MGF IHC150 User manual

mgf.co.uk

EXCAVATOR

MOUNTED COMPACTOR

IHC150 MODEL

CREATING SAFE WORKING ENVIRONMENTS

With 40 years of experience, MGF is a privately-owned company whose primary focus is the

provision of fully engineered excavation support solutions to the civil engineering, construction,

rail and utilities sectors. We combine technical expertise and operational performance to ensure

the highest levels of customer service. With a focus on developing and promoting industry

best practice in excavation safety we aim to assist our customers in creating safe working

environments for their employees.

CUSTOMER SERVICE AND SUPPORT

The hire and sale of our products is fully supported by our team of qualified engineers,

experienced Technical Sales Representatives, hire desk and operational staff. Our hire centres

provide the focal point for service delivery where our hire desk team will be pleased to receive

your enquiry.

DELIVERY CAPABILITIES

Our dedicated fleet of vehicles offer a flexible solution to quickly meet our customers delivery

needs throughout the UK. We partner with several global shipping companies to ensure we can

quickly deliver our products on a global scale.

CREATING SAFE

WORKING ENVIRONMENTS

2

CONTENTS

SECTION 1: INTRODUCTION 4

SECTION 2: TECHNICAL DATA 5

SECTION 3: PARTS DESCRIPTION / IDENTIFICATION 6

SECTION 4: COMPONENT WEIGHTS & DIMENSIONS 7

SECTION 5: RISK ASSESSMENT CHECKLIST 8

SECTION 6: DO’S / DON’TS 9

SECTION 7: COMPACTOR OPERATION 11

7.1 DELIVERY

7.2 CONNECTING TO THE COMPACTOR VIA AN EXCAVATOR QUICK HITCH

7.3 CONNECTING THE HYDRAULIC LINES

7.4 PREUSE CHECKS

7.5 OPERATING INSTRUCTIONS

7.6 GENERAL ADVISE / INSTRUCTIONS

SECTION 8: MAINTENANCE 16

SECTION 9: CHECKS / FREQUENCY OF CHECKS 16

SECTION 10: STEPS TO ATTEMPT RELEASE OF

HYDRAULIC PRESSURE IN ‘PECKER CIRCUIT’ OF

AN EXCAVATOR 17

ISSUE 1

USER GUIDE

EXCAVATOR MOUNTED COMPACTOR

Excavator mounted compactors (also named compaction plates) can be used to provide

safe, fast, efficient compaction for surfaces including soil sand gravel hardcore or recycled

materials.

In addition to open areas, they can also be used within excavations and on embankments.

They can be used to drive in piles or formwork.

They work quickly and economically and are easy for even inexperienced operators to use.

There are many safety benefits to using an Excavator Mounted Compactor Plate as they can

be operated remotely completely removing humans from hazardous area.

Areas of use include:

• Floor levelling

• Soil compaction

• Trench compaction

• Foundation pile driving

• Compaction around pillars

• Guard rail driving

• Asphalt repair

• Maintenance work

INTRODUCTION

4

USER GUIDE SECTION 1

EXCAVATOR MOUNTED COMPACTOR

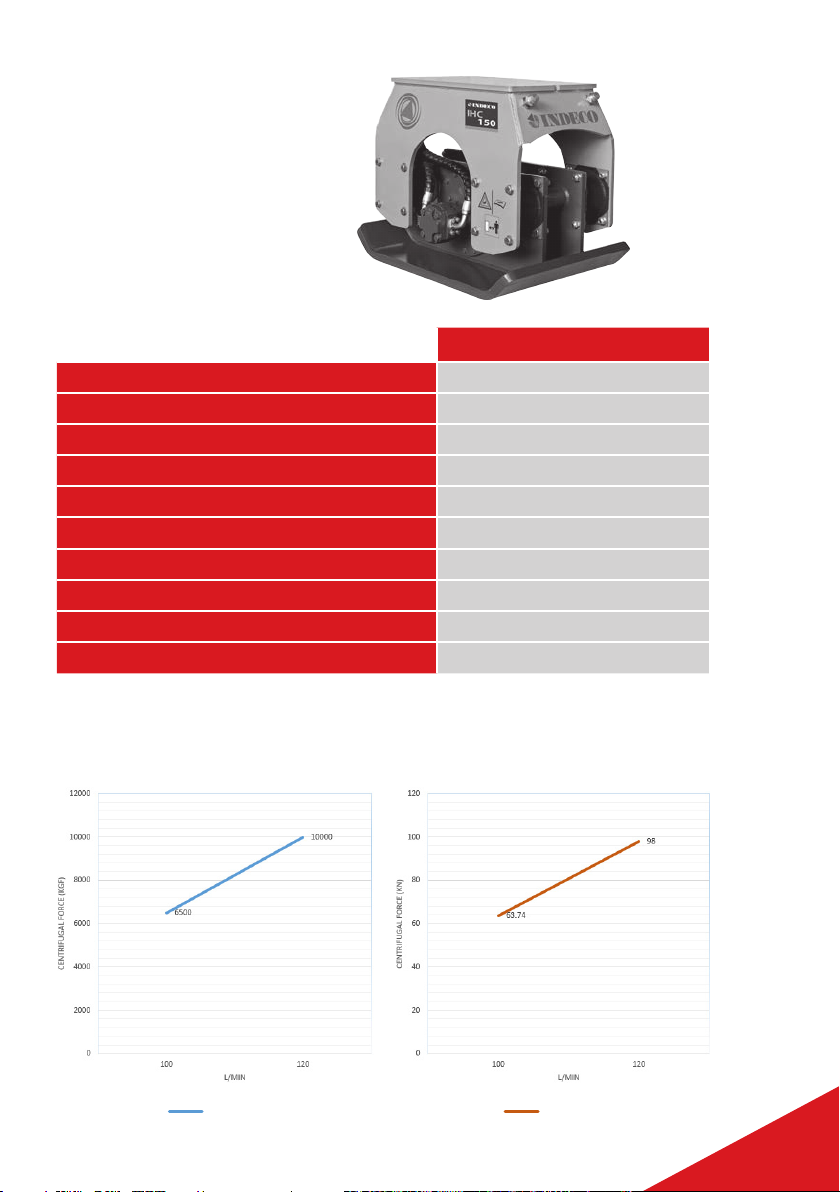

IHC150

Excavator Range 8 to 22 Tons

Equipment Weight 970 Kg

Height 790mm

Baseplate size 710 x 1200mm

Centrifugal Force 10’000 Kgf (98 KN)

Compacting Force 1.8 Kg/cm2(17.7 N/cm2)

Frequency 2000 rpm 33hz

Oil Flow to motor 120 L/min

Max Working Pressure adjusted to the excavator 200 bar

Max Backpressure 21 bar

Note: Weights stated above do not include QH connection bracket.

TECHNICAL

DATA

IHC150 CENTRIFUGAL FORCE VS FLOW IN

IHC150 IHC150

5

USER GUIDE SECTION 2

EXCAVATOR MOUNTED COMPACTOR

03

01

02

09

05

07

08

04

10

06

PARTS DESCRIPTION

/ IDENTIFICATION

01 Quick Hitch Connection Bracket

02 Compactor

03 Motor Impact Guard

04 Hydraulic Connections (on compactor)

05 Elastomer Block – or – Cushion Plate

06 Transport Skid (compatible with 7t – 15t Forklift)

07 Alternate size QH Bracket Pins (IHC 150 only – Ø65 & Ø80 pin options provided)

08 Spare QH Pin – Locking Bar

09 4 x Lift Point (suitable for – MGF Std Duty 4 Leg Chain)

10 4 x Ratchet Strap attachment points – see blue lines in image above for strap pathway

