Microflex MicroLink-HM 101-0029 User manual

Setup Software

Installation

Operation

& Specifications

Manual

620-0018 R1.1 © Microfl ex 2016, 2017

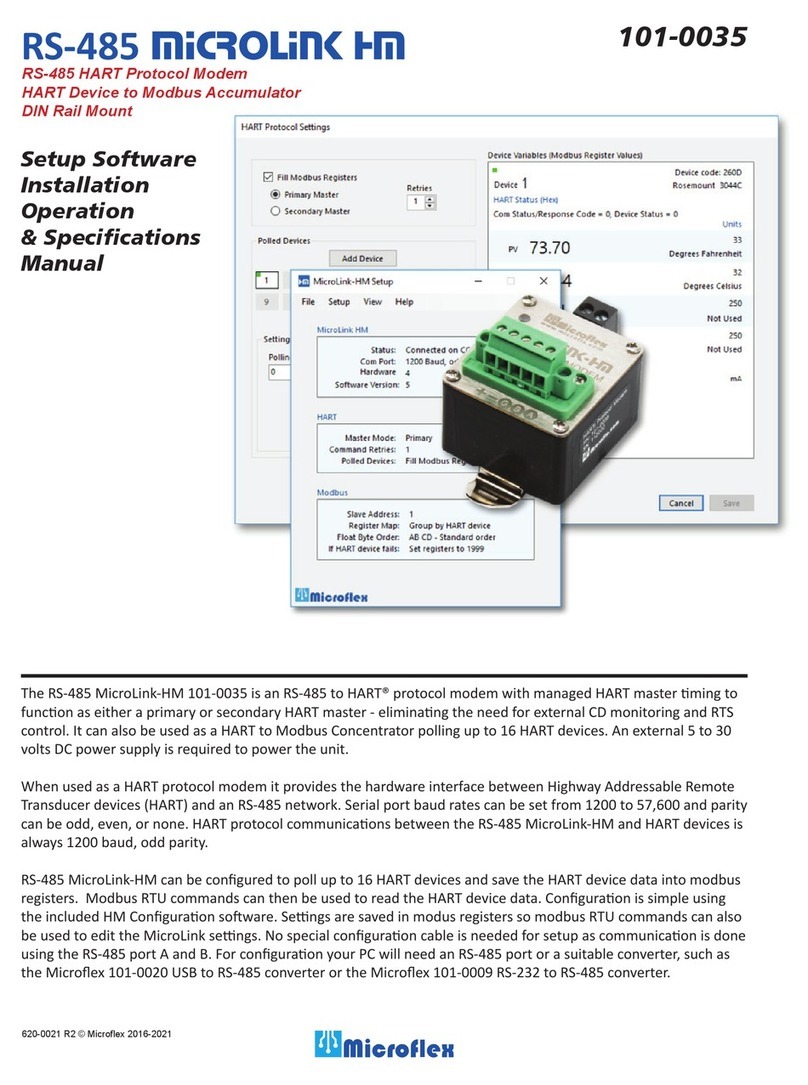

101-0029

MicroLinK HM

RS-232 HART Protocol Modem

HART Device to Modbus Accumulator

DIN Rail Mount

The MicroLink-HM 101-0029 is an RS-232 to HART® protocol modem with managed HART master timing to

function as either a primary or secondary HART master - eliminating the need for external CD monitoring and RTS

control. It can also be used as a HART to Modbus Concentrator polling up to 16 HART devices. Power can be taken

from the serial port DTR handshake line or an external 5 to 30 volts DC power supply.

When used as a HART protocol modem it provides the hardware interface between Highway Addressable Remote

Transducer devices (HART) and a computer with an RS-232 port. Unlike many HART modems, communications

direction control is handled internally so there is no need to handle tricky request-to-send (RTS) handshake timing,

greatly simplifying software development and enabling the MicroLink-HM modem to be compatible with common

USB to RS-232 serial converters. Serial port baud rates can be set from 1200 to 57,600 and parity can be odd, even,

or none. HART protocol communications between the MicroLink-HM and HART devices is always 1200 baud, odd

parity.

MicroLink-HM can be confi gured to poll up to 16 HART devices and save the HART device data into modbus reg-

isters. Modbus RTU commands can then be used to read the HART device data. Confi guration is simple using the

included MicroLink-HM Confi guration software. Settings are saved in modus registers so modbus RTU commands

can also be used to edit the MicroLink settings. No special confi guration cable is needed for setup as communica-

tions is done using the MicroLink-HM serial port.

Finding the COM Port Number

You will need to know the COM port number the MicroLink-HM modem is connected to. To see a list of COM ports

installed on your PC, open the Device Manager and select View > Devices by Type. Expand Ports (COM & LPT) to see the

list of available COM ports. MicroLink-HM is compatible with USB to serial converters as well as RS-232 serial ports.

HART Protocol Modem

MicroLink-HM ships confi gured to operate as a HART protocol modem. No additional drivers or external power sourc-

es are needed. Simply connect the 9-pin D-sub connector to a standard RS-232 port. Power can be supplied by the DTR

handshake line or by an external supply. Refer to the Power Supply section in this manual for details.

MicroLink-HM is compatible with most HART confi guration and test software. Included on the CD is the PACTware

FDT frame, HART Protocol DTM, and Microfl ex Generic DTM software. For information on installing PACTware and

the DTM, please reference the PACTware Quick Start Guide.

To function as a HART protocol modem the serial port is typically set to 1200 baud, odd parity. Most HART software

will require this setting. It is possible to set the serial port to other baud rates and parity settings. This is helpful when

connecting the MicroLink-HM to a device that does not off er 1200 baud. In this case MicroLink-HM will receive the

HART command at the higher baud rate then transmit the HART data at 1200 baud, odd parity onto the HART loop. The

1200 baud, odd parity HART reply packet is received by the MicroLink-HM modem and then transmitted back at the

higher baud rate.

If MicroLink-HM is confi gured to Fill Modbus Registers and the serial port detects a HART packet on the RS-232 port,

MicroLink-HM will temporarily switch to HART mode and stop polling devices. HART protocol packets always begin

with the hex FF preamble character. Modbus packets begin with the slave address. If no HART commands are received

over the serial port, MicroLink-HM will return to polling and fi lling modbus registers after 30 seconds. Also, if a mod-

bus command is received MicroLink will exit HART mode and return to polling and fi lling modbus registers.

