MHG Heating EcoStar 720 User manual

© MHG Heating Ltd

1

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Installation and Operating Manual for the

EcoStar 720 & 750 Oil Condensing Floor Standing Range

Output Range 20.0 – 62.0 kW

© MHG Heating Ltd

2

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Section

1.0 Appliance Type

3

1.1 EcoStar 720 High Efficiency 3

1.2 EcoStar 750 Condensing 3

2.0 Installation Regulations and Requirements 4

2.1 Appliance Warranties 5

3.0 Dimensions EcoStar 720 Range 6

3.1 Dimensions EcoStar 750 Range 6

3.6 Installation Clearances 7

4.0 Delivery, Mobility and Assembly 8

5.0 Technical Data 25

5.1 Fluing Options 26

6.0 Pressure Relief Valve 28

7.0 Electrical Connections 29

7.1 Internal Wiring Diagrams 31

8.0 Hydraulic Configurations 33

8.1 Hydraulic Single Unit 33

8.13 Hydraulic Cascade Unit 35

9.0 Filling The System 36

9.1 Pressure Vessel 37

10.0 System Water Quality 37

11.0 Appliance Controls 38

12.0 Appliance Fault Codes 38

13.0 Commissioning 100

13.1 Pre-Commissioning Checks. 100

13.2 Combustion System Commissioning 100

14.0 Routine Inspection and Servicing 101

14.1 Routine Service Inspection 101

14.2 Routine Cleaning and Maintenance 101

15.0 Weather Compensation Slope Graph and Sensor Curves 102

16.0 Optional System Controls 104

17.0 Exploded Spares Diagrams 105

18.0 Parts List 106

18.0 Installer / End Users Note 116

© MHG Heating Ltd

3

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

1.0 Appliance Type

There are eight versions within the EcoStar 700 range. Each unit can be supplied with or without a

secondary condensing heat exchanger.

Please ensure you have the correct unit for the application prior to beginning the installation.

1.1 The EcoStar 720 High Efficiency unit without secondary condensing heat exchanger appliances are

designed to be applied to systems where there is not a need for a condensing boiler.

1.2 The EcoStar 750 Condensing unit with secondary condensing heat exchanger appliances are designed

to be applied to systems where the operating temperature of the system would benefit from the

application of a condensing boiler or a higher level of efficiency is required even though the systems

operating temperature is elevated.

The product codes for the standard range are:

Product Name Output kW Product Code

EcoStar 723 High Efficiency Boiler 28 94.10000-5423

EcoStar 753 Condensing Boiler 31 94.10000-5453

EcoStar 724 High Efficiency Boiler 37 94.10000-5424

EcoStar 754 Condensing Boiler 41 94.10000-5454

EcoStar 725 High Efficiency Boiler

45 94.10000-5425

EcoStar 755 Condensing Boiler 51 94.10000-5455

EcoStar 726 High Efficiency Boiler 56 94.10000-5426

EcoStar 756 Condensing Boiler 62 94.10000-5456

If a condensing EcoStar 753-756 boiler is being used the following flue and condensate connection kit is

also required.

Product Name Boiler Type

Product Code

Flue and Condensate Connection Kit 753 to 756 94.62200-4820

© MHG Heating Ltd

4

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

2.0 Installation Regulations and Requirements

The installation of EcoStar 700 boilers must be in accordance with the relevant requirements of Gas Safety

(Installation & Use) Regulations 1994, Health & Safety at Work Act, Building Regulations, IEE Regulations,

Construction (Design & Management) Regulations 1994, Local Authority Bye-Laws, National, Fire

Regulations and Insurance Company requirements.

The following Codes of Practice are also applicable:-

BS 5440-1: 2000 Installation of flues and ventilation for gas appliances of rated input not exceeding 70

kW net (1st, 2nd and 3rd family gases).

Part 1: Specification for the installation of flues.

BS 5440-2: 2000 Installation of flues and ventilation for gas appliances of rated input not exceeding 70

kW net (1st, 2nd and 3rd family gases).

Part 2: Specification for installation and maintenance of ventilation for gas appliances.

BS 5449: 1990 Specification for forced circulation hot water central heating systems for domestic

premises.

BS 6644: 2005 Specification for gas fired hot water boilers of rated inputs between 70kW (net) and

1.8MW(net) (2nd and 3rd family gases).

BS 6798: 1987 Specification for installation of gas fired hot water boilers of rated input not exceeding 60

kW.

BS 6880: 1988 Code of Practice for low temperature hot water heating systems of output greater than

45kW. Parts 1, 2 & 3.

