MHS Boilers IDEAL SB Operating and maintenance manual

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 1-35

MAINTENANCE AND

OPERATING MANUAL

CIRCULAR KNIFE

BREAD CUTTING MACHINE

MHS IDEAL SB

MHS IDEAL SBT

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 2-35

Table of contents Seite

1. General instructions 4

1.1. Warranty information

1.2. Proper use

1.3. Residual risks

1.4. Copyright

2. Safety and safety equipment 6

2.1. Safety symbols

2.2. General safety regulations

2.2.1. Information for maintenance personnel

2.2.2. Information for trained operating personnel

2.3. Safety devices

2.4. Safety check

3. Technical description 11

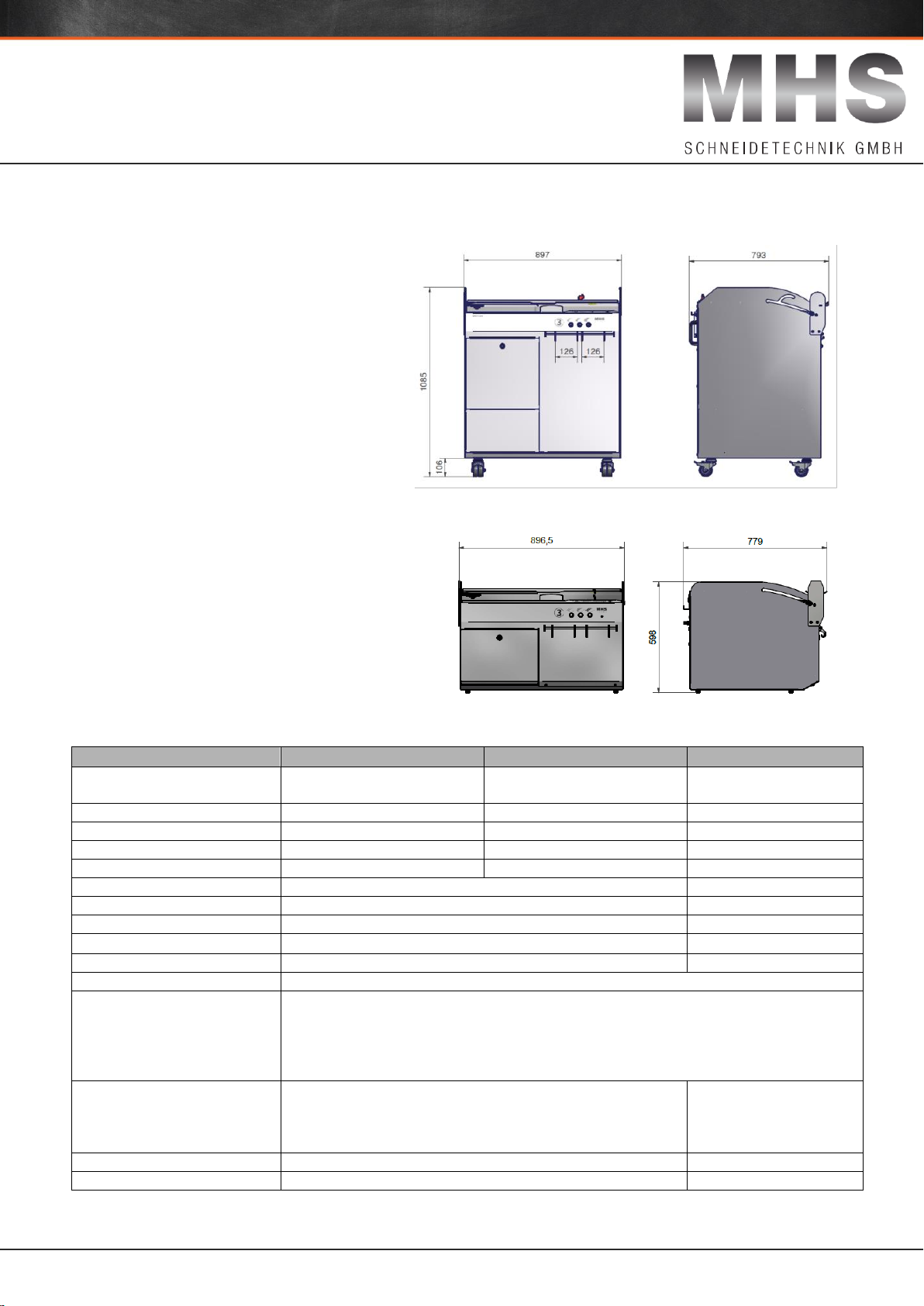

3.1. Dimensioned drawing IDEAL SB

3.2. Technical data IDEAL SB

3.3. Function description

3.4. Controls

3.5. Environmental influences

4. Device installation 13

4.1. Information on installation location

4.2. Information on allergens

4.3. Information on tool storage and passwords

5. Operation 15

5.1. Trial operation

5.2. Positioning of the goods to be cut

5.3. Closing the protective screen

5.4. Cutting slices

5.5. Opening the flap

5.6. Reading out the bread counter

5.7. Reading out the error memory

5.8. Troubleshooting

6. Cleaning and caring for devices 22

6.1. Preparing for cleaning

6.2. Cleaning

6.3. Cleaning the protective screen

6.4. Cleaning the bread chute

6.5. Cleaning the bread claw

6.6. Cleaning the cutter area

6.7. Cleaning the machine housing

6.8. Cleaning the circular knife / knife linkage

6.9. Cleaning the bread gripper

6.10. Care

7. Maintenance and repair 32

7.1. Replacing the blade

7.2. Readjusting the feed belt

7.3. Recommended maintenance intervals

8. Repairs 35

9. Final decommissioning and disposal 35

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 3-35

EC Declaration of Conformity

In accordance with Machinery Directive 2006/42/EC, Annex IIA

1. Equipment manufacturer MHS SCHNEIDETECHNIK GMBH

Im Deboldsacker 6

D-74232 Abstatt, Germany

2. Device decription: Designation: CIRCULAR KNIFE

BREAD CUTTING MACHINE

TYPE: MHS IDEAL SB

We hereby declare that the CIRCULAR KNIFE BREAD CUTTING MACHINE of TYPE IDEAL SB corresponds

with the following authoritative specifications, which were applicable at the date of issue indicated below:

EC Directives observed

- EC - Machinery Directive 2006/42/EC, Annex 1

- EC - Directive "Electromagnetic Compatibility" 2014/30/EU

- EC - Low Voltage Directive 2014/35/EC

Applied harmonised European standards

- EN ISO 12100 (Safety of machinery -- General principles for design -- Risk assessment and risk

reduction)

- EN ISO 13857 (Safety of machinery - Safety distances)

- EN ISO 14120 (Safety of machinery - Guards)

- EN ISO 14119 (Safety of machinery - Interlocking devices associated with guards). guards

- EN 1672-2 (Food processing machinery - Basic concepts - Part 2: Hygiene requirements)

- EN 61000-6-1+3 (Household EMC)

- EN 60204-1 (Electrical equipment)

- EN 13954 (Bread slicers)

Other standards and directives

- Ordinance 1935/2004

- Ordinance 2023/2006

- Ordinance 10/2011

Authorised representative for the creation of documentation

- Christoph Stöcker, Im Deboldsacker 6, D-74232 Abstatt, Germany

