Table of contents

1. afety instructions.......................................................................4

2. Application.................................................................................6

3. Features.....................................................................................6

4. Technical Data............................................................................7

4.1 General.................................................................................7

4.2 Electrical Data........................................................................7

4.3 Output- ignals.......................................................................7

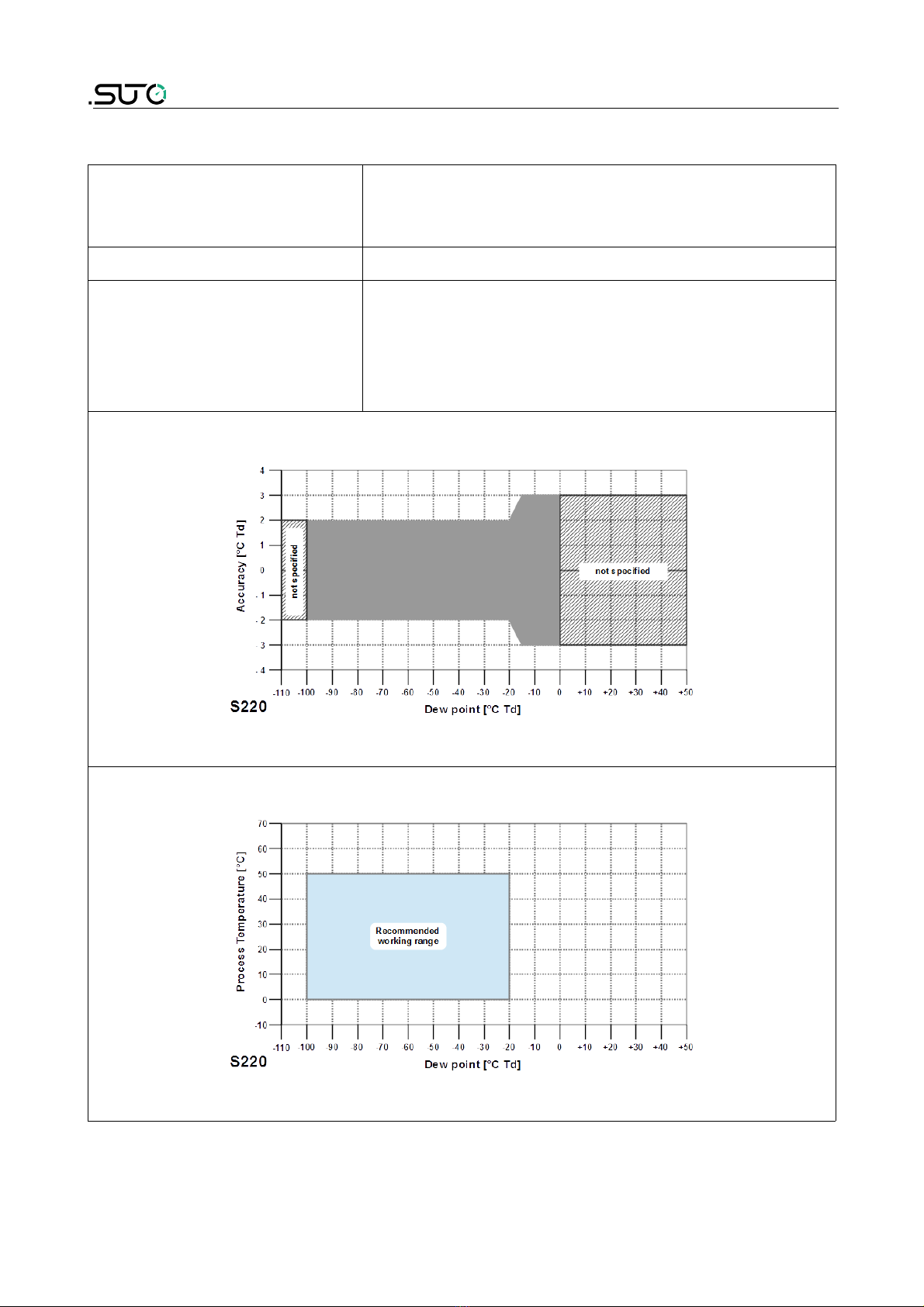

4.4 Accuracy ..............................................................................8

5. Dimensional drawing....................................................................9

6. Determination of the installation point..........................................10

7. Installation ..............................................................................10

7.1 Installation Requirements......................................................10

7.2 Installation Procedure ...........................................................11

7.3 Electrical connection ............................................................12

8. ignal outputs...........................................................................13

8.1 Analog output ......................................................................13

8.2 Modbus output ....................................................................14

9. Optional extra accessories..........................................................15

9.1 Measuring chambers ............................................................15

9.2 ervice kit...........................................................................15

10. Calibration..............................................................................16

11. Maintenance............................................................................16

12. Disposal or waste.....................................................................16

13. Warranty................................................................................17

Appendix A - Modbus communication example..................................18

Appendix B - LRC and CRC calculation..............................................20

S220 3