Connecting to the HART Loop

Connect the two screw terminals to the HART device

or HART loop. Microlink provides electrical isolation

between the HART loop and the serial port so it is safe

to ignore grounding and polarity issues when making

the HART connections. The HART protocol requires

a loop resistance of 230 to 600 ohms, typically 250

ohms. Refer to your equipment installation instructions

for details on connecting a HART master or confi gura-

tion device to the loop.

HART Status LED Operation

The LED on the front panel of the MicroLink-HM is

used to monitor HART communications activity. The

LED will be green while transmitting or sending a pack-

et to your HART protocol devices, and will be red when

HART protocol replies are received.

LOOP

POWER

SUPPLY HART

DEVICE

250Ω

LOOP

POWER

SUPPLY HART

DEVICE

250Ω

Figure 1. Connecting HART modem to device loop.

Connecting across the loop resistor.

Connecting across the HART device.

Mounting

The DIN rail mounting clip is compatible with widely used 35mm EN 50022 rails. It can be snap mounted and removed

from the mounting rail without tools for quick installation and servicing.

Power Supply

The MicroLink-HM is powered through the 9-pin RS-232

connector using the RS-232 Data-Terminal-Ready (DTR)

handshake line - pin 4. When using DTR for power, no external

power supply is required.

An external DC power supply in the 5 to 30Vdc range can also

be used. Connect the positive side to DTR (pin 4) and nega-

tive to Ground (pin 5). Maximum supply current ranges from

2mA at 30 volts to 10.5mA at 5 volts. The RS-232 transmit and

receive will share the ground (pin 5) with the power supply

ground. If external power is used then DTR should not be con-

nected to the mating RS-232 port. Only transmit, receive, and

ground are required for communications.

5 - GROUND

2 - RX ←

3 - TX →

4 - DTR (5-30Vdc)

Figure 2. DB-9 Wiring Diagram

HART Status LED

Power

Supply

RS-232

Driver/Rcvr HART

Modem

Microcontroller

Modbus Register

Tables

TX

RX

CD

RTS

1

2 - RX

3 - TX

4 - DTR

5 - GND

6

7

8

9

9-Pin RS-232

D-Sub Connector HART Loop

Terminals

HART Status LED

MicroLink-HM Block Diagram

RS-232 Cable Schematic

The RS-232 extension cable connecting the Mi-

croLink-HM to the RS-232 serial port requires only

4 wires. If external power is used then only trans-

mit, receive, and ground are needed on the RS-232

port side.

)(0$/( 0$/(

5;

7;

'75

*1'

56

3257

0LFUR/LQN+0

)(0$/( 0$/(

5;

7;

'75

*1'

WR9GF

*5281'

Power from DTR line External power supply

Setting COM Port

The MicroLink-HM software must be set to use the same COM

port that the modem is connected to. From the top menu select

Setup>Com Port. Choose the COM port number from the list

of available ports. After choosing, click Connect to attempt to

connect using the settings selected. The connection process will

fi rst try the last good baud rate and parity settings. If it fails to

connect the process will work

through other settings to try to

fi nd the correct MicroLink-HM

settings for communications. If it

still does not connect - verify that

you have chosen the correct COM

number, connections are correct,

and power is on before trying

again.

MicroLink-HM HART - Modbus Accumulator

In addition to being an RS-232 HART Protocol Modem, the MicroLink HM can be set to collect and store process

variable information from up to 16 HART devices. HART devices are continuously polled and variable information

is accumulated into a table of Modbus registers. Using the MicroLink-HM serial port, the registers can be read using

Modbus RTU command 3. Variable data can be read as 16 bit integers or 32 bit fl oating point. Up to 4 variables for each

polled HART device.

In the accumulate mode, MicroLink-HM will function as a HART master (primary or secondary) polling devices and

storing variable values into registers. No additional HART software is needed. The HART loop may contain a single

device or up to 16 devices. When more than one device is in the loop each HART device must have a unique HART

polling address. The address for each device is set before wiring the device into the multi-drop loop. The device polling

address for each device is stored in the MicroLink-HM using the MicroLink-HM confi guration software.

Modbus slave address, baud rate, parity, and other settings are set using the MicroLink-HM confi guration software.

Confi guration is done using the same RS-232 port that Modbus will use so no additional setup cable is required. After the

confi guration is completed, the RS-232 port is connected to the Modbus controller. At power on the MicroLink-HM will

begin polling and accumulating values. Modbus RTU command 3 is used to read the accumulated values.

MicroLink HM Installation - Windows

The MicroLink-HM confi guration software is included on a CD with the unit. Simply insert the CD and follow the on-

screen prompts to install the software. If AutoRun is not confi gured to run the CD fi le when the CD is inserted you will

need to navigate to the SetupHM.exe fi le on the CD and double-click the fi le name to run it.

After Installation the MicroLink-HM icon will be added to your system.

If you do not have a CD Rom device on your computer, contact sales@microfl x.com to inquire

about a digital download version of the software.

Home Screen

The home screen displays a summary of the MicroLink-HM

status, HART modem settings, and Modbus settings. Use the top

drop-down menus to confi gure the MicroLink-HM modem.

Figure 3. COM Port List.

Figure 4. MicroLink-HM Setup home screen.

Polling HART Devices - Fill Modbus Registers

To enable Modbus register accumulation, check the Fill Modbus Registers option. The Hart Protocol Settings window will

expand to show the Polled Devices settings.

Retries

If a HART devices is polled but does not respond, or errors are detected, MicroLink-HM can retry up to 3 times before

indicating a bad device. If a device is not responding the Modbus values are fi lled with Hart Device Failed register val-

ues - setup is done in the Modbus confi guration section.

Polled Devices

In the example screen shot (Figure 5), MicroLink-HM is set to poll one HART device using polling address 0 and will

retry 1 time before reporting a communications error. The Device Variables (Modbus Register Values) box on the right

displays the register values for the active polled device. Click Add Device to add a polled HART device. Be sure to set

the Polling Address

for each device. Each

device must have a

unique HART polling

address. Polling

addresses must be

setup for each HART

device before it can

be connected to a

multi-drop HART

loop and can be set

from 1 to 63.

