Microflex Microlink-HM+ Owner's manual

Installation

Operation

Specifications

620-0034 R1 © Microflex 2016-2020

101-0097

MicroLinK HM+

HART Protocol Modem

HART to Modbus Accumulator

USB, RS-485 or RS-232 Communications Port

DIN Rail Mount

Safety Consideraons............................................................................................................................................ 1

Overview............................................................................................................................................................... 2

Configuraon ........................................................................................................................................................ 2

Block Diagram ....................................................................................................................................................... 3

Mounng .............................................................................................................................................................. 4

Power Supply ........................................................................................................................................................ 4

Connecng to a HART Loop .................................................................................................................................. 4

Serial Port.............................................................................................................................................................. 5

USB Port ................................................................................................................................................................ 5

USB Drivers ....................................................................................................................................................... 5

Modbus Registers.................................................................................................................................................. 6

Specificaons ........................................................................................................................................................ 7

Warranty ............................................................................................................................................................... 9

Table of Contents

• Read and understand this manual before starƟng the configuraƟon and installaƟon.

• InstallaƟon and wiring should be performed by a professional to meet all facility, local, and state

requirements and regulaƟons.

Safety Considerations

Conformity in accordance with Part 2, and Part 15, Subparts A and B of

the Federal Communications Rules and Regulations, and ICES-003 of the

Industry Canada standards.

This device complies with part 15 of the FCC rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interfer-

ence, and (2) this device must accept any interference received, including

interference that may cause undesired operation. Changes or modifications

not expressly approved by Microflex could void the user’s authority to oper-

ate this equipment.

Emissions EN55022: 1998

Electrostatic Discharge EN61000-4-2: 1995, A1: 1998, A2: 2001

Radiated Immunity EN 61000-4-3: 2002

Safety Compliance EN 60950-1: 2002

This device is not intended for connection to the phone line through the

appropriate converters and shall not be connected to telecommunication

lines because it has no protection against over-voltages which may exist in

these lines.

The user shall ensure the protection of the operator from access to areas

with hazardous voltages or hazardous energy in their equipment.

The user shall ensure that the connection port of the field device and the

modem is separated at least by basic insulation from any primary circuit

existing in the field device.