The machine of type IDEAL SB may be used exclusively for cutting foods such as bread. Other

applications are explicitly prohibited.

This declaration shall be void in the event that modifications are undertaken without prior agreement with

MHS.

Issuing representative: Christoph Stöcker

place, date: Abstatt, Germany, dated 09/02/2022

Signed: ______________________

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 4-35

1 General instructions

Dear Customer,

this operating and maintenance manual will help you become familiar with the MHS IDEAL SB

bread cutting machine and benefit from its intended applications. The Operating and

Maintenance Manual contains important information required to use the device safely, properly

and economically. Observing this information helps to avoid risks, repair costs and downtime,

as well as increasing the reliability and operational lifetime of the machine.

Before activation, the conditions for maintaining safety described in chapter 2 of the operating

manual must always be fulfilled.

Cleaning and care work may only be undertaken by trained personnel.

Trained personnel are considered to be employees who have, for example, used this Operating

Manual to make themselves familiar with the machine or who have been trained by a trained

member of staff. The operator of the equipment is responsible for ensuring that this process is

documented.

All maintenance work must be undertaken within the specified intervals by an approved MHS

service engineer. Failure to do so will cause our guarantee obligations to be voided.

We wish to stress that we are not liable for any damage or operational disruptions resulting from

failure to observe information contained in the Operating and Maintenance Manual, the use of

non-approved spare parts or improper use of the equipment.

Please contact MHS either directly or via our customer service department should you have

questions not covered by this Operating and Maintenance Manual or if you have suggestions

which could improve this Operating and Maintenance Manual.

MHS Schneidetechnik GmbH

Im Deboldsacker 6

D-74232 Abstatt, Germany

Telephone: +49 (0) 70 62 97 89 6 - 0

Telefax: +49 (0) 70 62 / 97 89 6 - 29

Internet: www.mhs-schneidetechnik.de

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 5-35

1.1 WARRANTY INFORMATION

The guarantee is valid for a period of 24 months after installation of the machine and covers the

mechanical and electrical components. The following wearing parts are not subject to the

guarantee: blade, guide ring, and sliding bearing.

Unauthorised modifications or improper use of the machine/unit by the operator shall void the

warranty.

1.2 PROPER USE

The IDEAL SB cutter may be used exclusively for cutting fresh bread. Using it to slice other

bakery products (e.g. cake, Danish pastries, etc.), dried or spoiled bread as well as any non-

bakery products is strictly prohibited. Using the machine for slicing bread containing raisins or

fruit will lead to increased cleaning requirements due to the high proportion of fat and sugar

contained in such products. This can lead to the machine failing in case of deficient cleaning /

maintenance.

