MHP JNR User manual

www.mhpgrills.com 1

JNR GAS GRILL HEAD

Assembly Manual

SCAN THE

QR CODE FOR

ASSEMBLY VIDEO English

2

DANGER: IF YOU SMELL GAS

1. Shut off the main gas supply to the grill

2. Extinguish any open flame

3. Open lid

4. If odor continues, keep away from the grill and

immediately call your gas supplier or your fire department.

Failure to follow these instructions could result

in fire or explosion which could cause property

damage, personal injury or death.

WARNING: FOR YOUR SAFETY

1. Do not store or use gasoline or other flammable liquids or

vapors in the vicinity of this or any other appliance

2. An LP cylinder not connected for use should not be stored

in the vicinity of this or any other appliance.

3. Follow all leak-test procedures on page 10 of this manual

carefully before using. Do this even if the grill was dealer

assembled. Do not test for leaks with a match or any

open flame. Do not try to light this grill without reading

the “Lighting” instructions.

The appliance is FOR OUTDOOR USE ONLY. It is not to be used inside a

garage, other building or any type of enclosed area. Combustible materials

should never be within 18 inches of the bottom, back or sides of your MHP

Gas Barbecue Grill.

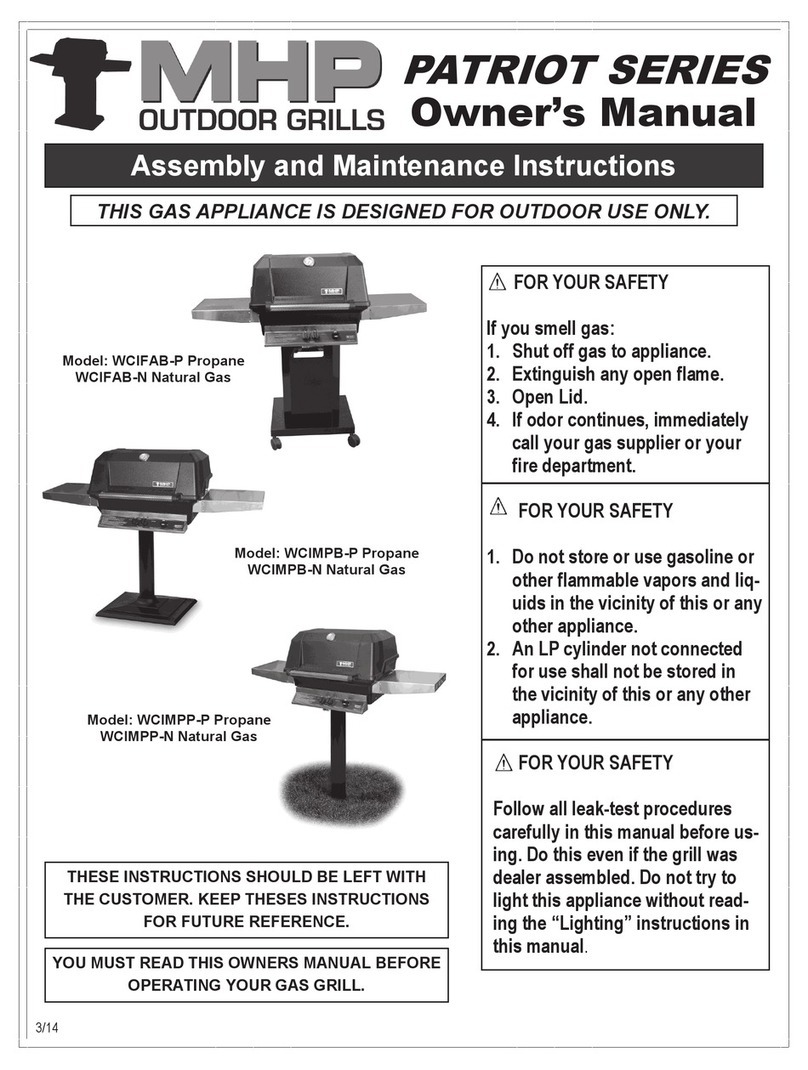

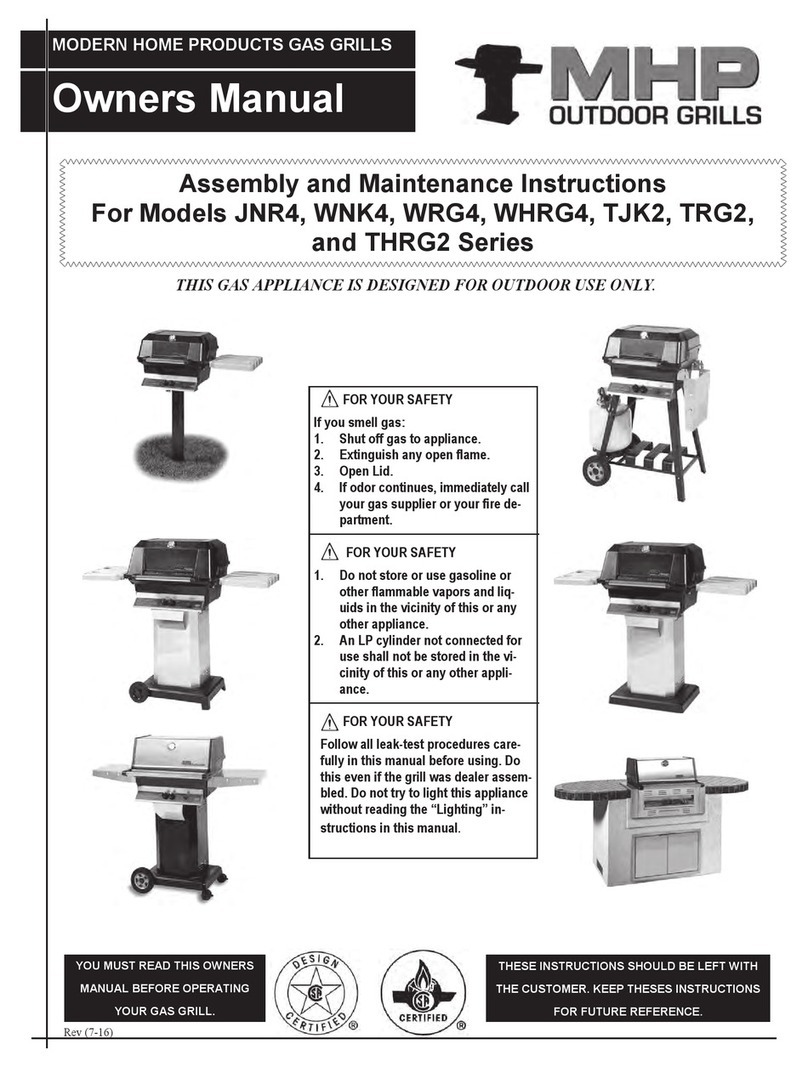

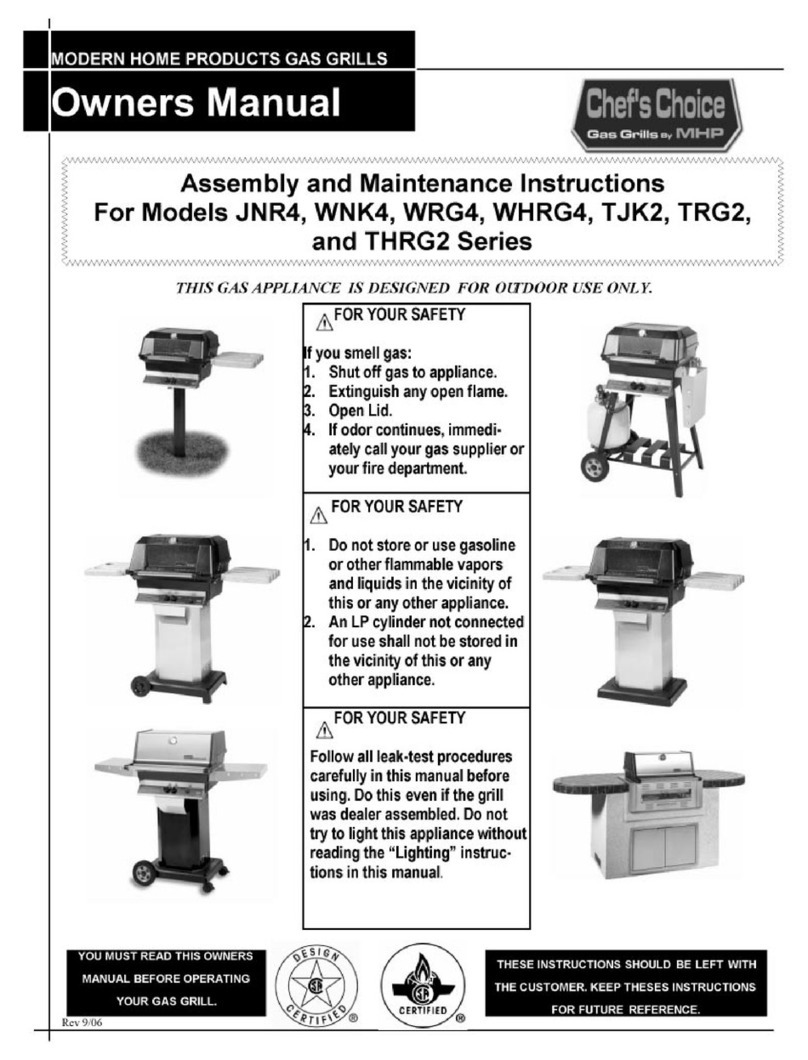

•The JNR Grill head is specifically designed to fit these MHP mounting options.

- JC4 Four Legged Open Cart - OCOL/OCOLB with OM Base

- MPP In-ground Post - OCOL/OCOLB with OP Base

- MPB Patio/Deck Base - OCOL/OCOLB with OC Base

•The gas supply may be either LP or Natural Gas

BOXES/BAGS:

IMPORTANT SAFETY WARNINGS

TOOLS LIST:

ADJUSTABLE WRENCH 3/4" COMBINATION

WRENCH

7/16" COMBINATION

WRENCH (2)

3/8" COMBINATION

WRENCH

PHILLIPS

SCREWDRIVER

HH-GRATE-SS

Briquette Grate

JNR-LP

Control Panel for LP Gas Grill

(includes hose and regulator)

sJNR-SEAR-PK

SearMagic Cooking Grids

OWNER'S MANUAL BAG

Includes:

• Owner's Manual

• Temperature Gauge

• Venturi Tube Cleaner

• (2) Lid Pivot Pins

s

HH-SS-GRID2

Stainless Steel Cooking Grid

HHDDSK

Side Shelf Kit

BRIQUETTE BAG

53 Briquettes

END CAPS/HANDLE

Includes hardware

JNR-NAT

Control Panel for Natural Gas Grill

You should have the following boxes/bags containing the different parts and hardware needed to assemble your grill.

OR OR

Make sure your base is

assembled before continuing.

The base assembly instructions

should be included with your base.

Visit our website mhpgrills.com/

info/owners-manuals/

for a complete list of assembly

videos & manuals

www.mhpgrills.com 3

Remove the Burner

•Remove the grill burner by taking out

the two small cotter pins located on the

underside of the bottom grill casting (fig. a)

•Pull the burner up and out of the

grill head (fig. b).

