MHP OCOL User manual

www.mhpgrills.com | 1

OCOL

Installation Manual

SCAN THE

QR CODE FOR

ASSEMBLY VIDEO English

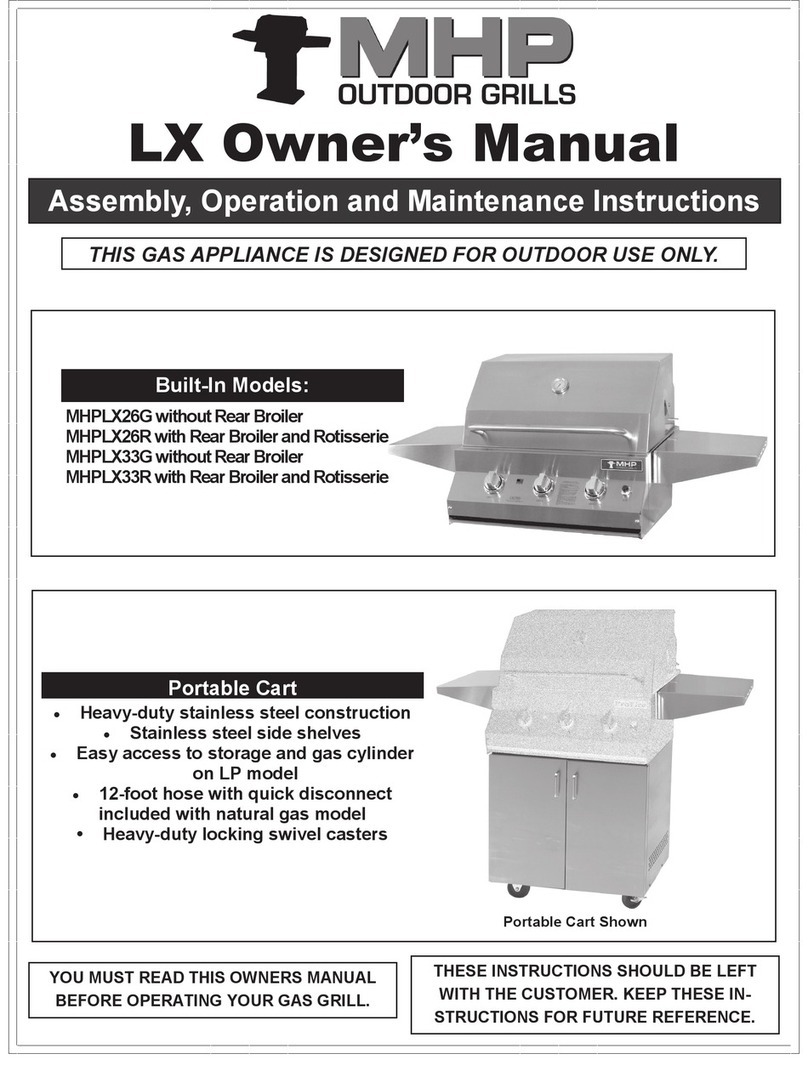

OCOLOMN

OCOLOMP

OCOLOPN

OCOLOPP

OCOLOCN

OCOLOCP

2 | www.mhpgrills.com

DANGER: IF YOU SMELL GAS

1. Shut off gas to the appliance

2. Extinguish any open ame

3. Open lid

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your re department. Failure to

follow these instructions could result in re or

explosion which could cause property damage,

personal injury or death.

WARNING: FOR YOUR SAFETY

1. Do not store or use gasoline or other ammable

liquids or vapors in the vicinity of this or any other

appliance

2. An LP cylinder not connected for use shall not be

stored in the vicinity of this or any other appliance.

3. Follow all leak-test procedures in your owner’s

manual (included with your grill head) carefully

before using. Do this even if the grill was dealer

assembled. Do not try to light this appliance

without reading the “Lighting” instructions.

The appliance is FOR OUTDOOR USE ONLY. It is not to be used inside a garage, other

building or any type of enclosed area.

WARNING:

• All MHP Grill Heads may be mounted on the column.

• The gas supply may be either LP or Natural

• The grill head should not be attached to the column until the column and base have been completely

PARTS LIST:

IMPORTANT SAFETY WARNINGS

OCOL STAINLESS STEEL COLUMN BOX

TOOLS LIST:

ADJUSTABLE WRENCH 3/4" OPEN END

WRENCH 7/16" OPEN END

WRENCH

GGOTB

TANK LOCK BAR

GGOGC

STAINLESS STEEL

GREASE CUP

GGOCOLR

STAINLESS STEEL

COLUMN

GGAC

STAINLESS STEEL

FRONT ACCESS COVER

HARDWARE KIT

GGM11

STAINLESS STEEL

WASHERS (QTY. 16)

GGOTBS

NYLON TANK BAR

SPACERS (QTY. 2)

GGM4

KEP NUTS

(QTY. 12)

GGM6

1/4 X 20" X 3/4"

HEX BOLTS (QTY. 8)

GGM14

1/4 X 20" X 1-1/4"

HEX BOLTS (QTY. 4)

GGGSKA/GGGSKB

2-PIECE GASKET (1)

LEFT AND RIGHT

7/16" NUT DRIVER RUBBER MALLET

www.mhpgrills.com | 3

Place the stainless steel column facing up. Carefully peel 2 inches of the

thin, white protective lm covering from the top and bottom of the stainless

steel surfaces paying special attention to areas that will be partically hidden

after being assembled. Once assembly is complete you can go back and safely

remove all the of the protective lm.

