Middleby CTX G-26 Operation manual

OWNER'S

OPERATING

&

installation

manual

G-26

CONVEYOR

OVEN

CTO®

•

1400

Toastmaster

A

Middle

by

Company

®

<§•

Drive

•

Elgin,

IL

60120

•

(708)741-3300

•

FAX

(708)741-0015

Middleby

Corporation

24

Hour

Sorv,ce

Hotline

1-800-2384)444

*

K

CTX®

OVEN

LIMITED

WARRANTY

The

seller

warrants

equipment

manufactured

by

it

to

be

free

from

defects

in

material

and

workmanship

for

which

it

is

responsible.

The

Seller's

obligation

under

this

warranty

shall

be

limited

to

replacing

or

repairing

at

Seller's

option,

without

charge,

F.O.B.

Seller's

factory,

any

part

found

to

be

defective

and

any

labor

and

material

expense

incurred

by

Seller

in

repairing

or

replacing

such

part,

such

warranty

to

be

limited

to

a

period

of

one

(1)

year

from

date

of

original

installation

or

eighteen

(18)

months

from

date

of

shipment

from

Seller's

factory,

whichever

is

earlier,

provided

that

terms

of

payment

have

been

fully

met.

All

labor

shall

be

performed

during

regular

working

hours.

Overtime

premium

will

be

charged

to

the

Buyer.

THIS

WARRANTY

IS

NOT

VALID

UNLESS

EQUIPMENT

IS

STARTED

AND

DEMONSTRATED

UNDER

THE

SUPERVISION

OF

A

FACTORY

CERTIFIED

INSTALLER.

Normal

maintenance

functions,

including

lubrication,

thermostat

calibration,

and

replacement

of

light

bulbs,

fuses

and

indicating

lights,

are

not

covered

by

warranty.

Any

repairs

or

replacements

of

defective

parts

shall

be

performed

by

Seller's

authorized

service

personnel.

Seller

shall

not

be

responsible

for

any

costs

incurred

if

the

work

is

performed

by

other

than

Seller's

authorized

service

personnel.

When

returning

any

part

underwarranty,

the

part

must

be

intact

and

complete,

without

evidence

of

misuse

or

abuse,

freight

prepaid.

This

warranty

is

made

to

the

original

purchaser/user

and

is

not

transferable.

Seller

shall

not

be

liable

for

consequential

damages

of

any

kind

which

occur

during

the

course

of

installation

of

equipment,

or

which

result

from

the

use

or

misuse

by

Buyer,

its

employees

or

others

of

the

equipment

supplied

hereunder,

and

Buyer's

sole

and

exclusive

remedy

against

Seller

for

any

breach

of

the

foregoing

warranty

or

otherwise

shall

be

for

the

repair

or

replacement

of

the

equipment

or

parts

thereof

affected

by

such

breach.

The

foregoing

warranty

shall

be

valid

and

binding

upon

Seiler

if

and

only

if

Buyer

loads,

operates

and

maintains

the

equipment

supplied

hereunder

in

accordance

with

the

instruction

manual

provided

to

Buyer.

Seller

does

not

guarantee

the

process

of

manufacture

by

Buyer

or

the

quality

of

product

to

be

produced

by

the

equipment

supplied

hereunder

and

Seller

shall

not

be

liable

for

any

prospective

or

lost

profits

of

Buyer.

THE

FOREGOING

WARRANTY

IS

EXCLUSIVE

AND

IN

LIEU

OF

ALL

OTHER

EXPRESS

AND

IMPLIED

WARRANTIES

WHATSOEVER.

SPECIFICALLY

THERE

ARE-NO

IMPLIED

WARRANTIES

OF

MERCHANTABILITY

OR

OF

FITNESS

FOR

A

PARTICULAR

PURPOSE.

The

foregoing

shall

be

Seller's

sole

and

exclusive

obligation

and

Buyer's

sole

and

exclusive

remedy

for

any

action,

whether

in

breach

of

contract

or

negligence.

In

no

event

shall

seller

be

liable

for

a

sum

in

excess

of

the

purchase

price

of

the

item.

©1993

CTX

CTX®

•

1400

Toastmaster

Dr.

•

Elgin,

IL

60120-9272

•

(708)

741-3300

•

FAX

(708)

741-0015

i

retain

this

manual

for

future

reference

be

™

S

"

»

^SSSSS

FOR

YOUR

SAFETY

■

-

S

iSa,

NOTICE

Using

any

parts

other

than

[

genuine

CTX

factory

manufactured

parts

relieves

the

manufacturer

of

all

liability.

notice

#=sss.

the

buyer

to

corresponding

changes

im

provements,

additions

or

replacement

previously

purchased

equipment.

