MICRO-AIR DDT4830 User manual

MICRO-AIR DOWNDRAFT TABLES

INSTALLATION AND OPERATION MANUAL

DDT4830 & DDT7230

Includes Installation, Operation, and Service Instructions

IMPORTANT

This manual contains specic cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all of the hazards of dust control equipment. It is important that use of the equipment

be discussed with a Micro-Air® Representative. Persons involved with the equipment or systems should be instructed

to operate in a safe manner.

MICRO AIR® DDT

CLEAN AIR SYSTEMS

2

DDT MICRO AIR®

CLEAN AIR SYSTEMS

3

!

CAUTION

• Avoid mixing combustible materials, such as bufng

lint, paper, wood, aluminum, and magnesium dust,

and with dust generated from grinding ferrous metals

due to the potential re hazard caused by sparks in

the dust collector.

• Under no conditions should the persons operating

the dust collector be allowed to put cigarettes or any

burning object into the hood or ducting of any dust

collector system.

• All users of Micro-Air® Equipment should comply

with all National and Local Fire Codes and / or other

appropriate codes when determining the location and

operation of dust control equipment.

SPECIFICATIONS

CABINET DIMENSIONS AND WEIGHTS

4830 57 3/4” max. H x 48 3/8” W x 30” D 255lbs.

7230 57 3/4” max. H x 72 3/8” W x 30” D 285lbs.

DUST TRAY CAPACITY (OPTIONAL)

432 Cubic inches total

INSTALLATION

INSPECTION

The Micro-Air® Clean Downdraft Table is shipped on

multiple skids. All skids should be inspected for any

visible damage that may have occurred during shipment.

Additional equipment that maybe shipped separately

includes:

Drop-Out Kits Dust-Tray Kits

Hopper Collars Wheel Kit

Grills

EQUIPMENT / TOOLS REQUIRED

Equipment and tools needed for proper installation will

include the following:

Crane or Lift Truck 1/2” Concrete Drill Bit

Wrench 1/2” Anchors

Drill

ASSEMBLY OF UNIT

1. Remove packaging from table and legs.

NOTE: Leg assembly can be completed while unit is

upside down on skid.

2. Place leg on the inside of leg bracket. Align holes in

leg to corresponding holes in leg bracket (See FIG. 1).

The leg can be installed in three different positions.

The shortest position will give an approximate table

height of 30”, the middle setting 33” and the tallest

setting 36”.

3. Attach leg with provided hardware. Insert all 4 bolts

before tightening the nuts.

FIG. 1

4. Install optional components prior to turning the unit

over. See installation procedure for optional

components on pages 3 through 7.

5. Determine location for downdraft table. The table

must be located on a hard at surface capable of

holding 1/2” anchor bolts.

6. Move table to location and mark location for anchor

bolts. (Unless wheel kit is installed)

7. Move table out of area, drill appropriate holes and

place 1/2” anchor bolts.

8. Move/lift table back into position over anchors.

9. Secure table with appropriate nuts/washers.

10. Place appropriate grills on the table.

11. Proceed with installation of optional components.

12. Connect ductwork to collars on the bottom of the

hoppers.

Recommended air ow:

Operation Face Velocity CFM 48” Table CFM 72” Table

Heavy Grinding 250-300 FPM 2500 CFM 3750 CFM

Welding 200-250 FPM 2000 CFM 3000 CFM

Fine Dusts 175-200 FPM 1750 CFM 2625 CFM

USE 5/16” HARDWARE

(PROVIDED)