DO NOT scrape off the lm. This can cause damage to the stainless steel.

Locate the Tank Lock Bar from the OCOL Box

•Align the holes on the bar to the pre-drilled holes on the column.

• Use the 1/4 x 20" x 3/4" Hex Bolt, Nylon Lock Bar Spacer, and a

Kep Nut on each side to fasten the Tank Lock Bar in place. This

spreads and holds the correct spacing at the back of the column.

• Use 7/16" open end wrench to hold the Kep Nut while using

the second open end wrench to tighthen the Bolt.

AFTER CONNECTING THE TANK LOCK BAR YOU CAN ATTACH THE BASE AND THE GAS LINE. FOLLOW THE STEPS FOR YOUR SPECIFIC BASE.

PEELING OFF PROTECTIVE PLASTIC

STEP 1

Choose a location where you are going to set up your grill. Make sure the

surface is at and that there will be enough room to complete the assembly.

CONNECTING THE TANK LOCK BAR

STEP 2

HEX BOLT

NYLON LOCK BAR SPACER

PRE-DRILLED HOLES

KEP NUT

PARTS NEEDED TOOLS NEEDED

GGOTB

TANK LOCK BAR

GGOCOLR

STAINLESS STEEL

COLUMN

HARDWARE NEEDED

GGM6

1/4 X 20" X 3/4"

HEX BOLTS (2)

GGM4

KEP NUTS (2)

7/16" OPEN END GGOTBS

NYLON TANK

BAR SPACERS

OP BASE

Step 3C-OP Page 7-8

Step 3 Page 9

Step 4C-OP Page 12-13

Step 5 Page 14

OM BASE

Step 3B-OM Page 5-6

Step 3 Page 9

Step 4B-OM Page 11

Step 5 Page 14

OC BASE

Step 3A-OC Page 4

Step 3 Page 9

Step 4A-OC Page 10

Step 5 Page 14

4 | www.mhpgrills.com

ATTACH THE BASE TO THE COLUMN (OC BASE)

STEP 3A-OC

PARTS NEEDED FROM OC BOX

OC

CAST ALUMINUM BASE

GGAXL

AXLE

GGGC

AXLE CLIPS (2)

GGWL1

6" WHEELS (2)

OCOL

HUB CAPS (2)

ASPCL1

12' NATURAL

GAS HOSE

(Quick Disconnect)

HARDWARE NEEDEDPART NEEDED (FROM OCOL BOX)

GGM4

KEP NUTS

(QTY. 6)

GGM6

1/4 X 20" X 3/4"

HEX BOLTS (QTY. 6)

GGM11

STAINLESS STEEL

WASHERS (QTY. 12)

TOOLS NEEDED

ADJUSTABLE

WRENCH

7/16" OPEN

END WRENCH

GGGSKA/GGGSKB

2-PIECE GASKET (1)

LEFT AND RIGHT

ATTACH THE GASKET

•Before bolting the column to the base, the

2-piece gasket must be installed to create a

barrier between the two dissimilar metals.

•Remove the backing strips from the gasket to

expose the adhesive and stick the gasket to

the bottom lip of the column. Make sure to

align the holes.

ATTACH THE COLUMN TO THE BASE

•Attaching the column to the base will be easier

to handle by laying the column face down and

matching the holes on the column lip to the holes

on the base.

•Slide a 1/4 x 20" x 3/4" Hex bolt and stainless

steel round washer down to the underside of the

base through the pre-drilled hole on the column

and secure using a Kep Nut.

•Use a 7/16" wrench to hold the Kep Nut while

using a second adjustable wrench to tighten

the bolt. There are a total of six pre-drilled holes

which should be secured.

HEX BOLT

ROUND WASHER

ROUND WASHER

ATTACH WHEELS

• For accessibility, lay the column on it's side.

•Attach the wheels by slipping the axle

through the pre-drilled holes in the

base, slide the wheels onto the axle

and secure with the axle clips.

•Finish by snapping the hub caps on

before standing the unit upright.

AXLE CLIP

AXLE

AXLE

AXLE CLIP

HUBCAP

HUBCAP

HEX BOLT

Included with natural

gas bases only

SCAN THE

QR CODE FOR

ASSEMBLY VIDEO

www.mhpgrills.com | 5

Attach the Column to the Base

•Attaching the column to the base will

be easier to handle by laying the column

face down and matching the holes on

the column lip to the holes on the base.

