MHS Boilers IC 700-1100/24 User manual

Type IC Version 2014-1_Translation of the original manual Page 1-56

OPERATION- AND

MAINTENANCE MANUAL

INDUSTRIAL

SLICING- AND PORTIONING MACHINE

TYPE IC

IC 700-1100/24

IC 700-1100/24B

IC 700-1100/24BS

IC 700-1100/24BSL

IC 700/36

IC 700/36B

Ma. No.

030914

Type IC Version 2014-1_Translation of the original manual Page 2-56

Table of Contents

1 General

1.1 Warranty information

1.2 Field of application

1.3 Final danger

1.4 Table of comparison

1.5 Copyright

2 Safety and safety installations

2.1 Safety symbols

2.2 General safety regulations

2.3 Safety installations

2.4 Daily safety inspection

3 Technical description

3.1 Dimensions

3.2 Technical Data

3.3 Description of function

3.4 Controls

3.4.1 Keypad / Display

3.4.2 Icons

3.4.3 Display

3.5 Environmental influences

4 Installation

4.1 Set up

4.2 Electrical connection

4.3 Service menu

4.3.1 Display settings

4.3.2 Machine settings

4.3.3 Statistics

4.3.4 Hardware settings

4.3.5 Password protection

4.3.6 Help menu

4.3.7 Single cut

Type IC Version 2014-1_Translation of the original manual Page 3-56

5 Operation

5.1 Trial operation

5.2 Positioning of product

5.3 Cutting process

5.4 Programming

5.4.1 Creating a program

5.4.2 Open program

5.4.3 Copy program

5.4.4 Rename program

5.4.5 Delete program

5.5 Product menu

5.6 Input error messages

5.7 Switching to double-blade operation

5.8 Inspecting the blades

5.9 Slicing with frame

5.10 Rectifying faults

5.11 Fault messages

6 Cleaning and care of the appliance

6.1 Preparing for cleaning

6.2 Cleaning and disinfection

6.3 Care

7 Maintenance and Inspection

7.1 How to change the blade

7.2 Greasing the knife shaft bearings

7.3 Maintenance of feed

7.4 Changing forward belt

7.5 Exchanging of the conveyor belt

7.6 Maintenance of the electrical system

7.7 Adjustment of the motor brake

8 Special features

8.1 Inlay belt

8.2 Automatic flap opener

9 Spare part list (Enclosure)

Type IC Version 2014-1_Translation of the original manual Page 4-56

EC declaration of conformity

As defined by machinery directive 2006/42/EC, Annex IIA

1. Machine manufacturer MHS SCHNEIDETECHNIK GMBH

Seestraße 7

D- 74232 Abstatt

2. Device type: Description: INDUSTRIAL SLICING AND PORTIONING MACHINE

Type: IC

Machine No.: 030914

Herewith we declare that the supplied model of INDUSTRIAL SLICING AND PORTIONING MACHINE

Type IC complies with the following provisions applying to it:

EC- directives

- EC- Machinery Directive 2006/42/EC, Annex 1

- EC- Electromagnetic compatibility Directive EMC, 2004/108/EC

Applied harmonised standards in particular

- EN ISO 12100-1+2

- EN ISO 13857

- EN 953

- EN 13849-1

- EN 983

- EN 1088

- EN 1672-2

- EN ISO 14121-1

- EN 61000-6-2+4

- EN 60204-1

- EN 13870

Other standards and directives

- Directive 1935-2004

- Directive 10/2011

Person authorised to compile the technical file

- Christoph Stöcker, Seestraße 7, D-74232 Abstatt

The machines of type IC are exclusively use to cut foods, for instance sausages, bacon, meat,

cheese and fish. Another application is not allowed.

This declaration will cease to be valid, if there are made an alteration at the machine, which has not

been agreed with MHS.