MICRO AIR® DDT

CLEAN AIR SYSTEMS

2

DDT MICRO AIR®

CLEAN AIR SYSTEMS

3

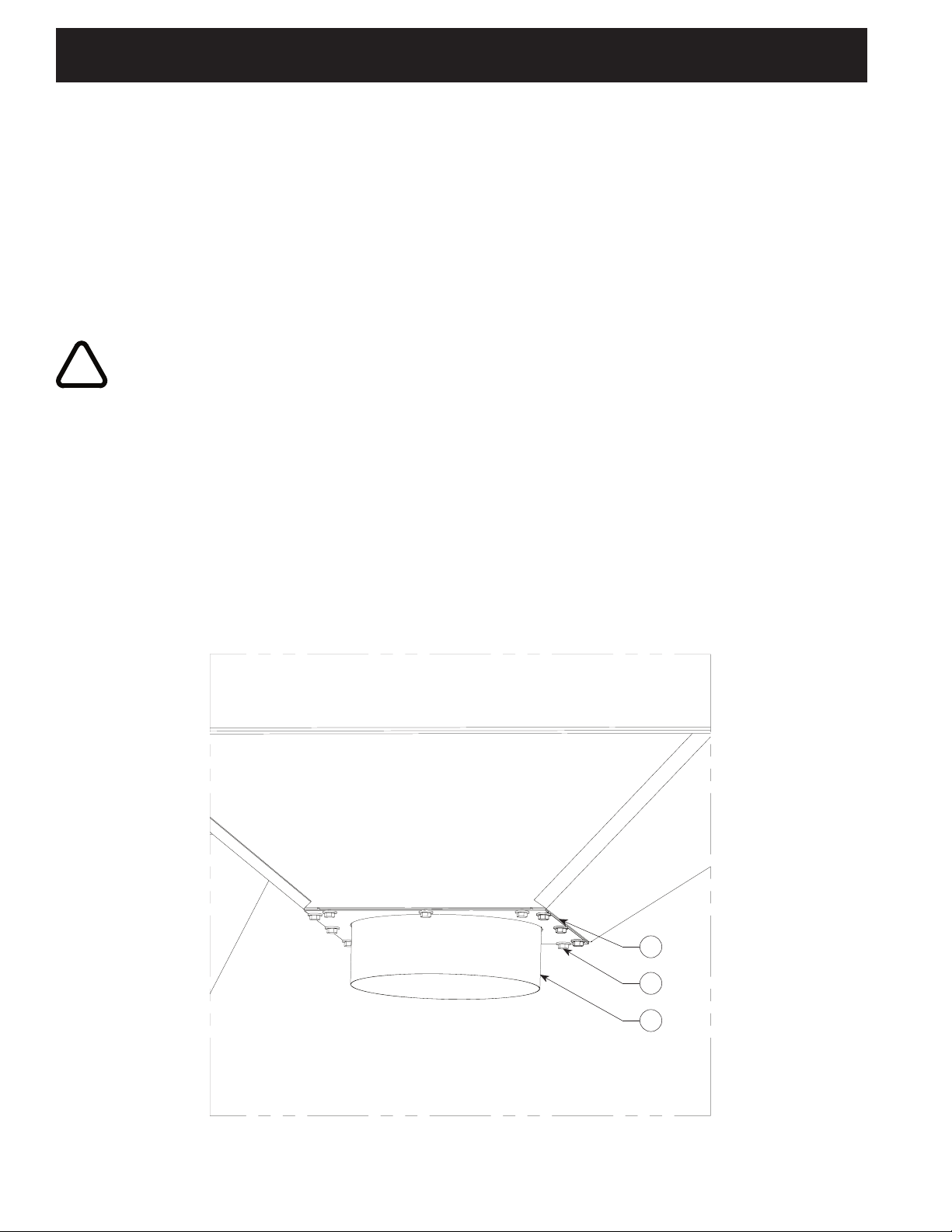

DDT SHIELD INSTALLATION PROCEDURE

This Kit Includes:

ITEM PART NO. DESCRIPTION QTY ADDITIONAL INFORMATION

1 37825-01 Shield Assembly 1 DDT4830 Only

37825-02 Shield Assembly 1 DDT7230 Only

2 P3543 Self Tapping Screw 3 DDT4830 Only

P3543 Self Drilling/Self Tapping Screw 5 DDT7230 Only

INSTALLATION

1. Remove Shield Assembly from packaging. Inspect for any possible damage incurred during shipment.

NOTE: Grills must be installed prior to installing Shield Assembly.

2. Set Shield Assembly on top of the assembled Downdraft Table. The Screw Plates should overlap at the rear of the

table.