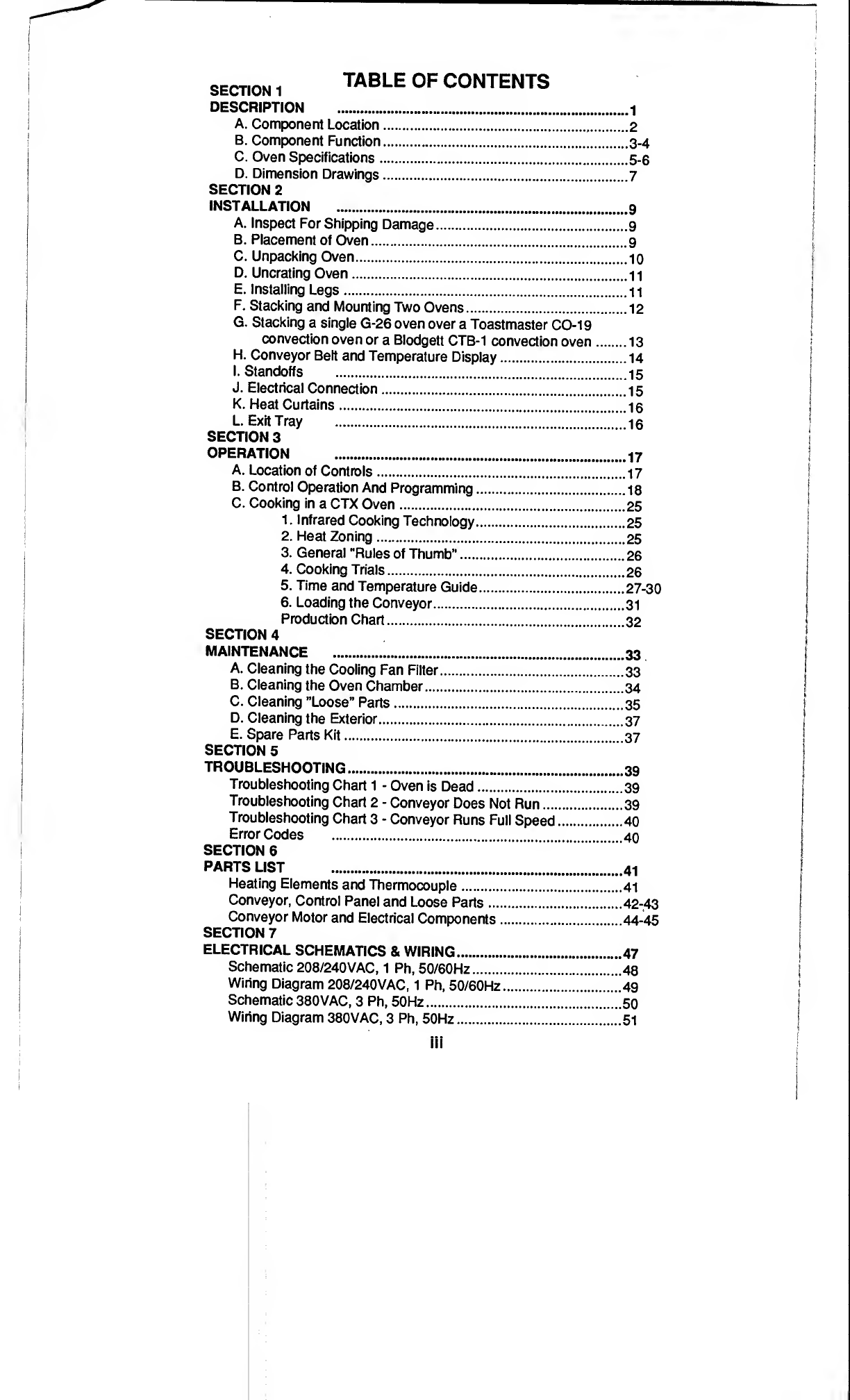

TABLE

OF

CONTENTS

SECTION

1

DESCRIPTION

.

1

A.

Component

Location.2

B.

Component

Function.

3

.4

C.

Oven

Specifications.

5

-6

D.

Dimension

Drawings.

7

SECTION

2

INSTALLATION

.

9

A.

Inspect

For

Shipping

Damage.

9

B.

Placement

of

Oven.

9

C.

Unpacking

Oven.

1

0

D.

Uncrating

Oven.

1

1

E.

Installing

Legs.

1

1

F.

Stacking

and

Mounting

Two

Ovens.

1

2

G.

Stacking

a

single

G-26

oven

over

a

Toastmaster

CO-19

convection

oven

or

a

Blodgett

CTB-1

convection

oven.13

H.

Conveyor

Belt

and

Temperature

Display.

1

4

I.

Standoffs

.

1

5

J.

Electrical

Connection.

1

5

K.

Heat

Curtains.

1

6

L.

Exit

Tray

.

16

SECTION

3

OPERATION

.

1

7

A.

Location

of

Controls.

1

7

B.

Control

Operation

And

Programming.18

C.

Cooking

in

a

CTX

Oven.25

1

.

Infrared

Cooking

Technology.25

2.

Heat

Zoning.25

3.

General

"Rules

of

Thumb".26

4.

Cooking

Trials.26

5.

Time

and

Temperature

Guide.27-30

6

.

Loading

the

Conveyor.

3

1

Production

Chart.

32

SECTION

4

MAINTENANCE

.

33

A.

Cleaning

the

Cooling

Fan

Filter.

3

3

B.

Cleaning

the

Oven

Chamber.

3

4

C.

Cleaning

"Loose"

Parts.

3

5

D.

Cleaning

the

Exterior.

3

7

E.

Spare

Parts

Kit.

37

SECTION

5

TROUBLESHOOTING.

3

9

Troubleshooting

Chart

1

-

Oven

is

Dead.

3

9

Troubleshooting

Chart

2

-

Conveyor

Does

Not

Run.

3

9

Troubleshooting

Chart

3

-

Conveyor

Runs

Full

Speed.40

Error

Codes

.

40

SECTION

6

PARTS

LIST

..

Heating

Elements

and

Thermocouple.

4

1

Conveyor,

Control

Panel

and

Loose

Parts.42-43

Conveyor

Motor

and

Electrical

Components.

44-45

SECTION

7

ELECTRICAL

SCHEMATICS

&

WIRING.

4

7

Schematic

208/240VAC,

1

Ph,

50/60HZ.

4

8

Wiring

Diagram

208/240VAC,

1

Ph,

50/60Hz.

4

9

Schematic

380VAC,

3

Ph,

50Hz.

5

0

Wiring

Diagram

380VAC,

3

Ph,

50Hz.

5

1

iii

Model

G-26

ovens

are:

SECTION

1

Electrically

heated

.

r

™

.

^

arcr

-s=s?

controlled

and

-

*-

-

waves

as

*

,s

xSSS

approved

adjustable

le^sjieartcurtains^ciumb^rays^^^^'^

6

^^a^o

includes

a*

wtof

^fom^^^NSF

Figure

1-1

G-26

1

SECTION

1

-

DESCRIPTION

A.

Component

Location

Control

Compartment

Cooling

Fan_

Conveyor

Motor

Heat

Curtain

Controls

Oven

Data

Plate

located

under

conveyor

(CTX)

MODEL

NO.

SERIAL

NO.

VOLTS

KW

A

MIDDLEBY

COMPANY

|1

PH

|3

PH

I

MAXIMUM

AMPS]

DO

NOT

OPERATE

WITHOUT

BASE

MODEL

OR

ON

METAL

TABLE

Figure

1-2

B.