Issuer: Christoph Stöcker

Place, Date: Abstatt, 01

st

Jan. 2013

Signature: ________________________

Type IC Version 2014-1_Translation of the original manual Page 5-56

1. GENERAL

Dear customer,

This operation and maintenance manual makes it easy for you to get to know the Slicing

and Portioning machine IC and how to use it properly. This manual contains important

information and instructions which help make it possible to operate the Slicing and

Portioning machine safely, correctly, and economically. Your attention and consideration of

the material contained in this manual will help to reduce potential danger, repairs and out

of operation time as well as extending the dependability and life-expectancy of the

machine.

It is necessary to comply with all safety requirements before bringing the machine into

operation.

The general safety and accident prevention regulations as well as those from local trade

and professional associations must be abided by at all times. All safety instructions from

this manual are to be observed. Only qualified and trained personnel are allowed to

operate the Slicing and Portioning machine. The machine may only be used according to

regulations.

We can no longer uphold our guarantee obligations as specified in the terms of delivery in

the case when maintenance work is negligibly or improperly executed. Only our original

spare parts guarantee quality and exchangeability. We draw your attention to the fact that

we assume no liability for damage or operational disturbances resulting from failure to

comply with the guidelines and instructions set out in this Operation and Maintenance

Manual.

The recognised technical regulations for safe and correct work procedures must be

complied with in addition to the accident prevention regulations expressed in this manual,

those regulations valid in the country where the machine is to be used and to those

regulations mandatory at the workplace.

Should you have any questions which are not sufficient answered by this manual, please

turn to our customer service.

MHS Schneidetechnik GmbH

Seestrasse 7

D-74232 Abstatt

Telephone: +49 (0) 7062 9789 - 60

Fax: +49 (0) 7062 9789 - 629

Internet: www.mhs-schneidetechnik.com

Type IC Version 2014-1_Translation of the original manual Page 6-56

1.1 WARRANTY INFORMATION

The warranty period is 12 months from time of commissioning or 3,000 hours of operation.

It excludes wear parts.

Compliance with the terms of the warranty assumes servicing by MHS every 1,000 hours

of operation, at the owner's expense.

Wear parts, such as the blades, belts, rollers (see Spare part list), are not covered by the

warranty. Our machines are designed for single-shift operation.

Unauthorised modifications or improper use of the machine/unit by the operator shall void

the warranty.

1.2 FIELD OF APPLICATION

The machine is intended for single-shift cutting of meat and sausage in cooked, raw or

frozen condition, in accordance with the technical data contained in this operation and

maintenance manual. This includes chapter 3.2, Technical Data. The lower limit

temperature of -4 C for the cutting product must be strictly observed. The quality of the cut

which can be achieved is determined by the product being cut and the cutting parameters.

Alternative or additional uses of the machine count as improper use. The manufacturer or

supplier shall not be held liable for any damage resulting from such use. The risk shall be

borne solely by the user.

Proper usage also includes compliance with all safety regulations and following

specifications on maintenance and cleaning tasks.

The unit must not be operated without the conveyor belt fitted.

The machine is intended exclusively for use in a commercial

environment.

1.3 FINAL DANGER

The machine is designed according the standards for chop cutting machines, however the

following final dangers lasts:

-

Working on the drive, danger of squeezing, retracting and cutting

- Grab into the output side, danger of cutting off of fingers or hand or

- grasping and retracting / squeezing into

- Working at the blade, danger of cutting

- Working in wrong blade operation, danger of cutting

- Automatic Flap opener, danger of hits and strokes

Type IC Version 2014-1_Translation of the original manual Page 7-56

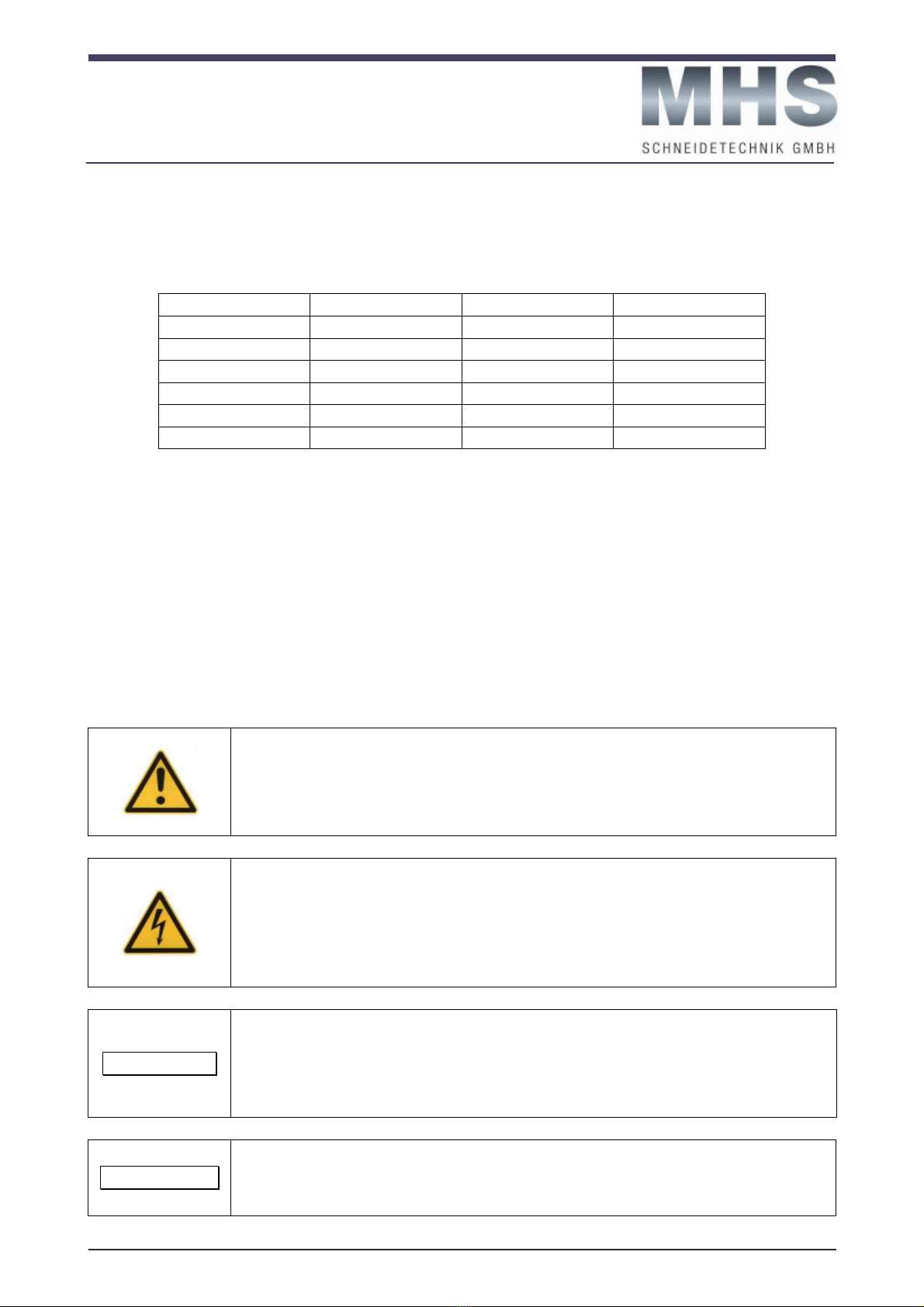

1.4 TABLE OF COMPARISON

The following table shows you the model which was delivered to you. Comments in the

chapters to follow will help you when operating and servicing the machine.

Model Model

IC 700/24

IC 1100/24

IC 700/24B

IC 1100/24B

IC 700/24BS

IC 1100/24BS

IC 700/24BSL

IC 1100/24BSL

IC 700/36

IC 700/36B

x

1.5 COPYRIGHT

The description remains in all details property of MHS Schneidetechnik GmbH. Copies

also in detail needs a permission of us.

2. SAFETY AND SAFETY INSTALLATIONS

2.1 SAFETY SYMBOLS

The Danger! Symbol is used in this Opera

tion and Maintenance

Manual to warn the user in situations where high danger to life

and limb exist. Pay utmost attention to these instructions and

work with particular care in these cases. Pass on all work safety

instructions to other users.