1

Overview

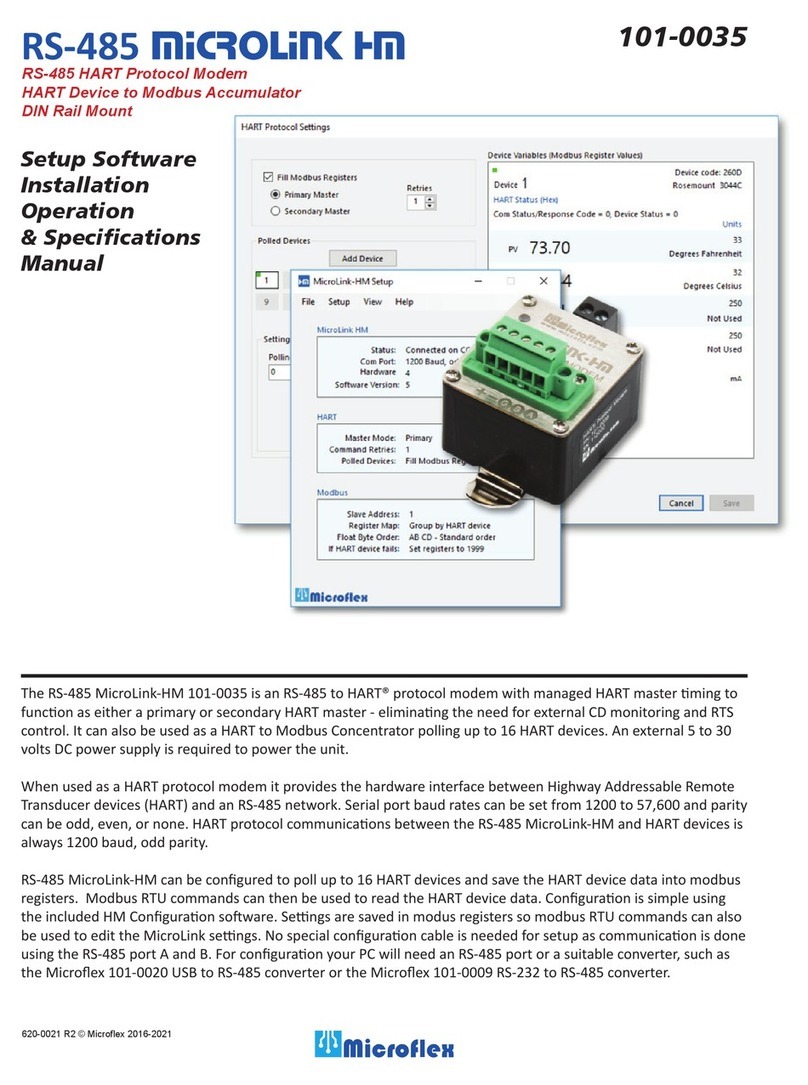

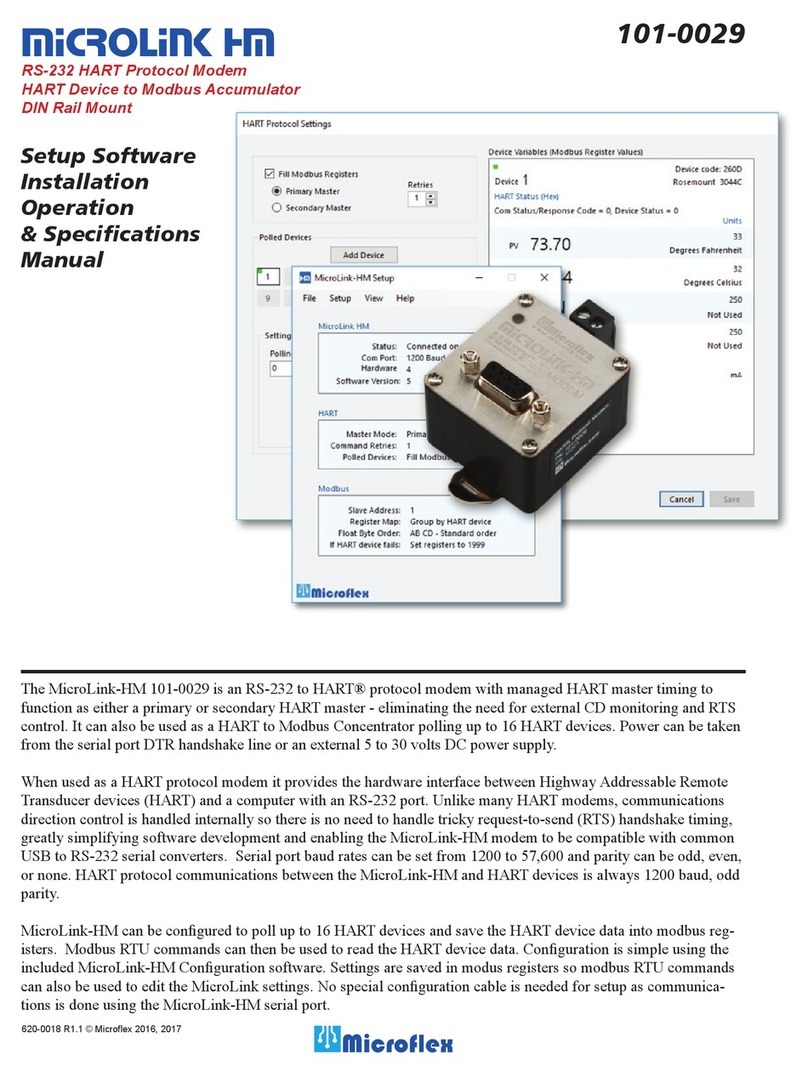

MicroLink-HM+ is a HART®protocol modem to USB/RS-485/RS-232 serial interface. In addion to funconing as a HART

protocol modem, it can also be configured to connuously poll HART devices, filling modbus registers with device values

without any addional HART soware. Modbus registers can then be read using modbus-RTU command 3 from the USB

and/or RS-485/RS-232 serial ports.