Component

Function

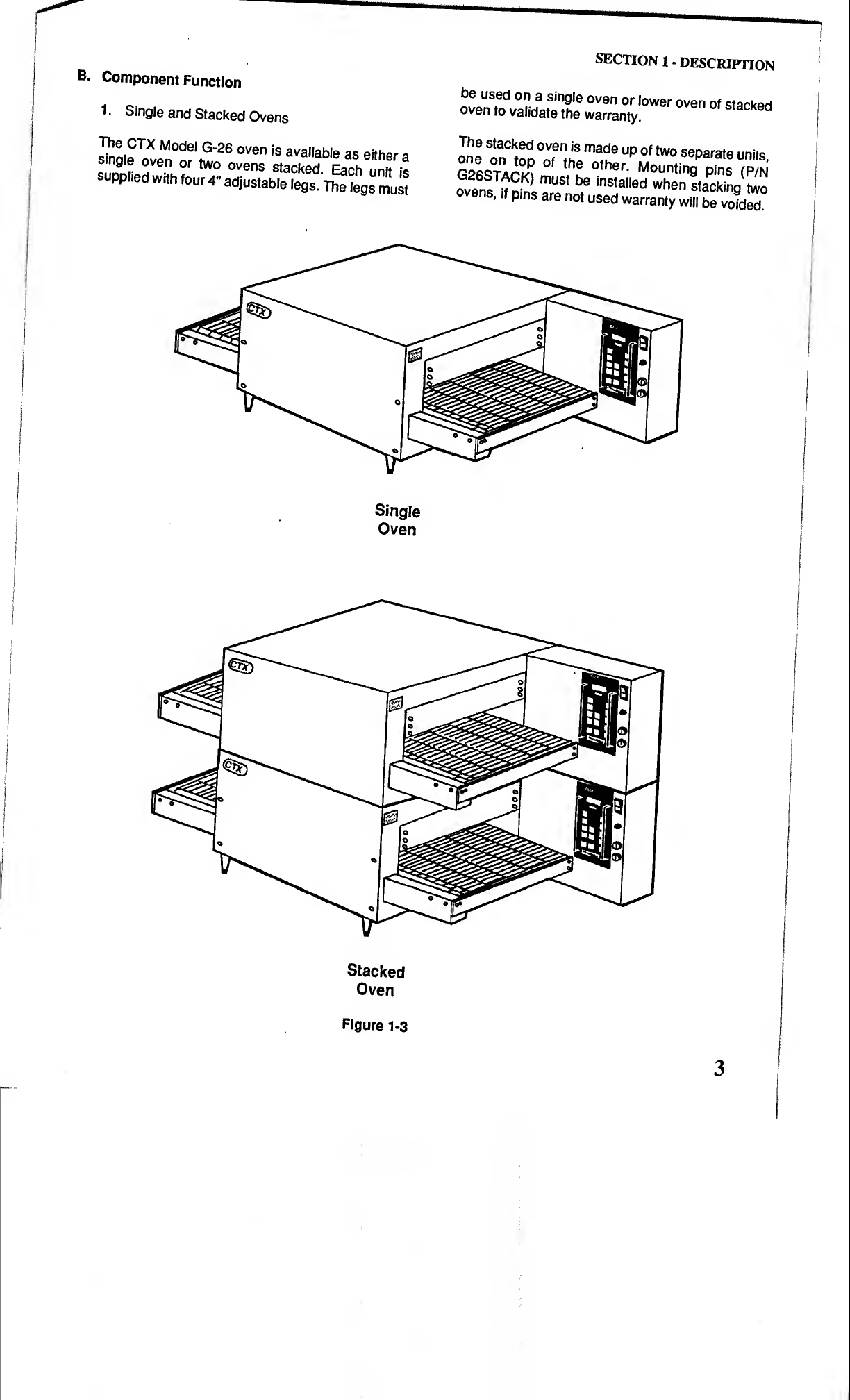

1

•

Single

and

Stacked

Ovens

single^v^or'twcf

ovens

backed^Each

6

'^^

3

supplied

with

four

4"

adjustLrteteg^

The

tegs

must

SECTION

1

-

DESCRIPTION

be

used

on

a

single

oven

or

lower

oven

of

stacked

oven

to

validate

the

warranty.

one

Up

°

f

tw0

ssparate

units,

CPRCTAoJ?

°

f

ot

^

er

-

Mounting

pins

(P/N

ovens

^£T

USt

b

®

inSta,led

when

stacking

two

ens,

if

pms

are

not

used

warranty

will

be

voided.

Single

Oven

Stacked

Oven

Figure

1-3

3

SECTION

1

-

DESCRIPTION

2

.

Cooking

Area

The

CTX

Model

G-26

has

a

26"

(660

mm)

long

cooking

deck

(chamber)

with

a

16"

(406

mm)

wide

conveyor

belt.

3.

Controller

The

Controller

controls

both

the

temperature

and

conveyor

belt

speed

(cook

time)

of

the

oven.

Cook

temperature

can

be

set

from

200°Fto

950°F

(93°C

to

509°C)

and

cook

time

can

be

set

from

01:00

minute

to

30:00

minutes.

4.

Infrared

Heating

Panels

Patented

heating

panels

are

positioned

above

and

below

the

conveyor

belt

of

each

oven

deck

(cham¬

ber).

When

energized

these

panels

emit

infrared

long

waves.

These

waves

do

not

heat

the

air

through

which

they

pass.

Instead

the

waves

are

absorbed

by

the

outer

surface

of

the

product

transported

through

the

oven

on

the

conveyor

belt.

Using

this

application

food

is

placed

on

the

conveyor

and

the

unique

properties

of

the

infrared

waves

cause

it

to

cook

from

the

outside

to

the

center

in

traditional

fashion.