Only auth

orized electricians are allowed to carry out work on the

electrical control and switching units or on any other electrical

parts of the machine. All safety elements must be tested for

complete functionality upon completion of the maintenance or

service. Only after fulfilling these requirements the worker can be

released for production use.

ATTENTION!

This manual uses “ATTENTION!” to bring particular attention to

situations in which the guidelines, regulations, directions, and

work procedures are to be strictly observed in order to prevent

damage or destruction of the Slicing and Portioning Machine and

components.

IMPORTANT!

“IMPORTANT” pertains to special information regarding the

economical use of the Slicing and Portioning Machine or to

particular technical requirements the user must regard.

Type IC Version 2014-1_Translation of the original manual Page 8-56

2.2 GENERAL SAFETY REGULATIONS

The Slicing and Portioning Machine IC are operationally safe according to the guideline of

the council of the European community (2006/42/EG) and according to the requirements of

the valid accident prevention regulations.

The Slicing and Portioning Machine can be dangerous when used improperly and applied

unduly in a way in a way contrary to instructions. For this reason, the safety precautions

and regulations must be adhered to by those responsible for installation, operation,

maintenance and repair of the Slicing and Portioning Machine.

The following laws, rules and regulations ensuring work protection and safety are to be

complied with:

- Guidelines on the use of work equipment

All other commonly valid laws and associated regulations concurring accident prevention

and environmental protection are, in addition to those outlined in this manual, to be

complied with and instructed.

Such duties could, for example, concern the handling of dangerous materials or the

making available/wearing of protective personal gear.

All safety and precautionary measures are to be observed when using the Slicing and

Portioning Machine.

Only authorized and trained personnel older than 14 years are a

llowed

to operate, clean, maintain and install the Slicing and Portioning

Machine. These persons should be specially instructed regarding the

potential dangers involved.

The operator must ensure that unauthorized persons are not allowed to work on the

machine.

Work on the machine/unit's electrical equipment may only be performed by an electrician

or by properly instructed personnel under the direction and supervision of an electrician, in

accordance with electro technical standards.

Type IC Version 2014-1_Translation of the original manual Page 9-56

Work to be perfor

med on the electrical control and switching unit

and/or electrical installation work on the machine may only be

carried out by an authorized electrician. After such work is

complete, the function of all safety equipment must be checked by

this specialist and the unit approved for use. Only then may the

machine/unit be used again for production.

Personnel must be qualified to work in their assigned area and role, and must undergo

regular training. This operation and maintenance manual may be used as the basis for

such training. The training sessions must be documented by the operator.

No modifications may be carried out on the safety equipment

during care or maintenance work. Care or maintenance work may

only be performed when the machine is switched off and

safeguarded against being switched back on without permission.

If the machine/unit is fully shut down for maintenance or repair work, it must be

safeguarded against being switched back on unexpectedly:

Switch the master switch “OFF” and lock!

When work is being performed on the unit's electrical system, the mains plug must

also be pulled out and the unit checked for zero potential. The plug must be

protected against water with a protective cap.

After care and maintenance work are complete, any protective covers which have been

removed or opened must be set back in their original position.

The machine/unit may only be used in a technically sound

condition, in the proper manner, with the appropriate awareness of

safety and any hazards, and in following the operation and

maintenance manual.

It poses no risk of fire from external sources, and no risk of

explosion. The unit may not be operated in explosive atmospheres.

If the machine catches fire, personnel should keep their distance

due to the risk of suffocation.

Particularly faults which may impact on safety must be rectified immediately.

Type IC Version 2014-1_Translation of the original manual Page 10-56

If the operator notices changes in the operating behaviour of the machine/unit, they are

obliged to bring it to an immediate stop and to inform the person responsible of the fault.

Additions or modifications which alter the technical characteristics of the machine/system

or impair the function of safety equipment may only be made following written approval

from the manufacturer.