Address 0 can only be

used when one device

is in the HART loop.

Polling addresses

16-63 should only be

used with HART revi-

sions 6 and higher.

For HART 3-5 use

addresses 1-15 for

multi-drop systems.

HART Protocol Settings

With Fill Modbus Registers unchecked, MicroLink-HM will function as a standard HART protocol modem and not poll

HART devices to fi ll Modbus registers. In this mode HART packets are received and then retransmitted at the HART

1200 baud, odd parity. Received reply packets are retransmitted at the

selected baud rate. RTS timing and carrier detect are handled internally

by the MicroLink-HM allowing RS-232 communications at higher than

1200 baud. HART loop data is handled at the standard HART protocol

1200 baud, odd parity but because MicroLink-HM buff ers the data

the RS-232 port can be set for higher rates as well as odd, even, or no

parity. Port settings can be set in the Modbus Settings section.

Since MicroLink-HM manages network timing it needs to be confi g-

ured for either a primary or secondary master. Portable confi guration

modems are typically set to be secondary masters.

Figure 5. HART protocol settings dialog when fi lling modbus registers is enabled.

Modbus - RTU Setup

Modbus-RTU Settings can be accessed and changed by clicking Setup>Modbus from the top drop-down menu.

Modbus Address

Each device on a Modbus network must have a unique address. Set

this to match the address that your Modbus master will use to com-

municate with the MicroLink-HM. The Modbus address can be set

to any value from 1 to 247. The MicroLink-HM confi guration soft-

ware will discover this address as part of the connection process.

Baud Rate & Parity

The MicroLink-HM baud rate and parity must be set to the

same settings as your Modbus master. If you are using the Mi-

croLink-HM as a HART protocol modem these should be set to

1200 baud, odd parity. Click Use HART Protocol Settings to set the

correct values for a HART modem.

Holding Registers Map

Accumulated data is stored in Modbus registers that are grouped or

mapped by HART device or by variable type. Choose the register

map that best fi ts your application. Register maps can be viewed

using the MicroLink-HM confi guration software. From the top

drop-down menu select View -> Modbus Registers Maps (Figure 7.)

Decimal Places

When device data is stored into a 16 bit signed Modbus register the value can range from -32768 to 32767. To allow the

16 bit integer to represent a smaller number and include fractional information, the number of decimal places is stored in

a separate Modbus register and applied later. The number of decimal places can be set from 0 to 5. Decimal places can

be set for each variable. The Device Variables box shows the eff ect of the decimal place setting. Decimal place settings are

not used for the Modus fl oating point register values.

Figure 6. Modbus settings dialog.

Figure 7. Menu for viewing modbus register maps.

Floating Point Byte Order

Modbus 32 bit fl oating point numbers are stored in two

consecutive 16 bit registers using the IEEE-754 standard

big endian byte order (AB-CD). The most signifi cant byte

(A) is sent fi rst. For compatibility with some modbus

systems you may need to use the word swapped format

(CD-AB).

HART Device Failed Register Value

If a polled HART device fails to respond, or has commu-

nications errors it will retry for the number of times set

in the HART Protocol Settings dialog. If after retries the

device does not respond you can choose to hold the last

value, set to a preset number, or set to the IEEE-754 NaN

fl oating point value. This can help the modbus master

determine when a HART device is no longer responding.

Setup Registers

The MicroLink-HM confi guration can be changed using the setup and confi guration software or by writing to modbus

registers using modbus-RTU commands 6 or 16. Command 6 writes to a single register and command 16 writes to a

range of modbus registers. The confi guration register values are saved in nonvolatile memory and are not lost when

MicroLink-HM power is removed.

HART Settings

Bits 9, 8 HART failed mode 0 = Hold last value after HART retries

1 = Preset to register 772 value after HART retries

2 = Preset to IEEE-754 NaN (0 for integers)

Bits 7, 6 HART poll retries Sets number of HART device poll retries from 1 to 3.

After poll retries, the HART failed mode value is stored in the variable register.

Bits 3 - 0 Number of polled devices -1 Range is 0 to 15. 0 = 1 polled device. 15 = 16 polled devices.

ϭϱϭϰϭϯϭϮϭϭϭϬϵϴϳϲϱϰϯϮϭϬ

,Zd&ĂŝůĞĚDŽĚĞ;ŝƚϭͿ

,Zd&ĂŝůĞĚDŽĚĞ;ŝƚϬͿ

,ZdZĞƚƌŝĞƐ;ŝƚϭͿ

,ZdZĞƚƌŝĞƐ;ŝƚϬͿ

Ϭс&ŝůůZĞŐŝƐƚĞƌƐϭс,ZdDŽĚĞŵ

ϭсWƌŝŵĂƌLJϬс^ĞĐŽŶĚĂƌLJDĂƐƚĞƌ

EƵŵďĞƌŽĨƉŽůůĞĚĚĞǀŝĐĞƐͲϭ

ϬсϭWŽůůĞĚĞǀŝĐĞ;ϬƚŽϭϱͿ

ϳϳϯͲ,Zd^ĞƚƚŝŶŐƐ

DŽĚďƵƐ

ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ;ŚŝŐŚďLJƚĞůŽǁďLJƚĞͿ

ϳϳϮ ,Zd&ĂŝůĞĚŽĚĞWƌĞƐĞƚsĂůƵĞ

ϳϳϯ ,ZdDŽĚĞ^ĞƚƚŝŶŐƐ

ϳϳϰ DŽĚďƵƐ^ĞƚƚŝŶŐƐ

ϳϳϱ DŽĚďƵƐWŽƌƚ^ĞƚƚŝŶŐƐ

ϳϳϲ ,ĂƌĚǁĂƌĞZĞǀ^ŽĨƚǁĂƌĞZĞǀ

ϳϳϳ WŽůůĞĚĚĞǀŝĐĞƐƚĂƚƵƐ

Serial Port Settings

ϭϱϭϰϭϯϭϮϭϭϭϬϵϴϳϲϱϰϯϮϭϬ

ϭсKĚĚƉĂƌŝƚLJ

ϭсǀĞŶƉĂƌŝƚLJ

ĂƵĚ;ďŝƚϯͿ

ĂƵĚ;ďŝƚϮͿ

ĂƵĚ;ďŝƚϭͿ

ĂƵĚ;ďŝƚϬͿ

ϳϳϱͲDŽĚďƵƐWŽƌƚ^ĞƚƚŝŶŐƐ

DŽĚďƵƐ^ůĂǀĞĚĚƌĞƐƐ;ϭͲϮϰϳͿ

Bits 13, 12

00 = No parity

01 = Even

10 = Odd

Mode Settings

Bit 9 - Floating point value byte order 0 = Standard byte order (AB - CD)