Each Lift point (4 total) has

1.0 Tonne WLL (FOS 6.0)

6

USER GUIDE SECTION 3

EXCAVATOR MOUNTED COMPACTOR

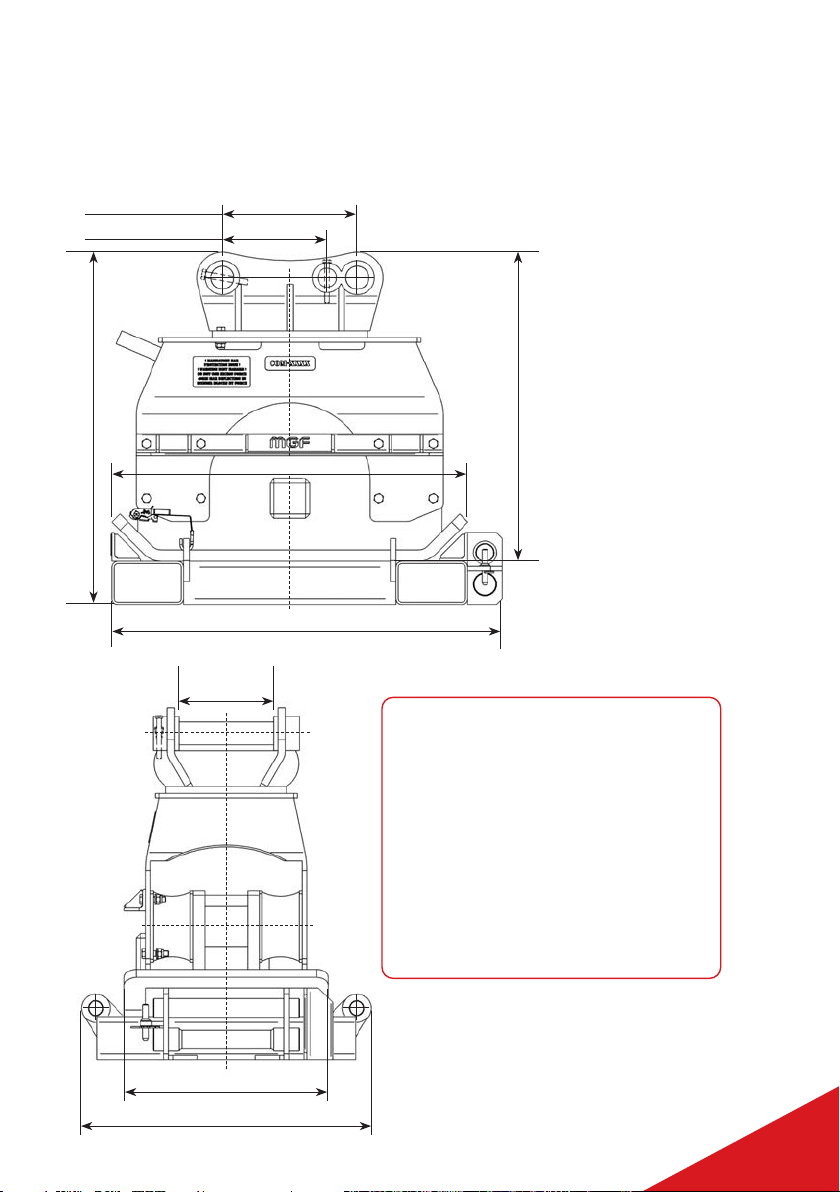

COMPONENT WEIGHTS

& DIMENSIONS

1360

1230 max height (on transport skid)

1080 max height (not on skid)

1240

470 (Ø80 pin centres)

365 (Ø65 pin centres)

1010 - max transport with skid

710 - compactor plate width

330 - max QH

frame width

IHC150 WEIGHTS:

• Compactor IHC150 = 800kg

• Quick Hitch Connection Bracket

(with 2 pins fitted) = 190kg

• Spare Pins (2off) = 30kg total (15kg ea)

