Midwest Industries ShoreStation SSV60120EAC User manual

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 1 09/06/07

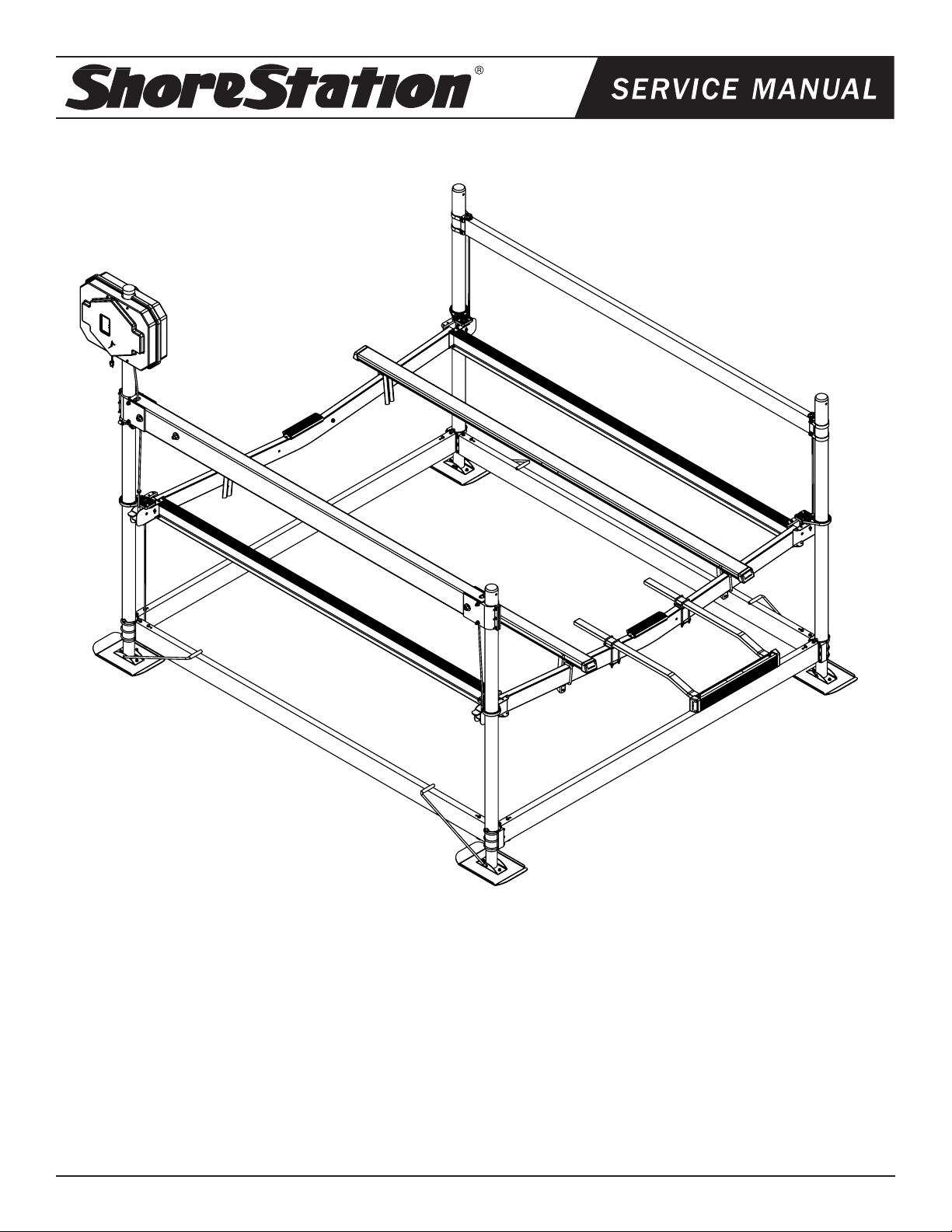

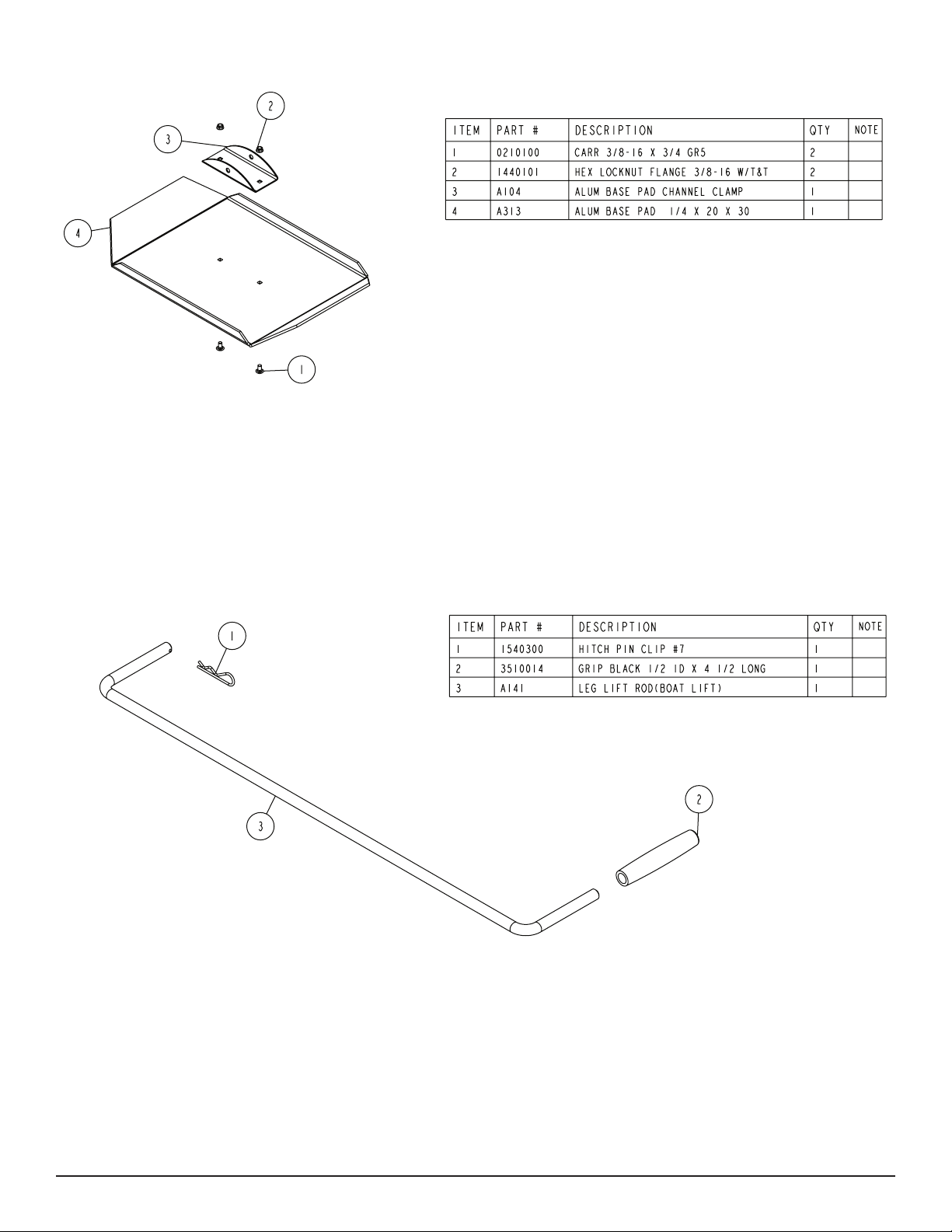

SSV60120EAC & SSV60120EACDW

SSV60120EAC Hoist Alum SS V-Frame - EAC

68204 Hardware Box - SSV60120 Hoist

62683 Lower Frame Bundle - SSV60120

62866 Platform Bundle - SSV60120

6941701 Winch Assembly - AC 6000 lb Hoist

69626 Winch Tube Bundle - SSV60120

68203 Leg Bundle - SSV60120

HA0024 Motor Stop Bundle Alum 5” V-Frame

HA0021 Bunk Poly V40H-60108/120 - 60132H

69631 Lit Packet, V60120EAC/DW

NOTE: When referencing the front of hoist, this represents the winch end. When referencing the hoist end, this represents opposite of the

winch end. Which side is also referred to the right side of the hoist.