3. Center Shield Assembly on table. Verify side shields can move freely.

4. Attach Shield Assembly with provided Self Drilling/Self Tapping Screws.

1

2

FIG. 2

MICRO AIR® DDT

CLEAN AIR SYSTEMS

4

DDT MICRO AIR®

CLEAN AIR SYSTEMS

5

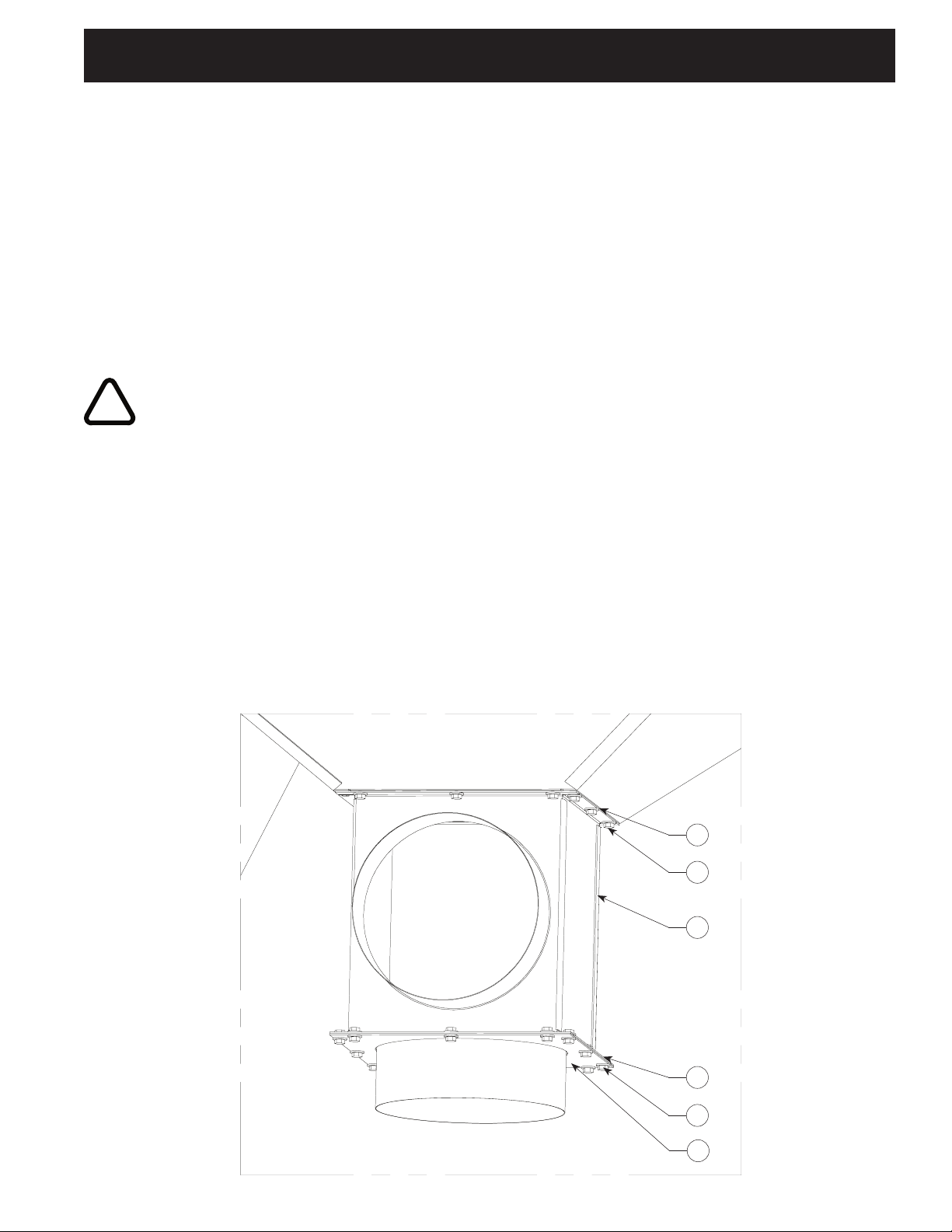

DDT COLLAR KIT INSTALLATION PROCEDURE

This Kit Includes:

ITEM PART NO. DESCRIPTION QTY

1 37815-01 Hopper Collar 2

2 P3543 Self Drilling/Self Tapping Screw 24

3 P1031 1/4” x 1/2” Foam 80 Inches

INSTALLATION

1. Remove Collar Kit from packaging. Inspect for any possible damage incurred during shipment. If this is a new

table, assembly can be done while table is upside down.