•Slide a 1/4 x 20" x 3/4" Hex bolt and

stainless steel round washer down to

the underside of the base through the

pre-drilled hole on the column and

secure using a Kep Nut.

•Use a 7/16" wrench to hold the Kep Nut

while using a second adjustable wrench

to tighten the bolt. There are a total

of six pre-drilled holes which should

be secured.

Attach the Gasket

•Before bolting the column to the base, the

2-piece gasket must be installed to create

a barrier between the two dissimilar metals.

•Remove the backing strips from the gasket

to expose the adhesive and stick the gasket

to the bottom lip of the column.

Make sure to align the holes.

HEX BOLT

HEX BOLT

ROUND WASHER

ROUND WASHER

PARTS NEEDED FROM OC BOX

OM

CAST ALUMINUM BASE

GGAXL

AXLE

GGGC

AXLE CLIPS (2)

GGWL

8" WHEELS (2)

OCOL

HUB CAPS (2)

ASPCL1

12' NATURAL

GAS HOSE

(Quick Disconnect)

HARDWARE NEEDED

GGM4

KEP NUTS

(QTY. 6)

GGM6

1/4 X 20" X 3/4"

HEX BOLTS (QTY. 6)

GGM11

STAINLESS STEEL

WASHERS (QTY. 12)

TOOLS NEEDED

ADJUSTABLE

WRENCH

7/16" OPEN

END WRENCH

PART NEEDED (FROM OCOL BOX)

GGGSKA/GGGSKB

2-PIECE GASKET (1)

LEFT AND RIGHT

KKWL

CASTERS (2)

ATTACH THE BASE TO THE COLUMN (OM BASE)

STEP 3B-OM

Included with natural

gas bases only

RUBBER

MALLET

SCAN THE

QR CODE FOR

ASSEMBLY VIDEO

6 | www.mhpgrills.com

ATTACH WHEELS

• For accessibility, lay the column on it's side.

•Attach the wheels by slipping the axle through the pre-drilled holes in

the base, slide the wheels onto the axle and secure with the axle clips.

•Finish by snapping the hub caps on before standing the unit upright.

ATTACH CASTERS

• Place caster stem into stem opening of the portable base.

• Press and tap into place using a rubber mallet, if needed.

STEM OPENING

CASTER

PARTS NEEDED

PARTS NEEDED

OCOL

HUB CAPS (2)

GGAXL

AXLE

GGGC

AXLE CLIPS (2)

GGWL1

8" WHEELS (2)

KKWL

CASTERS (2)

TOOLS NEEDED

ATTACH THE BASE TO THE COLUMN (OM BASE) continued

STEP 3B-OM

RUBBER MALLET

AXLE CLIP

AXLE

AXLE

AXLE CLIP HUBCAP

HUBCAP

www.mhpgrills.com | 7

OP BASE

CAST ALUMINUM BASE

Attach the Gasket

•Before bolting the column to the base, the

2-piece gasket must be installed to create

a barrier between the two dissimilar metals.

•Remove the backing strips from the gasket

to expose the adhesive and stick the gasket

to the bottom lip of the column.

Make sure to align the holes.

Attach the Column to the Base

•Attaching the column to the base will

be easier to handle by laying the column

face down and matching the holes on

the column lip to the holes on the base.

•Slide a 1/4 x 20" x 3/4" Hex bolt and

stainless steel round washer down to

the underside of the base through the

pre-drilled hole on the column and

secure using a Kep Nut.

•Use a 7/16" wrench to hold the Kep Nut

while using a second adjustable wrench

to tighten the bolt. There are a total

of six pre-drilled holes which should

be secured.

HEX BOLT

HEX BOLT

ROUND WASHER

ROUND WASHER

PART NEEDED

3/8" FLARE COUPLING

ADDITIONAL ITEMS NEEDED FOR

PATIO BASE INSTALLATION

(Not Included)

LAG BOLTS (2)

HARDWARE NEEDED

GGM4

KEP NUTS

(QTY. 6)

GGM6

1/4 X 20" X 3/4"

HEX BOLTS (QTY. 6)

GGM11

STAINLESS STEEL

WASHERS (QTY. 12)

TOOLS NEEDED

ADJUSTABLE

WRENCH

7/16" OPEN

END WRENCH

PART NEEDED (FROM OCOL BOX)

GGGSKA/GGGSKB

2-PIECE GASKET (1)

LEFT AND RIGHT

GGCTSS

FLEX TUBE

ATTACH THE BASE TO THE COLUMN (OP BASE)

STEP 3C-OP

Included with

natural gas

bases only

SCAN THE

QR CODE FOR

ASSEMBLY VIDEO

8 | www.mhpgrills.com

The grill head should not be attached to the column until the

base has been permanently mounted to a at and level deck or

patio surface. Not recommended for use on patio pavers.