ASSEMBLY PREPARATION

Choose a Location where you are going to set up your grill. Make sure

there is enough room and you have a flat surface. Improper assembly

may be dangerous. Please carefully follow the assembly instructions in

this manual.

•Place the box facing up

•Remove the packaging material followed by the grill head components

•Set the components on a flat surface

•Check to see if all components are included and that you

have the appropriate tools to begin the assembly. Remove all

components and discard the box.

At this point you should already have your bottom casting attached to your

mounting (See your mounting assembly manual for these steps).

Make sure your base is assembled before continuing. The base assembly

instructions should be included with your base.

Visit our website mhpgrills.com/info/owners-manuals/ for a complete list of

assembly videos & manuals

s

CONTINUED

CONTROL PANEL

ASSEMBLY

KEP NUTS (6)

BRACKETS (2)

JNR-LP

Control Panel for LP Gas Grill

(includes hose and regulator)

JNR-NAT

Control Panel for Natural

Gas Grill

PARTS INCLUDED IN BOX:

PUSH BUTTONPHILLIPS HEAD

BOLTS

(2)

(2)

BATTERY VENTURI

CLEANER

KNOBS (2) LP GAS HOSE &

REGULATOR

Included with

LP Gas Grills only

(pre-attached)

INSTALLING THE CONTROL PANEL

STEP 1

PHILLIPS

SCREWDRIVER

7/16" COMBINATION

WRENCH

TOOLS NEEDED:

fig. a

fig. b

4

Attaching the Control Panel Assembly to the Front of

the Bottom Casting

•Attach the complete control panel assembly to the front

of the grill bottom casting with two 1/4-20 Kep Nuts and

hand tighten

•Make sure the valve orifices on the control panel align

with the burner venturi correctly and that the venturi tubes

go over the valve orifices at least 1/4" to 3/8". (see Valve

Stem Engagement below)

•Tighten all nuts using a 7/16" combination wrench

INSTALLING THE CONTROL PANEL, CONTINUED

STEP 1

Connecting the Control Panel Support Brackets

Two support brackets are connected beneath the control panel

to the grill bottom casting for added support.

• Push 1/4 - 20 x 1-1/4" Phillips Head Bolts down through the

grill bottom casting from the inside and continue through the

back hole on the support brackets. Secure the brackets with

1/4 - 20 Kep Nuts.

• Attach the control panel to the support brackets by pushing up

a 1/4 - 20 x 1/2" Phillips Head Bolt through the front hole of each

support bracket and the lower lip of the control panel. Fasten

brackets with a 1/4-20 Kep Nut.

•Tighten all nuts using a screwdriver and a 7/16" combination wrench

Venturi Engagement

At the top end of each valve there is a tiny

gas opening known as the orifice. Gas exits

the orifice and enters a venturi where it mixes

with air coming in from the side air shutter.

The proper mixture of air and gas produces

a clean blue flame at the burner.

Make sure the valve orifice on the control

panel aligns with the burner venturi tube

correctly. The orifice should fit into the

venturi tube 1/4" to 3/8".

1/4-20 x 1/2"

PHILLIP

HEAD BOLT

1/4-20 x 1/2"

PHILLIP

HEAD BOLT

1/4-20"

KEP NUT

1/4-20"

KEP NUT

SHELF

BRACKETS

Reinstall the Burner

•Drop the burner into the bottom of the

grill casting making sure the venturi tubes

go through the bottom opening.

•The burner leg pins pins should align with

the predrilled holes in the bottom of the

grill pit.

•Reattach small cotter pins onto the

burner leg pins

OPENING FOR

VENTURI TUBES

COTTER PIN

LEG PIN

HOLES

CORRECT INCORRECT

www.mhpgrills.com 5

INSTALLING THE CONTROL PANEL, CONTINUED

STEP 1

Ignitor Wire Connection

Attach the wire from the ignitor

module, located behind the

control panel, to the porcelain

insulator found on the underside

of the bottom casting.

