4.1 STORAGE

It is important to understand that when the keg of wine is delivered it must be properly stored.

• White wine must be stored inside the cooler as soon as possible, as it may take as many as

24 hours for the temperature to be reduced to the desirable range.

• It is recommended to store both reds and whites at room temperature (approximately 72°F.)

• Wine kegs stored in a walk-in cooler (approximately 38°F) may dramatically effect the time it

takes to reach the desired serving temperatures.

• Allow 24 hours for kegs to reach the desired serving temperature (45°F for whites and 55°F

for reds).

• Just like a bottle of wine, the best temperature to store white or red wines is between

45-60°F: neither too cold, nor too warm. Remember, wines are both cold- and heat-stabilized.

Most white wines are cold-stabilized to approximately 36°F. If the wine gets any colder for

any length of time, the risk arises that the naturally occurring “tartrates” may drop out of

solution and appear as “sediment” in the bottom of a wine glass.

4.2 SERVING

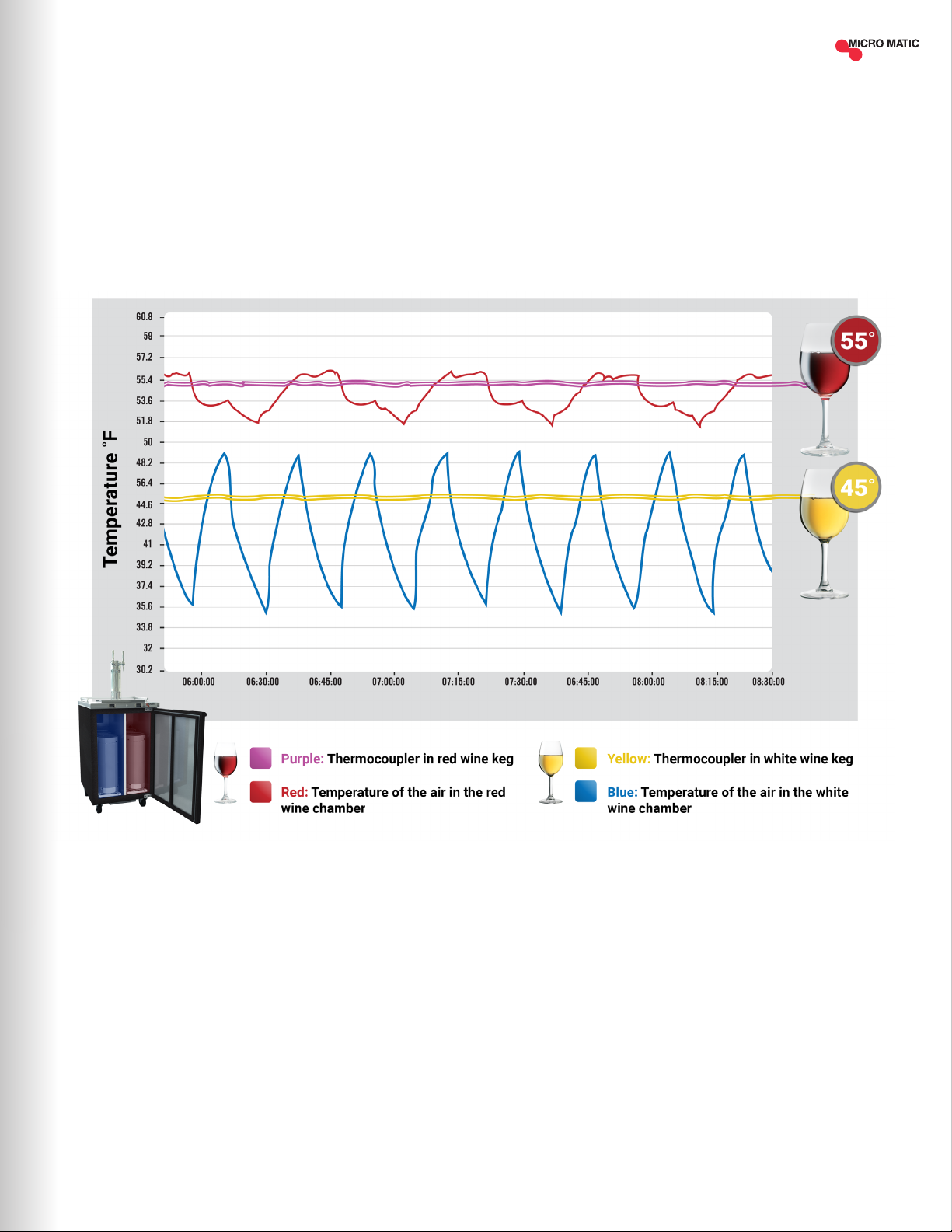

Pro-Line Wine units are designed to maintain your wine keg temperature within the vintners

recommended temperature serving range:

• White wines: 45°F (range: 40-45°F)

• Red wines: 55°F (range: 55-60°F)

4KEG

TEMPERATURE

IMPORTANT NOTICE

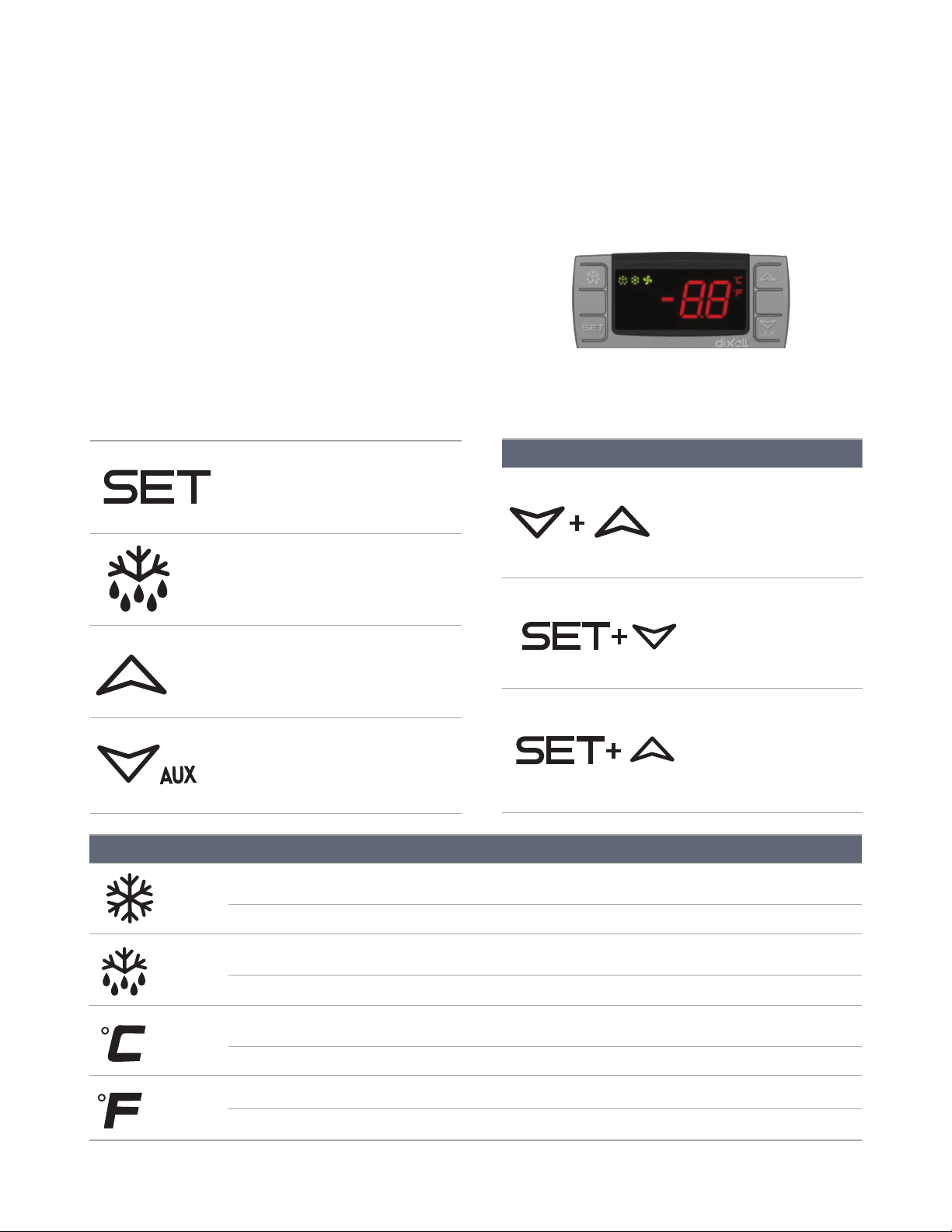

The thermostats on the Pro-Line Wine units have been factory preset at approximately 45°F

for white wine dispensing and approximately 55°F for red wine dispensing. Any change to the

factory settings will affect performance of unit and void the warranty.

Factory testing has produced results that show consistent wine (liquid) temperatures are

being maintained by the unit. The Pro-Line Wine unit operates like any refrigeration unit; the

compressor is engaged when the interior air temperature reaches the pre-determined maximum

level, cooling the unit until it reaches the pre-determined minimum level. The goal is consistent

wine (liquid) temperature inside the keg. Thermostat displays are reading the air temperature

setting and may be dramatically different than the keg (liquid) temperatures. To verify, measure

the temperature of the wine dispensed in the glass.

|8 PRO-LINE WINE INSTALLATION, USE AND MAINTENANCE GUIDE