• Carry Frame = 208kg

• Max In-Use Weight Total (no skid) =

1000kg

• Max Transport Weight Total (with skid 7

spare pins) = 1230kg

7

USER GUIDE SECTION 4

EXCAVATOR MOUNTED COMPACTOR

RISK ASSESSMENT CHECKLIST

• Consult manufacturers manuals before use of any equipment / plant if in doubt

• Ensure a pre-hire checklist has been completed

• All site activity must be thoroughly planned before work commences to identify hazards

and assess risks

• Ensure that a site/task specific Risk Assessment/Method Statement has been prepared

prior to use

• Ensure that lifting operations have been appropriately planned prior to use

• Ensure that all associated equipment is of sound condition, rated appropriately and is

tested in accordance with legislative requirements

• Ensure that Temporary Works Coordinators (TWC) and Temporary Works Supervisors

(TWS) have been consulted prior to operations commencing

• For any non standard applications (or if application in doubt) - a suitably qualified

engineer should be consulted for approval

• Ensure appropriate PPE is specified and worn. This should include both eye and ear

protection, in addition to other PPE required by site

• Ensure all personnel are properly briefed and adequately supervised by a competent

person(s)

• Ensure control measures are in place for the protection of operatives, third parties, plant

and structures in the proximity of operations prior to them commencing

• Any excavator fitted with a compactor should only be operated from stable ground

• Ensure any overhead cable hazards and associated risks are identified and controlled

• Ensure that regular checks are carried out to ensure that hazards are controlled and the

equipment is in good working order

• Ground vibrations may lead to substantial nuisance or hazard to the adjoining areas.

*MGF Ground Vibration Monitors are available for hire.

• Improper use of the compactor can lead to dangerous situations

CONSIDER THE FOLLOWING WHEN PREPARING YOUR RAMS

The following list is not exhaustive:

• Have all relevant persons been consulted prior to operations commencing

• The selection of competent fitters and operatives and slinger/bankspersons

• Items that could fall from height

• High pressure fluid injection

• Overturning of plant/equipment

• Proximity of operatives

• Third parties and plant in proximity of operations

• Trapping/impact and other mechanical hazards

• Heat from compactor when in use and post use

• Proximity of overhead cables and underground services

• Ground conditions

• Flying Stone chips/etc – due to compaction

• Environmental impacts

8

USER GUIDE SECTION 5

EXCAVATOR MOUNTED COMPACTOR

DO’S/DON’TS

DO’S:

Wear appropriate safety equipment

Only operate the compactor if you are suitably qualified and competent to do so

Ensure the excavator has sufficient load (tonnage) capacity for the compactor

being used

Ensure the quick hitch is fully locked and all hydraulic connections are secure

and leak free

Set up and enforce an ‘Exclusion Zone’

Complete all the required weekly, daily and pre-use checks and report any

defects

Ensure there is always visual contact between the operator and any operatives

near operations

Monitor the compactor operation constantly, interrupt the process immediately

if there are operational issues or any dangerous (or suspected dangerous)

situation occurs

Follow the agreed (and briefed) safe system of work/RAMS

Be aware of any buried services (gas water pipes - or electric cable)

Use the compactor flat to the surface being compacted

Store the compactor in a safe clean area, on or with its transport skid when not

in use

Place compactor onto transport skid and fit ratchet straps when ready for re-

collection

Have hydraulic spill kits available (can be sourced from MGF) before

commencing works

Employ Safe manual handling techniques where applicable

9

USER GUIDE SECTION 6

EXCAVATOR MOUNTED COMPACTOR

DONT’S:

Do not operate the compactor if anyone is in the exclusion zone

Do not enter the ‘Exclusion Zone’ if the compactor is being operated

Do not use the compactor if it is faulty in any way

Do not touch the compactor during the operating process (even if the excavator

is switched off) as it can become hot

Do not over compact and this can lead to services damage. If in doubt STOP and

consult relevant engineers

Do not submerge the compactor in water or operate submerged

Do not obscure the ‘line of sight’ of the operator

Do not use excessive force to disconnect quick release couplings, if they will not

disconnect by normal force they likely have pressure trapped within them. (see

section 8). Do not use levers or tools to force fittings apart as this can result in

damage/charges and could lead to operatives being sprayed by forced hot oil

Do not re-use nyloc nuts on vibration equipment, use a new part when

re-fitting

Do not put yourself or other in danger of falling from the excavator or

equipment during fitting or use

Do not operate the compactor whilst moving the excavator or travelling across

site

Do not position or pass the compactor above or over operatives. No one should

ever be under the compactor even whilst moving position

Do not expose operatives to danger of ‘Working at Height’ - when connecting

or disconnecting hoses. Always lower and position the excavator stick arm to

assist and minimise working from height

10

USER GUIDE SECTION 6

EXCAVATOR MOUNTED COMPACTOR

COMPACTOR OPERATION

7.1 DELIVERY

The compactor will be supplied on a transport skid. Choose an area where the skid can be

left and the compactor can be placed when not in use. It is suggested to move the skid to

this area.

If moving the skid at any point the ratchet straps must always be used and secured.

(For IHC150 only) the compactor will be supplied with a Quick Hitch bracket that can have

either Ø65 or Ø80 pin options fitted.

Pre-hire the customer can specify which size connection is preferred and MGF will supply

the compactor in this configuration. The Quick Hitch bracket is inspected as per LOLER

pre-hire, but this inspection is void if customer changes configuration themselves.

Whichever pin size is not fitted the spare pins are secured to and located on the transport

skid.

If the customer wishes they can swap the pin configuration, but this is done at their own

risk and they are entirely responsible for any misfitting outcomes, with no liability to MGF.

65 PIN CONFIG*** 80 PIN CONFIG**

***Note: Rear pin in 65 configuration is dog bone shaped - inner section is Ø65, with two outer

Ø80 sections for where it engages in bracket.

**Note: Rear pin in 80 config is a pin Ø80 across its full length.

Note: Each pin must be secured to Quick Hitch bracket - via 2 off M20 bolts and 2 off (unused

before fitting) M20 Nyloc nuts.

Failure to correctly secure pins could result in equipment falling from the excavator during

use.

Pins not being used should be stored in the purpose made area on the transport skid and

secured using the locking pin.

Remove ratchet straps and the compactor can either be lifted from the skid using slings

securely passed through/around the compactors quick hitch pins - or the excavator can

connect to the QH bracket, and once locked to the excavator quick hitch the compactor can

be moved or lifted via that connection.

