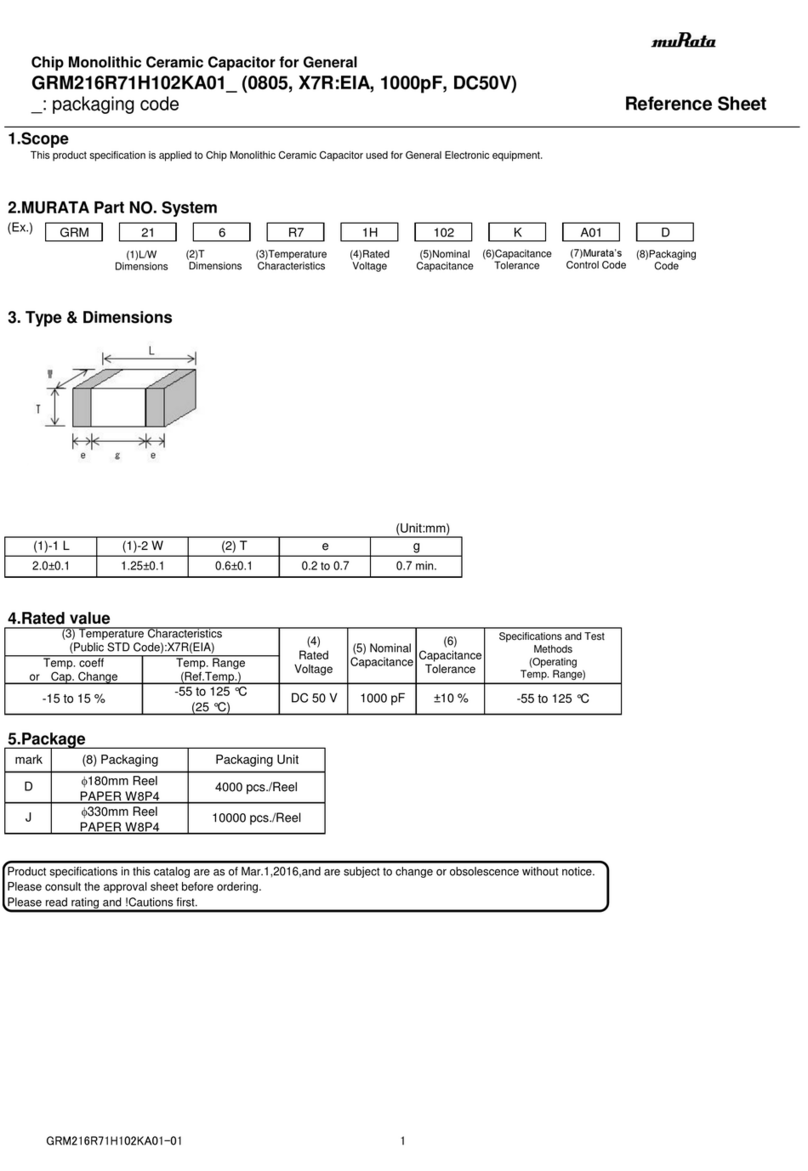

2 – Dynload interface part list ........................................................................... 6

3 – Autolab part list .......................................................................................... 8

4 – Electronic load part list ................................................................................ 9

5 – Polarity convention.................................................................................... 10