1 = Swapped words (CD - AB)

Bit 8 - Modbus device map 0 = Map register data by HART device

1 = Map register data by variable type

ϭϱϭϰϭϯϭϮϭϭϭϬϵϴϳϲϱϰϯϮϭϬ

ϬсĨůŽĂƚďLJƚĞŽƌĚĞƌϭс

ϬсďLJĞǀŝĐĞDĂƉϭсďLJsĂƌŝĂďůĞDĂƉ

ϳϳϰͲDŽĚĞ^ĞƚƚŝŶŐƐ

Bits 11 - 8

1 = 1200 Baud

2 = 2400

3 = 4800

4 = 9600

5 = 14400

6 = 19200

7 = 38400

8 = 57600

9 = 115200

,Zd DŽĚďƵƐ

ĞǀŝĐĞ ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ;ŚŝŐŚďLJƚĞůŽǁďLJƚĞͿ

ϭ ϳϬϬ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϬϭ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϬϮ /Ϯ/ϯ

Ϯ ϳϬϯ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϬϰ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϬϱ /Ϯ/ϯ

ϯ ϳϬϲ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϬϳ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϬϴ /Ϯ/ϯ

ϰ ϳϬϵ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϭϬ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϭϭ /Ϯ/ϯ

ϱ ϳϭϮ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϭϯ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϭϰ /Ϯ/ϯ

ϲ ϳϭϱ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϭϲ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϭϳ /Ϯ/ϯ

ϳ ϳϭϴ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϭϵ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϮϬ /Ϯ/ϯ

ϴ ϳϮϭ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϮϮ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϮϯ /Ϯ/ϯ

ϵ ϳϮϰ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϮϱ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϮϲ /Ϯ/ϯ

ϭϬ ϳϮϳ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϮϴ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϮϵ /Ϯ/ϯ

ϭϭ ϳϯϬ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϯϭ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϯϮ /Ϯ/ϯ

ϭϮ ϳϯϯ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϯϰ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϯϱ /Ϯ/ϯ

ϭϯ ϳϯϲ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϯϳ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϯϴ /Ϯ/ϯ

ϭϰ ϳϯϵ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϰϬ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϰϭ /Ϯ/ϯ

ϭϱ ϳϰϮ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϰϯ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϰϰ /Ϯ/ϯ

ϭϲ ϳϰϱ WƌĞĂŵďůĞƐDĂŶŽĚĞŽƌdLJƉĞ

ϳϰϲ ĞǀŝĐĞdLJƉĞ/ϭ

ϳϰϳ /Ϯ/ϯ

Polled HART Devices Long Address Table

Device ID information is read from each polled device using the devices polling address and HART command 0. The

reply to command 0 for each polled device is used to populate the long address table. When MicroLink-HM needs to

poll for the device variables, using HART command 3, this table holds the information needed to build the 5-byte long

address. Table values can be read using Modbus-RTU command 3. Only the polled device you have confi gured will

contain valid information. The table is updated after each valid device poll.

DŽĚďƵƐ ,ZdĞǀŝĐĞWŽůůŝŶŐĚĚƌĞƐƐ

ZĞŐŝƐƚĞƌ ;ŚŝŐŚďLJƚĞůŽǁďLJƚĞͿ

ϳϰϴ ĞǀŝĐĞϭĞǀŝĐĞϮ

ϳϰϵ ĞǀŝĐĞϯĞǀŝĐĞϰ

ϳϱϬ ĞǀŝĐĞϱĞǀŝĐĞϲ

ϳϱϭ ĞǀŝĐĞϳĞǀŝĐĞϴ

ϳϱϮ ĞǀŝĐĞϵĞǀŝĐĞϭϬ

ϳϱϯ ĞǀŝĐĞϭϭĞǀŝĐĞϭϮ

ϳϱϰ ĞǀŝĐĞϭϯĞǀŝĐĞϭϰ

ϳϱϱ ĞǀŝĐĞϭϱĞǀŝĐĞϭϲ

HART Device Polling Address Table

The polling address for each polled device is stored in this table. Two polling addresses in each 16 bit register. If ad-

dress 0 is used then only one device can be polled and Device 1 should be set to 0. Address 0 is not valid in multi-drop

systems. For HART devices with HART revision 3 through 5 you should use polling addresses 1 - 15. Addresses 16-63

require HART revision 6 or higher.

,Zd DŽĚďƵƐ EƵŵďĞƌŽĨĞĐŝŵĂůWůĂĐĞƐ

ĞǀŝĐĞ ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ;ŚŝŐŚďLJƚĞůŽǁďLJƚĞͿ

ϭ ϳϱϲ WsͲ^dsͲ&s

Ϯ ϳϱϳ WsͲ^dsͲ&s

ϯ ϳϱϴ WsͲ^dsͲ&s

ϰ ϳϱϵ WsͲ^dsͲ&s

ϱ ϳϲϬ WsͲ^dsͲ&s

ϲ ϳϲϭ WsͲ^dsͲ&s

ϳ ϳϲϮ WsͲ^dsͲ&s

ϴ ϳϲϯ WsͲ^dsͲ&s

ϵ ϳϲϰ WsͲ^dsͲ&s

ϭϬ ϳϲϱ WsͲ^dsͲ&s

ϭϭ ϳϲϲ WsͲ^dsͲ&s

ϭϮ ϳϲϳ WsͲ^dsͲ&s

ϭϯ ϳϲϴ WsͲ^dsͲ&s

ϭϰ ϳϲϵ WsͲ^dsͲ&s

ϭϱ ϳϳϬ WsͲ^dsͲ&s

ϭϲ ϳϳϭ WsͲ^dsͲ&s

Number of Decimal Places Table

When storing the HART variable data in 16-bit modbus registers the maximum range is -32768 to 32767. To increase the

possible resolution, the variable value read from the HART device is decimal position adjusted before being saved in the

16-bit register. When the register is read, the value must be corrected by the number of decimal placed to produce the

correct value. The number of decimal places for each variable occupies 4-bits in the register with one register for each

polled device.

