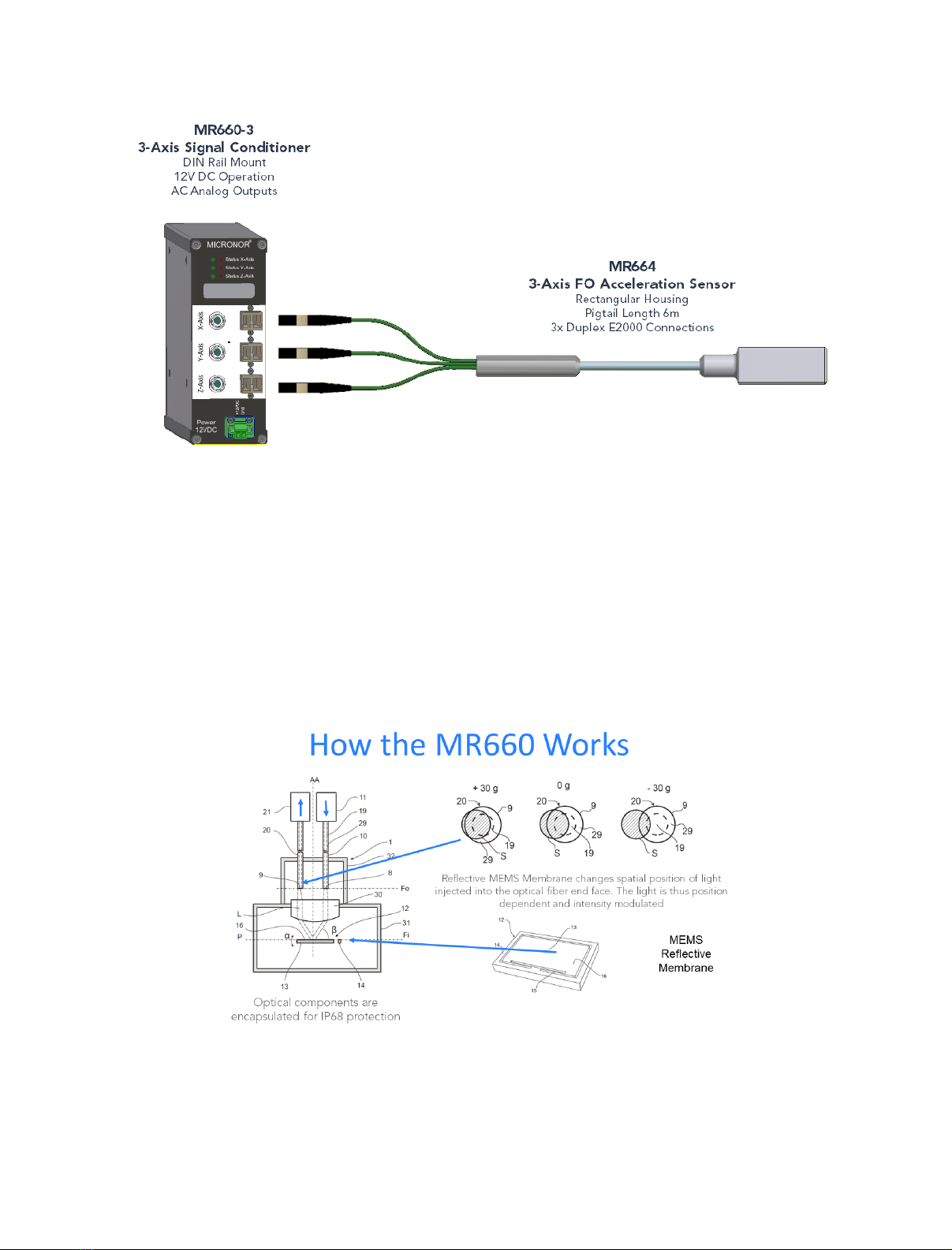

MICRONOR SENSORS MR660 Series FO Acceleration Sensor System

Page 3 of 21

Table of Contents

Revision History ...........................................................................................................2

1. Product Description ............................................................................................. 5

1.1 MR660 Fiber Optic Acceleration Sensor Product Family................................ 5

1.2 How the MR660 FO Acceleration Sensor Works ............................................ 7

2. Initial Preparation .................................................................................................9

2.1 Unpacking and Inspection ............................................................................. 9

2.2 Damage in Shipment ..................................................................................... 9

2.3 Standard Contents......................................................................................... 9

2.4 Warranty Information ...................................................................................10

3. Installation and Operation.................................................................................. 11

3.1 Mounting the Sensor Unit............................................................................ 11

3.2 Mounting Signal Conditioner Module.......................................................... 12

3.3 Sensor Optical Connection to the Signal Condition..................................... 14

3.4 Electrical Connections to Signal Conditioner............................................... 14

4. Specifications ..................................................................................................... 15

4.1 1-Axis System (MR660-1 Signal Conditioner + MR661/MR662 Sensor)........ 15

4.2 2-Axis System (MR660-2 Signal Conditioner + MR663 Sensor) .................... 16

4.3 3-Axis System (MR660-3 Signal Conditioner + MR664 Sensor) .................... 17

4.4 Response Curves ......................................................................................... 18

5. Mechanical Reference Drawings......................................................................... 19

5.1 MR660-1 1-Axis Signal Conditioner ............................................................. 19

5.2 MR660-2 2-Axis Signal Conditioner ............................................................. 19

5.3 MR660-3 3-Axis Signal Conditioner ............................................................. 19

5.4 MR661 1-Axis Round Sensor........................................................................ 20

5.5 MR662 1-Axis Rectangular Sensor ............................................................... 20

5.6 MR663 2-Axis Rectangular Sensor ............................................................... 21

5.7 MR664 3-Axis Rectangular Sensor ............................................................... 21