BS 6891: 1988 Specification for installation of low pressure gas pipework of up to 28mm (R1) in domestic

premises (2nd family gases)

BS 7593: 1992 Code of Practice for treatment of water in domestic hot water central heating systems.

BS 7671: 1992 Requirements for electrical installations. IEE Wiring Regulations. Sixteenth edition.

CISBE Guide reference sections B7, B11 and B13.

CP342 Part 2: 1974 Code of Practice for centralized hot water supply.

IGE/UP/2 Gas installation pipework, boosters and compressors on industrial and commercial premises.

IGE/UP/4 Commissioning of gas fired plant on industrial and commercial premises

IGE/UP/10 Installation of gas appliances in industrial and commercial premises. Part 1: Flued appliances.

The prevailing OFTEC regulations.

And any addition prevailing regulation and or code of practice not detailed above.

© MHG Heating Ltd

5

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

2.1 Appliance Warranties

All MHG appliances enjoy a full 36 month warranty as detailed in our terms and conditions.

The guarantee period shall begin on the day of commissioning, or at latest 3 months after delivery has

been made.

The customer shall only be able to claim against MHG under guarantee if the commissioning of the object

of delivery has been carried out by MHG staff or the authorized supplier, if the customer has followed

MHG's instructions relating to the treatment and maintenance of the object of delivery, and if no

replacement parts of outside origin have been fitted.

Parts subject to wear such as ignition electrodes, seals etc. are strictly excluded from the guarantee.”

In addition to the above warranties, the Heat Exchangers carry a 60 month guarantee against

manufacturing or material defect.