Decimals Variable Range

0 -32768 to 32767

1 -3276.8 to 3276.7

2 -327.68 to 327.67

3 -32.768 to 32.767

4 -3.2768 to 3.2767

5 -0.32768 to 0.32767

ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ

ϳ >ŽŽƉƵƌƌĞŶƚ/ŶƚĞŐĞ

ƌ

ϮϱϰϮϱ

ϱ

>ŽŽƉƵƌƌĞŶƚ&ůŽĂ

ƚ

ĞǀŝĐĞϰ

ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ

Ϭ Ws/ŶƚĞŐĞƌ Ϯϰ Ws/ŶƚĞŐĞƌ

ϭ ^s/ŶƚĞŐĞƌ Ϯϱ ^s/ŶƚĞŐĞƌ

Ϯ ds/ŶƚĞŐĞƌ Ϯϲ ds/ŶƚĞŐĞƌ

ϯ &s/ŶƚĞŐĞƌ Ϯϳ &s/ŶƚĞŐĞƌ

ϰ ,Zd^ƚĂƚƵƐ Ϯϴ ,Zd^ƚĂƚƵƐ

ϱ D^сWshKD>^с^shK

D

Ϯϵ D^сWshKD>^с^shK

D

ϲ D^сdshKD>^с&shK

D

ϯϬ D^сdshKD>^с&shK

D

ϮϱϲϮϱ

ϳ

Ws&ůŽĂƚ ϮϴϬϮϴ

ϭ

Ws&ůŽĂƚ

ϮϱϴϮϱ

ϵ

^s&ůŽĂƚ ϮϴϮϮϴϯ ^s&ůŽĂƚ

ϮϲϬϮϲ

ϭ

ds&ůŽĂƚ ϮϴϰϮϴ

ϱ

ds&ůŽĂƚ

ϮϲϮϮϲϯ &s&ůŽĂƚ ϮϴϲϮϴ

ϳ

&s&ůŽĂƚ

ĞǀŝĐĞϮ ĞǀŝĐĞϱ

ϴ Ws/ŶƚĞŐĞƌ ϯϮ Ws/ŶƚĞŐĞƌ

ϵ ^s/ŶƚĞŐĞƌ ϯϯ ^s/ŶƚĞŐĞƌ

ϭϬ ds/ŶƚĞŐĞƌ ϯϰ ds/ŶƚĞŐĞƌ

ϭϭ &s/ŶƚĞŐĞƌ ϯϱ &s/ŶƚĞŐĞƌ

ϭϮ ,Zd^ƚĂƚƵƐ ϯϲ ,Zd^ƚĂƚƵƐ

ϭϯ D^сWshKD>^с^shK

D

ϯϳ D^сWshKD>^с^shK

D

ϭϰ D^сdshKD>^с&shK

D

ϯϴ D^сdshKD>^с&shK

D

ϮϲϰϮϲ

ϱ

Ws&ůŽĂƚ ϮϴϴϮϴ

ϵ

Ws&ůŽĂƚ

ϮϲϲϮϲ

ϳ

^s&ůŽĂƚ ϮϵϬϮϵ

ϭ

^s&ůŽĂƚ

ϮϲϴϮϲ

ϵ

ds&ůŽĂƚ ϮϵϮϮϵϯ ds&ůŽĂƚ

ϮϳϬϮϳ

ϭ

&s&ůŽĂƚ ϮϵϰϮϵ

ϱ

&s&ůŽĂƚ

ĞǀŝĐĞϯ ĞǀŝĐĞϲ

ϭϲ Ws/ŶƚĞŐĞƌ ϰϬ Ws/ŶƚĞŐĞƌ

ϭϳ ^s/ŶƚĞŐĞƌ ϰϭ ^s/ŶƚĞŐĞƌ

ϭϴ ds/ŶƚĞŐĞƌ ϰϮ ds/ŶƚĞŐĞƌ

ϭϵ &s/ŶƚĞŐĞƌ ϰϯ &s/ŶƚĞŐĞƌ

ϮϬ ,Zd^ƚĂƚƵƐ ϰϰ ,Zd^ƚĂƚƵƐ

Ϯϭ D^сWshKD>^с^shK

D

ϰϱ D^сWshKD>^с^shK

D

ϮϮ D^сdshKD>^с&shK

D

ϰϲ D^сdshKD>^с&shK

D

ϮϳϮϮϳϯ Ws&ůŽĂƚ ϮϵϲϮϵ

ϳ

Ws&ůŽĂƚ

ϮϳϰϮϳ

ϱ

^s&ůŽĂƚ ϮϵϴϮϵ

ϵ

^s&ůŽĂƚ

ϮϳϲϮϳ

ϳ

ds&ůŽĂƚ ϯϬϬϯϬ

ϭ

ds&ůŽĂƚ

ϮϳϴϮϳ

ϵ

&s&ůŽĂƚ ϯϬϮϯϬϯ &s&ůŽĂƚ

ĞǀŝĐĞϭ

Modbus Register Map - Grouped by HART Device (1 of 3)

Modbus Register Map - Grouped by HART Device (2 of 3)

