FOREWORD

WEAM009500 1

1.1 FOREWORD

qThis manual has been compiled by Komatsu Utility S.p.A. in order to supply customers with all the necessary in-

formation on the machine and on safety regulations, as well as the use and maintenance instructions that enable

the operator to exploit the capacity of the machine with optimal results and to keep the machine efficient over

time.

qThe operation manual, together with the spare parts catalogue, is an integral part of the machine and must ac-

company it, even when it is resold, until its final disposal.

qThe manual must be handled with the greatest care and always kept on board the machine, so that it can be

consulted at any moment; it must be placed in the appropriate compartment inside the seat support, where the

registration documents and the logbook are usually kept.

qThis manual must be given to the staff who have to use the machine and carry out the routine maintenance op-

erations; they must read the contents carefully more than once, in such a way as to clearly understand what are

the correct operating conditions and the dangerous conditions that must be avoided.

In case of loss or damage, request a new copy to Komatsu or your Komatsu Dealer.

qThe illustrations contained in this manual may represent machine configurations available on request.

Komatsu machines are constantly improved in order to increase their efficiency and reliability; this manual sums

up all the information regarding the most recent technology applied at the moment in which the machine is

launched.

For any further and/or updated information, contact your Komatsu Dealer.

qPunctual periodic annotations regarding the maintenance operations that have been carried out are important,

since they provide a clear report on the situation and say exactly what has been done and what has to be done

after the next maintenance interval. Therefore, it is advisable to consult both the hour meter and the mainte-

nance plan frequently.

qOver the years Komatsu Dealers have gathered considerable experience in customer service.

If more information is needed, do not hesitate to contact your Komatsu Dealer: he always knows how to get the

best performance from the machine, he can recommend the equipment that is most suitable for specific needs

and can provide the technical assistance necessary for any change that may be required to conform the ma-

chine to the safety standards and traffic rules.

Furthermore, Komatsu Dealers also offer assistance for the supply of Komatsu genuine spare parts, which guar-

antee safety and interchangeability.

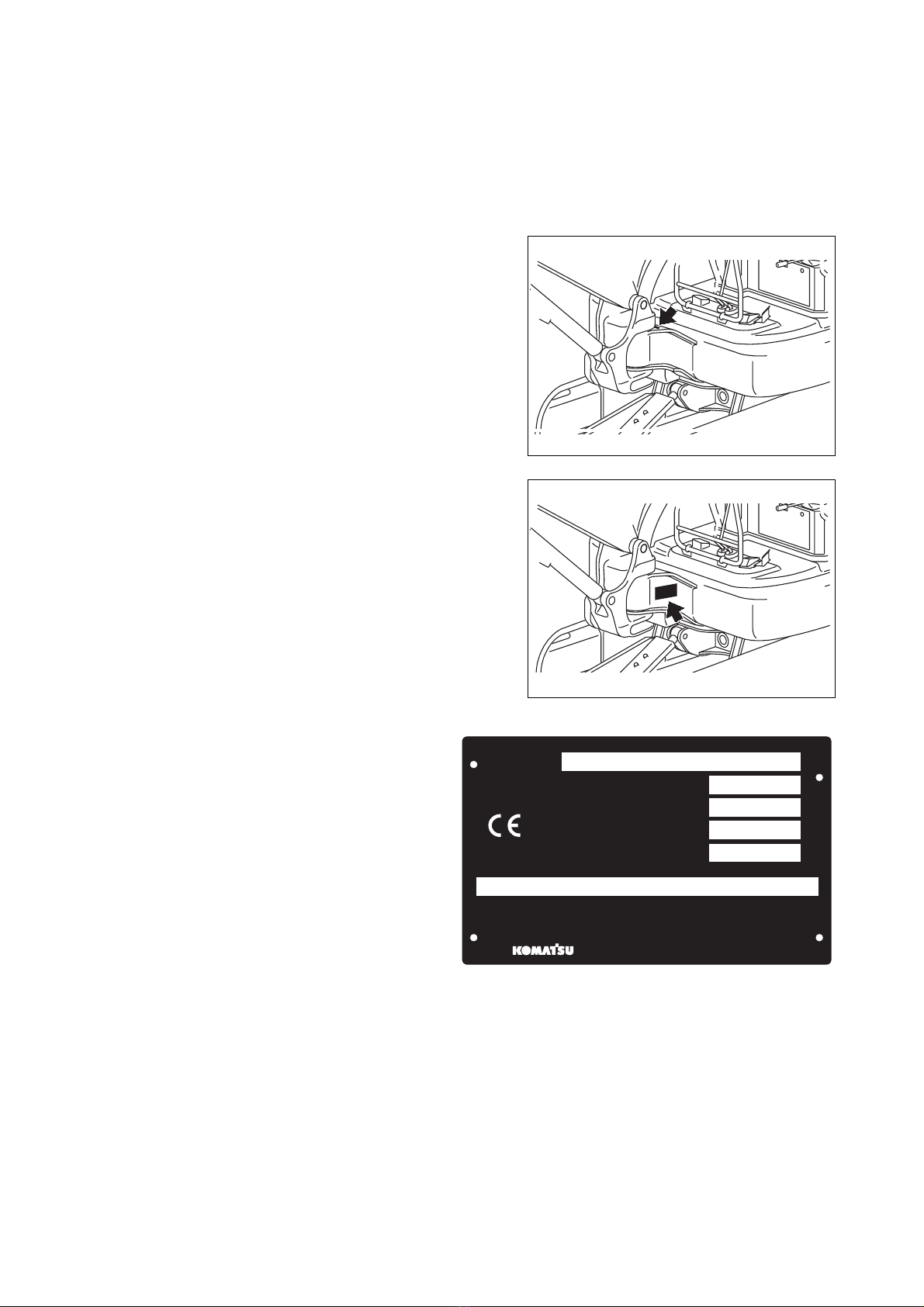

qThe table included in this manual must be filled in with the machine data, which are also the data that must be

communicated to the Dealer when requiring assistance and ordering spare parts.

CAUTION

qThe incorrect use of the machine and inappropriate maintenance operations may cause serious injury

and even death.

qOperators and maintenance personnel must carefully read this manual before using the machine or per-

forming maintenance operations.

qAny serious accident that may occur during the use of the machine or during maintenance operations is

due to failure to comply with the instructions given herein.

qThe application of the procedures and precautions described in this manual will ensure safety only pro-

vided that the machine is used correctly.

If the machine is used for any purpose or in any way other than those described herein, the operator

shall be responsible for his own safety and for the safety of any other person involved.