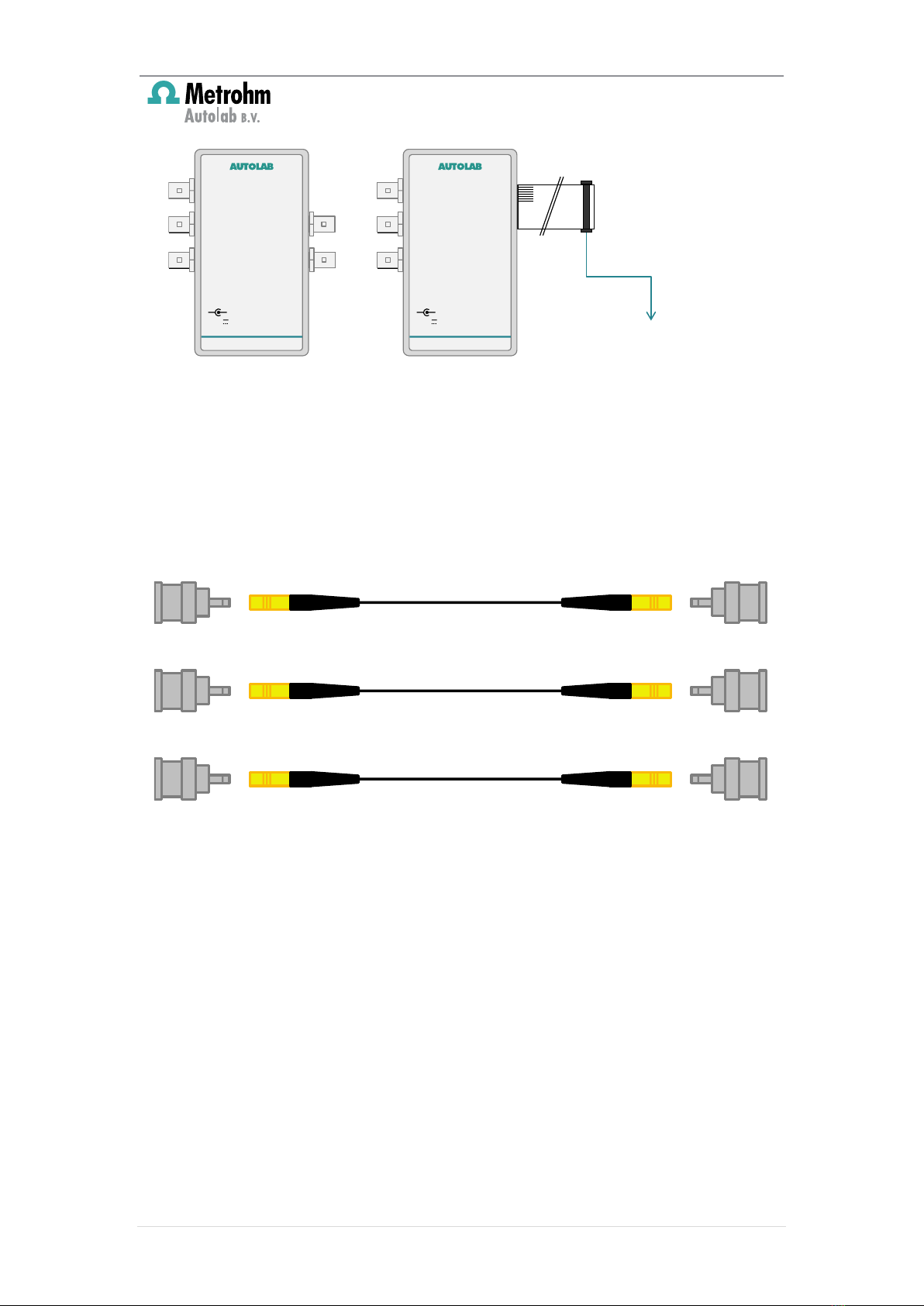

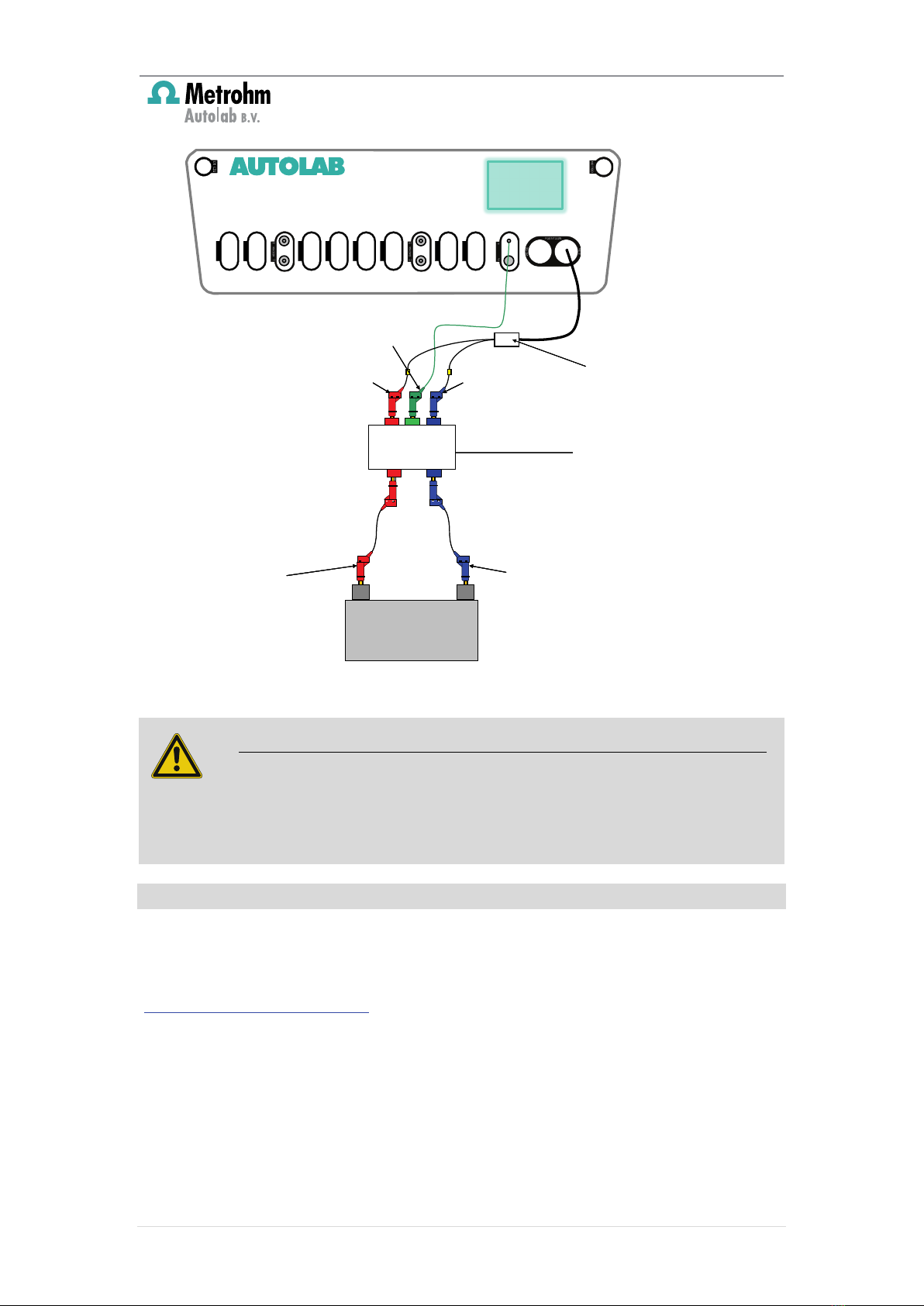

6 – Connections to the Dynload interface ....................................................... 10