ATTACH THE BASE TO THE COLUMN (OP BASE) continued

STEP 3B-OP

•Choose a location where you are going to set

up your grill. Make sure the surface is at and

level and be certain that there are no combustible

materials above, behind, left or right closer than

18" away.

•Insert a Lag Bolt into the two pre-drilled holes

located around the center cutout on the OP base.

• Securely tighten lag bolts so that base and column

are stablized.

•Choose a location where you are going to

set up your grill. Make sure the surface is at

and be certain that there are no combustible

materials above, behind, left or right closer than

18" away.

•Run your natural gas line through the notch

located on the back side of the OP base and

continue it up through the center cutout.

Directions for connecting the natural gas line

to the GCTSS exible tubing is outlined in

Step 3B-OP on page 12.

•Insert a Lag Bolt into the two pre-drilled holes

located on the sides of the center cutout of the

OP base.

• Securely tighten lag bolts so that base and

column are stablized.

LAG BOLTS (2)

Not supplied by MHP

Use appropriate

Lag Bolts for

your application

HARDWARE NEEDED

SECURE THE BASE (FOR LP GAS INSTALLATIONS)

SECURE THE BASE (FOR NATURAL GAS INSTALLATIONS)

NOTCH FOR

NATURAL GAS

NATURAL

GAS LINE

CENTER

CUTOUT

LAG BOLT HOLES

LAG BOLT HOLES

www.mhpgrills.com | 9

Attach the Grill Head

• With the column in the upright position,

carefully place the grill head bottom onto

the column aligning the pre-drilled holes

on both the grill bottom and the column.

• Use a 1/4 x 20" x 1-1/4" Hex bolts and

washer through each of four pre-drilled

holes in the bottom of the grill head.

• On the underside of the column lip,

secure each of the Hex bolts with a

Kep Nut. Use a 7/16" nut driver to

hold the Hex Bolt inside the grill while

tightening the Kep Nut on the underside

of the grill head using a 7/16" Open-End

Wrench or Socket Wrench.

Install the Grease Cup

• With the column in the upright

position, locate the grease cup

opening which can be accessed from

the back side of the grill.

•Drop the grease cup into the opening.

• The grease cup should t snuggly

into place.

Remove the Burner (optional)

• Remove the grill burner by taking out the cotter

pins located under the bottom grill head (g. a)

• Pull the burner up and out of the the grill head (g. b).

This will allow access to hold the Kep nuts inside the

post while attaching the bottom casting.

CONNECT THE GRILL HEAD BOTTOM

STEP 4

HEX BOLT

ROUND WASHER

KEP NUT

g. a

g. b

HARDWARE NEEDED

GGM11

STAINLESS STEEL

WASHERS (QTY. 4)

GGOGC

STAINLESS STEEL

GREASE CUP

GGM4

KEP NUTS

(QTY. 4)

GGM14

1/4 X 20" X 1-1/4"

HEX BOLTS (QTY. 4)

TOOLS NEEDED

GGOGC

STAINLESS STEEL

GREASE CUP

GREASE CUP

OPENING

GREASE CUP

BACK OF GRILL

If you are using an OP Base the grill head should not be attached to the column until the base has been permanently

mounted to a deck or patio surface. If this has not been done, see step 3X-OP for steps to secure the OP base.

7/16" NUT DRIVER7/16" OPEN

END WRENCH

10 | www.mhpgrills.com

CONNECTING THE GAS SUPPLY LINE (OC BASE)

STEP 5A-OC

CONNECT THE GAS LINE (FOR LP GAS INSTALLATIONS)

•The LP Hose and Regulator are factory-installed onto

your grill head's LP Valve

•Make sure your gas line runs through the hose

retaining notch opening and continues under

the heat shield as shown in the picture.

•Attach the LP Regulator to your propane tank

and securely hand tighten the coupling nut to

the cylinder valve.

• Before using your grill check for any gas leaks with

a soap and water solution before using your grill.

CONNECT THE GAS LINE (FOR NATURAL GAS INSTALLATIONS)

•Attach the swivel connector end of the ASCPL1 hose

to the gas valve located under the control panel.

•Make sure your gas line runs through the hose

retaining notch opening and continues under the

shelf as shown.

•The socket (quick disconnect) end of the ASCPL1

hose attaches to your gas supply line at your gas

supply line's shut-off valve. Depending on the size of

your gas line you may need a reducer (not supplied

by MHP) to connect your gas line to the quick

disconnect socket (3/8" male pipe thread).

•Tighten all gas connections securely. The use

of two wrenches is recommended—one wrench

is used to hold tting while the other is used

to tighten.

• Before using your grill check for any gas leaks with

a soap and water solution before using your grill.

INCLUDED WITH NATURAL GAS BASES

ASCPL1

12' NATURAL GAS HOSE

(QUICK DISCONNECT)

The swivel connector connects

to the grill's gas valve

The Quick Disconnct

Socket connects to your

gas supply line

The gas supply line must be regulated (in the case of natural gas that means it should be connected after your

gas meter and regulator) and you must have an easily accessible main shut-off valve to your grill’s gas

supply. Grills are designed to operate on a pressure of 7" w.c. in. for Natural or 11"w.c. in for Propane at the

grill valve connection.