Cutting hot bread (temperatures >60°C) is not permitted. Bread to be cut must have at least one

flat support side, the edges of which have a radius no greater than 2cm. At the ends, the bread

must have a minimum height of 3 cm, so that at least 2 gripper claws can reach the bread.

Otherwise it is not possible to guarantee the automatic gripping of the bread.

A prerequisite for good cutting results and a fault-free process is that the bread be placed in the

machine by the customer with the intended orientation and with the flat side down.

ATTENTION!

This machine is designed to be used by the end customer for inserting

and slicing bread. Cleaning and care work may only be undertaken by

trained personnel. Maintenance work must be completed by trained

technical personnel.

Use in bakeries, supermarkets or discount stores by the end customer

is only permissible if trained staff are present in the store. However,

there is no obligation to provide continuous supervision.

The safety and operating instructions attached by the manufacturer may

not be covered up or hidden by other labels.

1.3 RESIDUAL RISKS

The machine has been built in accordance with the specifications set out in the Machinery

Directive. However, the following residual risks remain:

- Risk of cuts in the event of contact with the blade.

- Risk of crushing by the flap.

- Contamination of the sliced product due to deficient cleaning

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 6-35

1.4 COPYRIGHT

The contents of this operating manual in all its parts shall remain the property of MHS

Schneidetechnik GmbH. Reproduction, even extracts thereof, shall require our approval.

2 Safety and safety equipment

2.1 SAFETY SYMBOLS

This symbol is used in this Operating and Maintenance Manual in all

work safety instructions where there is a risk to life and limb of

persons. Please pay attention to this information and take special care.

Provide all work safety instructions to other users as well.

This symbol is used in this Operating and Maintenance Manual in all

work safety instructions where there is a risk to life and limb of

persons resulting from electric shocks. Mortal danger!

ATTENTION!

This prompt is specified in the Operating and Maintenance Manual to

highlight information which is to be observed in order to maintain the

guidelines, regulations, notes and correct sequence of work as well as

to prevent potential damage or loss of the machine / system.

NOTE!

This note is provided in sections of the Operating and Maintenance

Manual where special details are provided relating to the economic use

of the machine / system and where technical requirements are to be

met which the user should pay special attention to.

2.2 GENERAL SAFETY REGULATIONS

The MHS IDEAL SB bread cutting machine is safe for use as per the requirements of the

Directive of the Council of the European Union for Machines (2006/42/EC).

However, the machine/system can present a risk in the event that it is used inappropriately or in

an improper manner. For this reason, the technical safety instructions and regulations must be

followed by all persons who are responsible for the set-up, operation, maintenance, and repair

of the MHS IDEAL SB bread cutting machine.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 7-35

Cleaning and care work may only be undertaken by trained personnel

above the age of 14 years old.

Use in the self-service area by the end customer is only permitted if

trained personnel are able to inspect the machine over the course of

daily cleaning for external damage and visible fouling due to debris

(e.g. damage due to vandalism, etc.).

Additions or modifications which alter the technical characteristics of the machine/system or

impair the function of safety devices may only be made following written approval from the

manufacturer.

Only original MHS spare parts or spare parts approved by MHS may be used for maintenance

and repair work. This applies in particular to safety-relevant components such as blades, safety

evaluation electronics, safety switches for flaps and doors, flap locking devices and contactors.

In addition, the regulations concerning safety at work in force where the machine is used and in

the country of operation must be observed.

Local statutory regulations and other regulations pertaining to accident prevention and

environmental protection are to be observed and applied in addition to the Operating and

Maintenance Manual.

2.2.1 Information for maintenance personnel:

Before switching on the machine, ensure that no persons will be put in danger by the machine

as it starts up.

Work to be performed on the electrical control and switching unit

and/or electrical installation work on the machine may only be carried

out by an authorised electrician. After such work is complete, the

function of all safety devices must be checked by this specialist and

the unit approved for use. The machine may only be authorised for

operation in this case.

Non-ionising radiation is not produced directly, but rather emitted only

due to the technology of the electrical operating equipment (e.g. by

electrical motors, power lines, or magnetic coils).

The machine also does not possess strong permanent magnets.

If the safety clearance (clearance of field source from implant) of 30 cm

is maintained, the influence on active implant (e.g. heart pacemakers,

defibrillators) may be ruled out with high probability.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 8-35

Maintenance personnel must be qualified to work in their assigned area and role, and must

undergo regular training. This operating and maintenance manual may be used as the basis for

such training.

No modifications may be carried out on the safety devices during care

or maintenance work. As far as possible, care and maintenance work

may only be performed on the machine if it is switched off and secured

against unauthorised reactivation. Remove the mains plug!

When work is being performed on the unit's electrical system, the unit must be

additionally checked for zero potential.

After care and maintenance work are complete, any protective covers which have been

removed or opened must be set back in their original position.

The machine may only be used in a technically sound condition, in the

proper manner, with the appropriate awareness of safety and any

hazards, and in following the Operating and Maintenance Manual.