!

CAUTION

Some assembly steps may require lifting and should only be done using proper lifting techniques.

2. Remove backing and place foam on Collar Plate. Foam should cover holes.

3. Line up hole pattern on Collar Plate with hole pattern on Hopper.

4. Screw in twelve screws.

5. Repeat for second hopper.

3

2

1

FIG. 3

MICRO AIR® DDT

CLEAN AIR SYSTEMS

4

DDT MICRO AIR®

CLEAN AIR SYSTEMS

5

5

DDT HOPPER DROP-OUT KIT INSTALLATION PROCEDURE

This Kit Includes:

ITEM PART NO. DESCRIPTION QTY.

1 37835-01 Hopper Drop-Out (1 Collar) 2

37835-02 Hopper Drop Out (2 Collars) Optional

2 P3543 Self Drilling/Tapping Screws 24

3 37848-01 Drop Out Blank Plate 2

37815-01 Collar Optional

INSTALLATION

1. Remove Hopper Drop-Out kit from packaging. Inspect for any possible damage incurred during shipment. If this is

a new table assembly can be done while table is upside-down.

!

CAUTION

Some assembly steps may require lifting and should only be done using proper lifting techniques.

2. Remove backing and place foam on Drop-Out anges.

3. Line up hole pattern on Hopper Drop-Out anges with hole pattern on Hopper. The Drop-Out Assembly

can be rotated to accommodate duct location.

4. Screw in twelve screws.

NOTE: Drop-Out Blank Plate can be modied to allow for custom Drop-Out containers.

5. Remove backing and place foam on the Blank Drop-Out Plate.

6. Line up hole pattern on Drop-Out Blank Plate with hole pattern on anges of Hopper Drop-Out.

7. Attach Drop-Out Blank Plate using provided 1/4” hardware.

8. Hopper Collar can be substituted for the Drop-Out Blank Plate (As Shown in FIG. 4).

9. Repeat for second hopper.

ITEM PART NO. DESCRIPTION QTY.

4 P164 1/4-20 Hex Bolt 12

P1729 1/4 Washer 24

P203 1/4-20 Nut 12

P242 1/4 Lock Washer 24

5 P1031 1/4 x 1/2 Foam 160 Inches

2

1

5

4

3

FIG. 4

MICRO AIR® DDT

CLEAN AIR SYSTEMS

6

DDT MICRO AIR®

CLEAN AIR SYSTEMS

7

DDT DUST TRAY KIT INSTALLATION PROCEDURE

This Kit (37840-01) Includes:

ITEM PART NO. DESCRIPTION QTY.

1 37841-01 Dust Tray Wrap 2

2 37842-01 Drawer 2

3 P3506 Knob 2

4 P3686 Foam 60 Inches

5 P164 1/4-20 Hex Bolt 12

P1729 1/4 Washer 24

P203 1/4-20 Nut 12

P242 1/4 Lock Washer 24

INSTALLATION

1. Remove Dust Tray Kit from packaging. Inspect for any possible damage incurred during shipment. If this is a new

table assembly can be done while table is upside-down.

!

CAUTION

Some assembly steps may require lifting and should only be done using proper lifting techniques.

2. Remove backing and place foam on Dust Tray Wrap anges.

3. Line up hole pattern on Dust Tray Wrap anges with hole pattern on Drop-Out. The Dust Tray Wrap can be

rotated to accommodate drawer removal.