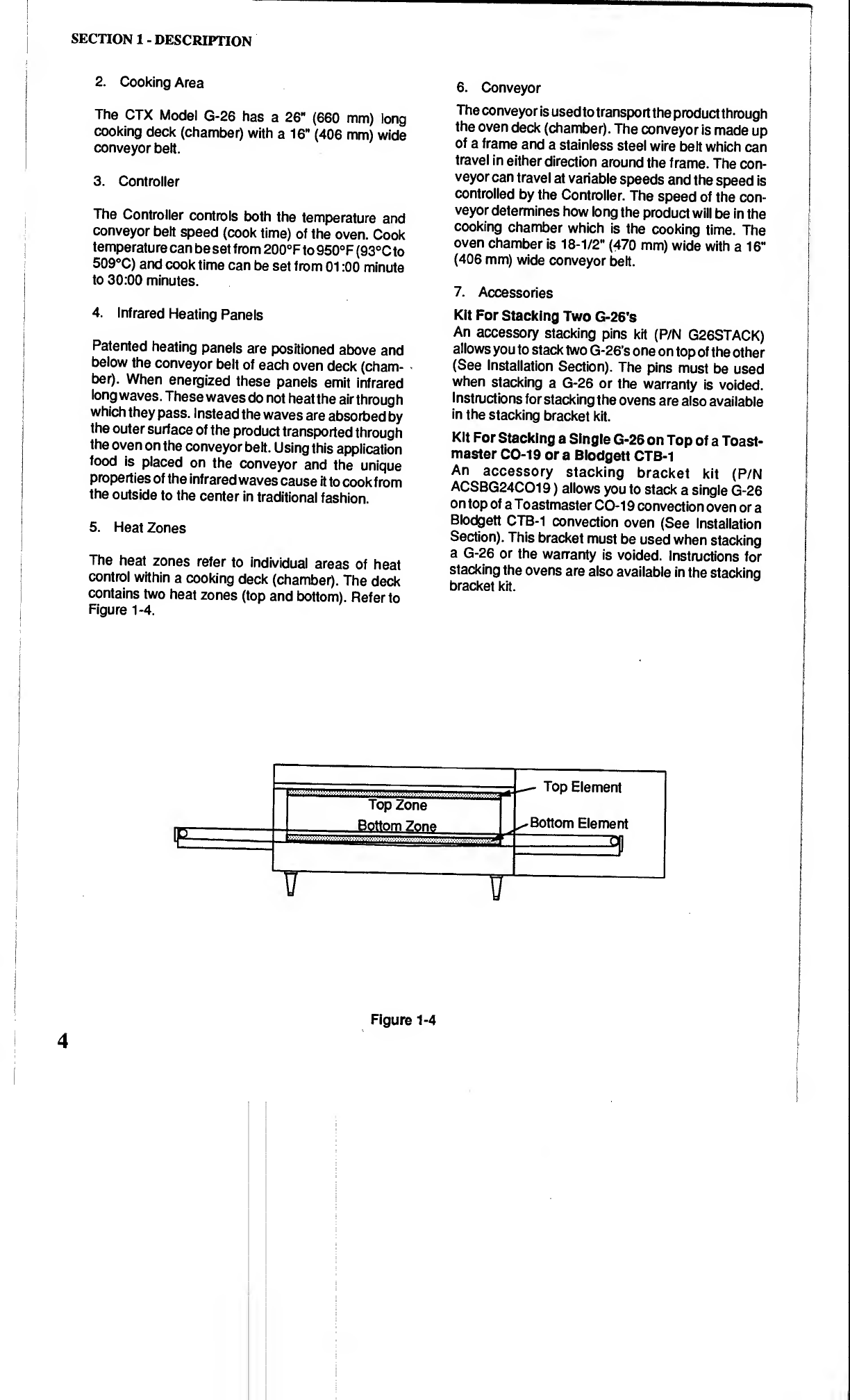

5.

Heat

Zones

The

heat

zones

refer

to

individual

areas

of

heat

control

within

a

cooking

deck

(chamber).

The

deck

contains

two

heat

zones

(top

and

bottom).

Refer

to

Figure

1-4.

6

.

Conveyor

The

conveyor

is

used

to

transport

the

product

through

the

oven

deck

(chamber).

The

conveyor

is

made

up

of

a

frame

and

a

stainless

steel

wire

belt

which

can

travel

in

either

direction

around

the

frame.

The

con¬

veyor

can

travel

at

variable

speeds

and

the

speed

is

controlled

by

the

Controller.

The

speed

of

the

con¬

veyor

determines

how

long

the

product

will

be

in

the

cooking

chamber

which

is

the

cooking

time.

The

oven

chamber

is

18-1/2"

(470

mm)

wide

with

a

16"

(406

mm)

wide

conveyor

belt.

7.

Accessories

Kit

For

Stacking

Two

G-26's

An

accessory

stacking

pins

kit

(P/N

G26STACK)

allows

you

to

stack

two

G-26’s

one

on

top

of

the

other

(See

Installation

Section).

The

pins

must

be

used

when

stacking

a

G-26

or

the

warranty

is

voided.

Instructions

for

stacking

the

ovens

are

also

available

in

the

stacking

bracket

kit.

Kit

For

Stacking

a

Single

G-26

on

Top

of

a

Toast¬

master

CO-19

or

a

Blodgett

CTB-i

An

accessory

stacking

bracket

kit

(P/N

ACSBG24C019)

allows

you

to

stack

a

single

G-26

on

top

of

a

Toastmaster

CO-19

convection

oven

or

a

Blodgett

CTB-1

convection

oven

(See

Installation

Section).

This

bracket

must

be

used

when

stacking

a

G-26

or

the

warranty

is

voided.

Instructions

for

stacking

the

ovens

are

also

available

in

the

stacking

bracket

kit.

Figure

1-4

SECTION

1

-

DESCRIPTION

C.

Oven

Specifications

Such

revisions do

not

entitle

the

buyer

to

c^res^nrf"'

S

^

product

desi

9

n

without

additions

or

replacements

for

previously

purged

^

improveme

"‘

s

-

equipment.

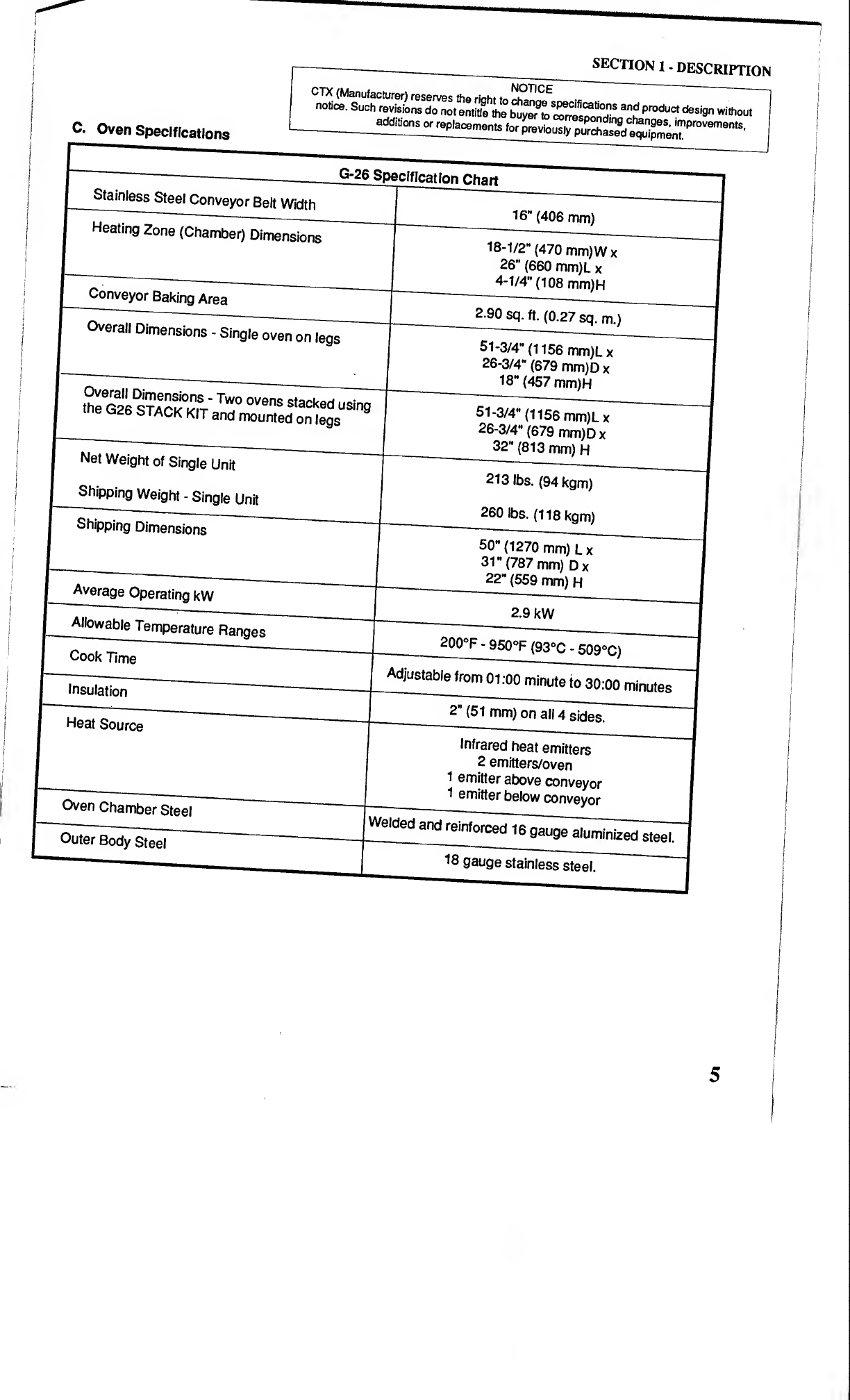

Stainless

Steel

Conveyor

Belt

Width

G-26

Specif

ication

Chart

i

-—-

Heating

Zone

(Chamber)