As a HART protocol modem the serial port is typically set to 1200 baud, odd parity. Most HART soware will require

these sengs. It is possible to set the serial port to other baud rates and parity sengs. In this case MicroLink-HM will

receive the HART command at the higher baud rate then transmit the HART data at 1200 baud, odd parity onto the

HART loop. The 1200 baud, odd parity HART reply packet is received by the MicroLink-HM modem and then transmied

back at the higher baud rate.

MicroLink-HM+ ships configured to operate as a HART protocol modem compable with most HART configuraon

and test soware. Included on the CD is the PACTware FDT frame, HART Protocol DTM, and Microflex Generic DTM

soware. For informaon on installing PACTware and the DTM, please reference the PACTware Quick Start Guide. Serial

communicaons to the HART modem can be USB, RS-485, or RS-232. The serial port is set for RS-485 protocol, 1200

baud, odd parity by default. Use the HM Configurator app, included on the CD, to change the port sengs.

If Fill Modbus Registers mode is enabled, MicroLink-HM will funcon as a HART master (primary or secondary) conn-

uously polling devices and storing variable values into registers. No addional HART soware is needed. The HART loop

may contain a single device or up to 16 devices. When more than one device is in the loop each HART device must have

a unique HART polling address. The address for each device is set separately before wiring the device into the mul-

drop loop. The HART Device Addresser soware applicaon, installed with the HM Configurator app, can be used to

assign addresses to HART devices.

Modbus-RTU command 3 is used to read the registers from the MicroLink-HM modbus slave. Variable data can be read

as 16 bit integers or 32 bit floang point. Up to 4 variables plus loop current for each polled HART device is available.

If configured to Fill Modbus Registers and a HART packet is received on the USB or RS-485/RS-232 port MicroLink-HM

will temporarily switch to HART modem mode and pause polling devices. A packet type is idenfied by monitoring the

first byte received in a new packet. HART protocol packets always begin with a hex FF preamble character and modbus

packets begin with the slave address. If no HART commands are received over the serial port for 60 seconds, or if a

modbus slave address is received, MicroLink-HM will exit HART modem mode and resume polling and filling modbus

registers.

Modbus port type, slave address, baud rate, parity, and other sengs are set using the HM Configurator app soware.

MicroLink-HM Configuration

Configuraon changes are done using the included HM Configurator app. The app can be connected to the MicroLink-

HM+ USB port or to the RS-485/RS-232 serial port. The serial port was set at the factory to RS-485 mode. To change the

serial port to RS-232 mode you must connect using the USB port first.

The USB port can supply power to the MicroLink-HM. This allows you to make configuraon changes without

connecng an external power supply.

Refer to the HM Configurator App manual for details on installing and using the configuraon soware.

2

Power

Supply

RS-485/RS-232

Transceiver

HART

Modem

Microcontroller

Modbus Register

Tables

TX

RX

CD

RTS

1 - DC (+)

2 - DC (-)