When installing a new gas line, it is recommended that you

contact a plumber, heating contractor or licensed gas tter to

install your new gas line to meet local building code. Be certain

there are no combustible materials closer than 18" away (above,

behind, left or right) from your assembled grill.

TOOLS NEEDED

3/4" OPEN END ADJUSTABLE

WRENCH

HEAT SHIELD

GAS HOSE

GAS VALVE

SWIVEL

CONNECTOR

HOSE RETAINING

NOTCH OPENING

GAS SUPPLY

LINE

GAS FLOW

SOCKET PLUG SWIVEL CONNECTOR

HOSE RETAINING

NOTCH OPENING

HEAT SHIELD

QCC-1 Cylinder Valve

Regulator

Coupling Nut

Turn clockwise to connect

Bleed Off Valve

Dust Cover

Pressure

Relief Valve

www.mhpgrills.com | 11

CONNECT THE GAS LINE (FOR LP GAS INSTALLATIONS)

•The LP Hose and Regulator are factory-installed onto

your grill head's LP Valve

•Make sure your gas line runs through the hose

retaining notch opening and continues under

the heat shield as shown in the picture.

•Attach the LP Regulator to your propane tank

and securely hand tighten the coupling nut to

the cylinder valve.

• Before using your grill check for any gas leaks with

a soap and water solution before using your grill.

CONNECT THE GAS LINE (FOR NATURAL GAS INSTALLATIONS)

The gas supply line must be regulated (in the case of natural gas that means it should be connected after your

gas meter and regulator) and you must have an easily accessible main shut-off valve to your grill’s gas

supply. Grills are designed to operate on a pressure of 7" w.c. in. for Natural or 11"w.c. in for Propane at the

grill valve connection.

When installing a new gas line, it is recommended that you

contact a plumber, heating contractor or licensed gas tter to

install your new gas line to meet local building code. Be certain

there are no combustible materials closer than 18" away (above,

behind, left or right) from your assembled grill.

TOOLS NEEDED

3/4" OPEN END ADJUSTABLE

WRENCH

•Attach the swivel connector end of the ASPCL1 hose

to the gas valve located under the control panel.

•Make sure your gas line runs through the hose

retaining notch opening and continues under the

shelf as shown.

•The socket (quick disconnect) end of the ASPCL1

hose attaches to your gas supply line at your gas

supply line's shut-off valve. Depending on the size of

your gas line you may need a reducer (not supplied

by MHP) to connect your gas line to the quick

disconnect socket (3/8" male pipe thread).

•Tighten all gas connections securely. The use of two

wrenches is recommended—one wrench is used to

hold tting while the other is used to tighten.

• Before using your grill check for any gas leaks with

a soap and water solution before using your grill.

CONNECTING THE GAS SUPPLY LINE (OM BASE)

STEP 5B-OM

INCLUDED WITH NATURAL GAS BASES

ASCPL1

12' NATURAL GAS HOSE

(QUICK DISCONNECT)

The swivel connector connects

to the grill's gas valve

The Quick Disconnct

Socket connects to your

gas supply line

HEAT SHIELD

GAS HOSE

GAS VALVE

SWIVEL

CONNECTOR

HOSE RETAINING

NOTCH OPENING

GAS SUPPLY

LINE

GAS FLOW

SOCKET PLUG SWIVEL CONNECTOR

HOSE RETAINING

NOTCH OPENING

HEAT SHIELD

QCC-1 Cylinder Valve

Regulator

Coupling Nut

Turn clockwise to connect

Bleed Off Valve

Dust Cover

Pressure

Relief Valve

12 | www.mhpgrills.com

CONNECT THE GAS LINE (FOR LP GAS INSTALLATIONS)

•The LP Hose and Regulator are factory-installed onto your grill head's LP Valve

•

Attach the LP Regulator to your propane tank and securely hand tighten the coupling nut to the cylinder valve.

• Before using your gril check for any gas leaks with a soap and water solution before using your grill.

CONNECTING THE GAS SUPPLY LINE (OP BASE)

STEP 5C-OP

HEAT SHIELD

LP GAS HOSE

HOSE RETAINING

NOTCH OPENING

QCC-1 Cylinder Valve

Regulator

Coupling Nut

Turn clockwise to connect

Bleed Off Valve

Dust Cover

Pressure

Relief Valve

www.mhpgrills.com | 13

The gas supply line must be regulated (in the case of

natural gas that means it should be connected after your

gas meter and regulator) and you must have an easily

accessible main shut-off valve to your grill’s gas

supply. Grills are designed to operate on a pressure

of 7" w.c. in. for Natural or 11"w.c. in for Propane at the

grill valve connection.