SSV60120EAC DW Hoist Alum SS V-Frame - EAC

68204 Hardware Box - SSV60120 Hoist

62683 Lower Frame Bundle - SSV60120

62866 Platform Bundle - SSV60120

6941701 Winch Assembly - AC 6000 lb Hoist

69626 Winch Tube Bundle - SSV60120

68206 Leg Bundle - SSV60120DW

HA0024 Motor Stop Bundle Alum 5” V-Frame

HA0021 Bunk Poly V40H-60108/120 - 60132H

69631 Lit Packet, V60120EAC/DW

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 2 09/06/07

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 3 09/06/07

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 4 09/06/07

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 5 09/06/07

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 6 09/06/07

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 7 09/06/07

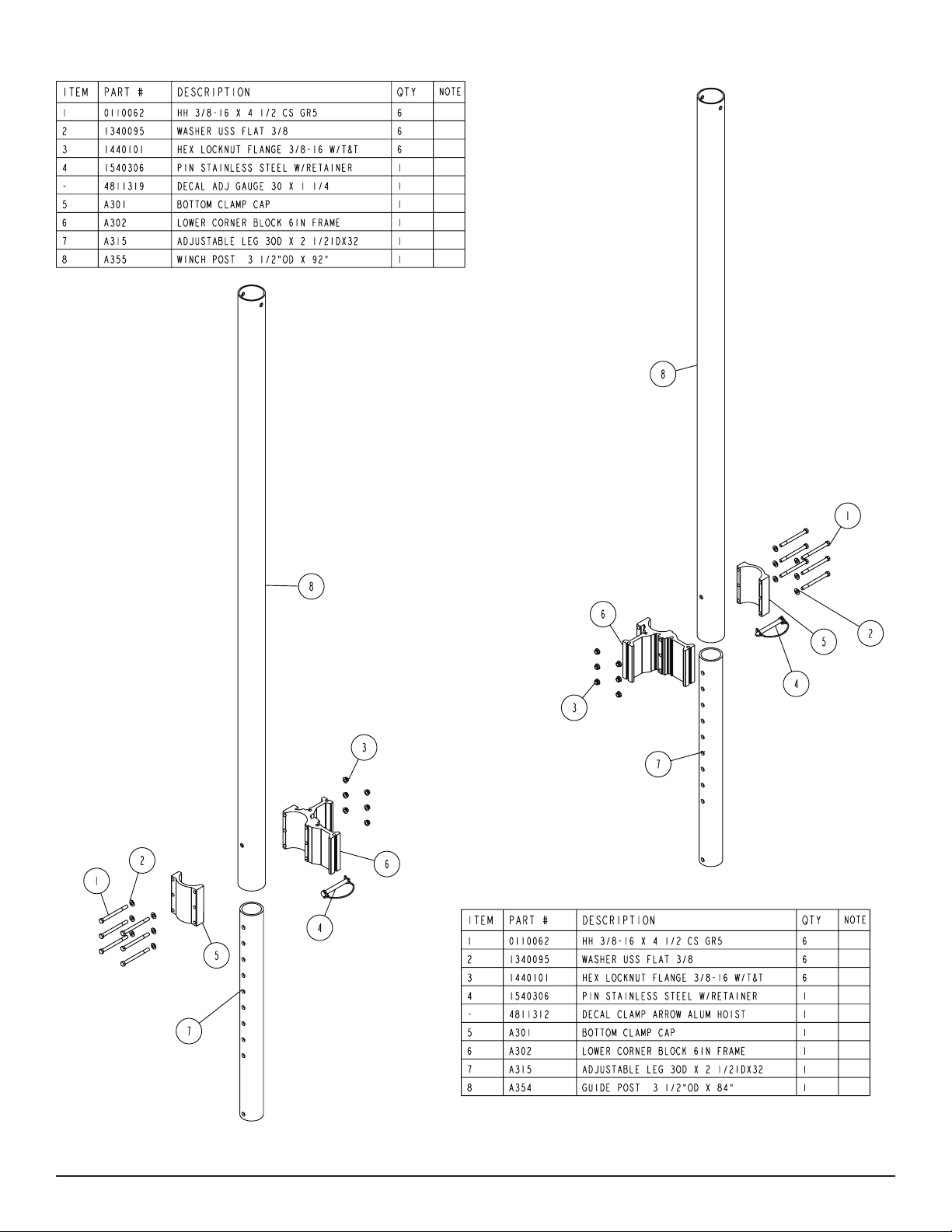

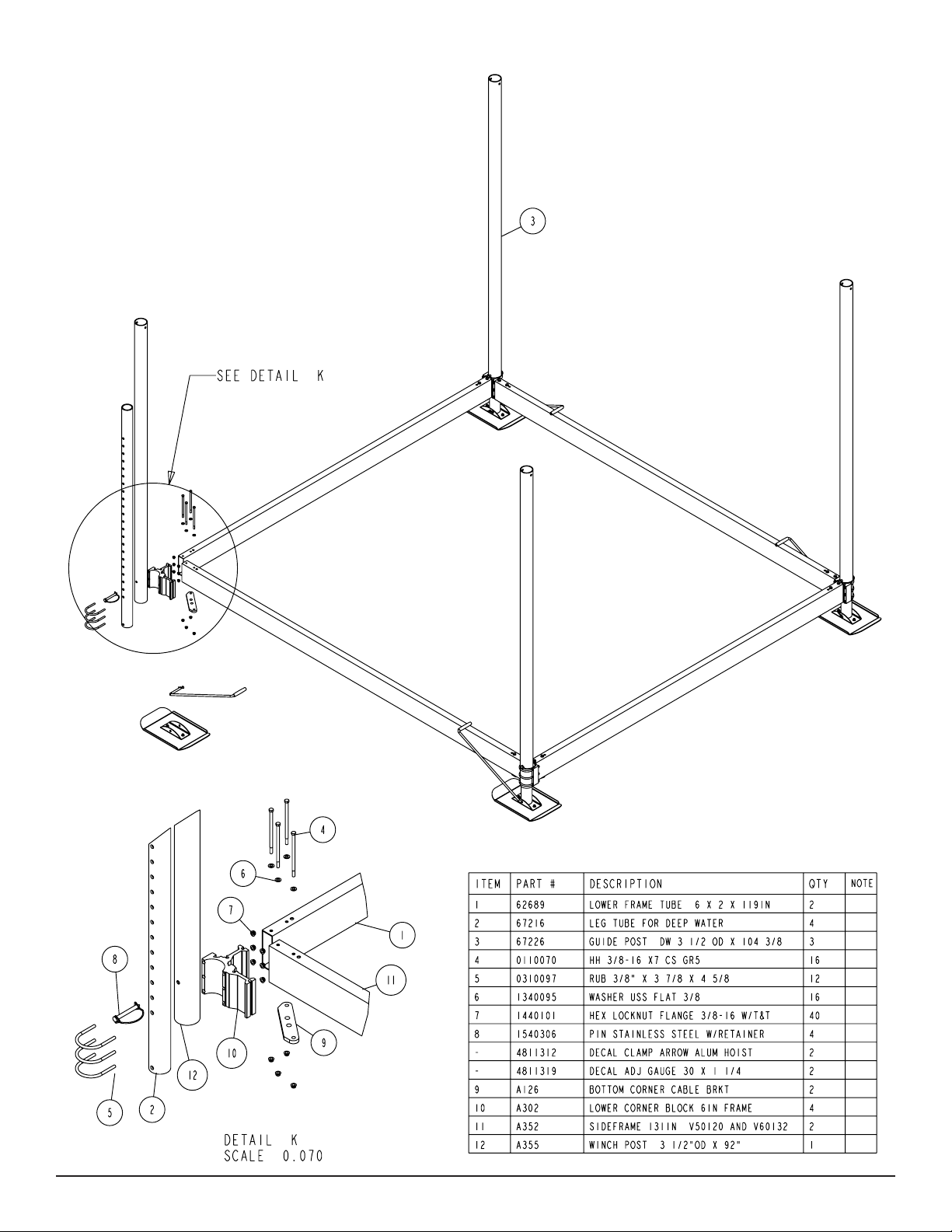

Winch Post Guide Post

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 8 09/06/07