3 - GND

4 - TX B

5 - RX A

5-Pin

Terminal Block

HART Loop

Terminals

HART LED

COM LED

USB

MicroLink-HM+ Block Diagram

HART Loop Screw Terminals

USB Port

HART Transmit/Receive LED

DIN Rail Release

Serial Port Transmit/Receive LED

+/- DC Power 5-30VDC

G Serial Port Common

B/A RS-485 Port

TX/RX RS-232 Port

3

Address 0

LOOP

POWER

SUPPLY 250Ω

Address 1

HART

DEVICE

Address 2

HART

DEVICE

Address 15

HART

DEVICE

LOOP

POWER

SUPPLY

HART

DEVICE

250Ω

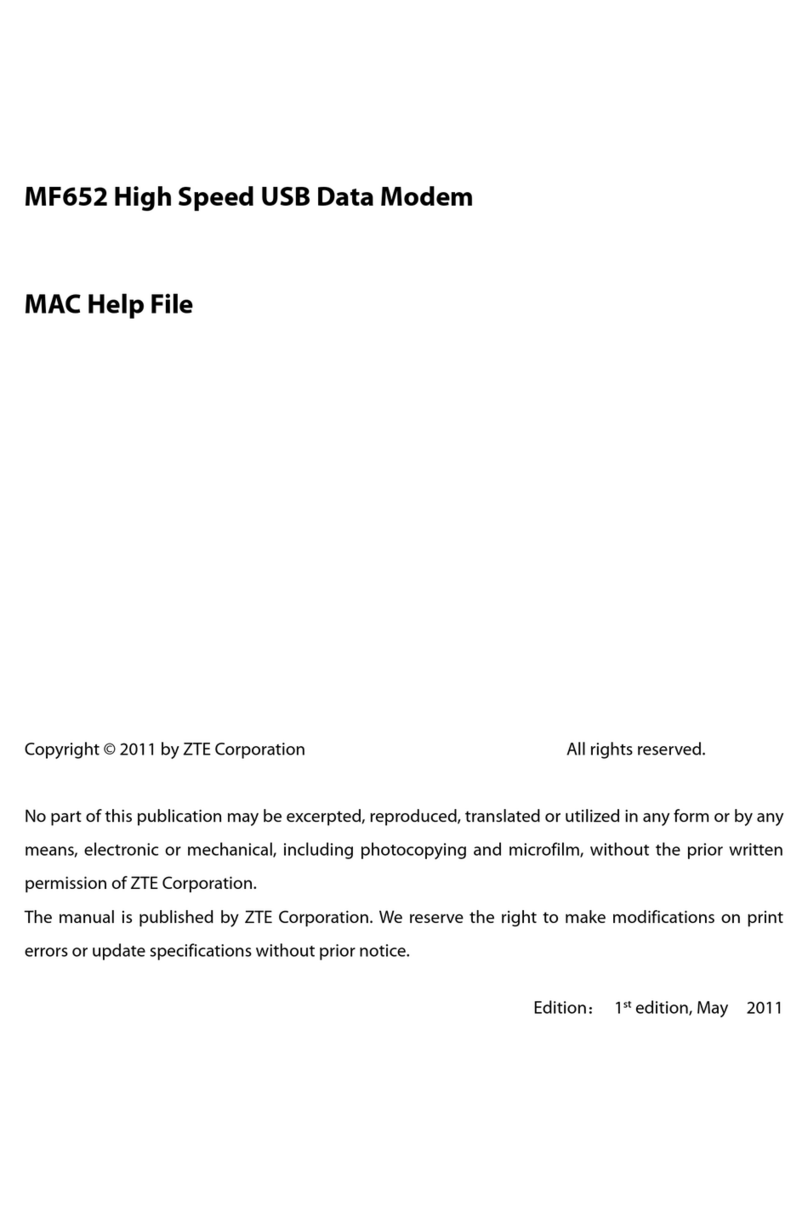

Figure 1. Connecting HART modem to device loop.

HART Loop with One Device

HART Multi-Drop Loop

Connect the two screw terminals to the HART device

or HART loop. Microlink provides electrical isolaon

between the HART loop and the serial port so it is safe

to ignore grounding and polarity issues when making

the HART connecons. Figure 1 shows one device and

mul-drop HART loop connecons.

The HART protocol requires a loop resistance of

230 to 600 ohms, typically 250 ohms.

Refer to your equipment installaon instrucons for

details on connecng a HART master or configuraon

device to the loop.

Mounting

The DIN rail mounting clip is compatible with widely used 35mm EN 50022 rails. It can be snap mounted and removed

from the mounting rail without tools for quick installation and servicing.

Power Supply

MicroLink-HM+ requires an external 5 to 30 volt DC power supply.