Be careful not to crack the

delicate porcelain insulator

Battery Installation

•Place the AAA battery "+" side down into the ignitor

module.

•Install push button over the battery and turn clockwise

to tighten in place.

Attach Knobs to Control Panel

Attach the two control knobs to the grill by pushing them

down securely onto the valve stems.

Connect the Gas Supply

Please reference the assembly manual that came with your grill mounting for directions on connecting the gas

supply to your grill.

+

-

IGNITOR MODULE

PORCELAIN INSULATOR

6

INSTALLING THE SIDE SHELF

STEP 2

Mount Side Shelf Brackets

•Shelf can be mounted to left or right side of grill

•Locate the side brackets and mount the brackets to the

side of the grill.

•Attach the brackets using the supplied Phillips Head Bolts and

Kep Nuts (2 Phillips Head Bolts and Kep Nuts per bracket).

•Insert the Phillips Head Bolts into the pre-drilled holes from

the inside of the bottom casting and attach the Kep Nuts

on the outside.

•Tighten the Kep Nuts while making sure the brackets

remain parallel with the grill using a screwdriver and

a 7/16" combination wrench.

Attach the Side Shelf

Once both brackets are in place, attach the Side Shelf.

•Place the left bottom shelf threaded screw into the left bottom

bracket slot.

•Gently spread the shelf apart to insert the right bottom shelf

threaded screw into the right bottom bracket slot.

•Tighten Nylock Nuts on the bottom threaded screws using

a screwdriver and a 3/8" combination wrench. Make sure

the nuts are snug but do not restrict movement of folding and

unfolding of the shelf.

Top threaded screws on shelf do NOT use nuts.

Remove Plastic Protective Sticker

Before installing the side shelf, remove the plastic protective sticker from

all sides of the shelf and shelf brackets.

SHELF

KEP NUTS (4) NYLOCK NUT (2)

SIDE BRACKETS (2) PHILLIPS HEAD

BOLTS (4)

PARTS INCLUDED IN BOX:

HHDDSK

Side Shelf Kit

7/16"

COMBINATION

WRENCH

3/8"

COMBINATION

WRENCH

PHILLIPS

SCREWDRIVER

TOOLS NEEDED:

www.mhpgrills.com 7

INSTALLING THE BRIQUETTE GRATE

STEP 3

Install the Stainless

Steel Briquette Grate

by placing it into the

bottom grill casting.

The grate should

rest level on the

shelf edge just

above the burner.

STAINLESS STEEL

BRIQUETTE GRATE

PARTS INCLUDED IN BOX:

HH-GRATE-SS

Briquette Grate

INSTALLING THE BRIQUETTES

STEP 4

•Place the porcelain briquettes on top of the grate.

•Place one at a time

•Carefully place the porcelain briquettes on the

grate in the pattern shown making sure to only

have one layer.

•This pattern helps to distribute heat evenly and

reduce flare-ups.

The bag includes 53 briquettes—you will need

all 53 to fill the briquette grate properly.

BRIQUETTE BAG

53 Briquettes

ATTACHING THE TOP CASTING

STEP 5

Attach the Top Casting

•Locate the top casting for your grill and place it on the back

of the bottom casting, aligning the two back hinges.

•Slide the Lid Pivot Pin through both hinge holes and secure

with a Hitch Pin.

•Repeat on opposite side.

LID PIVOT PINS HITCH PINS

PARTS NEEDED:

OWNER'S MANUAL BAG

You will find the parts you need

in the bag with your owner's

Manual

It is recommended

someone assist you

with this step.

8

Install one end cap first, followed by the center shaft handle,

then enclose it by securing the second end cap.

Attaching the Handle

•Attach the first end cap to the grill lid using a 1/4-20 x 1-1/2"

Hex Bolt and Kep Nut making sure that the Graphite Gasket

(purple element) is positioned between the end cap and

the grill lid as shown.