Before switching on the machine/unit, ensure that no-one will be put in danger by the

machine as it starts up.

In addition, the regulations concerning safety at work in force where the machine is used

and in the country of operation must be observed.

2.3 SAFETY INSTALLATIONS

In order to protect the operator, the machine/unit is equipped with safety devices to

guarantee smooth operation and to safeguard the user from nearby hazards:

Operation:

- Protective cover for infeed belt / insertion side (1)

- Protective cover for removal belt / removal side (2)

- Stop button on display (3)

- EMERGENCY STOP button (4)

Maintenance:

- Locking mechanism on blade housing (5)

- Master switch (6)

Protective covers on the removal belt (2), insertion side (1) and cutting chamber (5)

1

2

6

5

4

3

Type IC Version 2014-1_Translation of the original manual Page 11-56

The machine is equipped with protective covers (1+2) in the vicinity of the cutting

chamber, which prevent the user from unintentional interference and immediately put the

machine out of action when opened.

The STOP button (3) on the machine's display (see 3.4) allows operation to be interrupted

at any point in the cutting process. The machine can be put back into operation at any

time.

The EMERGENCY STOP button (4) puts the machine out of operation. It can only be

restarted after the Emergency Stop button has been unlocked.

The Master switch (6) puts the machine out of operation. It can only be restarted after the

Master switch has been unlocked. After unlocking the switch and pressing the arrow

button, the gripper (optional) opens and returns to its home position. Leftover material

must be removed by hand. Optionally, the gripper can travel forwards after unlocking, eject

the leftover material, and only then return to the home position.