In particular, faults that could impair the safety must be corrected immediately.

2.2.2 Information for trained operating personnel:

Passwords or tools for opening the safety guards must not be kept visibly near the

machine.

After cleaning the machine, make sure that all of the machine's protective devices are

closed.

If the machine has been used to cut products containing liquids or toxic substances, it

must be cleaned. If necessary, have the machine checked by a service technician for

risks such as electric shocks, fire hazards and health risks before putting it back into

operation.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 9-35

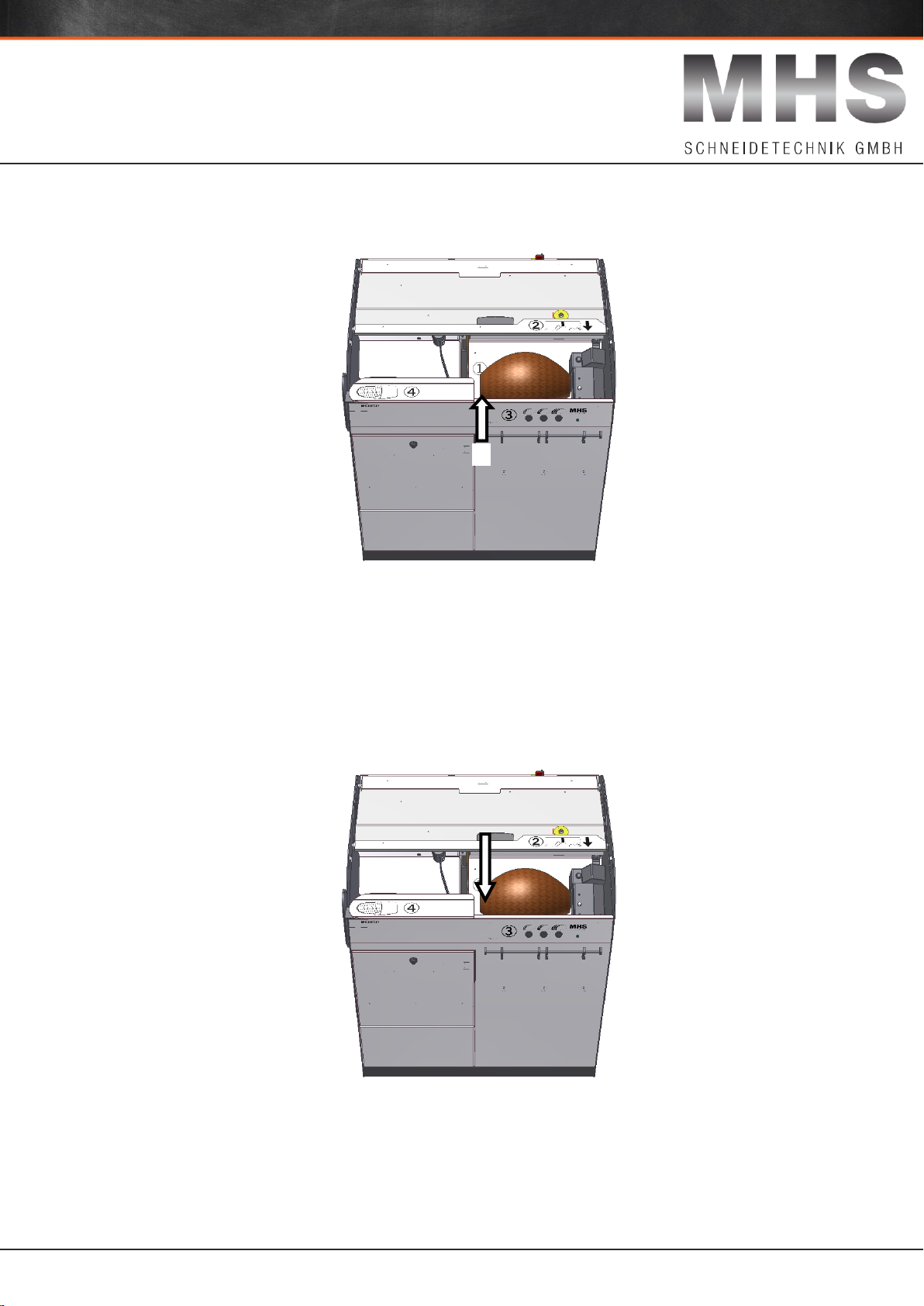

2.3 SAFETY DEVICES

To protect the operator, the machine is equipped

with safety devices that ensure smooth operation

and protect the operator against immediate

dangers:

In operation:

- Cutting area protective disc (1) with

mechanical lock

- Start - button (2)

- Panel insert (3)

- Rear insertable panel (4)

- EMERGENCY STOP master switch (5)

- Operating display rear (6)

For maintenance and cleaning:

- Safety switch insertable panel (7)

- Rear insertable panel safety switch (8)

- Protective screen safety switch (9)

The machine features a protective screen (1) in the cutting area, which protects the user against

unwanted access and is secured against opening during operation.