ĞǀŝĐĞϳ ĞǀŝĐĞϭϬ

ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ

ϰϴ Ws/ŶƚĞŐĞƌ ϳϮ Ws/ŶƚĞŐĞƌ

ϰϵ ^s/ŶƚĞŐĞƌ ϳϯ ^s/ŶƚĞŐĞƌ

ϱϬ ds/ŶƚĞŐĞƌ ϳϰ ds/ŶƚĞŐĞƌ

ϱϭ &s/ŶƚĞŐĞƌ ϳϱ &s/ŶƚĞŐĞƌ

ϱϮ ,Zd^ƚĂƚƵƐ ϳϲ ,Zd^ƚĂƚƵƐ

ϱϯ D^сWshKD>^с^shK

D

ϳϳ D^сWshKD>^с^shK

D

ϱϰ D^сdshKD>^с&shK

D

ϳϴ D^сdshKD>^с&shK

D

ϯϬϰϯϬ

ϱ

Ws&ůŽĂƚ ϯϮϴϯϮ

ϵ

Ws&ůŽĂƚ

ϯϬϲϯϬ

ϳ

^s&ůŽĂƚ ϯϯϬϯϯ

ϭ

^s&ůŽĂƚ

ϯϬϴϯϬ

ϵ

ds&ůŽĂƚ ϯϯϮϯϯϯ ds&ůŽĂƚ

ϯϭϬϯϭ

ϭ

&s&ůŽĂƚ ϯϯϰϯϯ

ϱ

&s&ůŽĂƚ

ĞǀŝĐĞϴ ĞǀŝĐĞƌϭϭ

ϱϲ Ws/ŶƚĞŐĞƌ ϴϬ Ws/ŶƚĞŐĞƌ

ϱϳ ^s/ŶƚĞŐĞƌ ϴϭ ^s/ŶƚĞŐĞƌ

ϱϴ ds/ŶƚĞŐĞƌ ϴϮ ds/ŶƚĞŐĞƌ

ϱϵ &s/ŶƚĞŐĞƌ ϴϯ &s/ŶƚĞŐĞƌ

ϲϬ ,Zd^ƚĂƚƵƐ ϴϰ ,Zd^ƚĂƚƵƐ

ϲϭ D^сWshKD>^с^shK

D

ϴϱ D^сWshKD>^с^shK

D

ϲϮ D^сdshKD>^с&shK

D

ϴϲ D^сdshKD>^с&shK

D

ϯϭϮϯϭϯ Ws&ůŽĂƚ ϯϯϲϯϯ

ϳ

Ws&ůŽĂƚ

ϯϭϰϯϭ

ϱ

^s&ůŽĂƚ ϯϯϴϯϯ

ϵ

^s&ůŽĂƚ

ϯϭϲϯϭ

ϳ

ds&ůŽĂƚ ϯϰϬϯϰ

ϭ

ds&ůŽĂƚ

ϯϭϴϯϭ

ϵ

&s&ůŽĂƚ ϯϰϮϯϰϯ &s&ůŽĂƚ

ĞǀŝĐĞϵ ĞǀŝĐĞϭϮ

ϲϰ Ws/ŶƚĞŐĞƌ ϴϴ Ws/ŶƚĞŐĞƌ

ϲϱ ^s/ŶƚĞŐĞƌ ϴϵ ^s/ŶƚĞŐĞƌ

ϲϲ ds/ŶƚĞŐĞƌ ϵϬ ds/ŶƚĞŐĞƌ

ϲϳ &s/ŶƚĞŐĞƌ ϵϭ &s/ŶƚĞŐĞƌ

ϲϴ ,Zd^ƚĂƚƵƐ ϵϮ ,Zd^ƚĂƚƵƐ

ϲϵ D^сWshKD>^с^shK

D

ϵϯ D^сWshKD>^с^shK

D

ϳϬ D^сdshKD>^с&shK

D

ϵϰ D^сdshKD>^с&shK

D

ϯϮϬϯϮ

ϭ

Ws&ůŽĂƚ ϯϰϰϯϰ

ϱ

Ws&ůŽĂƚ

ϯϮϮϯϮϯ ^s&ůŽĂƚ ϯϰϲϯϰ

ϳ

^s&ůŽĂƚ

ϯϮϰϯϮ

ϱ

ds&ůŽĂƚ ϯϰϴϯϰ

ϵ

ds&ůŽĂƚ

ϯϮϲϯϮ

ϳ

&s&ůŽĂƚ ϯϱϬϯϱ

ϭ

&s&ůŽĂƚ

Modbus Register Map - Grouped by HART Device (3 of 3)