© MHG Heating Ltd

6

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

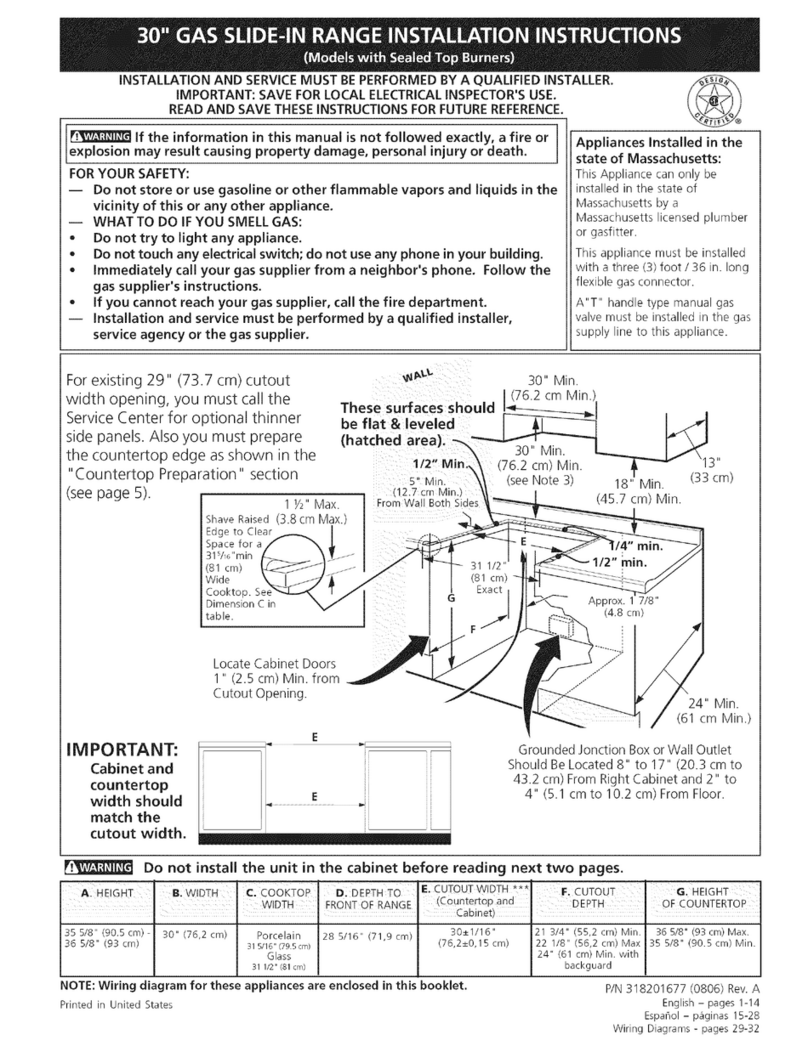

3.0 Dimensions. EcoStar 720

Item Description Units 723 724 725 726

Boiler Output (80/60) kW 27.8 37.0 45.4 55.6

A Initial Connection BSP 1

KFE Drain BSP ½

KSG Safety Set

L1 Overall Length mm 910 1040 1170 1300

L2 Support Separation mm 255 385 515 645

VL Flow Connection BSP 1 ½

RL Return Connection BSP 1 ½

Hydraulic Pressure Loss @ 20∆T mbar 10 12 13 14

Dry Weight kg 185 230 270 310

3.1 Dimensions. EcoStar 750

Item Description Units 753 754 755 756

Boiler Output (80/60) kW 28.8 38.5 47.1 57.7

Boiler Output (50/30) kW 31.0 41.4 50.7 62.1

A Initial Connection BSP 1

KFE Drain BSP ½

KSG Safety Set

L1 Overall Length mm 1290 1420 1550 1680

L2 Support Separation mm 255 385 515 645

VL Flow Connection (Pump Kit) BSP 2

RL Return Connection (Pump Kit) BSP 2

Hydraulic Pressure Loss @ 20∆T mbar 50 52 53 54

Dry Weight kg 205 250 290 330

© MHG Heating Ltd

7

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

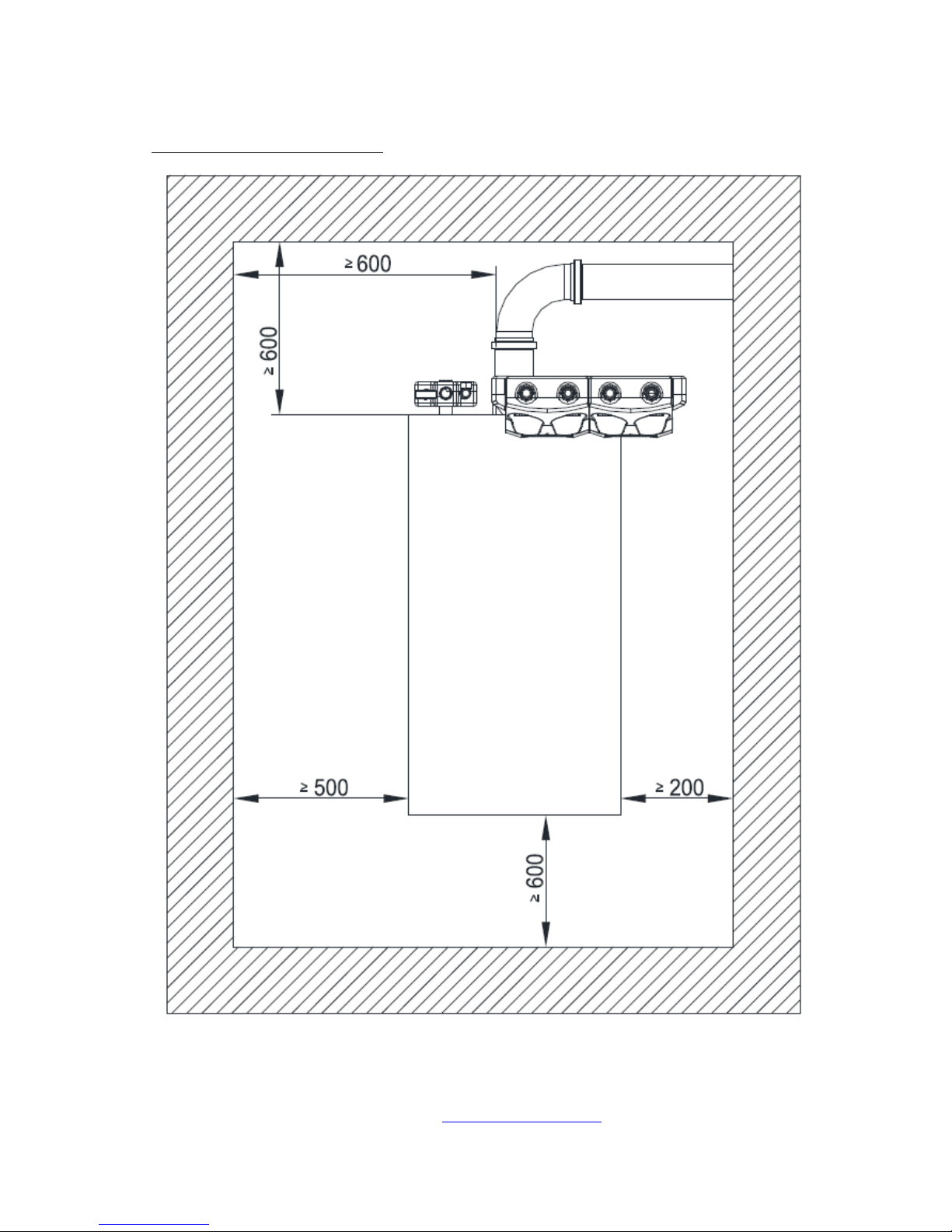

3.6 Installation and Service Clearances

© MHG Heating Ltd

8

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

4.0 Delivery and Mobility

All EcoStar 700s are supplied fully tested and therefore may contain residual test water.