Posive side to Pin 1, and negave side to Pin 2 on the 5-pin screw terminal block.

Maximum supply current ranges from 5mA at 30 volts to 25mA at 5 volts.

In most cases the transmier loop power supply can be used to power MicroLink-HM, eliminang the need for a

dedicated MicroLink-HM supply.

Power can also be supplied by an acve enumerated USB port, making configuraon possible with only a USB

connecon. MicroLink-HM+ can funcon as a USB to HART protocol modem without the need for an external power

supply.

Connecting to a HART Loop

4

USB Port

The USB port can be used for device configuraon, monitoring, or as a USB to HART protocol modem. MicroLink-HM

can disnguish between HART and modbus packets. When a HART protocol packet is received on USB it will be routed

directly to the HART modem and transmied onto the HART loop. If MicroLInk-HM is polling devices the polling process

will be disabled while the HART command is being processed. Polling will be re-enabled aer 60 seconds of no HART

packet acvity on the USB port or if a modbus packet is received on the USB port.

USB Drivers

USB drivers create a virtual serial COM port that appears as a serial port to your applicaon soware. If your PC is

connected to the Internet the drivers will be automacally downloaded and installed when the HM modem is first

connected to a USB port. The drivers can also be installed before connecng to the USB port by running

file CDM21228_Setup.exe from the included CD. To download drivers got to www.microflx.com/pages/drivers.

The USB virtual serial port operates at 1200 baud and odd parity, slave ID 250, and uses standard modbus commands to

read and write registers.

Use the Windows Device Manager to determine the assigned Com port number. It will be listed under

Ports (COM & LPT) while the cable is aached to the MicroLink-HM+ USB port.

Serial Port

The serial port can be configured for RS-485 or RS-232 protocol using the HM Configurator app soware or by wring to

modbus register 775. The factory default is RS-485 mode, 1200 baud odd parity.

RS-485 Serial Protocol

An RS-485 bus can consists of mulple RS-485 devices connected in parallel to a bus cable. To eliminate line reflecons,

each cable end should be terminated with a terminaon resistor whose value matches the characterisc impedance

of the cable. This method, known as parallel terminaon, allows for higher data rates over a longer cable length.

MicroLink-HM+ does not include internal RS-485 terminaon internally.

• Connect terminal G to the RS-485 bus shield or ground wire. Internally connected to Supply (-) or ground

• Connect terminal B to the RS-485 bus B or (+)

• Connect terminal A to the RS-485 bus A or (-)

MicroLink-HM does not provide isolaon between the RS-485 port and power supply ground.

The G terminal is internally connected to the power supply (-) terminal.