ĞǀŝĐĞϭϯ ĞǀŝĐĞϭϱ

ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ ZĞŐŝƐƚĞƌ ĞƐĐƌŝƉƚŝŽŶ

ϵϲ Ws/ŶƚĞŐĞƌ ϭϭϮ Ws/ŶƚĞŐĞƌ

ϵϳ ^s/ŶƚĞŐĞƌ ϭϭϯ ^s/ŶƚĞŐĞƌ

ϵϴ ds/ŶƚĞŐĞƌ ϭϭϰ ds/ŶƚĞŐĞƌ

ϵϵ &s/ŶƚĞŐĞƌ ϭϭϱ &s/ŶƚĞŐĞƌ

ϭϬϬ ,Zd^ƚĂƚƵƐ ϭϭϲ ,Zd^ƚĂƚƵƐ

ϭϬϭ D^сWshKD>^с^shK

D

ϭϭϳ D^сWshKD>^с^shK

D

ϭϬϮ D^сdshKD>^с&shK

D

ϭϭϴ D^сdshKD>^с&shK

D

ϯϱϮϯϱϯ Ws&ůŽĂƚ ϯϲϴϯϲ

ϵ

Ws&ůŽĂƚ

ϯϱϰϯϱ

ϱ

^s&ůŽĂƚ ϯϳϬϯϳ

ϭ

^s&ůŽĂƚ

ϯϱϲϯϱ

ϳ

ds&ůŽĂƚ ϯϳϮϯϳϯ ds&ůŽĂƚ

ϯϱϴϯϱ

ϵ

&s&ůŽĂƚ ϯϳϰϯϳ

ϱ

&s&ůŽĂƚ

ĞǀŝĐĞϭϰ ĞǀŝĐĞϭϲ

ϭϬϰ Ws/ŶƚĞŐĞƌ ϭϮϬ Ws/ŶƚĞŐĞƌ

ϭϬϱ ^s/ŶƚĞŐĞƌ ϭϮϭ ^s/ŶƚĞŐĞƌ

ϭϬϲ ds/ŶƚĞŐĞƌ ϭϮϮ ds/ŶƚĞŐĞƌ

ϭϬϳ &s/ŶƚĞŐĞƌ ϭϮϯ &s/ŶƚĞŐĞƌ

ϭϬϴ ,Zd^ƚĂƚƵƐ ϭϮϰ ,Zd^ƚĂƚƵƐ

ϭϬϵ D^сWshKD>^с^shK

D

ϭϮϱ D^сWshKD>^с^shK

D

ϭϭϬ D^сdshKD>^с&shK

D

ϭϮϲ D^сdshKD>^с&shK

D

ϯϲϬϯϲ

ϭ

Ws&ůŽĂƚ ϯϳϲϯϳ

ϳ

Ws&ůŽĂƚ

ϯϲϮϯϲϯ ^s&ůŽĂƚ ϯϳϴϯϳ

ϵ

^s&ůŽĂƚ

ϯϲϰϯϲ

ϱ

ds&ůŽĂƚ ϯϴϬϯϴ

ϭ

ds&ůŽĂƚ

ϯϲϲϯϲ

ϳ

&s&ůŽĂƚ ϯϴϮϯϴϯ &s&ůŽĂƚ

Modbus Register Map - Grouped by Variable Type

ZĞǀϭ

ϭϭϮ

ϮϱϰϮϱϱ

,Zd Ws ^s ds &s ,Zd hKD hKD

ĞǀŝĐĞ /ŶƚĞŐĞƌ /ŶƚĞŐĞƌ /ŶƚĞŐĞƌ /ŶƚĞŐĞƌ ^ƚĂƚƵƐ Ws^s ds&s

ϭ Ϭ ϭϲ ϯϮ ϰϴ ϲϰ ϴϬ ϵϲ

Ϯ ϭ ϭϳ ϯϯ ϰϵ ϲϱ ϴϭ ϵϳ

ϯ Ϯ ϭϴ ϯϰ ϱϬ ϲϲ ϴϮ ϵϴ

ϰ ϯ ϭϵ ϯϱ ϱϭ ϲϳ ϴϯ ϵϵ

ϱ ϰ ϮϬ ϯϲ ϱϮ ϲϴ ϴϰ ϭϬϬ

ϲ ϱ Ϯϭ ϯϳ ϱϯ ϲϵ ϴϱ ϭϬϭ

ϳ ϲ ϮϮ ϯϴ ϱϰ ϳϬ ϴϲ ϭϬϮ

ϴ ϳ Ϯϯ ϯϵ ϱϱ ϳϭ ϴϳ ϭϬϯ

ϵ ϴ Ϯϰ ϰϬ ϱϲ ϳϮ ϴϴ ϭϬϰ

ϭϬ ϵ Ϯϱ ϰϭ ϱϳ ϳϯ ϴϵ ϭϬϱ

ϭϭ ϭϬ Ϯϲ ϰϮ ϱϴ ϳϰ ϵϬ ϭϬϲ

ϭϮ ϭϭ Ϯϳ ϰϯ ϱϵ ϳϱ ϵϭ ϭϬϳ

ϭϯ ϭϮ Ϯϴ ϰϰ ϲϬ ϳϲ ϵϮ ϭϬϴ

ϭϰ ϭϯ Ϯϵ ϰϱ ϲϭ ϳϳ ϵϯ ϭϬϵ

ϭϱ ϭϰ ϯϬ ϰϲ ϲϮ ϳϴ ϵϰ ϭϭϬ

ϭϲ ϭϱ ϯϭ ϰϳ ϲϯ ϳϵ ϵϱ ϭϭϭ

,Zd Ws ^s ds Ys

ĞǀŝĐĞ &ůŽĂƚ &ůŽĂƚ &ůŽĂƚ &ůŽĂƚ

ϭ ϮϱϲϮϱϳ ϮϴϴϮϴϵ ϯϮϬϯϮϭ ϯϱϮϯϱϯ

Ϯ ϮϱϴϮϱϵ ϮϵϬϮϵϭ ϯϮϮϯϮϯ ϯϱϰϯϱϱ

ϯ ϮϲϬϮϲϭ ϮϵϮϮϵϯ ϯϮϰϯϮϱ ϯϱϲϯϱϳ

ϰ ϮϲϮϮϲϯ ϮϵϰϮϵϱ ϯϮϲϯϮϳ ϯϱϴϯϱϵ

ϱ ϮϲϰϮϲϱ ϮϵϲϮϵϳ ϯϮϴϯϮϵ ϯϲϬϯϲϭ

ϲ ϮϲϲϮϲϳ ϮϵϴϮϵϵ ϯϯϬϯϯϭ ϯϲϮϯϲϯ

ϳ ϮϲϴϮϲϵ ϯϬϬϯϬϭ ϯϯϮϯϯϯ ϯϲϰϯϲϱ

ϴ ϮϳϬϮϳϭ ϯϬϮϯϬϯ ϯϯϰϯϯϱ ϯϲϲϯϲϳ

ϵ ϮϳϮϮϳϯ ϯϬϰϯϬϱ ϯϯϲϯϯϳ ϯϲϴϯϲϵ

ϭϬ ϮϳϰϮϳϱ ϯϬϲϯϬϳ ϯϯϴϯϯϵ ϯϳϬϯϳϭ

ϭϭ ϮϳϲϮϳϳ ϯϬϴϯϬϵ ϯϰϬϯϰϭ ϯϳϮϯϳϯ

ϭϮ ϮϳϴϮϳϵ ϯϭϬϯϭϭ ϯϰϮϯϰϯ ϯϳϰϯϳϱ

ϭϯ ϮϴϬϮϴϭ ϯϭϮϯϭϯ ϯϰϰϯϰϱ ϯϳϲϯϳϳ

ϭϰ ϮϴϮϮϴϯ ϯϭϰϯϭϱ ϯϰϲϯϰϳ ϯϳϴϯϳϵ

ϭϱ ϮϴϰϮϴϱ ϯϭϲϯϭϳ ϯϰϴϯϰϵ ϯϴϬϯϴϭ

ϭϲ ϮϴϲϮϴϳ ϯϭϴϯϭϵ ϯϱϬϯϱϭ ϯϴϮϯϴϯ

>ŽŽƉƵƌƌĞŶƚͲ/ŶƚĞŐĞƌ

>ŽŽƉƵƌƌĞŶƚͲ&ůŽĂƚ

ϯϮͲďŝƚ&ůŽĂƚZĞŐŝƐƚĞƌƐ

ϭϲͲďŝƚ^ŝŐŶĞĚZĞŐŝƐƚĞƌƐ ϭϲͲďŝƚhŶƐŝŐŶĞĚ

Enclosure

Polycarbonate plastic with Stainless Steel Cover

Weight ..................................................................................... 5 ounces