•Tighten the end cap by using two 7/16" Combination Wrenches—

one to hold the bolt head and one to tighten the Kep Nut.

•Insert the handle into both the installed end cap and second

end cap

•Installl the second end cap using the same method

as outlined above.

ATTACHING THE FRONT HANDLE

STEP 6

HANDLE END CAP ASSEMBLY (2)

Each End Cap Includes:

• End Cap

• Graphite Gasket

• 1/4-20 x 1-1/2" Hex Bolt

• Kep Nut

PARTS INCLUDED IN BOX:

END CAPS/HANDLE

Includes hardware

Installing the Temperature Gauge

•Insert the temperature gauge through

one washer into the pre-drilled hole

on the grill top casting making sure

the gauge is facing outward.

•On the inside of the grill lid, install

the second washer, then the Wing Nut

to the temperature gauge post.

•Hand tighthen the Wing Nut until

temperature gauge is snug against

the casting.

INSTALLING THE TEMPERATURE GAUGE

STEP 7

TEMPERATURE GAUGE ASSEMBLY

Includes:

• Temperature Gauge

• Washer (2)

• Wing Nut

PARTS NEEDED:

OWNER'S MANUAL BAG

The Temperature Gauge

is included in the

Owner's Manual bag

TEMPERATURE

GAUGE

PRE-DRILLED HOLE FOR

TEMPERATURE GAUGE

END CAPS

GRAPHITE GASKETS

WASHER

WING NUT

WASHER

TOOLS NEEDED:

7/16" COMBINATION

WRENCH (2)

www.mhpgrills.com 9

STAINLESS STEEL COOKING GRIDS (2) SEARMAGIC COOKING GRIDS (2) GRID CLEANING TOOL

(GGWB5)

PARTS INCLUDED

HH-SS-GRID2 BOX:

PARTS INCLUDED

JNR-SEAR-PK BOX:

JNR-SEAR-PK

SearMagic Cooking Grids

HH-SS-GRID2

Stainless Steel

Cooking Grid

OR

ADDING THE STAINLESS STEEL OR SEARMAGIC COOKING GRIDS

STEP 8

Installing Stainless Steel Cooking Grids

•The two stainless steel cooking grids should easily

drop in side-by-side above both briquette grate and

porcelain briquettes

•The top side of the Stainless Steel Grids has

the rods on top of the frame.

Installing SearMagic Cooking Grids

•The two SearMagic cooking grids should easily drop

in side-by-side above both the briquette grate and the

porcelain briquettes.

•The SearMagic Grids are reversible. Use the ribbed side

for making sear marks on steaks and use the smooth

side for more delicate items.

ADDING THE WARMING RACK

STEP 9

Installing the JNR Warming Rack

•Rest the warming rack on the notches located in the back top edge of the

bottom casting.

•The top side of the warming rack has the rods on top of the frame.

WARMING RACK

PART INCLUDED:

HHSSTS

Warming Rack REST WARMING RACK

ON NOTCHES

10

ATTACHING TO GAS LINE

LEAK TESTING

Do not make sharp bends when bending your flexible

stainless-steel tubing to match the feed of your grill

valve and position in the top notch of the post.

The LP Hose and Regulator is factory installed on your

control panel. Make sure the LP hose runs through

the hose retention notch or clip (depending on your

specific grill mounting). For additional information,

reference your grill mounting assembly manual.

FOR NATURAL GAS & HARD-PLUMBED LP GAS

INSTALLATIONS

BENDING STAINLESS STEEL TUBING

FOR LP GAS INSTALLATIONS

After you have successfully assembled your grill—hook up your gas lines and check all connections.

For complete steps on connecting your grill to a gas line please refer to the instructions included

in the assembly manual for your specific mounting.

LEAK TEST ALL GAS CONNECTIONS BEFORE USING YOUR GRILL.

DO NOT SMOKE WHILE LEAK TESTING.