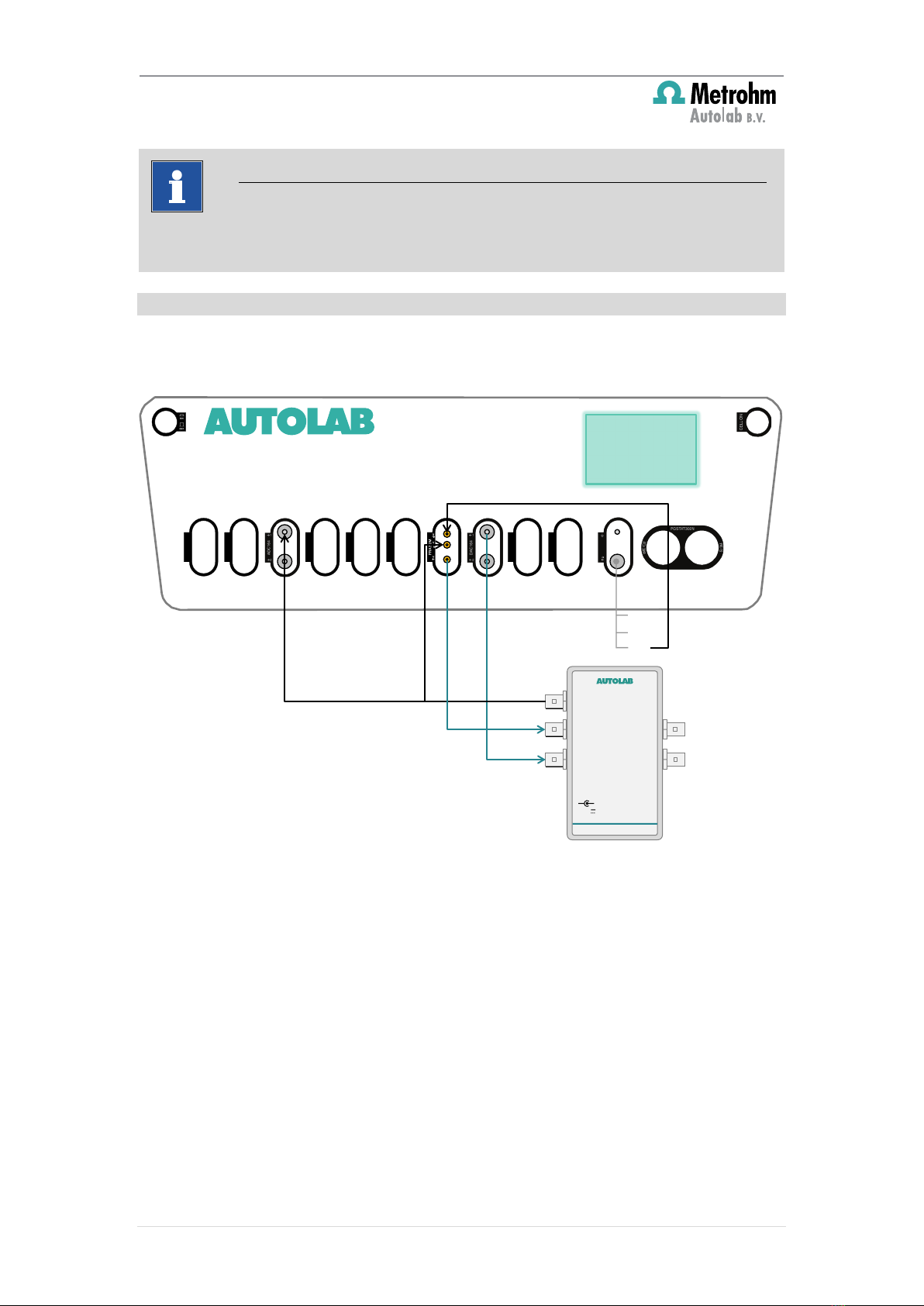

6.1 – Connections without a FRA module .................................................. 10

6.2 – Connections with a FRA32M module ................................................ 12