Dimensions

16"

(406

mm)

Conveyor

Baking

Area

Overall

Dimensions

-

Single

oven

on

legs

Overall

Dimensions

-

Two

ovens

the

qTAnv

Lsi-r

uvens

stacked

using

me

C

26

STACK

KIT

and

mounted

on

legs

Net

Weight

of

Single

Unit

Shipping

Weight

-

Single

Unit

Shipping

Dimensions

18-1/2"

(470

mm)Wx

26"

(660

mm)L

x

4-1/4"

(108

mm)H

2.90

sq.

ft.

(0.27

sq.

m.)

51-3/4"

(i

156

mm)Lx

26-3/4"

(679

mm)D

x

18"

(457

mm)H

51-3/4"

(1156

mm)Lx

26-3/4"

(679

mm)Dx

32"

(813

mm)

H

213

lbs.

(94

kgm)

260

lbs.

(118

kgm)

Average

Operating

kW

Allowable

Temperature

Ranges

50"

(1270

mm)

Lx

31"

(787

mm)

Dx

22"

(559

mm)

H

2.9

kW

Cook

Time

200°F

-

950°F

(93°C

-

509°C)

Insulation

Adjustable

from

01:00

minute

to

30:00

minutes

Heat

Source

2

”

(51

mm)

on

all

4

sides.

Oven

Chamber

Steel

Infrared

heat

emitters

2

emitters/oven

1

emitter

above

conveyor

1

smitter

below

conveyor

Outer

Body

Steel

Welded

18

gauge

stainless

steel.

SECTION

1

-

DESCRIPTION

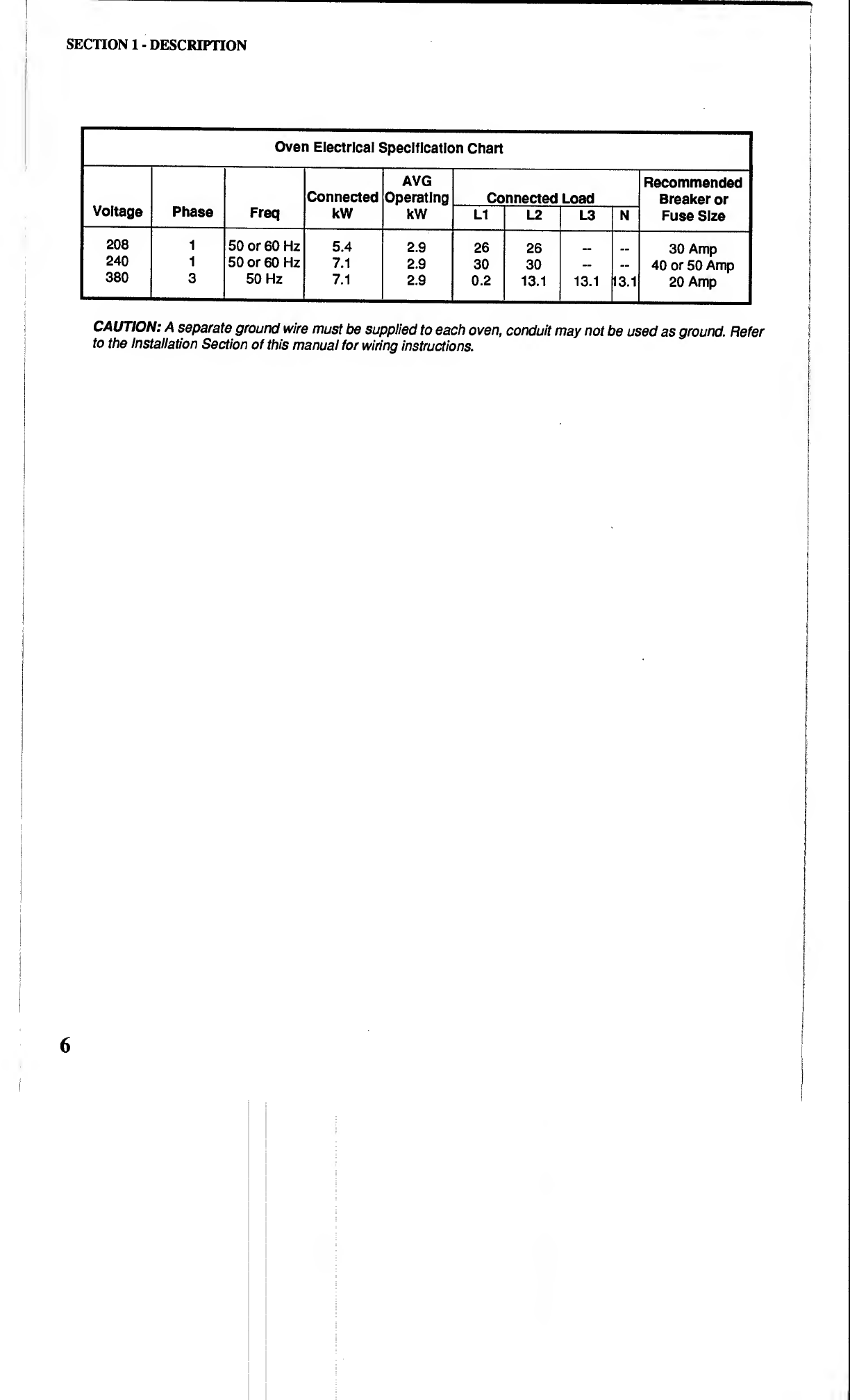

Oven

Electrical

Specification

Chart

Voltage

Phase

Freq

Connected

kW

AVG

Operating

kW

Connected

Load

Recommended

Breaker

or

Fuse

Size

LI

L2

L3

N

208

1

50

or

60

Hz

5.4

2.9

26

26

_

30

Amp

240

1

50

or

60

Hz

7.1

2.9

30

30

—

m

40

or

50

Amp

380

3

50

Hz

7.1

2.9

0.2

13.1

13.1

m

20

Amp

CAUTION:

A

separate

ground

wire

must

be

supplied

to

each

oven,

conduit

may

not

be

used

as

ground.

Refer

to

the

Installation

Section

of

this

manual

for

wiring

instructions.

6

SECTION

1

-

DESCRIPTION

Oven

Dimension

Drawings

51-3/4"

1315mm

26-3/4"

—679mm-

16-1/2“

_

'470mm

Single

Oven

on

Legs

SECTION

2

INSTALLATION

A.