4. Attach Dust Tray Wrap using provided 1/4” hardware.

5. Slide Drawer into Dust Tray Wrap and secure using provided Knobs.

6. Repeat for second hopper.

3

2

5

4

1

FIG. 5

MICRO AIR® DDT

CLEAN AIR SYSTEMS

6

DDT MICRO AIR®

CLEAN AIR SYSTEMS

7

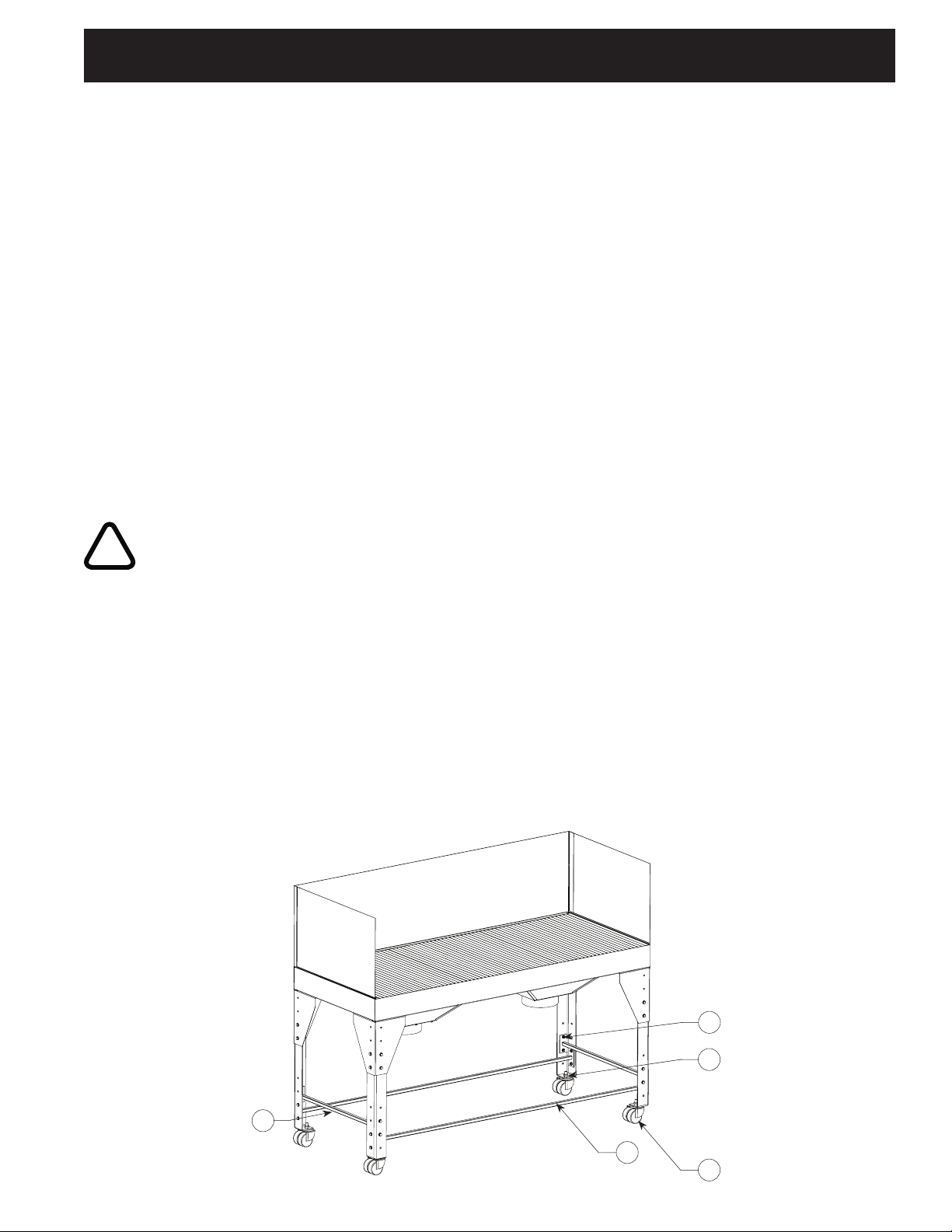

DDT WHEEL KIT INSTALLATION PROCEDURE

This Kit Includes:

ITEM PART NO. DESCRIPTION QTY. ADDITIONAL INFORMATION

1 P2334 Swivel Caster Wheel 4

2 37820-03 30” Leg Brace 2

3 37820-01 48” Leg Brace 2 (DDT4830 Only)

37820-03 72” Leg Brace 2 (DDT7230 Only)

4 P164 1/4-20 Hex Bolt 16

P1729 1/4 Washer 32

P203 1/4-20 Hex Nut 16

P242 1/4 Lock Washer 32

5 P146 1/2-13 Hex Nut 4

P147 1/2 Lock Washer 4

P3314 1/2 Flat Washer 4

INSTALLATION

1. Remove wheel kit from packaging. Inspect for any possible damage incurred during shipment. If this is a new

table assembly can be done while table is upside-down.

!

CAUTION

Some Assembly steps require lifting and should only be done using proper lifting techniques.

2. Lift the short end of the table approximately 6” above the oor.

3. Insert threaded shaft of caster through the hole in the bottom of the leg.

4. Repeat for second leg.

5. Place washers and nut on the threaded shaft, Tighten.

6. Lower the end and block so it cannot move.

7. Repeat steps 2 through 6 for the opposite end.

8. Using the provided 1/4” hardware attach the leg braces (See Figure 6). The braces may be lowered or raised to

accommodate ductwork.

9. Remove blocks used to hold table.

2

4

1

3

5

FIG. 6

MICRO AIR® DDT

CLEAN AIR SYSTEMS

8

DDT MICRO AIR®

CLEAN AIR SYSTEMS

9

ITEM PART NO. DESCRIPTION

1. 37800-01 48” x 30” Downdraft Table

37800-02 72” x 30” Downdraft Table

2. 37825-01 48” Back/Side Shield

37825-02 72” Back/Side Shield

3. P2334 Swivel Caster Wheels

4. 37820-01 30” Leg Brace

5. 37820-02 48” Leg Brace

37820-03 72” Leg Brace

6. 37815-01 Hopper Collar

ITEM PART NO. DESCRIPTION

37840-01 Drawer/Wrap Assembly (Drawer, Knob,

& Wrap)

7. 37842-01 Dust Tray Drawer

8. P3506 Knob

9. 37841-01 Dust Tray Wrap

10. 37835-01 Hopper Drop-Out One Collar

37835-02 Hopper Drop-Out Two Collars

11. 37807-01 Black Painted Grill

37808-01 Rubberized Grill

P2330 Aluminum Grill

P2331 Fiberglass Grill

11

4

6

2

1

3

5

7

8

9

10

FIG. 7

DDT PARTS LIST

MICRO AIR® DDT

CLEAN AIR SYSTEMS

8

DDT MICRO AIR®

CLEAN AIR SYSTEMS

9

NOTES

P.O. BOX 1138 • WICHITA, KS. 67201

(316) 943-2351 • FAX (316) 943-2717

INFO@MTLFAB.COM

©METAL-FAB, INC. Form No. L2002 9-02

6981

Litho in U.S.A.