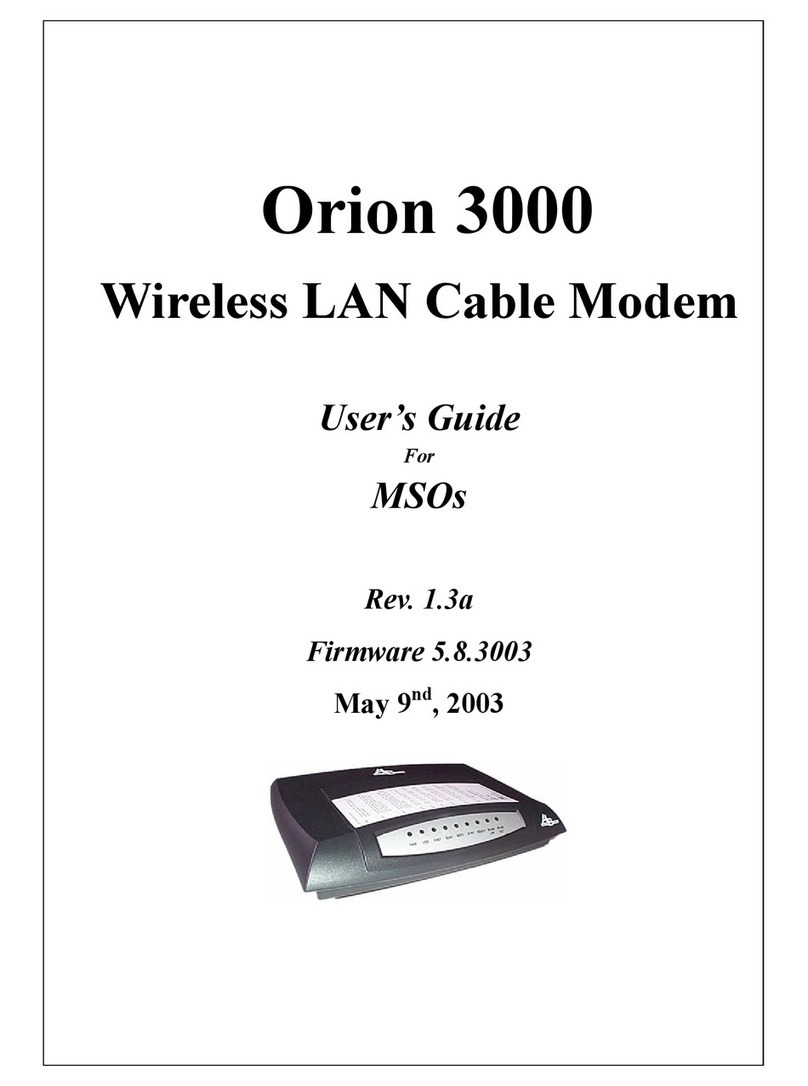

RS-232 Serial Protocol

By default the serial port is set to RS-485 protocol. Connect HM Configurator app soware to the MicroLink-HM USB port to change

the serial port to RS-232 mode using the Setup -> Modbus dialog.

Figure 2 shows typical wiring connecons to connect to a 9-Pin RS-232 connector. Only transmit, receive, and ground are used.

5 GND

2 RX

3 TX

+

G

TX

RX

5V to 30V

DC SUPPLY

MicroLink-HM+ HART

Loop

ĺ

ĸ

RS-232

Serial Port

DB-9 Female

Figure 2. Connecting to DB-9 RS-232 9-Pin serial port.

5

Modbus Registers

Register locaons and details can be found in the HM Configurator soware manual. The manual is included on the CD

and can be downloaded from www.microflx.com.

Write Locking

Wring to registers can be locked or write-protected aer seng the configuraon to prevent unwanted changes to the

configuraon. Refer to the HM Configurator soware manual for details on write locking and unlocking registers.

Polled HART Devices Long Address Table, 700 - 747

Device ID informaon is read from each polled device using the devices polling address and HART command 0. The

reply to command 0 for each polled device is used to populate the long address table. When MicroLink-HM needs to

poll for the device variables, using HART command 3, this table holds the informaon needed to build the 5-byte long

address. Table values can be read using modbus-RTU command 3. Only the polled devices you have configured will

contain valid informaon. The table is updated when the device address is unknown or a bad HART reply was received.

HART Device Polling Address Table, 748 - 755

The polling address for each polled device is stored in this table. Two polling addresses in each 16 bit register. If ad-

dress 0 is used then only one device can be polled and Device 1 should be set to 0. Address 0 is not valid in mul-drop

systems. For HART devices with HART revision 3 through 5 you should use polling addresses 1 - 15. Addresses 16-63

require HART revision 6 or higher.

Number of Decimal Places Table, 756 - 771

When storing the HART variable data in 16-bit modbus registers the maximum range is -32768 to 32767. To increase the

possible resoluon, the variable value read from the HART device is decimal posion adjusted before being saved in the

16-bit register. When the register is read, the value must be corrected by the number of decimal places to produce the

correct value. The number of decimal places for each variable occupies 4-bits in the register with one register for each

polled device.

Setup Registers, 772 - 777

The MicroLink-HM configuraon can be changed using the HM Configurator App or by wring to modbus registers using

modbus-RTU commands 6 or 16. Command 6 writes to a single register and command 16 writes to a range of modbus

registers. The configuraon register values are saved in nonvolale memory and are not lost when MicroLink-HM power

is removed.