The protective screen and other protective devices are inspected via the proximity switches (7,

8, and 9).

3

5

1

7

8

9

4

2

6

2

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 10-35

2.4 SAFETY CHECK

The machine must be checked for externally visible defects or fouling, for example, damage or

defects caused by vandalism, etc. as part of the daily cleaning process.

In addition, the functionality of the machine's safety devices are to be checked at suitable

intervals.

The frequency of the checks is to be determined by the operator in accordance with local

conditions (frequency of use, clientele, site of installation, etc.), but must be undertaken, at

minimum, annually as part of the annual inspection.

ATTENTION!

If irregularities are detected during inspection (e.g. damage) of the

machine, then it must be deactivated immediately

(pull out the power plug and secure it against reactivation)

Arrange to have the machined checked

by MHS Service prior to recommissioning.

An additional safety check can be undertaken as follows:

Preparation:

Insert and lock the insertable panel in the front and rear

Close the protective screen

Carry out a test run without product "START"

During the product detection process of the gripper (the gripper moves forwards and back

again), check if the protective screen is able to be opened.

ATTENTION!

If the protective screen is able to be opened, the

, shut down the machine immediately.

(pull out the power plug and secure it against reactivation)

Arrange to have the machine checked by MHS Service prior to

recommissioning.

During the product detection process of the gripped (the gripper moves forwards and back

again), open the front door.

The machine must switch off. The gripper must remain stopped!

ATTENTION!

If the gripper fails to stop,

, shut down the machine immediately.

(pull out the power plug and secure it against reactivation)

Arrange to have the machine checked by MHS Service prior to

recommissioning.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 11-35

3 TECHNICAL DESCRIPTION

3.1 DIMENSION IMAGE

3.2 TECHNICAL DATA

Data

IDEAL SB

IDEAL SBT

Dimension

Dimensions:

(length x width x height)

897 x 778 x 1085

897 x 778x 598

mm

Weight:

200

160

kg

Max insertion length:

400

400

mm

Max insertion width:

280

280

mm

Max insertable height:

140-160

140-160

mm

Slice thickness:

3 slice thicknesses (8, 10, and 12 mm pre-set)

mm

Configuration accuracy:

0,5

mm

Cutting speed:

95

Cuts / min

Connection values:

1.1 / 230 ± 10% / 50

kW / V / Hz

Connection plug:

Schuko CEE-7/7

Design:

Self-supporting stainless steel housing

Processed goods:

Bakery products such as fresh bread. Use of the equipment for other bakery

products (e.g. cake, Danish pastries, etc.), dried or spoiled bread as well as any

non-bakery products is strictly prohibited. Using the machine for slicing bread

containing raisins or fruit will lead to increased cleaning requirements due to the

high proportion of fat and sugar contained in such products.

Working noise level (LpA)

(determined according to

DIN EN ISO 11201 accuracy

class 2)

66.5 ± 2.5

dB(A)

Storage conditions:

-10°C to +45

°C

Operational conditions:

+5°C - +35

°C

All accuracy and throughput specifications are approximate values only and can be influenced by the product to

be sliced.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 12-35

3.3 FUNCTION DESCRIPTION

The MHS Ideal SB bread cutter enables bakery products to be cut in slices to predefined

thicknesses. This is completed using a rotating, toothed circular blade.

