3

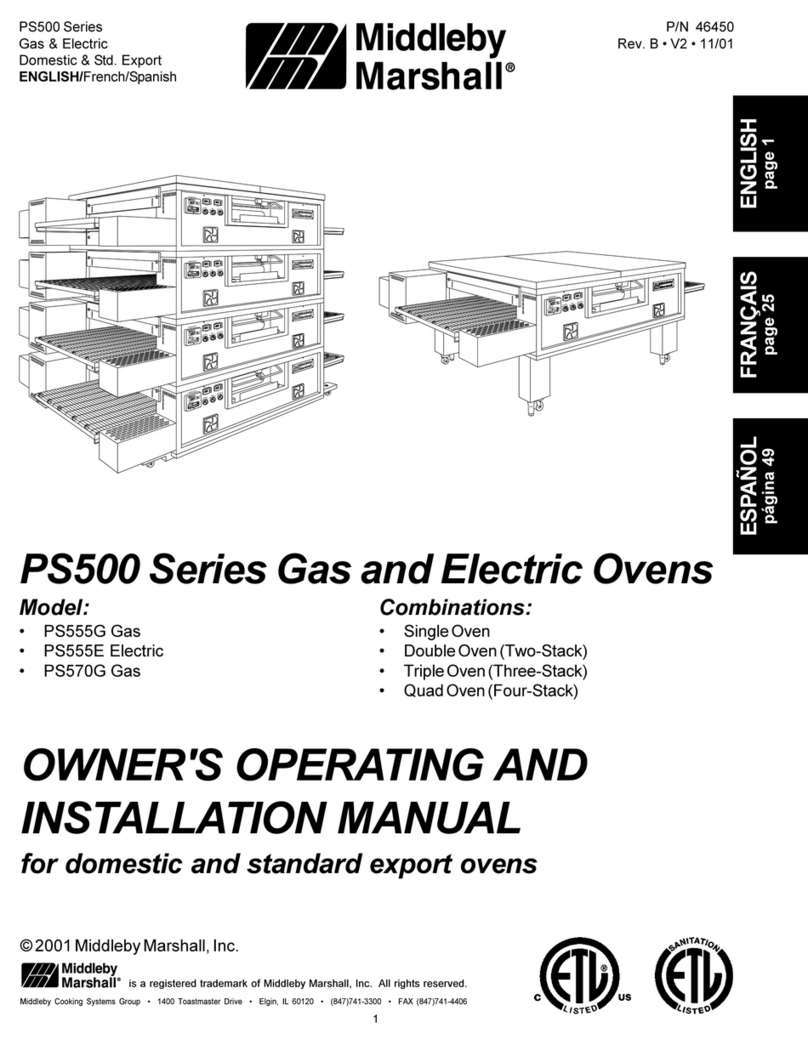

ENGLISH

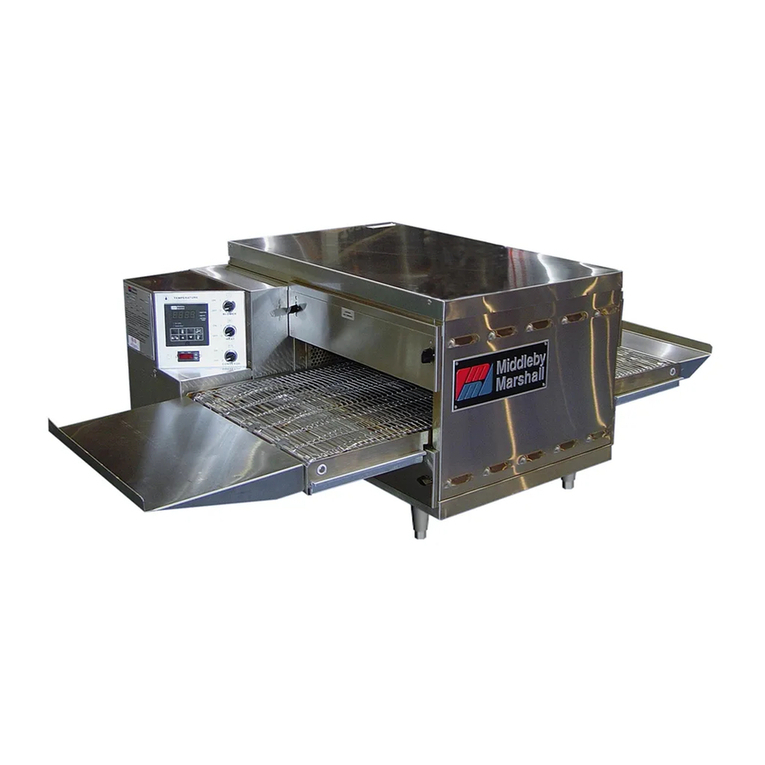

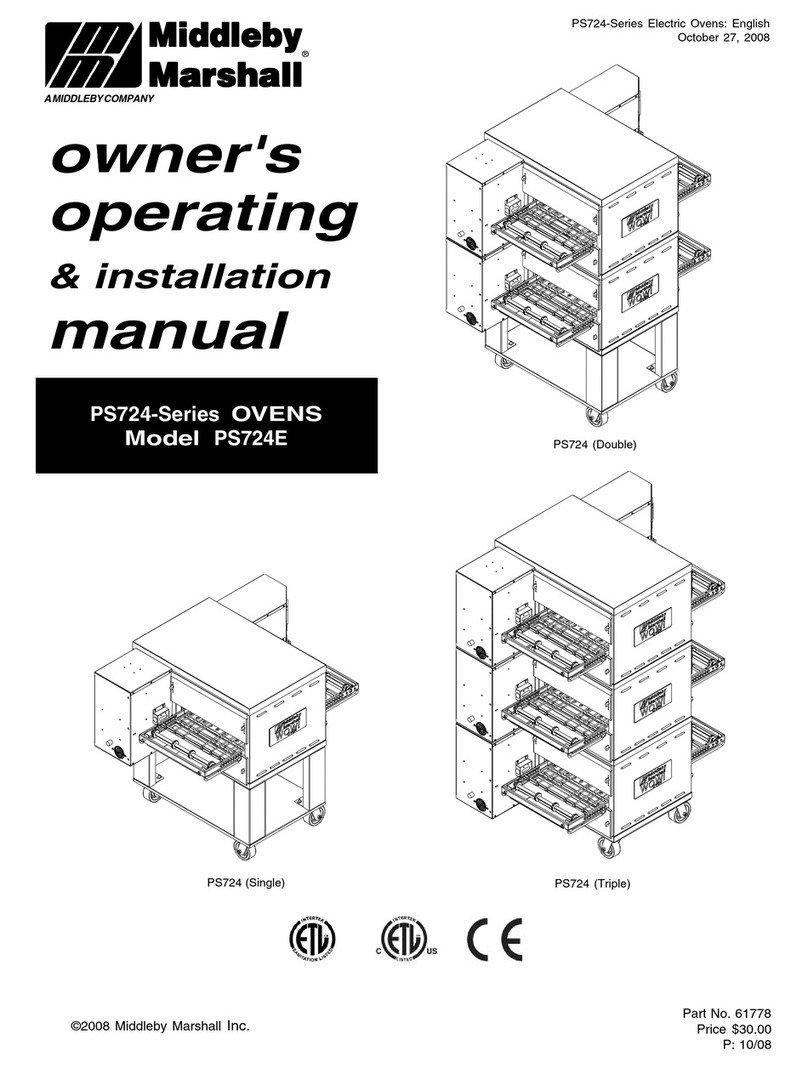

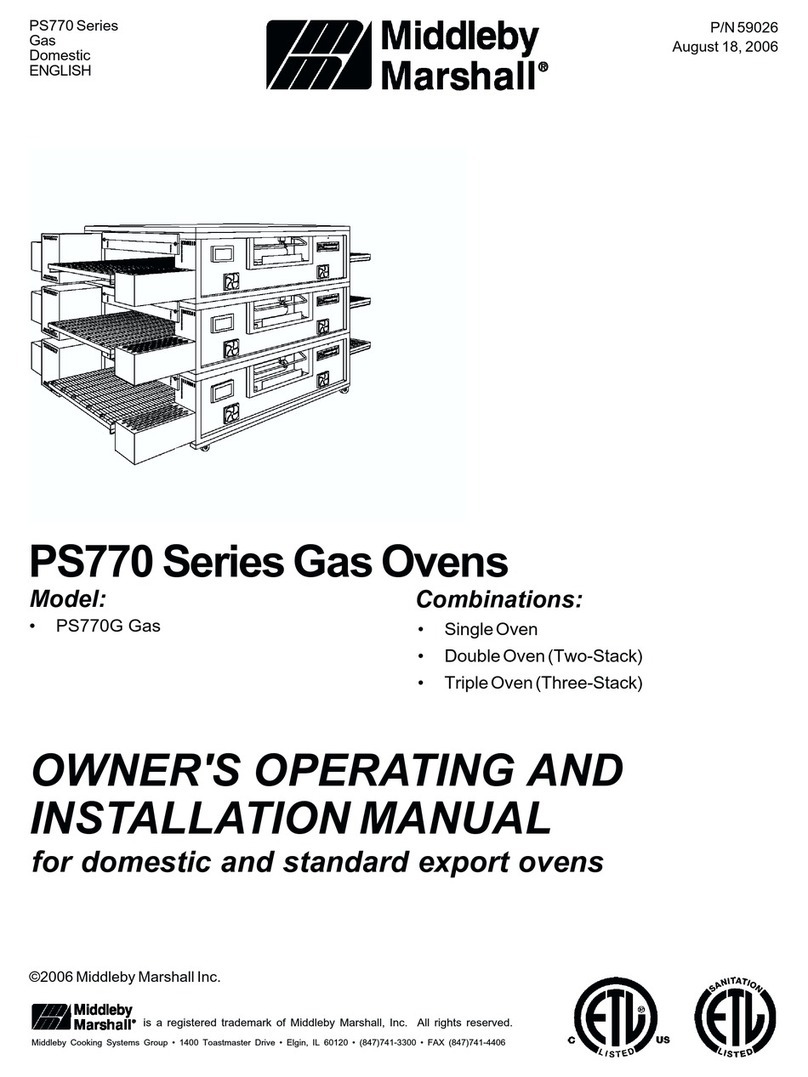

SECTION 1 - DESCRIPTION ................................................... 4

I. OVEN USES ............................................................. 4

II. OVEN COMPONENTS ............................................. 4

A. Window ............................................................. 4

B. Conveyor Exit Tray ............................................ 4

C. Eyebrows .......................................................... 4

. End Plugs ......................................................... 4

E. Control Panel .................................................... 4

F. Machinery Compartment Access Panel .......... 4

G. Serial Plate ....................................................... 4

H. Conveyor rive Motor ....................................... 4

I. Crumb Pans ..................................................... 4

J. Conveyor ........................................................... 4

K. Gas Burner or Heating Elements .................... 4