6

Specifications

Power

Supply Range..................................................................................................................................5 to 30 Volts DC

Max Operang Current .................................................................................................... 25mA @ 5V, 5mA @30V

Typical Operang Current ......................................................................................... 8.8mA @ 12V, 5.2mA @ 24V

Field Connections

Terminaon................................................................................................ Pluggable Screw Terminal, 26-16 AWG

+ Power Supply (+) ......................................................................................................................................... Pin 1

- Power Supply (-).......................................................................................................................................... Pin 2

G Serial Port Ground Internally connected to Supply (-)................................................................................. Pin 3

TX B RS-485 (+), RS-232 Transmit ................................................................................................................... Pin 4

RX A RS-485 (-), RS-232 Receive ..................................................................................................................... Pin 5

HART Modem

Terminaon...............................................................................................Pluggable Screw Terminals, 26-12 AWG

Connecon Method ............................................................................... Transformer Isolated, Capacitor Coupled

Loop Isolaon..................................................................................... 3000Vrms 1 min Pri-Sec Dielectric Strength

DC Loop Voltage.................................................................................................................................... 50Vdc Max

Demodulaon Jier ................................................................................................................. 12% of 1 bit Typical

Carrier Detect Threshold..................................................................................................................100mV Typical

Leakage to Process Loop .......................................................................................................................±10μA Max

Serial Port

Baud Rates .........................................................................1200, 2400, 4800, 9600, 14400, 19200, 39400, 57600

Parity............................................................................................................................................ None, Odd, Even

Protocol................................................................................................. HART or Modbus-RTU, Commands 3,6,16

Floang point byte order ............................................................................................ AD-CD or CD-AB (swapped)

Number of polled HART devices ..................................................................................................................1 to 16

Variables per polled HART device .................................................................................................(4) PV, SV, TV, FV

Supported Modbus-RTU Commands .......................................................................................................... 3, 6, 16

Surge Protecon.................................................................................................. 600W Silicone Avalanche Diodes

±15kV (HBM) ESD Protected Bus (RS-232 or RS-485)

RS-485 Mode

Driver Output Voltage................................................................................. 2V Min Unloaded, 1.5V Min RL = 50Ω

ΔInput Threshold Receive Voltage ............................................................................................................ +/- 0.2V

Receiver Input Hysteresis....................................................................................................................... 35 mV Typ

Receiver Input Current....................................................................................................................... +/- 1mA Max

Does not include RS-485 terminaon resistor

• Auto transmit control

• Power Up/Down glitch-free permits live inseron or removal

• Common mode range permits +/-7V ground difference

RS-232 Mode

Receiver Input Voltage Range ...................................................................................................................... +/-25V

Receiver Input Threshold ............................................................................................................VIL 1.1V, VIH 1.6V

Receiver Input Hysteresis...............................................................................................................................35mV

Transmier Output ..................................................................................................................................+/-5V Typ

USB

Connector ..................................................................................................................................................... USB-B

Type & Sengs ..................................................................................... FTDI Virtual Com Port, 1200 Baud, 8, O, 1

Protocol...................................................................HART or Modbus-RTU, Slave address 250, Commands 3,6,16

HART LED

Green ........................................................................................................................ HART Modem is transming

Red ................................................................................................................................. HART modem is receiving

COM LED

Green ............................................................................................................................. Serial Port is Transming

Red ......................................................................................................................................Serial Port is Receiving

7

Default Settings

Serial Port.........................................................................................RS-485 Mode, 1200 Baud, Odd Parity, 1 Stop

Modbus Address ................................................................................................................................................... 1

Fill Modbus Registers ..............................................................................Disabled (HART Protocol Modem Mode)

Poll Interval .............................................................................................................................................2 Seconds

Environmental

Operang Temperature............................................................................................-30°C to 60°C (-22°F to 140°F)

Storage Temperature ...............................................................................................-40°C to 85°C (-40°F to 185°F)