DO NOT LEAK TEST WITH A MATCH OR OPEN FLAME.

DO NOT USE A GRILL THAT IS LEAKING GAS.

YOU SHOULD TEST FOR GAS LEAKS EVERY TIME YOU

DISCONNECT AND RECONNECT A GAS FITTING.

PERFORM A LEAK TEST EVEN IF YOUR GRILL WAS DEALER

OR STORE ASSEMBLED.

DO NOT IGNITE BURNERS WHEN LEAK TESTING.

LEAK TESTING STEPS

1. Grill burner control valves should be turned off and

the gas turned on at source.

2. Apply soap solution to all gas connections.

To make soap solution, mix together equal amounts

of liquid detergent and water.

3. Soap bubbles will appear if there is a leak.

4. Tighten the connection using a 3/4" combination

wrench and adjustable wrench to make the proper

seal (one wrench is used to hold the fitting while the

other is used to tighten). Recheck for soap bubbles.

If a leak is detected…

If you have detected a leak

try tightening and securing all

connections. The use of two

wrenches is recommended—

one wrench is used to hold

fitting while the other is used

to tighten.

vFor LP models, leak test with a full propane cylinder.

vFor systems other than self-contained LP cylinders:

•The grill and its individual shut-off valve must be

disconnected from the gas supply piping systems

during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

•The grill must be isolated from the gas supply piping

system by closing its own manual shut off valve during

any pressure testing of the gas supply piping system at

pressures equal to or less than 1/2 psi (3.5 kPa).

www.mhpgrills.com 11

Enhance Your Grill

Our premium accessories have been designed specifically for our grills

with quality materials and craftsmanship

Visit your local dealer or our online store

www.mhponlinestore.com

Protect Your Grill

Our grill covers are constructed of a durable polyester lined vinyl,

designed to protect your grills from the elements.