Inspect

for

Shipping

Damage

All

shipping

containers

should

be

examined

for

dam¬

age

before

and

during

unloading.

This

equipment

was

carefully

inspected

and

packaged

at

the

factory.

The

freight

carrier

has

assumed

responsibility

for

its

safe

transit

and

delivery.

If

equipment

is

received

in

damaged

condition,

either

apparent

or

concealed,

a

claim

must

be

made

with

the

delivering

carrier.

1.

Apparent

Damage

or

Loss

-

If

damage

or

loss

is

apparent

it

must

be

noted

on

the

freight

bill

or

express

receipt

at

the

time

of

delivery,

and

it

must

be

signed

by

the

carrier’s

agent

(driver).

If

this

is

not

done,

the

carrier

may

refuse

the

claim.

The

carrier

will

supply

the

necessary

claim

forms.

2

.

Concealed

Damage

or

Loss

-

If

damage

or

loss

is

NOT

apparent

until

after

equipment

is

uncrated,

a

request

for

inspection

of

concealed

damage

must

be

made

with

carrier

within

15

days.

The

carrier

will

make

an

inspection

and

will

supply

necessary

claim

forms.

Be

certain

to

retain

all

contents

plus

external

and

internal

packaging/crating

materials

for

inspec¬

tion.

B.

Placement

of

Oven

Some

very

important

considerations

must

be

made

when

choosing

the

place

where

the

oven

is

to

oper¬

ate.

1.

This

oven

is

conveyorized

and

operates

continu¬

ously.

It

should

be

placed

so

it

fits

into

the

“flow”

of

the

operation.

2

.

Drafts

entering

the

oven

chambers

can

cause

inconsistent

cooking

results.

Check

the

area

sur¬

rounding

the

oven

and

eliminate

sources

of

drafts

such

as

open

windows

or

doors

and

fans

or

other

appliances

that

cause

air

circulation.

3.

Oven

should

be

positioned

so

hot

air

from

an¬

other

piece

of

equipment

cannot

enter

oven

cooling

fan

air

intake

on

the

control

compartment.

Serious

problems

could

occur.

NOTE:

To

validate

a

new

oven(s)

warranty

a

factory

certified

installer

must

verify

that

Steps

C

thru

K

have

been

performed

correctly.

9

SECTION

2

-

INSTALLATION

C.

Unpacking

Oven

The

oven

components

should

be

moved

as

close

as

possible

to

final

location

before

being

assembled/

stacked.

The

oven

setting

on

its

bottom,

requires

door

openings

wider

than

26-3/4"

(679

mm).

Open

carton

and

remove

it

from

around

oven,

then

remove

the

empty

carton

from

the

area.

Directions

for

removing

the

wooden

skid

are

on

the

following

page.

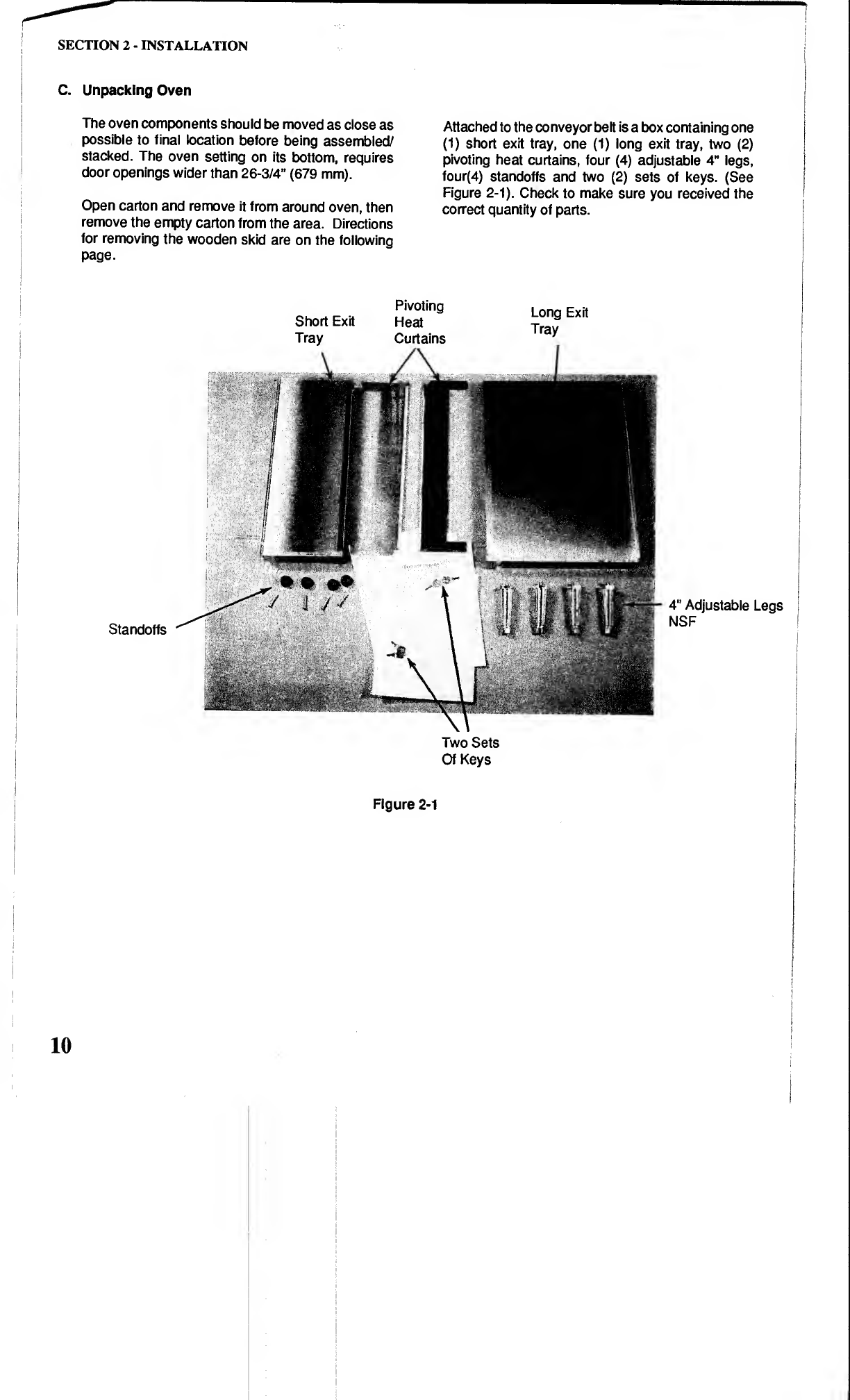

Attached

to

the

conveyor

belt

is

a

box

containing

one

(1)

short

exit

tray,

one

(1)

long

exit

tray,

two

(2)

pivoting

heat

curtains,

four

(4)

adjustable

4"

legs,

four(4)

standoffs

and

two

(2)

sets

of

keys.

(See

Figure

2-1).