The test water utilised contains additives that will help prevent associated pumps from sticking and other

metals from oxidising.

To maintain the structural integrity of the appliance the internal components should not be used during

the lifting and positioning of the unit.

EcoStar 700 Primary Heat Exchanger on transport pallet.

Boiler door carton.

© MHG Heating Ltd

9

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

The initial connections to the primary heat exchanger flow and return connections can be made with the

heat exchanger on the transport pallet.

1 & 2. Flow & Return 1.5”

3. Drain

If the secondary heat exchanger is being applied the interconnecting pipes and adapters can also be

applied.

Prior to positioning the primary heat exchanger on to its feet it is advisable to remove the casing panels.

© MHG Heating Ltd

10

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Once correctly positioned install the baffles as indicated above.

723-725 & 753-755 726 & 756

Baffle type 1 Yes No

Baffle type 2 Yes Yes

© MHG Heating Ltd

11

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Fit the door mounting hinge 1 on the required side and the blanking plate 2 on the other.

The arrowed items provide information relating to the location of the heat exchangers support legs.

Once the primary heat exchanger is in position the side cases can be reattached.

Install the double nipple to the top rear of the primary heat exchanger. This provides a connection point

for the pressure relief valve, pressure gauge and automatic air released group.

© MHG Heating Ltd

12

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Install the case transition section and interconnection pipework and seals.

When installing a 720 range appliance the flue can be connected directly to the DN180 flue spigot.

When installing a 750 range appliance the secondary heat exchanger must connected to the primary heat

exchanger flue outlet spigot.

Install the seal 1 into the recess of the secondary heat exchanger.

© MHG Heating Ltd

13

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Ensure that the vent plug is in place, tight and closed.

Install the seals and associated adapted fittings.

Mounted secondary heat exchanger.

Install the return connector from the secondary heat exchanger to the primary heat exchanger and the

common return pipe to the rear casing.

© MHG Heating Ltd

14

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Following the installation of the rear casing section the system pipework or pump group pipework can be

installed.

If a MHG pump group is being used, install the associated pipework.

Prior to installing any flue component ensure that the seal has been lubricated with a silicone grease.

Flue and condensate connection kit 94.62200-4820

When installing the first section of flue section into the secondary heat exchanger ensure that the male

section is only inserted a maximum of 30mm.

The flue limit sensor section has a definitive shoulder, whereas a DN100 elbow can be over inserted and

restrict the flue way.

© MHG Heating Ltd

15

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Flue and condensate connection kit 94.62200-4820

Ensure that all seals are installed in the condensate waste system.

1.Heat Exchanger drain. 2. Combined drain, 3. Flue system drain,

4. Y connector, 5. Neutralizing unit.

Flue and condensate connection kit 94.62200-4820

© MHG Heating Ltd

16

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Install the fascia onto the inner mounting frame ensuring that the wires and phials are not

snagged.

The control is secured with a combination of hanging lugs 1 and screws 2.

Attach the inner frame to the inner front frame.

Connect the fascia wiring to the frame mounted RVS controller.

1. QAA75 connection G+ CL- CL+

2. Burner control connection

3. RVS Power supply connection

4. Permanent power supply connection.

© MHG Heating Ltd

17

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Ensure that all Earthing straps are securely applied.

Install the Flue Limit Thermostat wiring. SK1 / SK2

Attached the boiler controller sensor to connection to B2/M

Install the boiler control sensor and limit thermostat phial into the pocket located in the casting adjacent

to the flow connection.

© MHG Heating Ltd

18

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Install the connecting pipework and safety group and drain valve.

© MHG Heating Ltd

19

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Install the burner mounting bolts and combustion chamber pressure test point onto the boiler door.

Mount the boiler door onto the hinge and ensure correct alignment when closed.

Leave the door open to ensure correct insertion of the burner.

Please refer to the burner technical manual for further guidance.

Once this has been achieved the burner door can be closed and the burner reattached.

Connect the electrical Wieland plug to the burner.

© MHG Heating Ltd

20

MHG Heating Ltd, Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey, KT20 5LR

010612 Draft

Once all electrical and operational checks have been completed the top case can be installed and secured.

Please refer to the following sections for electrical connections and commissioning guidance.

This manual suits for next models

1

Table of contents