Humidity ......................................................................................................................0 to 95% (non-condensing)

Enclosure

Polycarbonate plasc with Stainless Steel Cover

Weight....................................................................................................................................................2.3 ounces

Mounng ................................................................................................................................. 35mm DIN Rail Clip

8

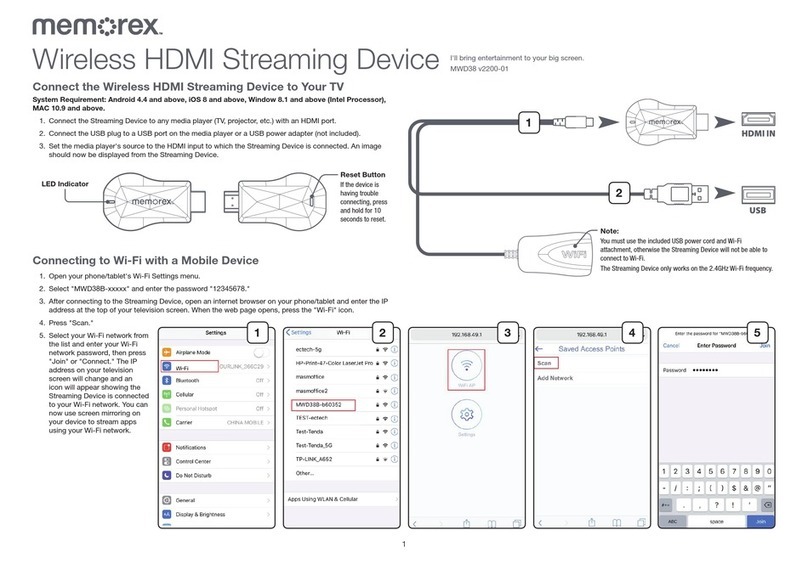

2.45

62.3 mm

3.32

84.2 mm

1.58

40.1 mm

1.03

26.2 mm

.42

10.6 mm

1.66

42.2 mm

SN: 123456

Limited Warranty

Microflex, LLC warrants this unit against defects in materials and workmanship for a

period of one year from the date of shipment. Microflex, LLC will, at its option, repair or

replace equipment that proves to be defective during the warranty period. This warranty

includes parts and labor.

A Return Materials Authorization (RMA) number must be obtained from the factory

and clearly marked on the outside of the package before equipment will be accepted for

warranty work.

Microflex, LLC believes that the information in this manual is accurate. In the event that

a typographical or technical error exist, Microflex, LLC reserves the right to make changes

without prior notice to holders of this edition. The reader should consult Microflex, LLC

if any errors are suspected. In no event should Microflex, LLC be liable for any damages

arising out of or related to this document or the information contained in it.

EXCEPTAS SPECIFIED HEREIN, MICROFLEX, LLC MAKES NO WARRANTIES OR

MERCHANTABILITY OR FITNESS FORA PARTICULAR PURPOSE. CUSTOMER’S

RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE

PART OF MICROFLEX SHALL BE LIMITED TO THE AMOUNT THERETOFORE

PAID BY THE CUSTOMER. MICROFLEX, LLC WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS,

OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE

POSSIBILITIES THEREOF. This limitation of the liability of Microflex, LLC will apply

regardless of the form of action, whether in contract or tort, including negligence. Any

action against Microflex, LLC must be brought within one year after the cause of action

accrues. The warranty provided herein does not cover damages, defects, malfunctions, or

service failures caused by owners failure to follow Microflex, LLC’s installation, operation,

or maintenance instructions; owners modification of the product; owner’s abuse, misuse, or

negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or

other events outside reasonable control.

Microflex, LLC

35900 Royal Road

Pattison, Texas 77423

USA

The HART protocol is supported by the HART Communications Foundation in Austin

Texas, www.hartcomm.org. HART is a registered trademark of the HART Communications

Foundation.

Phone 281-855-9639

Fax 832-422-4391

www.microflx.com

Table of contents

Other Microflex Modem manuals