Check

to

make

sure

you

received

the

correct

quantity

of

parts.

Standoffs

Pivoting

Short

Exit

Heat

Tray

Curtains

Long

Exit

Tray

4"

Adjustable

Legs

NSF

Two

Sets

Of

Keys

Figure

2-1

10

SECTION

2

-

INSTALLATION

D.

Uncrating

Lay

the

oven

on

its

front

side

then

remove

the

four

(4)

bolts

attaching

wooden

skid

to

bottom

of

oven

(Figure

2-2).

Figure

2-2

E.

installing

Legs

Install

the

four

4"

adjust¬

able

legs

as

shown

in

Fig¬

ure

2-3

then

lift

the

oven

onto

it’s

legs.

On

single

oven

installation

place

the

oven

in

it’s

permanent

position

and

then

skip

Step

F

and

go

directly

to

Step

G.

Figure

2-3

11

SECTION

2

-

INSTALLATION

F.

Stacking

and

Mounting

Two

Ovens

NOTE:

A

stacking

pins

kit(Kit

#

G26STACK)

is

required

when

stacking

two

ovens

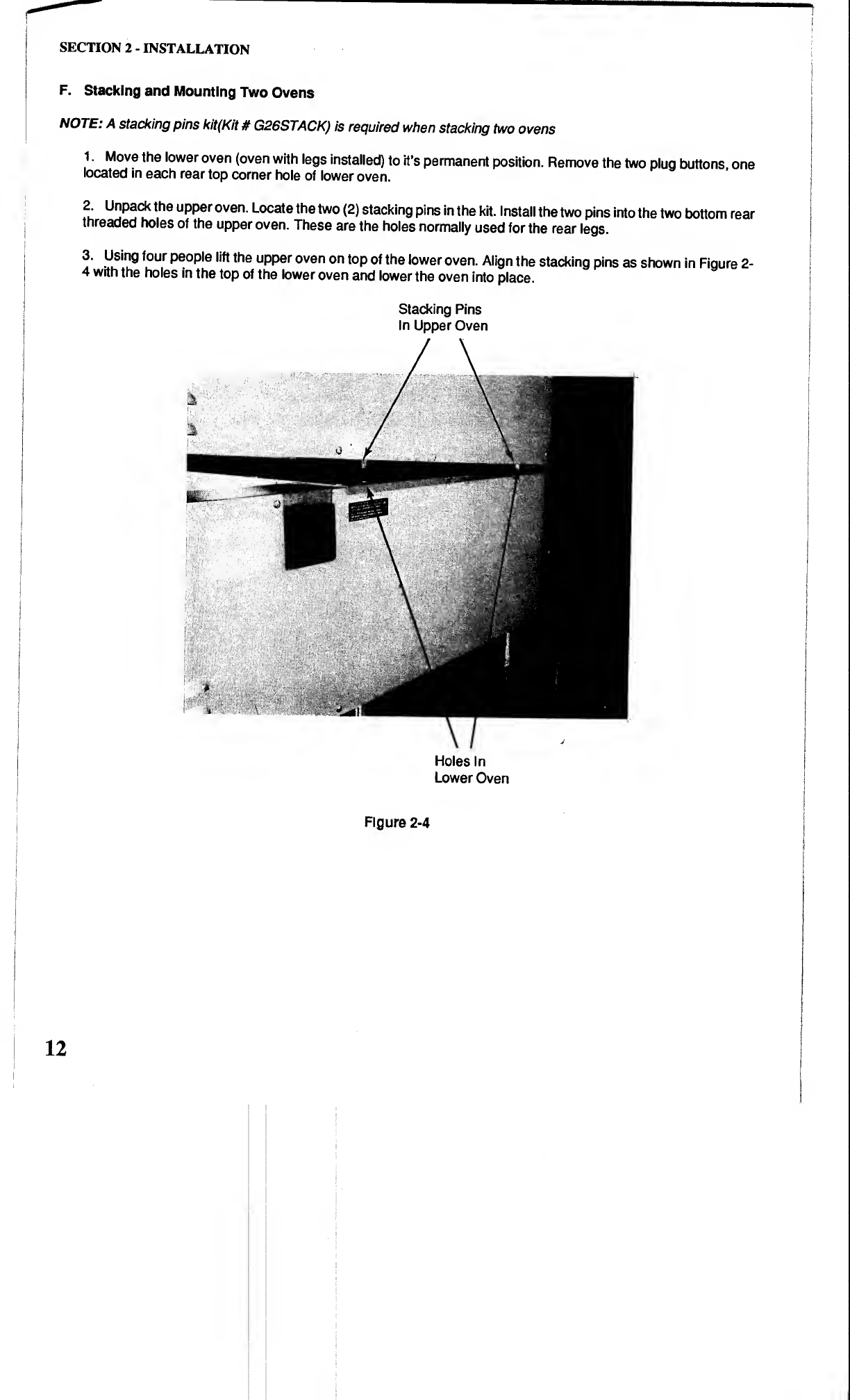

1.

Move

the

lower

oven

(oven

with

legs

installed)

to

it’s

permanent

position.

Remove

the

two

plug

buttons,

one

located

in

each

rear

top

corner

hole

of

lower

oven.

?•

u

"

pack

the

u

PPe

r

oven.

Locate

the

two

(2)

stacking

pins

in

the

kit.

Install

the

two

pins

into

the

two

bottom

rear

threaded

holes

of

the

upper

oven.

These

are

the

holes

normally

used

for

the

rear

legs.

3.

Using

four

people

lift

the

upper

oven

on

top

of

the

lower

oven.

Align

the

stacking

pins

as

shown

in

Figure

2-

4

with

the

holes

in

the

top

of

the

lower

oven

and

lower

the

oven

into

place.

Stacking

Pins

In

Upper

Oven

Holes

In

Lower

Oven

Figure

2-4

SECTION

2

-

INSTALLATION

)

j

i

4.

Once

the

ovens

are

stacked

and

secured

check

to

make

sure

the

oven(s)

are

level.

Adjust

the

legs

if

necessary

as

shown

in

Figure

2-5.

Figure

2-5

G.

Stacking

a

single

G-26

oven

over

a

Toastmas¬

ter

CO-19

convection

oven

ora

Blodgett

CTB-

1

convection

oven.

NOTE:

A

stacking

bracket

kit

(P/N

ACSBG24C019)

must

be

used

for

this

in¬

stallation

or

warranty

is

voided.

1-

Lay

the

G-26

on

its

front

side.

Then

using

the

four

bolts

supplied

in

the

kit,

secure

bracket

to

bot¬

tom

of

oven

using

the

threaded

holes

normally

used

for

legs.

Opening

in

sidewall

must

be

at

rear

of

oven

as

shown

in

Fiq-

ure

2-6.

Figure

2-6

13

SECTION

2

-

INSTALLATION

2

.

Using

four

people

lift

the

G-26

and

place

it

on

topof

the

convection

oven

as

shown

in

Figure

2-7.