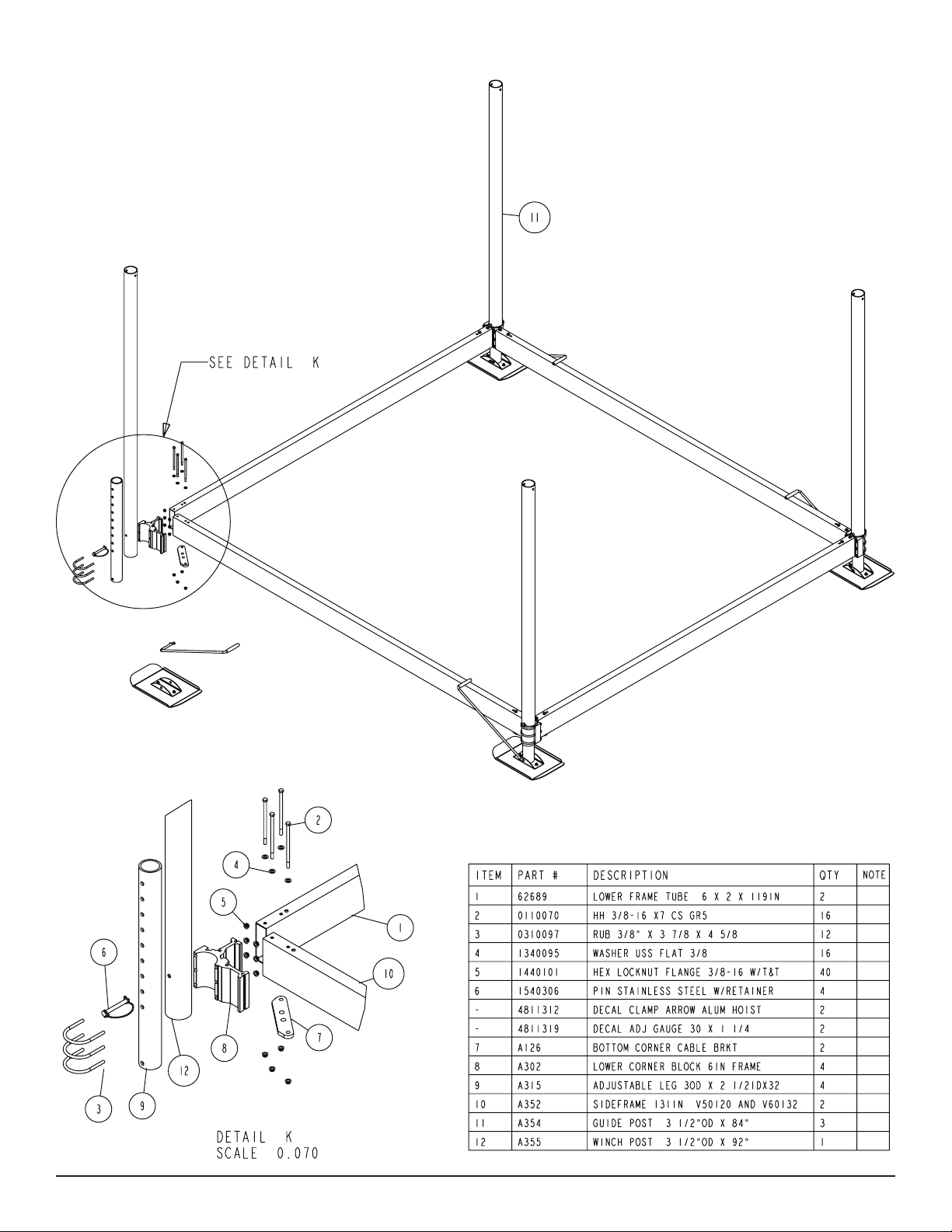

Lower Frame Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 9 09/06/07

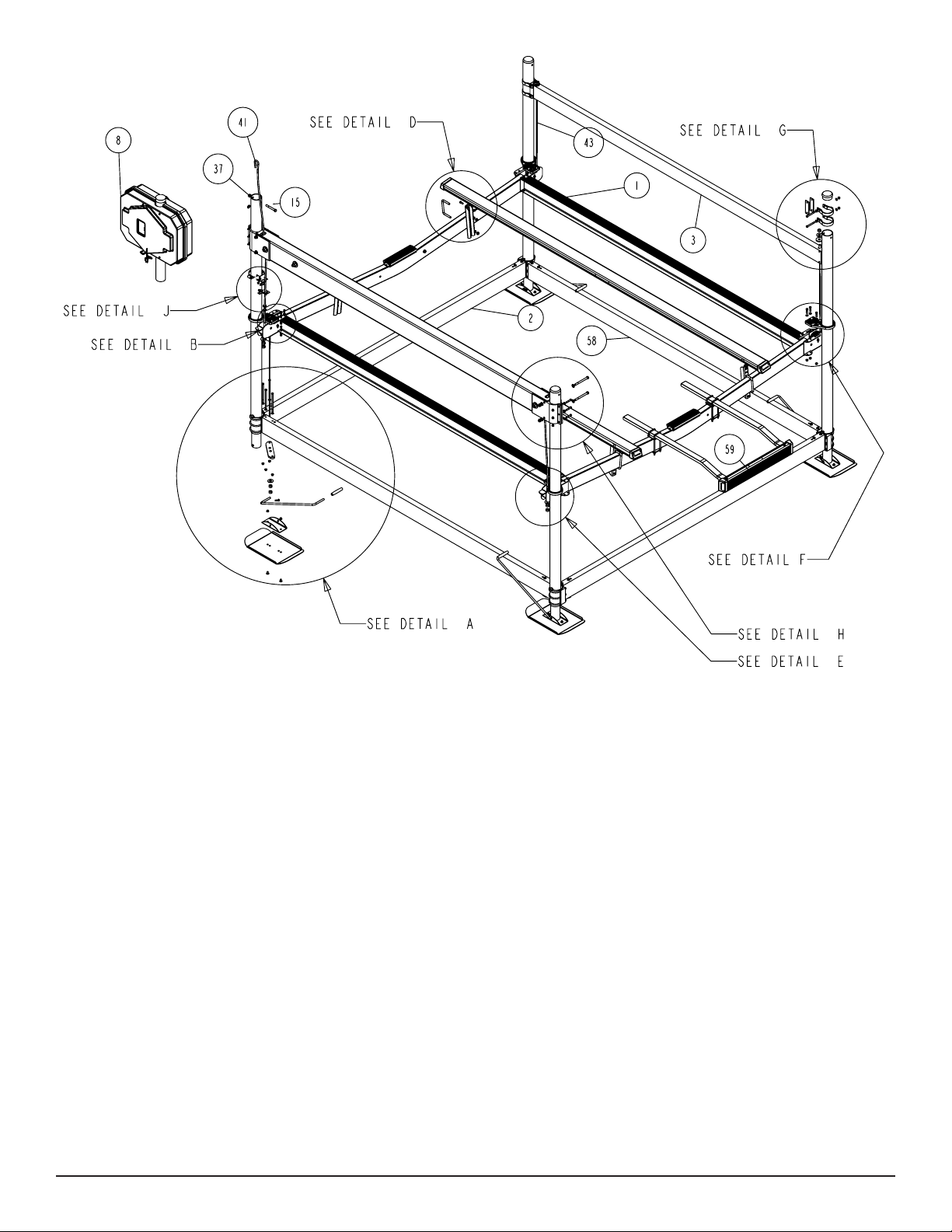

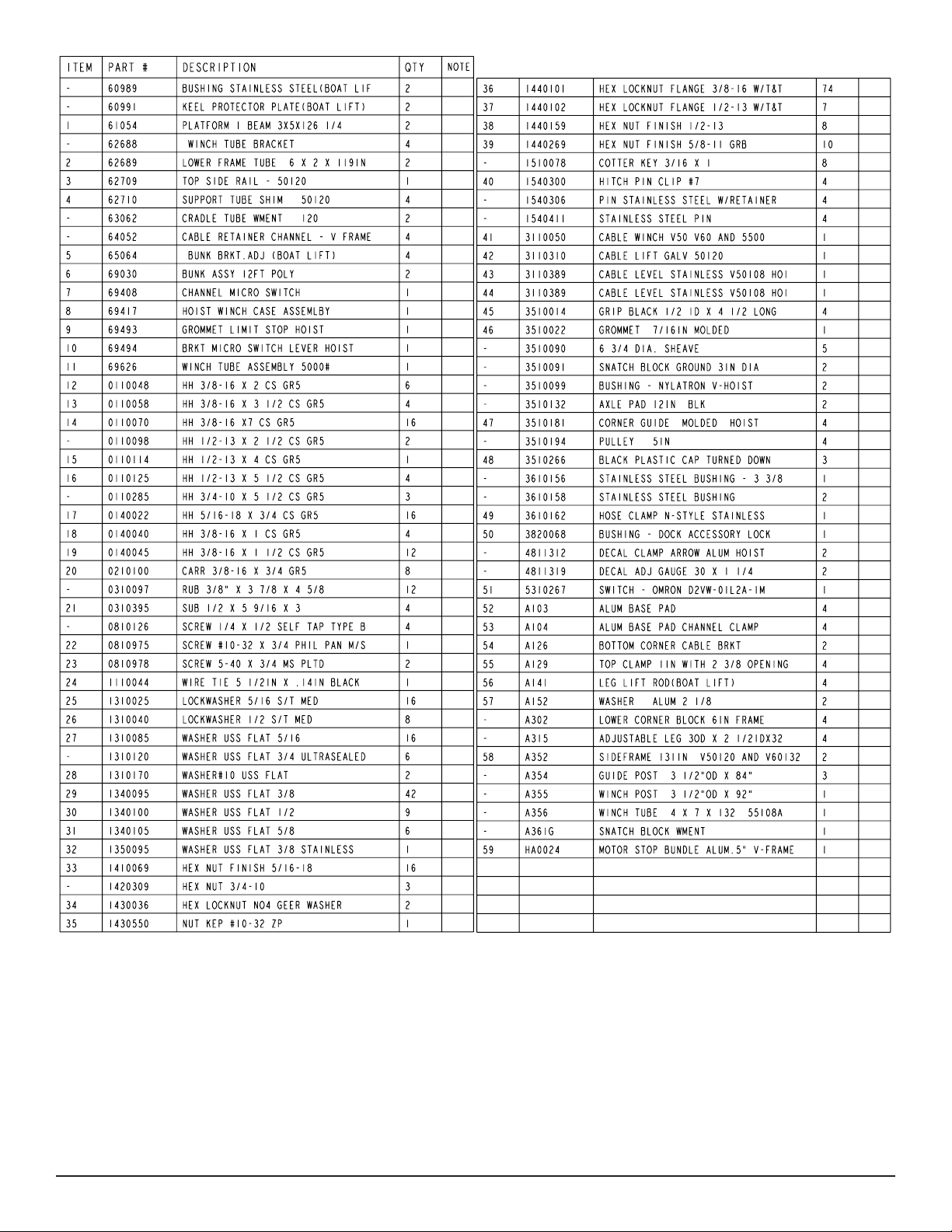