11

USER GUIDE SECTION 7

EXCAVATOR MOUNTED COMPACTOR

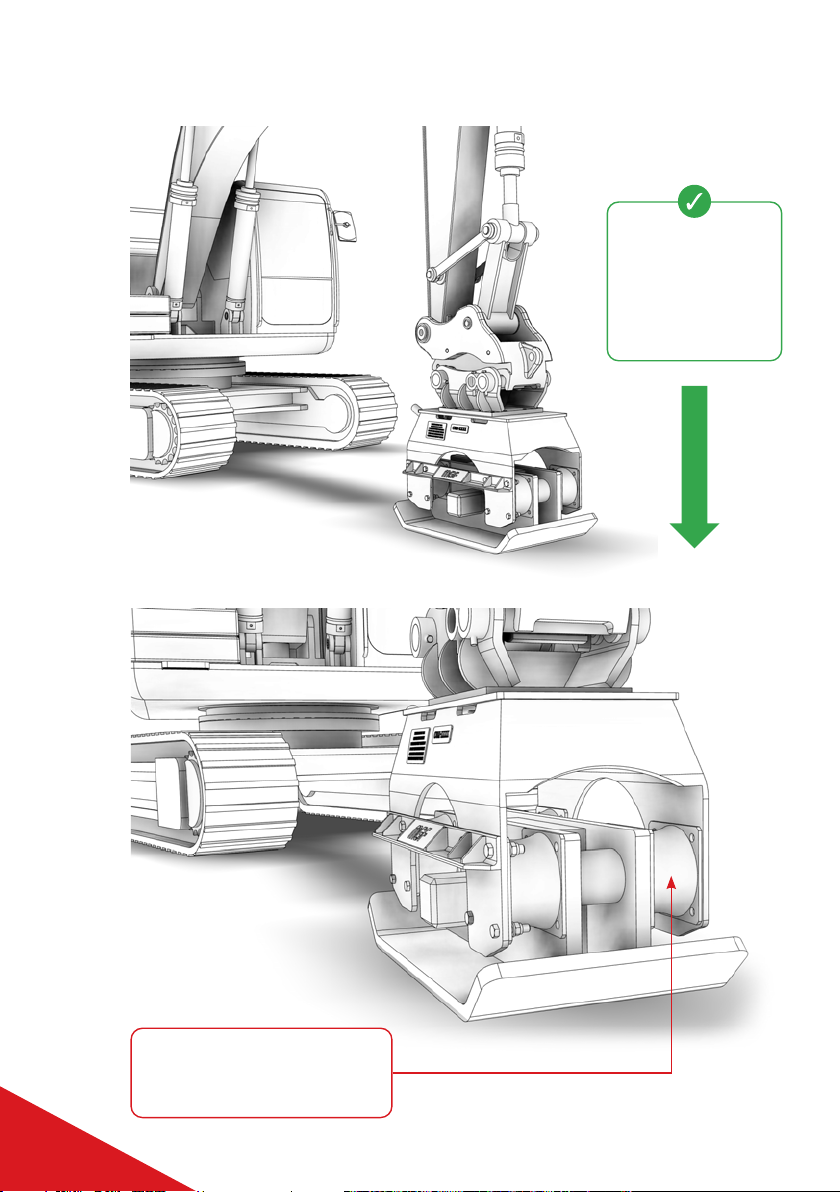

7.2 CONNECTING TO THE COMPACTOR VIA AN EXCAVATOR

QUICK HITCH

If a bucket is attached, remove from the Quick Hitch coupler by following the relevant

manufacturer’s instructions.

Place the dipper arm to ground level and shut down the excavator prior to connecting the

hydraulic auxiliary pipes to the connectors.

Engage the coupler to the pins and curl/crowd the coupler.

If using a fully automatic Quick Hitch, continue to fully curl/crowd the head. Switch to the

‘attach’ or ‘on’ position: the buzzer will cease. Hold the crowd lever for approximately 5 -

10 seconds to allow the hook to fully engage and clamp.

Note: For use of other types of Quick Hitch, refer to the relevant manufacturer’s instructions.

BEFORE OPERATING THE MACHINE, THE OPERATOR SHOULD EXIT THE

CAB AND, FROM A SAFE AREA, PERFORM A VISUAL CHECK TO ENSURE

THE HOOK HAS FULLY ENGAGED THE PINS.

7.3 CONNECTING THE HYDRAULIC LINES

IT IS ADVISED THAT THE COMPACTOR SHOULD BE FITTED BY AN MGF

SERVICE ENGINEER MAKING THE NECESSARY HOSE CONNECTIONS

AND CHECKING FOR FULL FUNCTIONALITY. THE COMPACTOR SHOULD

ONLY BE OPERATED BY SUITABLY TRAINED PERSONNEL.

SAFETY NOTES

• Extreme care and adequate precautions must always be taken to

prevent trapping fingers during connections or disconnections

• Do not use excessive force to disconnect quick release couplings - if they will not

disconnect by normal force they likely have pressure trapped within them. (See

section 8) - do not use levers or tools to force fittings apart as this can result in

damage/charges and could lead to operatives being sprayed by pressured hot oil.