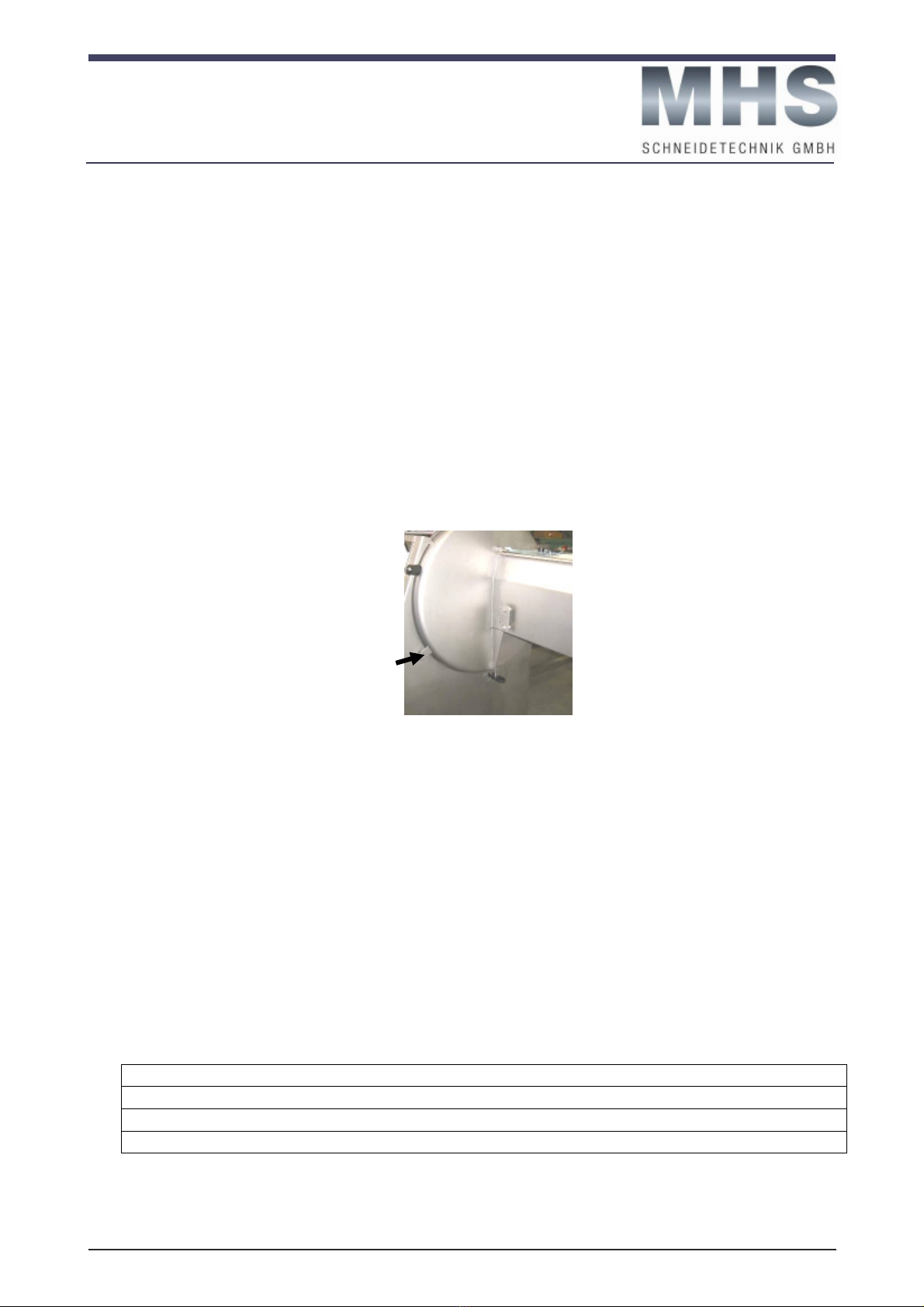

Locking cutting area (7)

The cutting area is protected against forbidden opening by a coded security switch.

2.4 DAILY SAFETY INSPECTIONS

Before taking the machine in production the following safety functions are to be inspected

daily for defective behaviour and functional capability. Please take care about the

regulation of VGB 77.

The corresponding work will be described and demonstrated by installation of the new

machine (see ch. 5.1)

To be inspected defective behaviour and functional capability:

Preparation:

Main switch „ON“

Close cutting area

Close output + input flap

Check that the blade operation corresponds to the blade that is installed

7

Type IC Version 2014-1_Translation of the original manual Page 12-56

Function check:

In preparation for the function check, switch on the machine at the master switch.

Close all flaps and doors, unlock EMERGENCY STOP.

Acti

vate EMERGENCY STOP, start the

machine with the Start button.

EMERGENCY STOP message appears.

Unlock EMERGENCY STOP – message

disappears

.

EMERGENCY STOP!

Locked

Open INSERTION SIDE flap, start the

machine with the Start button. Message

appears. Close INSERTION FLAP –

message disappears.

FLAP OPEN!

Insertion side

Open REMOVAL SIDE flap, start the

machine with the Start button. Message

appears. Close REMOVAL FLAP –

message disappears.

FLAP OPEN!

Removal side

Open BLADE HOUSING doors, start the

machine with the Start button. Message

appears. Close BLADE HOUSING –

message disappears.

FLAP OPEN!

Blade door

After this function check has been performed, it is guaranteed that the safety circuit is in

working order and that the machine is ready for use.

If, during the function check, the machine does not switch off or on consistently, the master

switch must be immediately set to “OFF” and the machine must be secured. The safety

circuit must be tested and repaired by an authorised electrician. Only once the machine

has been subjected to another function check by the specialist may it be approved for use.

All metal parts which could be touched by the user or by

maintenance personnel are integrated into the protective earth

system. A test of the protective earth conductor and the insulation

resistance have been performed. The protective earth system must

always be connected, otherwise persons who touch parts which

have become live due to faults can suffer serious electric shocks,

resulting in life-threatening injury or death.