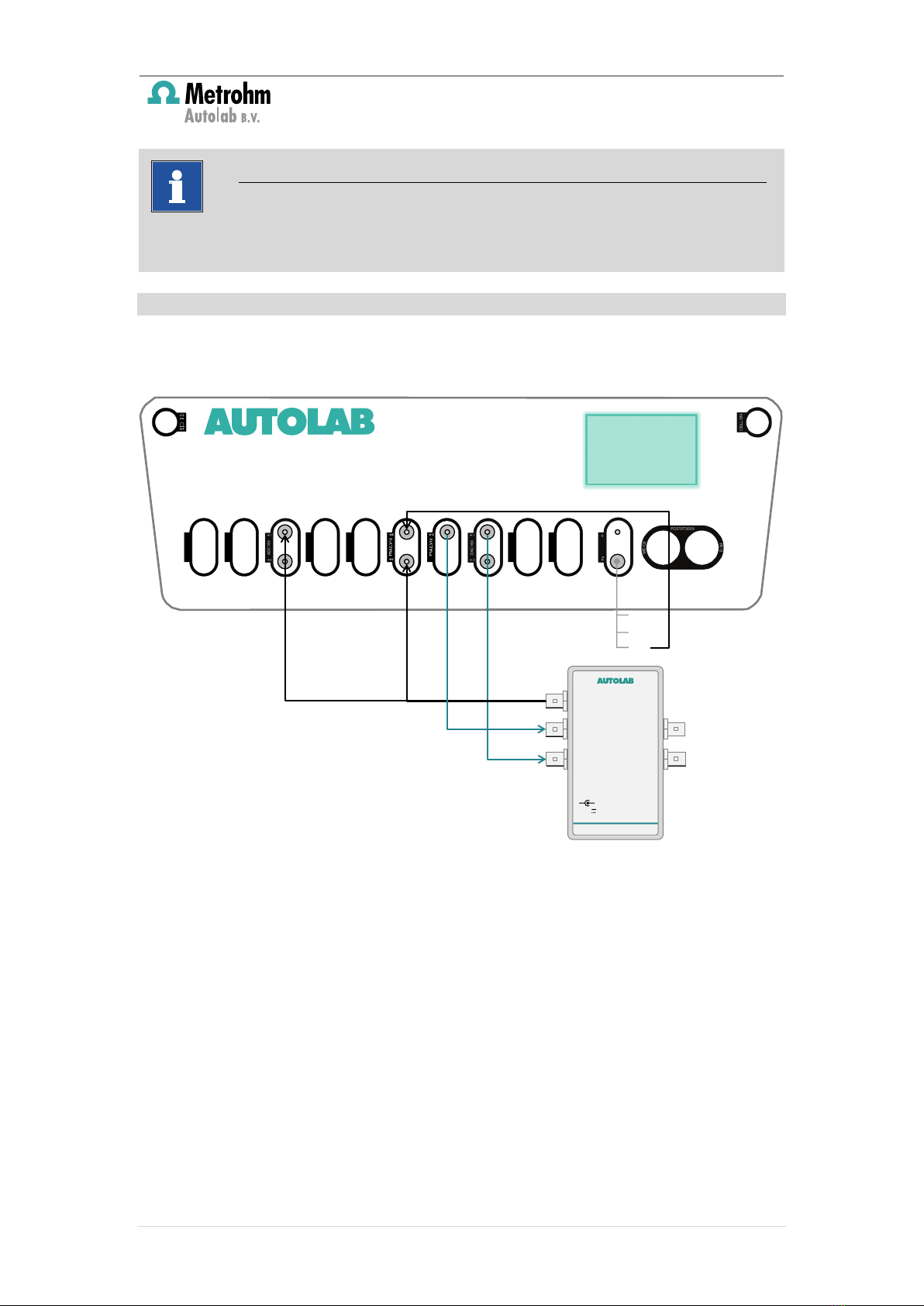

6.3 – Connections with a FRA2 module...................................................... 13

7 – Connections to the cell.............................................................................. 14

7.1 – Connections for cell voltages ≤ 10 V ................................................. 14

7.2 – Connections for cell voltages > 10 V ................................................. 15

7.2.1 – Voltage multiplier part list.......................................................... 15

7.2.2 – Connections to the instrument................................................... 16