• Ensure the compactor is only ever fitted to uni-directional flow systems,

unrestricted back to tank

• An MGF fitter will set up and identify hoses – by putting RED PVC tape around

the ‘flow in’ designated hose on the compactor. Red tape around also around

the excavator flow out QR fitting. Operatives can just match ‘red - to - red’ when

connecting

• The compactor will be fitted with TWO Male QR fittings - flow in to be identified by

red PVC tape. (Image right shows In - Out orientation of Compactor - ref for fitters)

• Excavator will be checked to have/or adapted to have TWO Female QRS fittings -

flow out identified by red PVC tape

12

USER GUIDE SECTION 7

EXCAVATOR MOUNTED COMPACTOR

7.4 PREUSE CHECKS

When all installation works are completed, check the following before operating the

compactor.

While moving the excavator’s bucket cylinder slowly in and out in the direction of ‘crowd’

and ‘dump’, check:

For any interference or obstruction between the compactor and excavator

Whether the length of the connecting hoses are too short or too long

For any twisting, excessive bending or squeezing of the connecting hoses

The fixing status of the mounting pins

While lifting the compactor above the ground (no-loading condition), check:

Whether the compactor runs normally without delay when the operating switch is

pressed ON, and that it stops when OFF

For any oil leaks from hoses, fittings, hydraulic motor or motor control valve

For loosening of bolts or nuts

For cracking or tears in the elastomers

If any abnormal vibration or noise occurs while the compactor is running

In – Out orientation of Compactor – ref for fitters

HVFK050F000

Manifold

Out

In

Return Hose

Pressure Hose

In

Out

A

B

13

USER GUIDE SECTION 7

EXCAVATOR MOUNTED COMPACTOR

7.5 OPERATING INSTRUCTIONS

Press down in a

direction vertical

to the ground, with

compactor plate

angled to match

ground angle.

Whilst applying force, elastomer

blocks must not deform/stretch

by more than 40mm.

14

USER GUIDE SECTION 7

EXCAVATOR MOUNTED COMPACTOR

Max deflection = half original elastomer diameter

• Place the compactor uniformly on the ground you want to compact

• Lower the excavator’s boom slowly to press the compactor vertically to the ground

Ensure that the Elastomer Block is deformed/stretched less than 40mm. If the

Elastomer Block is pressed more than the specified limit, it may be damaged or its life

might be shortened

• If you operate the compactor, having touched a very hard object such as a concrete floor

or bedrock, it would apply a very high impact which may result in a serious damage

• When the ground starts to be lowered by compacting, lower the excavator’s boom

gradually and keep a constant applying pressure: ensure the elastomer block is not

excessively stretched/deformed

• When compacting a wide area, advance working positions sequentially in a uniform

direction with some overlapped area

• For normal soil condition, recommended working time is 5 - 10 seconds. Operating

continuously for long periods will not improve compacting and may result in damage to

the compactor

7.6 GENERAL ADVISE/INSTRUCTIONS

• Keep Compactor Plate level to the floor/ground being compacted and apply a vertical

force

• Do not use the compactor as a breaker - or use it to push heavy items or plant onsite

• Do not support the excavator with the compactor - i.e. jack the excavator off the floor

• Do not apply excessive force

• Do not use the compactor for crane work or use to lift or pull objects

• Do not use underwater or submerge the compactor in water

• Temperature range for compactor oil - max 180F/82°C, min temp is 32°F/0°C. Idle the

excavator till warm and operate compactor unloaded if below min temperature

• Groundworkers should wear masks/filters and any other appropriate PPE if dust an

issue, or use dampening if an option

15

USER GUIDE SECTION 7

EXCAVATOR MOUNTED COMPACTOR

MAINTENANCE

SERVICING AND MAINTENANCE OF COMPACTORS TO BE CARRIED OUT BY

MGF ONLY. DO NOT ATTEMPT TO CARRY OUT MAINTENANCE OR REPAIRS.