When installing a new gas line, it is recommended that you contact a plumber, heating contractor

or licensed gas tter to install your new gas line to meet local building code. Be certain there are no

combustible materials closer than 18" away (above, behind, left or right) from your assembled grill.

Attach Natural Gas Line to the GGCTSS Flex Tube

• Connect a 3/8" are coupling (not supplied by MHP) to the

gas supply line then the exible stainless-steel tubing

(GGCTSS) using a 3/4" wrench. The use of two wrenches is

recommended—one wrench is used to hold tting while the

other is used to tighten.

Tighten very securely as are ttings are

a metal-upon-metal surface seal and no

additional gas sealant is needed.

GGCTSS

GAS

SUPPLY

LINE

CONNECT THE GAS LINE (FOR NATURAL GAS INSTALLATIONS)

3/8" FLARE

COUPLING

(Not supplied

by MHP)

CONNECTING THE GAS SUPPLY LINE (OP BASE) continued

STEP 5C-OP

Attach the GGCTSS Flex Tube to the

Gas Valve

•Attach the swivel connector end of

the GGCTSS Flex Tube to the gas

valve located under the control panel.

•Make sure your gas line runs through

the hose retaining notch opening and

continues under the shelf as shown.

•Tighten all gas connections

securely. The use of two wrenches

is recommended—one wrench is

used to hold tting while the other

is used to tighten.

• Before using your grill check for

any gas leaks with a soap and water

solution before using your grill. HEAT SHIELDGGCTSS

FLEX TUBE

GAS VALVESWIVEL

CONNECTOR

HOSE RETAINING

NOTCH OPENING

TOOLS NEEDED

3/4" OPEN END

ADJUSTABLE

WRENCH

PARTS NEEDED

GGCTSS

FLEX TUBE

3/8" FLARE COUPLING

(Not supplied by MHP)

14 | www.mhpgrills.com

Attach the Access Panel Cover

•The front access panel cover attaches directly under the control panel and hides

the access opening.

• Lift the access panel up behind the lip of the control panel (g. a).

• Slip the bottom double edge of the access panel cover over the edge of the access

opening (upward pressure may be needed) (g. b).

ATTACHING THE ACCESS PANEL

STEP 6

Do not attach the front access panel until the control panel has been attached to the grill head

bottom and the gas supply line has been properly connected and leak tested.

g. a

g. b

GGAC

STAINLESS STEEL

FRONT ACCESS COVER

www.mhpgrills.com | 15

=

Enhance Your Grill

Our premium accessories have been designed specically for our grills

with quality materials and craftsmanship

Visit your local dealer or our online store

www.mhponlinestore.com

Clean and Maintain Your Grill

Keep your grill running smoothly with these accessories

designed specifically to work with your MHP Grill.

BEER CAN CHICKEN ROASTER

Grill up a tender but juicy whole

chicken infused wth your favorite

beer, wine , juice or marinade.

beverage can easily t in the can

support ring.

Nickel-plated and dishwasher-safe.

CCR

STAINLESS STEEL SPATULA

This heavy-duty stainless steel

spatula is specially curved for perfect

ips everytime. Features a solid wood

grip handle and a sturdy stainless

steel hanger ring for easy storage.

18" long (end-to-end).

SF1

STAINLESS STEEL SMOKER BOX

Easily add authentic wood smoke

avor to your food with this smoker

box designed to work with all MHP

Grills. Insert moistened wood chips

(not included) for your favorite smoke

avor. Stainless steel construction

with a removable vented lid.

SSST

Brass Bristle SearMagic

Cooking Grid Brush

GGWB10

21" Stainless Steel Handle

Brass Bristle Brush

WB8

Replacement Brass

Bristle Brush Head

WB8RH

Stainless Steel

Grill Cleaner

SCC

SAUSAGE STUFFED JALAPEÑO PEPPERS

(makes 12 stuffed peppers)

Instructions:

• Cut top off jalapeno peppers, remove the seeds

& membranes

• Brown sausage in a skillet

• Mix cream cheese, Parmesan cheese, and sausage

• Stuff jalapeños with combined cheese & sausage

mixture then replace jalapeno caps

• Place stuffed pepper in your jalapeño pepper tray

Preheat your grill to 350° and grill for 30 minutes. During this time the spicy heat will be cooked

from the pepper and you can enjoy your jalapenos.

Ingredients:

• 12 Jalapeño Peppers

• 1/2 pound cooked bulk pork sausage

• 4 oz cream cheese

• 1/2 cup shredded Parmesan cheese

• Serve with y our favorite prepared

ranch dressing (optional)

JALAPEÑO PEPPER TRAY

Holds up to 24 jalapeño peppers.

Stainless steel. American made.

JPT

16 | www.mhpgrills.com © MHP 2020, All Rights Reserved

Family Owned & Operated Since 1957 AM-OCOL-0222

California Proposition 65 Warning: This product can expose you to chemicals including Chromium (hexavalent compounds),

which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more

information go to: www.P65Warnings.ca.gov.