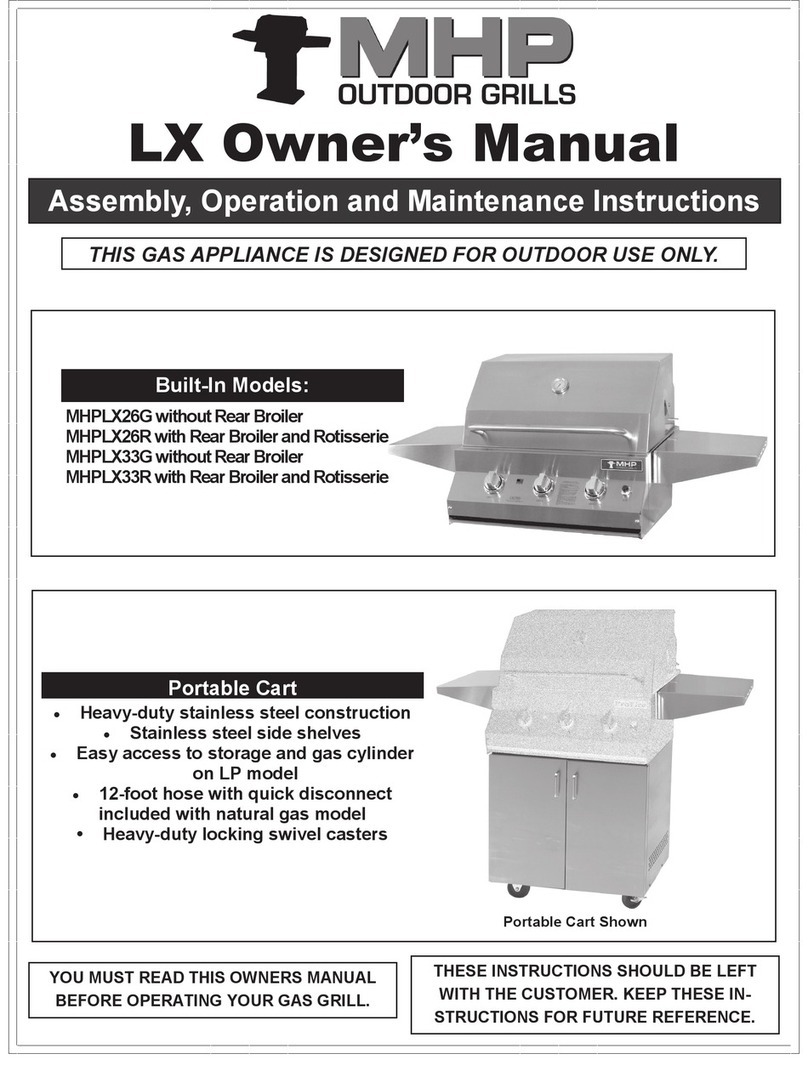

STAINLESS STEEL SIDE BURNER

The premium commercial grade stainless steel

side burner is 12,000 BTU rated, has its own

electronic ignition, and is factory assembled for

simple bolt-on installation. Available for both

Natural and LP Gas.

SBA3-N (Natural Gas) | SBA3-P (LP Gas)

ROTISSERIE KIT

Rotisserie Kit includes RO6 stainless

steel motor, motor mounting bracket,

rotisserie rod, handle, bushing, forks

and 3 ft. cord. Max. 25 lb. balanced load.

RKMHP

Mid-Length Grill Cover

Side Shelf Up

HHCVPREM

Full-Length Grill Cover

Side Shelf Up

CV2PREM

Full-Length Grill Cover

Side Shelf Down

DDCVPREM

12

TECHNICAL SUPPORT

© MHP 2020, All Rights Reserved

By

ProFire

DRAGON

FIRE

Family Owned & Operated Since 1957 AM-JNR-0321

Modern Home Products

150 S. Ram Road • Antioch, IL 60002

847.395.6556 • 888.647.4745

Make the most out of your grilling experience!

From side burners and rotisseries to grill covers and more—

we carry a complete line of grill upgrades, accessories and grill parts

designed specifically for your MHP Grill.

rVisit MHPGrills.com for more information

California Proposition 65 Warning: This product can expose you to chemicals including Chromium (hexavalent compounds),

which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to:

www.P65Warnings.ca.gov.

DON'T FORGET TO REGISTER YOUR GRILL!

It is the responsibility of the grill owner to complete and submit the warranty registration

form to MHP in order for the warranty to be valid.

What you will need to register your grill:

•A bill of sale, canceled check, or payment record is

required to verify the purchase date and establish

warranty period.

•Model Number

•Serial Number

•Type of Grill Purchased (Natural or LP Gas)

How to find your grill model #/serial #

The model number tag is located on the left end cap of the control panel.

Visit mhpgrillpartsonline.com/warranty-registration-form/

to register your grill online. A mail-in registration postcard is also included

with your owner's manual.

YOUR MODEL #: JNR YOUR SERIAL #:

Other manuals for JNR

1

Table of contents

Other MHP Grill manuals

Popular Grill manuals by other brands

BBQ

BBQ Grillware 164826 owner's manual

YAKINIKU

YAKINIKU SHICHIRIN instruction manual

Rational

Rational iVario 2-XS Original Installation Instructions

Jumbuck

Jumbuck GEN-SE-25T quick start guide

Anvil

Anvil GGA3004 R04 Installation, Operation and Care Manual

Garland

Garland XE24 Installation, operating & service instructions

Uniflame

Uniflame Outdoor Charcoal Barbecue Grill CBC701W owner's manual

Fagor

Fagor SE 60 Instruction manual for installation and use

Philips

Philips HD6320 quick start guide

Lakeland

Lakeland 16906 Instruction booklet

Cadac

Cadac Meridian 3 Woody Assembly instructions

Aussie

Aussie Koala 7900 Series Assembly and use manual