IHC150 = Reservoir Capacity = 4.8L (85/90W Gear Oil)

CHECKS / FREQUENCY

OF CHECKS

DAILY:

Check Quick Hitch connecting bracket for loose cracked or missing bolts (this is both

mounting bolts, and pin securing bolts)

Examine hydraulic hoses for leaking or signs of excessive abrasion

Visually inspect compactor for any signs of damage

Check hydraulic hose quick release fitting for secure fix or any signs or leakage

Check return line connection - if it becomes restricted or pinched motor failure/

damage charges could occur

WEEKLY:

Check fasteners for tightness. Any replacement fasteners must be the same size

specification and grade as originals

Inspect Elastomer Blocks for signs of tearing, or damage

Check oil level in Compactor reservoir

(To check oil level - remove 3/8” NPT plug from side of oil reservoir on the base plate

assembly of the compactor. Operating oil level should be flush with the bottom of the

plug hole)

16

USER GUIDE SECTION 8 & 9

EXCAVATOR MOUNTED COMPACTOR

STEPS TO ATTEMPT

RELEASE OF HYDRAULIC

PRESSURE IN ‘PECKER

CIRCUIT’ OF AN EXCAVATOR

ISSUE = WHEN ATTEMPTING TO RELEASE OR USE THE ‘QUICK RELEASE’

COUPLINGS OF THE COMPACTOR FROM AN EXCAVATOR ‘PECKER

CIRCUIT’, PRESSURE CAN BE TRAPPED IN THE CIRCUIT WHICH MEANS

THE QUICK RELEASE COUPLINGS ARE VERY HARD TO OPERATE, OR

CANNOT BE OPERATED DUE TO THE PRESSURE.

Turn the key back on

to ‘ignition’ stage,

but do not start the

engine.

2

Turn off the excavator

engine using the

ignition key.

1

17

USER GUIDE SECTION 10

EXCAVATOR MOUNTED COMPACTOR

Ensure the dead man

switch (usually a lever at

the side of the operator’s

seat) is up or enabled.

3

Drop or disable the dead man control

lever, then turn machines ignition ‘off’.

Pressure can be confirmed to be released,

as quick release couplings should

rotate relative to each other freely and

disconnect easily.

Dead man’s lever shown in the

dropped or disabled position

(machine controls off). Position can

vary dependant on machine.

5

Do not operate or move

the joysticks or other

controls, but carefully

move only the control

switch for the pecker

circuit. This should be

switched several times.

It is likely you will hear

a click as pressure

releases, and physically

see the taut pressurised

hoses sag as pressure

releases.

4

Do not move any

controls other than the

pecker control switch.

Move left and right. Note: On this machine pecker

circuit control was on right

stick thumb control. It can vary

from machine to machine.

18

USER GUIDE SECTION 10

EXCAVATOR MOUNTED COMPACTOR

WHAT IS HAPPENING BY THESE ACTIONS?

Modern excavators have a pressure accumulator built into them. This can be thought of as

a small capacity hydraulic battery.

What we are doing with the above steps, is to use the hydraulic power in the accumulator,

to open or move the spool in the pecker circuit, which releases the pressure in the

hydraulic line.

PROBLEM SOLVING

If experiencing issues with releasing the pressure:

a. Repeat the above steps several times

b. Complete the steps within approx. a 30 second period. (reason - accumulator pressure

can drop over time due to wear or seal leakage. A newer machine will give you more

time to complete the steps etc.)

If pressure cannot be released by this method contact an MGF fitter.

19

USER GUIDE SECTION 10

EXCAVATOR MOUNTED COMPACTOR

EXCAVATOR MOUNTED COMPACTOR

NOTES

20

Table of contents