L. Blowers............................................................. 4

M. Air Fingers ........................................................ 4

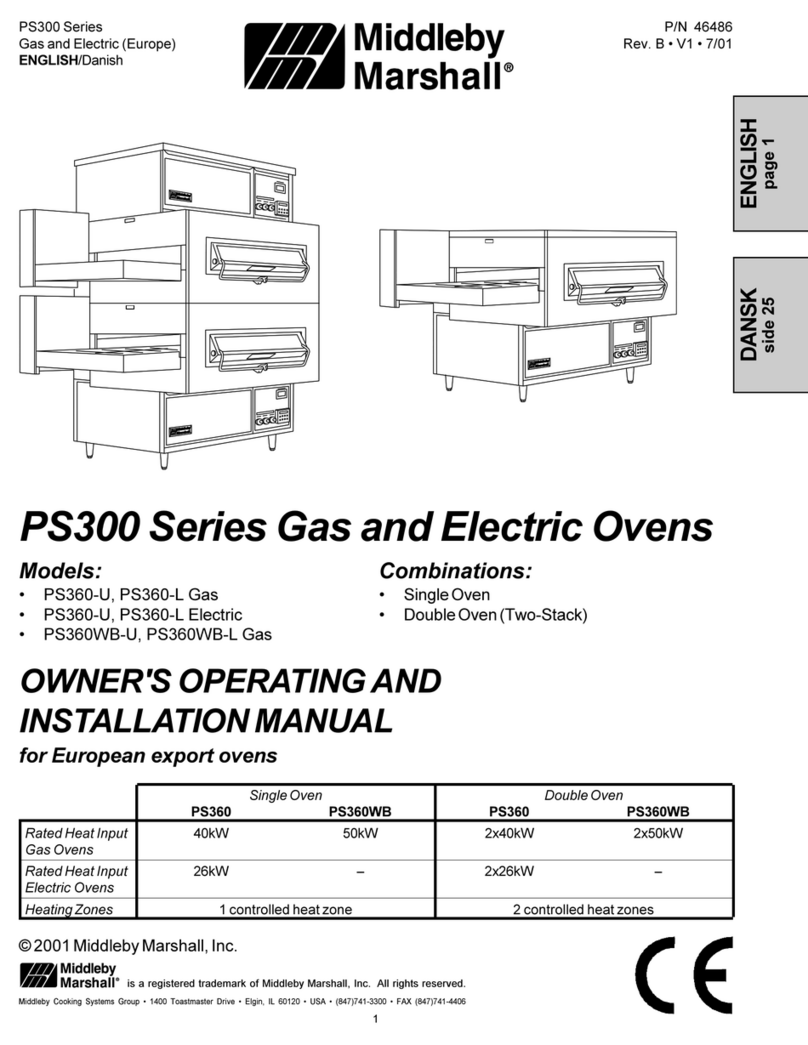

III. OVEN SPECIFICATIONS ......................................... 4

A. imensions ...................................................... 4

B. General Specifications ..................................... 4

C. Electrical Specifications - Electric Ovens ........ 5

. Electrical Specifications - Gas Ovens ............. 5

E. Gas Orifice and Pressure Specifications ........ 5

SECTION 2 - INSTALLATION .................................................. 6

I. INSTALLATION KIT .................................................. 7

II. BASE PA KIT.......................................................... 7

III. VENTILATION SYSTEM ........................................... 8

A. Requirements .................................................. 8

B. Recommendations .......................................... 8

C. Other Ventilation Concerns .............................. 8

IV. ASSEMBLY ............................................................... 9