MICRO AIR® DDT

CLEAN AIR SYSTEMS

NOTES

This manual suits for next models

1

Table of contents

Popular Desktop manuals by other brands

Sony

Sony PCV-R532DS - Vaio Digital Studio Desktop... Reference manual

Dell

Dell OptiPlex Gn+ Service manual

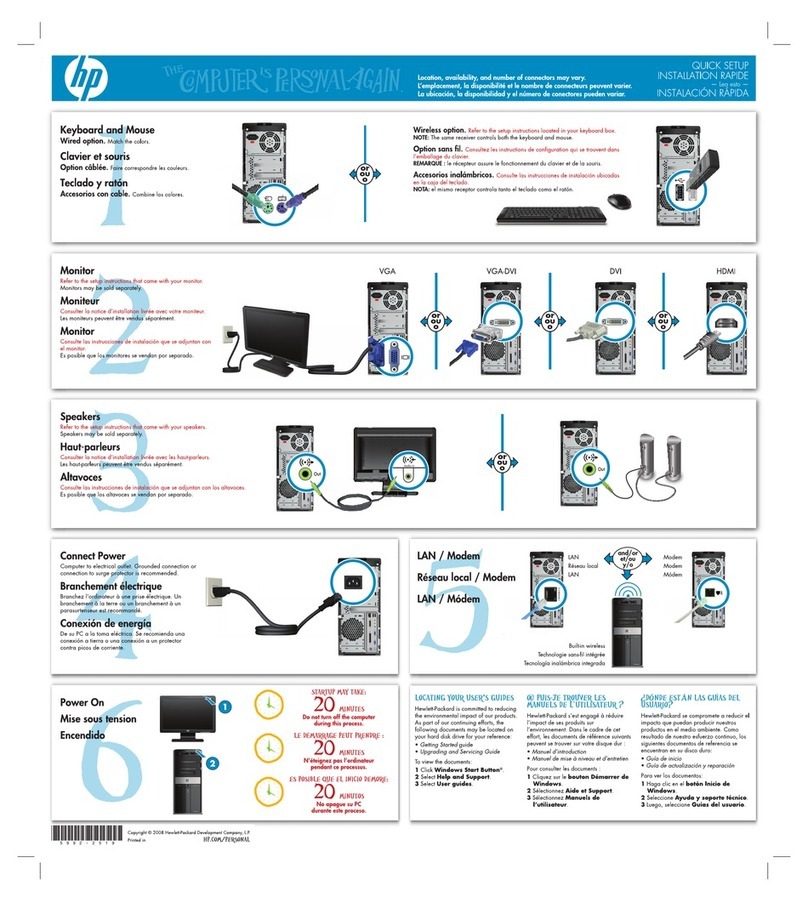

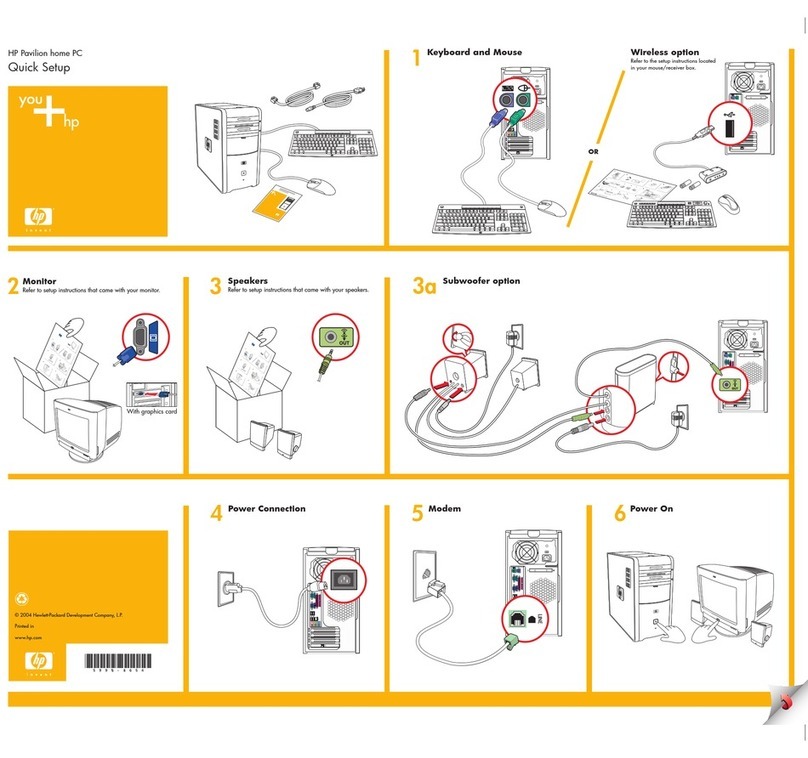

HP

HP VH677UA#ABA - Pavilion Dv6-1244sb... Quick setup

Sony

Sony VAIO Digital Studio PCV-RX490TV quick start

Sony

Sony VGC-LT20E - Vaio All-in-one Desktop Computer Safety information

Lenovo

Lenovo PC 300GL user guide