Figure

2-7

H.

Conveyor

Belt

and

Temperature

Display

The

conveyor

belt

is

designed

to

travel

in

either

direction

using

the

conveyor

Reversing

Key

Switch.

The

temperature

display

may

be

set

for

either

°F

or

°C.

Your

Certified

Installer

will

set

both

of

these

functions

for

you

during

the

installation.

If

you

require

a

change

in

the

degrees

display

(Fahrenheit

or

Centigrade)

in

the

future

call

your

local

Autho¬

rized

Service

Agency.

Figure

2-8

J.

Electrical

Connection

SECTION

2

-

INSTALLATION

I-

Standoffs

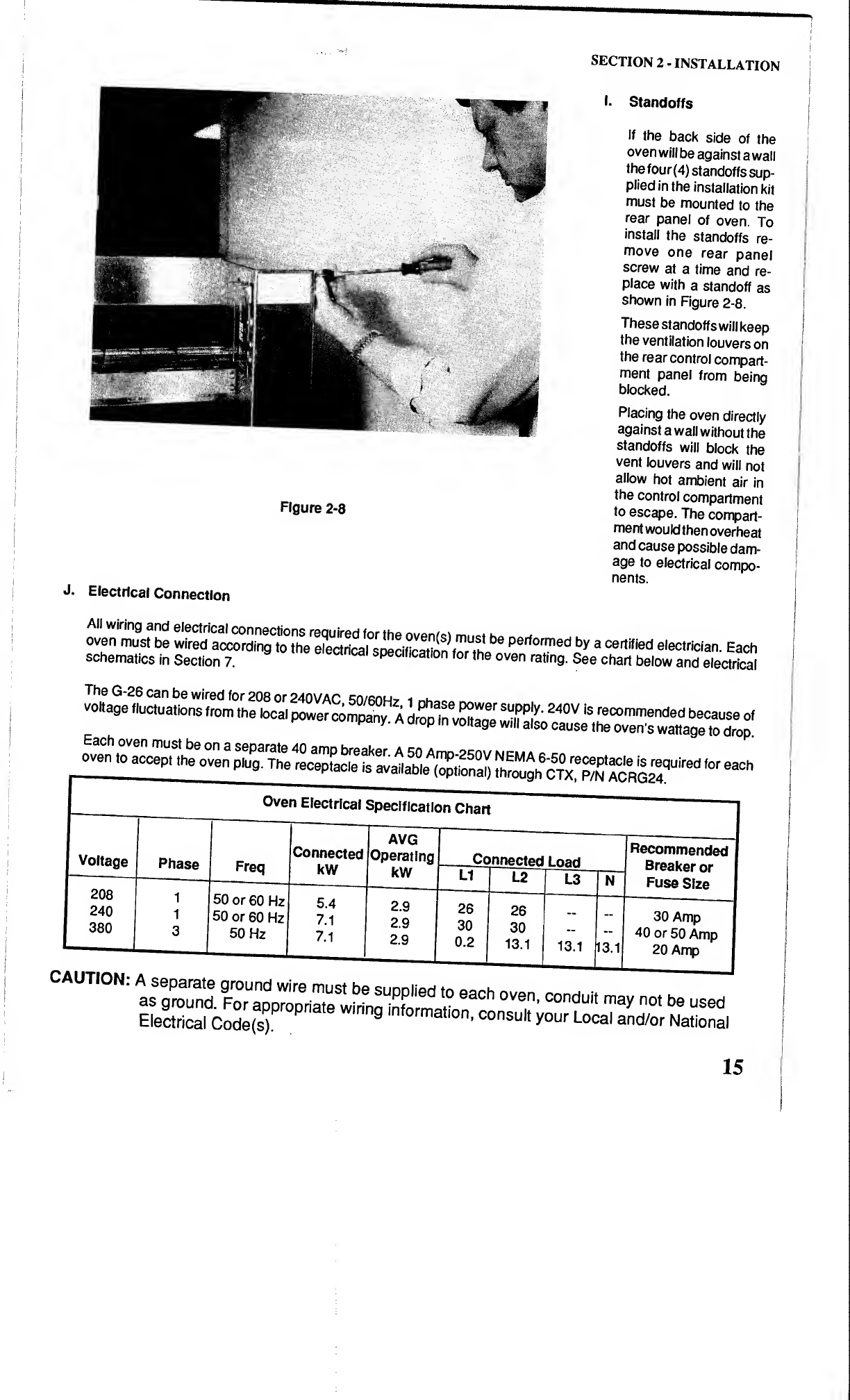

If

the

back

side

of

the

oven

will

be

against

a

wall

the

four

(4)

standoffs

sup¬

plied

in

the

installation

kit

must

be

mounted

to

the

rear

panel

of

oven.

To

install

the

standoffs

re¬

move

one

rear

panel

screw

at

a

time

and

re¬

place

with

a

standoff

as

shown

in

Figure

2-8.

These

standoffs

will

keep

the

ventilation

louvers

on

the

rear

control

compart¬

ment

panel

from

being

blocked.

Placing

the

oven

directly

against

a

wall

without

the

standoffs

will

block

the

vent

louvers

and

will

not

allow

hot

ambient

air

in

the

control

compartment

to

escape.

The

compart¬

ment

would

then

overheat

and

cause

possible

dam¬

age

to

electrical

compo¬

nents.

vo«ageS^

Oven

Electrical

Specification

Chart

Voltage

208

240

380

Phase

1

1

3

50

or

60

Hz

50

or

60

Hz

50

Hz

Connected

kW

5.4

7.1

7.1

AVG

Operating

I

kW

2.9

2.9

2.9

Connected

l

oad

26

30

0.2

26

30

13.1

13.1

N3.1

I

Recommended

Breaker

or

Fuse

Size

30

Amp

40

or

50

Amp

20

Amp

CAUTION;

A

=

9~e

,

™

-

Pleach

oven,

condui,

may

no,

be

used

Electrical

Code(s).

’

consu

*

y°

ur

Local

and/or

National

15

SECTION

2

-

INSTALLATION

K.

Pivoting

Heat

Curtains

The

oven

is

shipped

with

adjustable

heat

curtains

attached

to

the

oven

and

pivoting

heat

curtains

are

also

supplied

with

the

oven.

To

use

the

pivoting

heat

curtains

first

remove

adjustable

heat

curtains

and

then

install

the

pivot¬

ing

heat

curtains

by

hang¬

ing

them

on

the

steel

rod

as

shown

in

Figure

2-9.

Figure

2*9

Heat

Curtain

L.

Exit

Tray

Next

install

the

desired

exit

tray

at

the

exit

end

of

the

conveyor.

Two

exit

trays

are

supplied

with

each

oven,

one

short

and

one

long

as

shown

in

Fig¬

ure

2-10.

16

Figure

2-10

Exit

Tray

Table of contents

Other Middleby Oven manuals