A. Top Panel and Base Pad Assembly ............... 9

B. Stacking ........................................................... 10

C. Restraint Cable Installation ............................ 10

. Conveyor Installation ....................................... 11

TABLE OF CONTENTS

V. FINAL ASSEMBLY ................................................... 12

VI. ELECTRICAL SUPPLY ........................................... 13

A. Additional Information - Gas Ovens ................ 13

B. Additional Information - Electric Ovens .......... 13

C. Connection ...................................................... 13

VII. GAS SUPPLY .......................................................... 13

A. Gas Utility Rough-In Recommendations ....... 14

B. Connection ...................................................... 14

C. Gas Conversion .............................................. 14

SECTION 3 - OPERATION ..................................................... 15

I. LOCATION AN ESCRIPTION OF CONTROLS . 15

A. BLOWER ( ) Switch ...................................... 15

B. CONVEYOR ( ) Switch ............................... 15

C. Conveyor Speed Controller ............................. 15

. igital Temperature Controller ....................... 15

E. Machinery Cpt. Access Panel Safety Switch .. 15

II. NORMAL OPERATION, STEP-BY-STEP ................ 16

A. aily Startup Procedure .................................. 16

B. aily Shutdown Procedure ............................. 17

III. QUICK REFERENCE: IGITAL TEMPERATURE

CONTROLLERS ..................................................... 18

IV. QUICK REFERENCE: TROUBLESHOOTING ....... 20

SECTION 4 - MAINTENANCE ................................................. 21

I. MAINTENANCE - AILY .......................................... 21

II. MAINTENANCE - MONTHLY .................................. 22

III. MAINTENANCE - EVERY 3 MONTHS .................... 22

IV. MAINTENANCE - EVERY 6 MONTHS .................... 24

V. KEY SPARE PARTS KIT ......................................... 24

SECTION 5 - ELECTRICAL WIRING DIAGRAMS ................... 25

I. WIRING IAGRAM, PS536 GAS OVEN, ................. 25

208/230V, 60 Hz, 1 Ph

II. WIRING IAGRAM, PS536 ELECTRIC, ................. 26

208/230V, 60 Hz, 3 Ph

III. WIRING IAGRAM, PS536 ELECTRIC OVEN, ...... 27

380V, 50 Hz, 3 Ph

page page