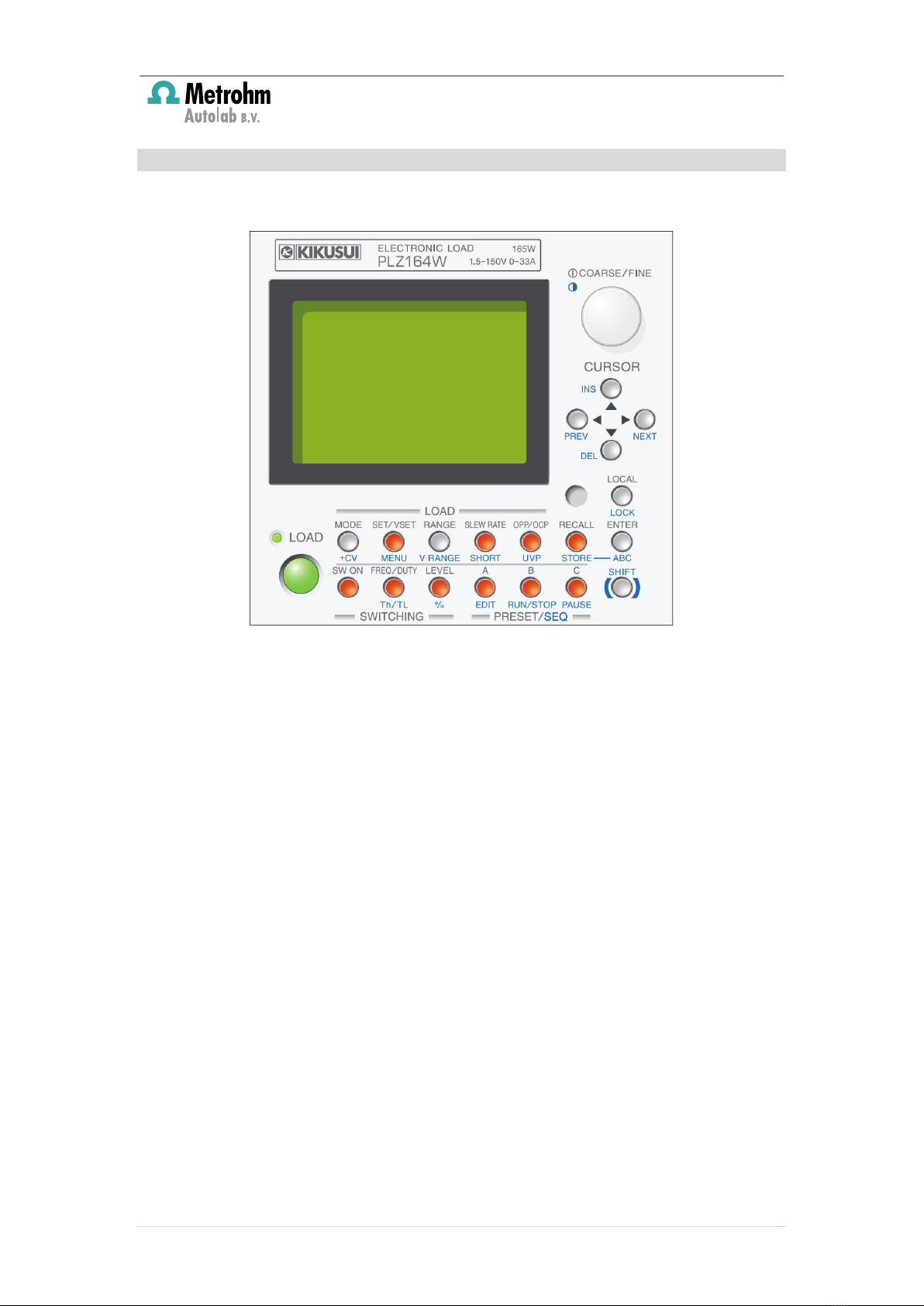

8 – Electronic load settings.............................................................................. 17

8.1 – Programming the load (TDI) .............................................................. 18

8.2 – Programming the load (Kikusui) ........................................................ 19

8.3 – Controlling the electronic load .......................................................... 20

8.3.1 – Controlling the electronic load (TDI)........................................... 20

8.3.2 – Controlling the electronic load (Kikusui)..................................... 20

9 – NOVA hardware setup .............................................................................. 21

9.1 – Analog input settings ........................................................................ 22

9.2 – Analog output settings...................................................................... 23

10 – Manual control of the electronic load (DC only)....................................... 24

11 – Procedure control of the electronic load (DC only)................................... 27

12 – Recording the output from the electronic load (DC only)......................... 30

13 – Impedance spectroscopy measurements ................................................. 33

13.1 – External settings.............................................................................. 35

13.1.1 – Settings for V ...................................................................... 35

13.1.2 – Settings for X ...................................................................... 36

13.1.3 – Settings for Y ...................................................................... 36

13.1.4 – Settings for Transfer function................................................... 37

13.2 – Frequency scan settings .................................................................. 38

13.3 – Sampler settings.............................................................................. 39

13.4 – Plots settings................................................................................... 41

13.5 – Running a measurement ................................................................. 42

14 – Measurement examples .......................................................................... 44

14.1 – iV/Power curve................................................................................ 44

14.1.1 – Running the measurement....................................................... 44