Mounting ................................................................ 35mm DIN Rail Clip

RS-232 Serial Port

Connector ............................................................9-Pin Female D-Shell

Receive Data .................................................................................Pin 2

Transmit Data .................................................................................Pin 3

Data Terminal Ready (DTR) ...........................................................Pin 4

Ground............................................................................................Pin 5

HART

Termination ............................ Pluggable Screw Terminals, 26-12 AWG

Connection Method ............... Transformer Isolated, Capacitor Coupled

DC Loop Voltage ..................................................................50Vdc Max

Demodulation Jitter .................................................12% of 1 bit Typical

Carrier Detect Threshold ................................................ 100mV Typical

Leakage to Process Loop ....................................................±10μA Max

Status LED

Green ...........................................................Transmitting HART packet

Red ..................................................................Receiving HART packet

Environmental

Operating Temperature ......................... -30ºC to 60ºC (-22ºF to 140ºF)

Storage Temperature ............................ -40ºC to 85ºC (-40ºF to 185ºF)

Humidity ......................................................0 to 95% (non-condensing)

Specifications

PP

PP

PP

+$57/223

:,5(6&5(:7(50,1$/6

PP

PP',15$,/&/,3

67$786/('

563257

Modbus RTU

Baud Rates ....................................................... 1200, 2400,4800, 9600

114400, 19200, 38400, 57600

Parity .......................................................................... None, Odd, Even

Floating point byte order .......................... AD-CD or CD-AB (swapped)

Number of polled HART devices .................................................1 to 16

Variables per polled HART device ............................(4) PV, SV, TV, FV

Supported Modbus Commands .................................................3, 6, 16

Default Settings

RS-232 ............................................................1200, Odd Parity, 1 Stop

Modbus Address ..................................................................................1

Fill Modbus Registers ..............................................................Disabled

Conformity in accordance with Part 2, and Part 15, Subparts A and B of

the Federal Communications Rules and Regulations, and ICES-003 of the

Industry Canada standards.

This device complies with part 15 of the FCC rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful interfer-

ence, and (2) this device must accept any interference received, including

interference that may cause undesired operation. Changes or modifications

not expressly approved by Microflex could void the user’s authority to oper-

ate this equipment.

Emissions EN55022: 1998

Electrostatic Discharge EN61000-4-2: 1995, A1: 1998, A2: 2001

Radiated Immunity EN 61000-4-3: 2002

Safety Compliance EN 60950-1: 2002

This device does not have protection from over-voltages which may exist

on RS-232 ports of computers and relies on the protection existing in a host

computer.

This device is not intended for connection to the phone line through the

appropriate converters and shall not be connected to telecommunication

lines because it has no protection against over-voltages which may exist in

these lines.

The user shall ensure the protection of the operator from access to areas

with hazardous voltages or hazardous energy in their equipment.

The user shall ensure that the connection port of the field device and the

modem is separated at least by basic insulation from any primary circuit

existing in the field device.

Safety Considerations

Limited Warranty

Microfl ex, LLC warrants this unit against defects in materials and workmanship for a

period of one year from the date of shipment. Microfl ex, LLC will, at its option, repair or

replace equipment that proves to be defective during the warranty period. This warranty

includes parts and labor.

A Return Materials Authorization (RMA) number must be obtained from the factory

and clearly marked on the outside of the package before equipment will be accepted for

warranty work.

Microfl ex, LLC believes that the information in this manual is accurate. In the event that

a typographical or technical error exist, Microfl ex, LLC reserves the right to make changes

without prior notice to holders of this edition. The reader should consult Microfl ex, LLC

if any errors are suspected. In no event should Microfl ex, LLC be liable for any damages

arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, MICROFLEX, LLC MAKES NO WARRANTIES OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S

RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE

PART OF MICROFLEX SHALL BE LIMITED TO THE AMOUNT THERETOFORE

PAID BY THE CUSTOMER. MICROFLEX, LLC WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS,

OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE

POSSIBILITIES THEREOF. This limitation of the liability of Microfl ex, LLC will apply

regardless of the form of action, whether in contract or tort, including negligence. Any

action against Microfl ex, LLC must be brought within one year after the cause of action

accrues. The warranty provided herein does not cover damages, defects, malfunctions, or

service failures caused by owners failure to follow Microfl ex, LLC’s installation, operation,

or maintenance instructions; owners modifi cation of the product; owner’s abuse, misuse, or

negligent acts; and power failure or surges, fi re, fl ood, accident, actions of third parties, or

other events outside reasonable control.

Microflex, LLC

35900 Royal Road

Pattison, Texas 77423

USA

The HART protocol is supported by the HART Communications Foundation in Austin Texas,

www.hartcomm.org. HART is a registered trademark of the HART Communications Foundation.

Phone 281-855-9639

Fax 832-422-4391

www.microflx.com

Other manuals for MicroLink-HM 101-0029

1

Table of contents

Other Microflex Modem manuals

Popular Modem manuals by other brands

ZyXEL Communications

ZyXEL Communications Omni 56K quick start guide

2N Telekomunikace

2N Telekomunikace 2N SmartCOM quick guide

Cradlepoint

Cradlepoint MC400 quick start guide

NXP Semiconductors

NXP Semiconductors TDA5051A Product data sheet

D-Link

D-Link DSL-500B user manual

Verizon

Verizon MiFi U620L user guide