TECHNICAL SUPPORT

Modern Home Products

150 South Ram Road • Antioch, IL 60002

847.395.6556 • 888.647.4745

[email protected] • www.mhpgrills.com

Make the most out of your grilling experience!

From side burners and rotisseries to grill covers and more—

we carry a complete line of grill upgrades, accessories and grill parts

designed specically for your MHP Grill.

rVisit MHPGrills.com for more information

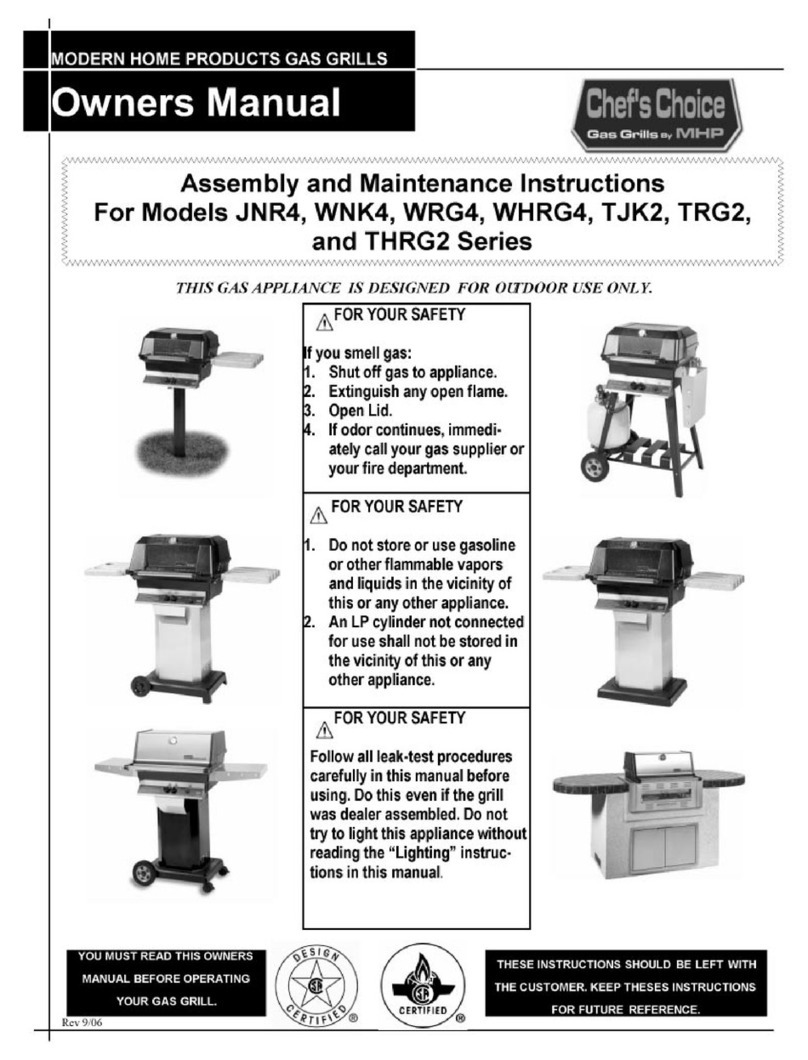

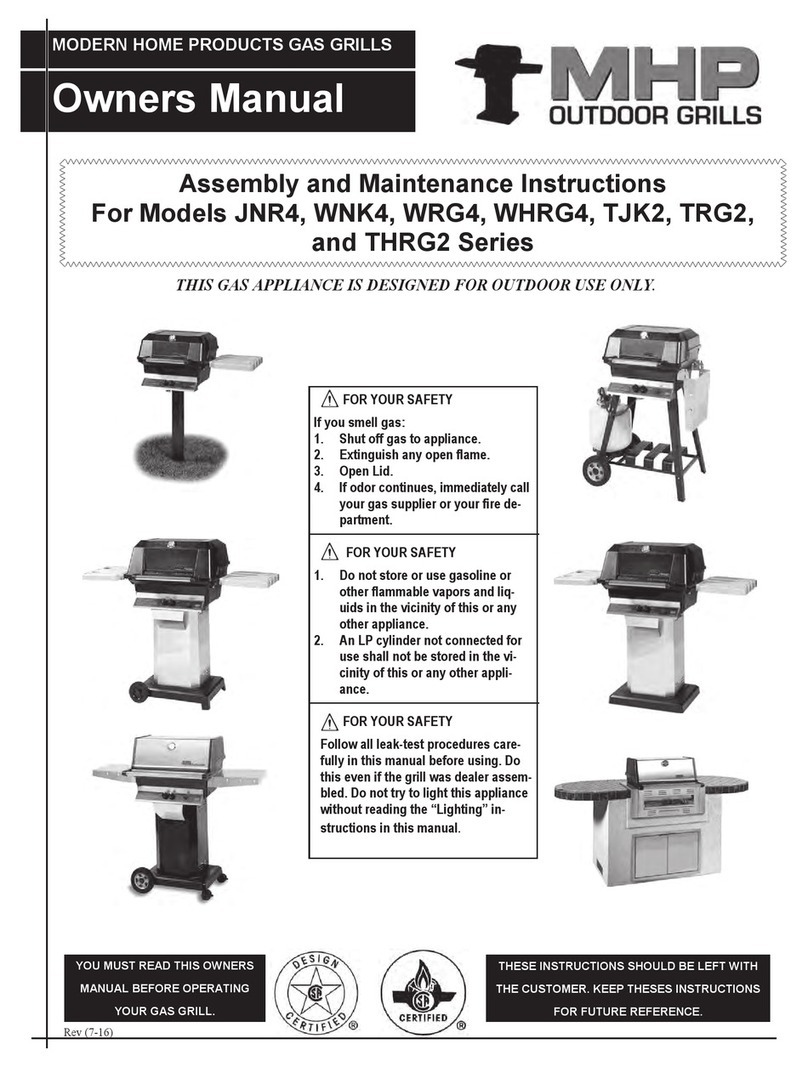

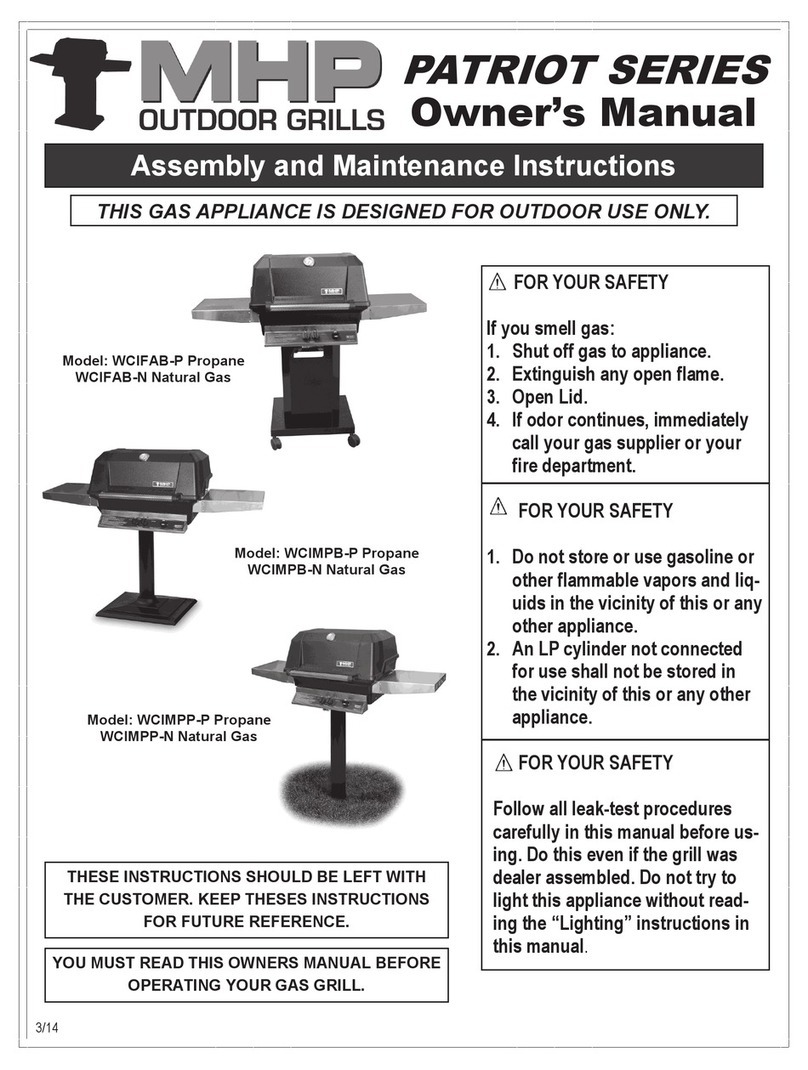

This manual suits for next models

6

Table of contents

Other MHP Grill manuals

Popular Grill manuals by other brands

Sunco

Sunco SC90-12 Assembly & operating manual

oneConcept

oneConcept 10028047 quick start guide

German pool

German pool KQB-12 user manual

Members Mark

Members Mark CG2036001-MM owner's manual

FCC BBQ

FCC BBQ Tjome large FCC-PG-19510 Instructions, manual, maintenance

Silvercrest

Silvercrest 306420 operating instructions

essentiel b

essentiel b EBGZ 6 user guide

Silvercrest

Silvercrest 379075 2110 operating instructions

MasterChef

MasterChef TF2201804-MC user manual

Silvercrest

Silvercrest STGG 1800 A1 operating instructions

GGM gastro

GGM gastro HKGK13 Installation and operation manual

MasterChef

MasterChef PRIME 85-3135-0 Assembly manual