Type IC Version 2014-1_Translation of the original manual Page 13-56

3. TECHNICHAL DESCRIPTION

3.1 DIMENSIONS

Type

Width

Height

A

Height

B

Input

C

Output

D

Machine

length

without belt

E

Machine

length with

belt

F*

IC 700/24

970 mm

1100 mm

1420 mm

1020 mm

900 mm

1920 mm

IC 700/24B

970 mm

1100 mm

1420 mm

1020 mm

900 mm

1920 mm

3065 mm

IC 1100/24

970 mm

1100 mm

1420 mm

1420 mm

900 mm

2320 mm

IC 1100/24B

970 mm

1100 mm

1420 mm

1420 mm

900 mm

2320 mm

3465 mm

IC 700/36

1175 mm

1215 mm

1450 mm

1020 mm

900 mm

1920 mm

IC 700/36B

1

175 mm

1215 mm

1450 mm

1020 mm

900 mm

1920 mm

3065 mm

Subject to alterations

* this measure is changing according the variable executions of the belts.

A

B

E

C

D

F

Type IC Version 2014-1_Translation of the original manual Page 14-56

3.2 TECHNICAL DATA

Data

IC 700/24B

IC 1100/24B

IC 700/36B

Dimension

Throughput: 300

up to 10 mm

slices/minute

thickness

Dimensions:

(Length x Width x

Height)

See ch. 3.1

mm

mm

mm

Recommended space: 2,5-3,5 m

2

Weight: 350 400 530 kg

Max. input length: 700 1100 700 mm

Cross section: 250 x 220 250 x 220 360 x 220 mm

Slice thickness: min. 0,5

max. 700

min. 0,5

max. 1100

mm

mm

Setting accuracy: +/- 0,1 mm

Connection:

(Option)

5,8 (7,0)

3~400 (3~230)

50 (60)

7,5

3~230

50 (60)

kW

V

Hz

Structural material:

Machine and blade are manufactured in corrosion resistant

stainless steel. The housing is protected against splashing

water.

Process able goods: Meat, chops, bacon, fish, cheese and sausage products up to

–4°C Additional products on request.

Min. temperature of

product to be cut - 4 °C

Drive blade: 3 phase gear motor

Knife speed: 120–300 (60-300) rpm

Advance: Servo motor + toothed belt

Operational noise

emission: >72 dB(A)

Storage conditions: -10°C – +45 °C

Operating conditions: +5°C – +25 °C

All precision and throughput parameters are approximate value and could be influenced by

the adjustment of the programs and the processed goods.

Type IC Version 2014-1_Translation of the original manual Page 15-56

3.3 DESCRIPTION OF FUNCTION

The IC-type slicing and portioning cutter allows you to cut meat, chops, bacon, fish,

cheese and sausage products into slices of a predetermined thickness. Depending on the

application, this is performed with a rotating, straight or serrated, single or double blade.

In addition, the machine/unit is divided into various areas/components:

1- Transport of the cutting product with the product gripper

2- Cutting zone with rotating blade

3- Removal area with optional conveyor belt

4- Cutting parameter setup (see chapters 3.4 + 5, Controls + Operation)

5- Master switch

1

2

5

4

3

Type IC Version 2014-1_Translation of the original manual Page 16-56

1. Transport of the cutting product by the gripper.

The cutting product which has been inserted into the cutting chamber is held by the

gripper. The gripper moves towards the cutting zone. A light barrier detects the leading

edge of the cutting product and the control unit calculates the total length from the distance

to the gripper. The value is processed in the cutting program.

2. Cutting zone with rotating blade

Depending on the feed rate of the gripper and the specified speed of the blade, the cutting

product can be cut into slices of different thicknesses.

3. Removal area with optional discharge belt

Once the cutting operation is complete, the slices can be removed. On machines with

discharge belt, the slices fall on the removal belt and are removed at the specified

transport speed.

4. Control unit, cutting parameter setup via the display

The control system determines all the parameters for the unit. These can be entered on

the unit display. The functions and the different cutting programs are explained in chapter

3.4, Controls, and in Chapter 5, Operation.

Type IC Version 2014-1_Translation of the original manual Page 17-56

3.4 CONTROLS

When the machine is switched on at the master switch, the following screen

appears on the display:

3.4.1 TASTATUR / ANZEIGE

LEFT SIDE

RIGHT SIDE

Start program

3x function keys (depending on the

icons on screen)

Stop program

Rotary pulse encoder (DIG)

Advance infeed

belt

Reverse infeed belt

Switching/modifying entry fields

The main functions (right side of the screen) can be accessed directly via the associated

function keys .