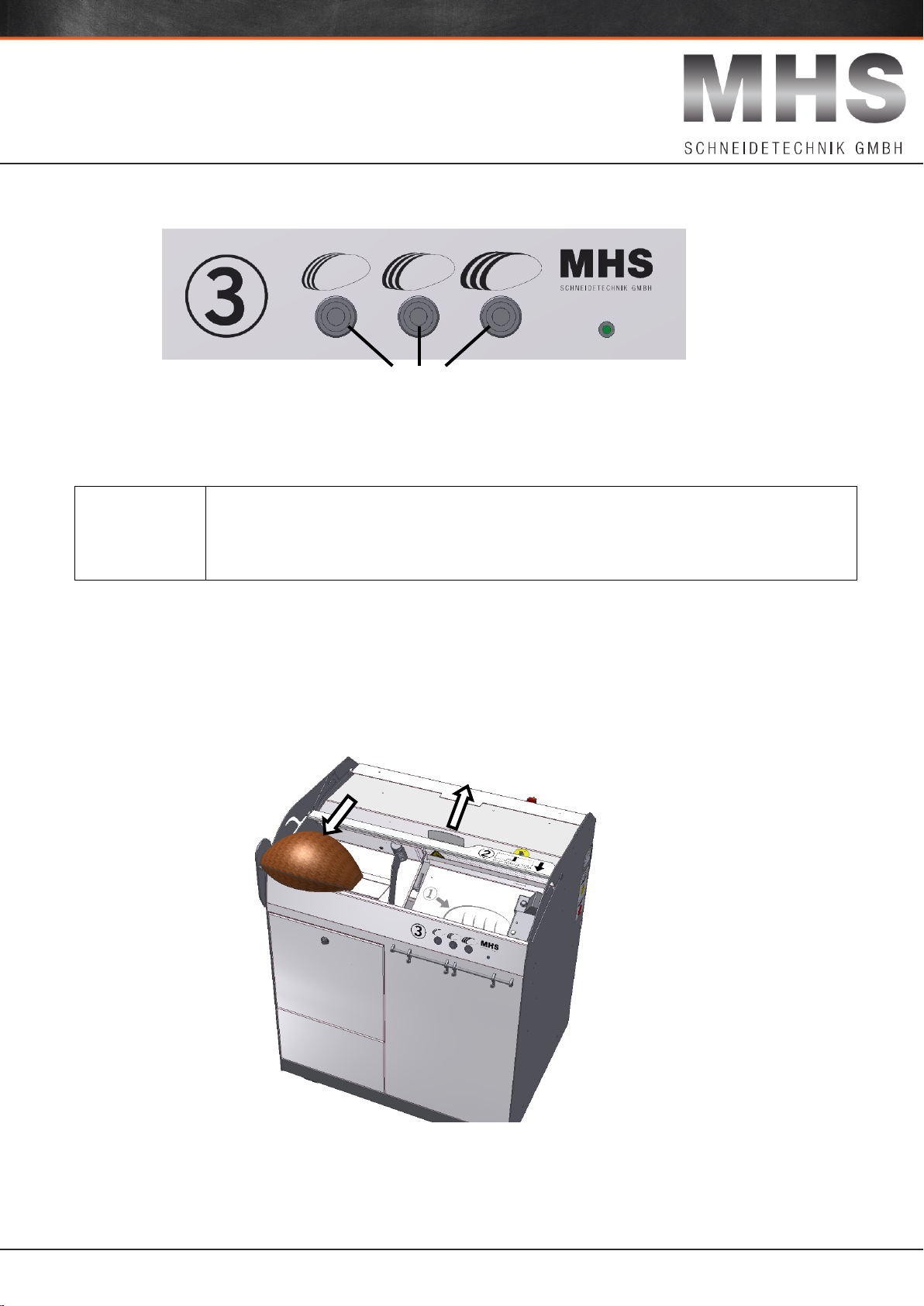

3.4 CONTROLS

3.5 ENVIRONMENTAL INFLUENCES

The machine is intended exclusively for use in dry areas.

The environmental temperature should be between 5°C and 35°C.

1

Slice thickness buttons

"Start" button for "thin, medium, thick" cutting

process

2

Status display

Green LED (button 1 glows alternatively)

3

Emergency stop master

switch

Mains switch and EMERGENCY STOP

4

MODE key

Switching over the display mode

5

SET key

Confirm

6

Blade cleaning button

Unlocking the protective screen in cleaning mode

7

7-segment display

1

2

7

6

4

5

3

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 13-35

4 DEVICE INSTALLATION

The transport, set-up, and commissioning of the MHS IDEAL SB bread slicer is carried out by

MHS Schneidetechnik GmbH Service in accordance with the device installation.

Setting up and commissioning the machine/system may only be

carried out by specialist personnel of MHS Schneidetechnik GmbH or

its authorised dealers. MHS - Schneidetechnik shall not be liable for

damage caused by the customer if commissioning is completed

independently.

The machine/system is supplied with a pre-installed connection cable. The customer must

ensure that the specified mains inlet is provided. Access to the mains connector must also be

ensured after the machine is installed.

4.1INFORMATION ON INSTALLATION LOCATION

The installation location should be selected such that walkways are not obstructed and

the risk of injury from protruding parts is minimised.

This concerns e.g. the wheels and the hooks for the bread bags.

4.2INFORMATION ON ALLERGENS

The operator shall place a warning on the machine that the sliced bread may contain

traces of allergens, even if the selected bread itself does not contain such allergens.

4.3INFORMATION ON TOOL STORAGE AND PASSWORDS

Passwords or tools for opening the safety guards must not be kept visibly near the

machine.

The standing machine must be aligned on a flat floor surface so that no

vibrations are generated during the cutting process. The travel rollers

must be locked.

The table machine must be aligned on a level table surface so that no

vibrations are generated during the cutting process.

If the optional moving table is used, then it must be aligned on a flat

floor surface so that no vibrations are generated during the cutting

process. The travel rollers must be locked.

The device may only be used in a suitable operating environment.

Operation in:

An area at risk of explosion

Ambient temperatures of less than 5°C or more than 40°C

Environments with high levels of moisture or precipitation

is not permitted.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 14-35

4.4 ELECTRICAL INSTALLATION

The machine is designed at the factory for an operating voltage of 230 V, 50 Hz alternating

current.

For further information regarding protection of the connection, refer to the type plate.

The machine must be connected to a protective system in order to

protect against hazardous electric shocks which could lead to life-

threatening injuries or death!

Note on machines with frequency inverters:

Frequency converters are equipped with an internal EMC filter, which

can lead to an increased leakage current of over 3.5mA.

