MSR-H01 Hexapod Assembly Guide

Updated: 18-Aug-2008

Read first: Safety First!

Read first: Servo Preparation Guide

Properly identify all screws, washers, stand-offs and

hardware etc. and gather together those necessary for

each step. Carefully read and study the drawings prior to

each assembly.

Print this 6 page document with the following settings:

Paper A4 or Letter, Margins 0.4", Scale 66%. tested in

IE7 & Firefox 3.0.1

Index

Coxa Bottom Plate Assembly MSR-H01_ASSY01

Coxa Top Plate Assembly MSR-H01_ASSY02

Coxa Top Plate & Servo Assembly MSR-H01_ASSY03

Coxa & Femur Servo Assembly MSR-H01-ASSY04

Tibia Plate & Servo Assembly MSR-H01-ASSY05

Right Leg Finish Assembly MSR-H01-ASSY06

Left Leg Assembly MSR-H01-ASSY07

Lower Body Assembly MSR-H01-ASSY08

Upper Body Assembly MSR-H01-ASSY09

p.Brain-SMB Circuit Board Installation

Leg & Body Attachment Assembly MSR-H01-ASSY10

Lower Body Attachment Assembly MSR-H01-ASSY11

Appendix A - Assembly Hardware

Appendix B - Aluminum Leg Parts

Appendix C - Aluminum Body Parts

MSR-H01 Right Leg Assembly

Coxa Bottom Plate

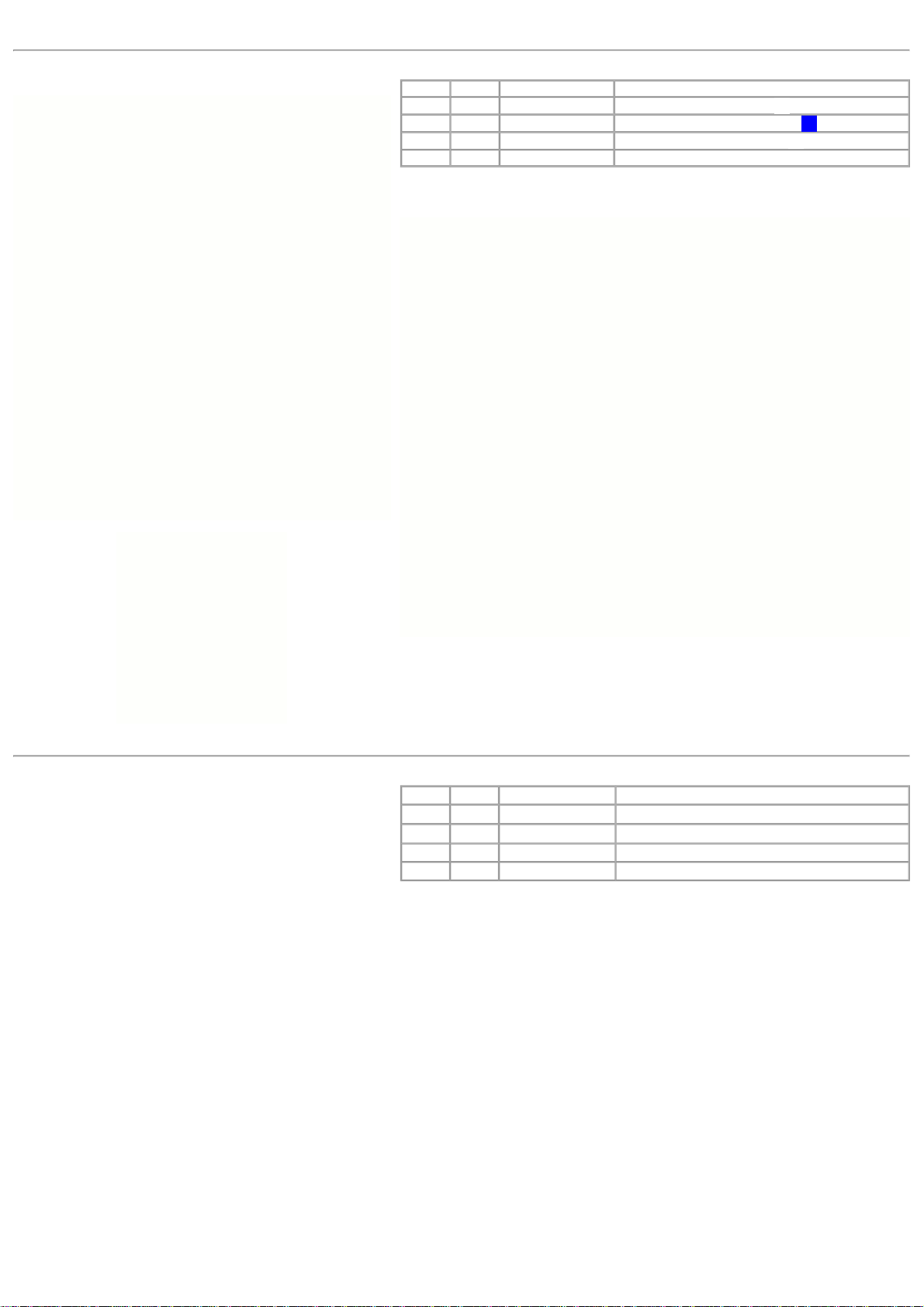

Assembly MSR-H01_ASSY01 Parts List

ITEM QTY PART NUMBER DESCRIPTION

1 1 MSR-H01-COXA02 MSR-H01 Coxa Bottom Plate

2 1 MSR-P004 M3 x 16 Hexagon Socket Button Head

3 1 MSR-P013 M3 Hex Full Nut

4 1 MSR-P005 9 x 6mm Round Zinc Plated Brass Spacer

Assemble as per diagram, pay attention to coxa bottom plate orientation.

Coxa Top Plate

Assembly MSR-H01_ASSY02 Parts List

ITEM QTY PART NUMBER DESCRIPTION

1 1 MSR-H01-COXA01 MSR-H01 Coxa Top Plate

2 2 MSR-P001 M3 x 40mm F-F Steel Hexagonal Spacer

3 2 MSR-P007 M3 x 10 Hexagon Socket Button Head

4 2 MSR-P014 M3 Plain Washer

Assemble as per diagram, pay attention of coxa top plate orientation.

When using HS-645MG servos for the femur joint, the M3 washer part (4) must be

fitted. If using 40mm standard case size servos such as HS-985MG, do not fit part

(4).