14.2 – Impedance spectroscopy measurement........................................... 45

Appendix 1 – Specifications of known electronic loads ................................... 48

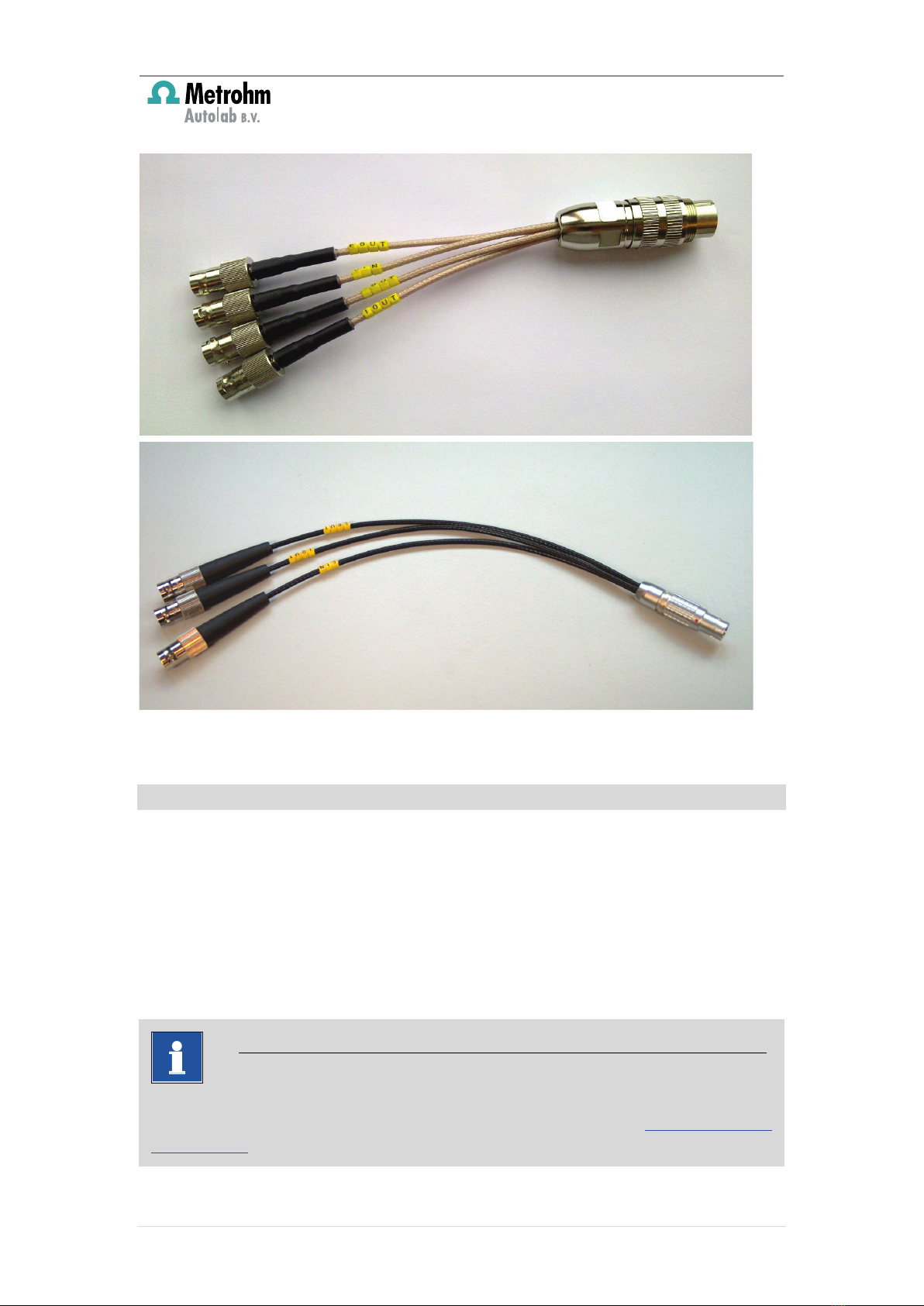

Appendix 2 – Modification of the FRA2 module.............................................. 49