If the installation regulations plan for upstream protection using a "fault

current contactor device" (FI/RCD switch), then a single-phase machine

must use RCD switches of the type "A", and 3-phase machines must

use RCD switches of the type "B" (fault current circuit breaker

designed for all types of current).

Furthermore, it is also recommended that the machine be additionally

safeguarded at a separate socket on the mains side with an automatic

circuit breaker of “type C16 A” for increased start-up currents. Too

many consumers connected to the mains power can otherwise cause

the breaker to trip when the machine is switched on.

Observe the information on the type plate!

In case of further questions please contact the manufacturer.

For other mains voltage, the connections must be changed in accordance with the

manufacturer's specifications and the corresponding electrical parts are to be exchanged.

Work to be performed on the electrical control and switching unit

and/or electrical installation work on the machine may only be carried

out by an authorised electrician. After such work is complete, the full

function of all safety devices must be checked by the specialist before

the machine may be approved for production once more.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 15-35

5 OPERATION

The machine may only be operated in compliance with all safety

requirements, and when safety devices are fully functional.

ATTENTION!

The machine must be clean and dry (check) prior to every start-up.

Furthermore, the machine must be checked at suitable intervals for

contamination during operation and cleaned if necessary. (see also

chap. 6)

If such regulations are not observed, the user risks being injured by the blade. In order to rule

out a risk to life and limb for the user, the machine must be checked regularly in accordance

with chapter 2.4. The machine may only be operated if it passes this inspection. In case of

malfunctioning, the machine must be deactivated immediately, secured against unauthorised

activation, and the repair service must be informed.

When handling the blade, take the utmost care because there is a high

risk of cutting yourself.

Wear cut-resistant gloves!

5.1 TRIAL OPERATION

After plugging in the mains connector and switching on the main switch (1), the machine is

ready for operation.

The machine can be started with the green start button (2) on the device.

NOTE!

You are recommended to first let the machine go through a trial run

without the cutting product in order to avoid damage. In this case, the

protective devices need to be checked (see chapters 2.3 + 2.4).

After completing the cutting process, the blade must disappear completely outside of the cutting

shaft.

1

2

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 16-35

5.2 POSITIONING THE GOODS TO BE CUT

The goods to be cut must be inserted into the long, straight side of the front section (1) on the

right-hand side of the machine.

5.3 CLOSING THE PROTECTIVE SCREEN

Next, close the protective screen.

1

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 17-35

5.4 CUTTING SLICES

Select the desired slice thickness by pressing the corresponding green button (1).

NOTE!

The start button only works if the protective panel is closed over the

cutting chamber and the inserted panel and rear doors are closed!

5.5 OPENING THE FLAP

After the cutting process is complete, the protective screen may be opened again and the sliced

bread may be removed.

Place the bread on the bread rail and then pull the bag over the bread and the rail.

1

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 18-35

5.6 READING OUT THE BREAD COUNTER

Press the MODE button on the rear display 1 x.

The display indicates the quantity of cut bread.

Press the MODE button on the rear display 2 x.

The display indicates the quantity of cut bread since the machine's last service.

Press the SET button to delete. The display blinks for 3 seconds.

Press and hold the SET button once more for a period of 5 seconds within this time to reset the