By turning the rotary pulse encoder (DIG), you can select the entry fields, and after

pressing the DIG, the setting can be modified (the background colour changes!). Pressing

the DIG again confirms the entry.

Type IC Version 2014-1_Translation of the original manual Page 18-56

3.4.2 ICONS

Working menu button

Programming

Service menu

menu button

button

Update

Confirm button Cancel button

program

button

Next page button Previous page button Save button

Create program Open program

Copy program

Rename program Delete program

Screen settings Machine settings Statistics

Hardware settings Password protection Help

Notices / Fault messages

3.4.3 DISPLAY

The display is divided into 2 main areas.

Part 1 (left area) displays the actual output range.

Part 2 (right area) displays the changing key functions, as explained in the section above

OUTPUT RANGE

KEYPAD FUNCTIONS

Type IC Version 2014-1_Translation of the original manual Page 19-56

3.5 ENVIRONMENTAL INFLUENCES

This machine can be used in meat processing companies without any kind of restrictions.

4. INSTALLATION

The MHS-service personnel is responsible for the transport, set-up, and installation of the

Slicing and portioning machine as described in the Installation manual.

The machine has to be operated with all safety equipment intact as

described in the safety instructions (see section 1.2). Failure to abide

with these regulations can result in danger of being exposed to

moving knives and shafts etc. In order to eliminate all danger to life

and limb it is necessary to execute daily functional inspection of all

protectional guards and apparatus. Only after a positive result to this

inspection the machine can be set into operation.

Only the specially trained MHS-service personnel are allowed to set-

up and install the machine. MHS will not be held liable for any damage

occurring through customer installation.

The slicing and portioning machine comes equipped with a power cord and plug. The

customer is to ensure a proper compliance with electrical power supply regulations.

4.1 SET UP

The machine has to be aligned in such a way that no vibrations of

tilting may occur.

The machine may not be lifted or carried by means of the output

channel.

For setting up the machine or for carrying the machine to an anther place the belts have to

be removed.

Type IC Version 2014-1_Translation of the original manual Page 20-56

4.2 ELECTRICAL CONNECTION

The machine is configured ex factory to an operating voltage of 400 V, 50 Hz AC three

phase current (clockwise field of rotation). Check the field of rotation of the mains

connection!

For further information regarding protection of the connection refer to the type plate.

The machine must be connected to a protective system in order to

protect against hazardous electric shocks which could lead to life-

threatening injuries or death!

Information for machines with a frequency converter (optional):

Frequency converters are equipped with an internal EMC filter,

which can lead to an increased leakage current of over 3.5mA.

If the installation specifications include upstream protection by

means of a "residual current device" (RCD) then single-phase

machines require an RCD of "type A" and three-phase machines

require an RCD of "type B" (universal current RCD).

Furthermore, it is also recommended that the machine be

additionally safeguarded at a separate socket on the mains side

with an automatic circuit breaker of "type C16 A" for increased

start-up currents. Too many consumers connected to the mains

power can otherwise cause the breaker to trip when the machine is

switched on.

Observe the information on the type plate!

In case of further questions please contact the manufacturer.

CAUTION!

When switching the machine on for the first time always ensure the

correct rotational direction of the blade

The rotational direction of the blade must be such that the blade

turns anti-clockwise in the cutting shaft.

If this is not the case then an electrician must change the direction

of rotation.

For other mains voltage, the connections must be changed in accordance with the

manufacturer's specifications and the corresponding electrical parts are to be exchanged.

Work to be performed on the electrical control and switching unit

and/or electrical installation work on the machine may only be

carried out by an authorized electrician. After such work is

complete, the full function of all safety equipment must be checked

by the specialist before the machine may be approved for

production once more.

This manual suits for next models

5

Table of contents

Other MHS Boilers Kitchen Appliance manuals