display.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 19-35

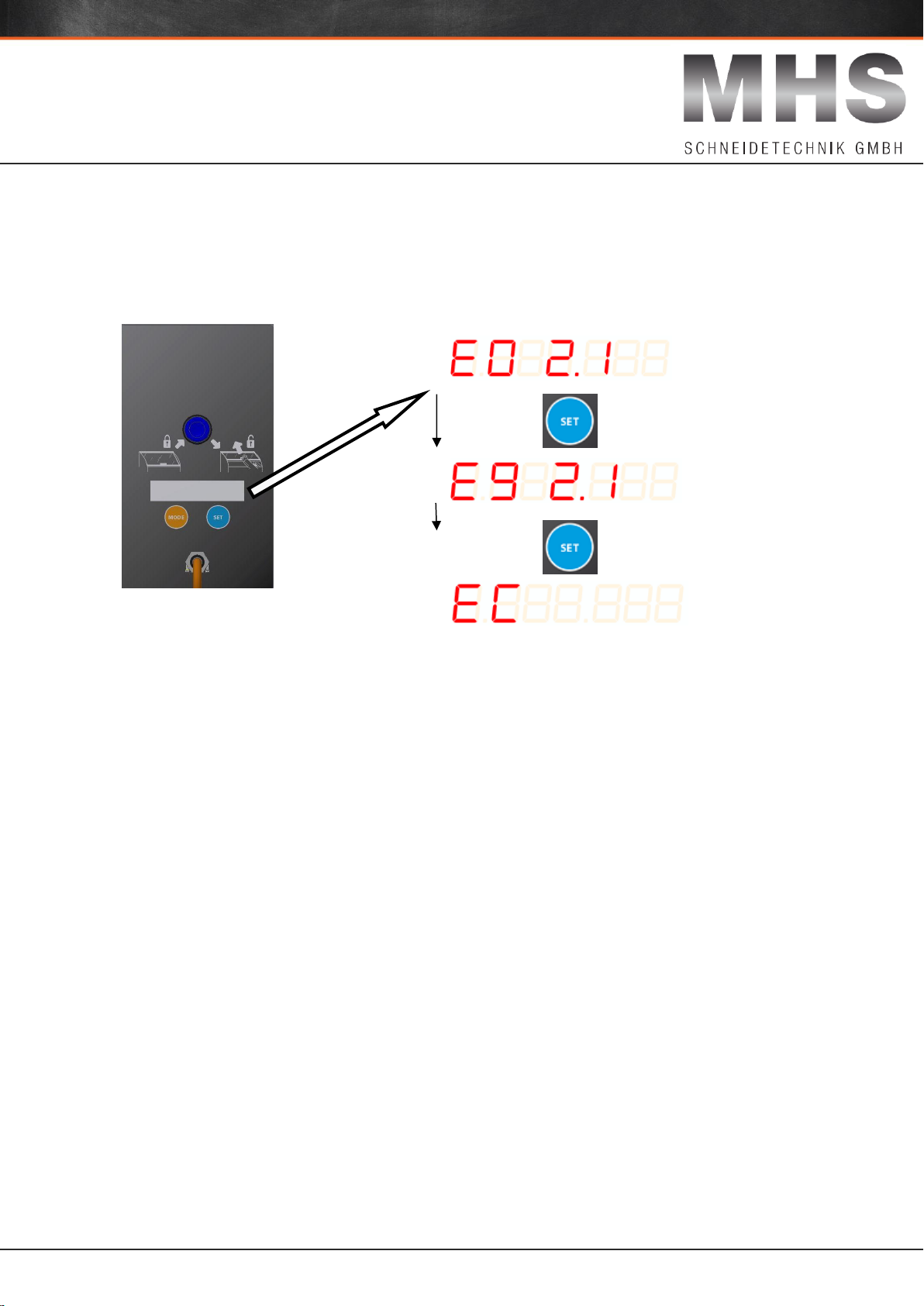

5.7 READING OUT THE ERROR MEMORY

Press the MODE button on the rear display 4 x.

The display now indicates the error memory.

…

…

…

…

…

…

The previous 10 errors can be displayed by successively pressing the SET button.

After display of the last 10 errors, the display indicates EC.

Press and hold the SET button for longer than 5 seconds to delete the error memory.

IDEAL SB series (EN) Vers.01 (02-2022→) Translation of the original Page 20-35

5.8 TROUBLESHOOTING

Provided that the regulations and information contained in the operating manual are complied

with, the MHS IDEAL SB bread slicing machine operates normally and without any errors.

In case of faults, we recommend checking the following points first before contacting the service

department:

Troubleshooting table

No.

Display/Fault

Cause

Remedial measures

1.

Machine does not start up

Plug not inserted

Insert plug

Building or machine fuse faulty

Have the fusing checked by an approved

electrician

One or more phases of the power

supply are not provided

Check the building's automatic circuit

breakers

2.

Untidy cutting

Blunt blade

Remove the blade and arrange to have it

sharpened

Debris accumulation on the blade

Clean blade

Display shows Error E.1.1.

Insertable panel down, flap back,

Protective screen open

Inform Service dept.

Inspect machine covers.

Display shows Error E.2.1

Error in blade position monitoring

system

Inform Service dept.

Check relays and initiators responsible for

blade position monitoring system

Display shows Error E.2.2.

Fault in brake monitoring, blade

incorrectly positioned

Inform Service dept.

Check the position and function of the

brake initiator. Check brake.

Display shows Error E.2.3.

Blade initiator error

Inform Service dept.

Display indicates Error E.2.4.

Direction of rotation fault (optional for

400V)

Display shows Error E.3.1

Feed limit switch not left

Inform Service dept.

Check feed for free movement

Display shows Error E.3.2.

Limit switch feed not reached

Inform Service dept.

Check feed for free movement

Display shows Error E.5.1

Manipulation monitoring or error with

locking device

Inform Service dept.

If faults that cannot be corrected should still occur, please contact our service department or

your authorised dealer immediately:

The address of our service department is:

MHS Schneidetechnik GmbH

Im Deboldsacker 6

D-74232 Abstatt, Germany

Tel.: +49 (0) 7062 / 9789 - 610

Fax: +49 (0) 7062 / 9789 - 619

e-mail: [email protected]

This manual suits for next models

1

Table of contents

Other MHS Boilers Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Trisa electronics

Trisa electronics 7716.70 Instructions for use

Summit Classic Collection

Summit Classic Collection CL18WC instruction manual

CombiSteel

CombiSteel 7455.0075 user manual

Orava

Orava Steameasy instruction manual

AGA

AGA RAYBURN benchmark 780KCD User instructions

NUTRICHEF

NUTRICHEF PKBRTP60 user manual