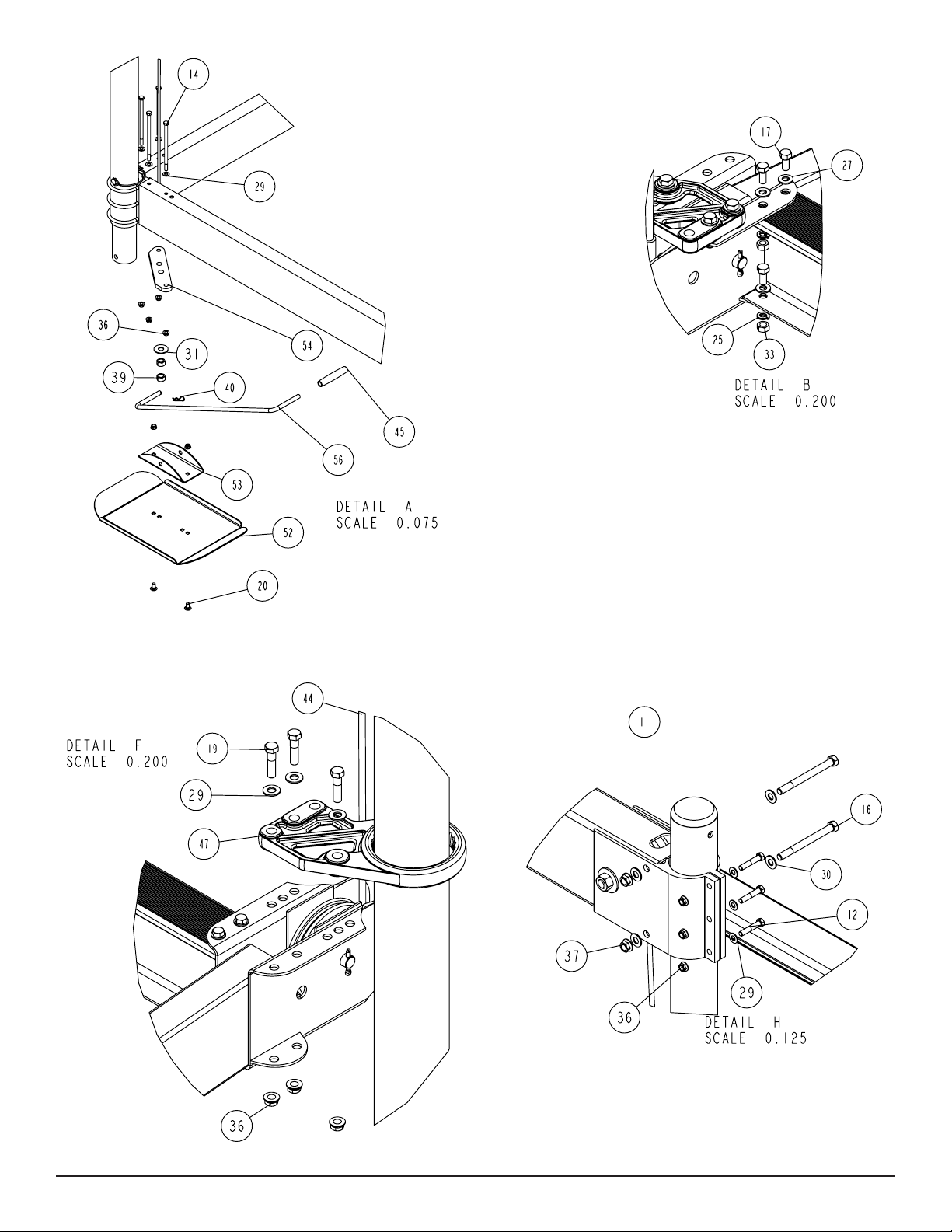

Platform Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 10 09/06/07

Winch Tube

WINCH TUBE SERVICE INSTRUCTIONS

The winch tube assembly was pre-assembled at the factory.

It is important that the internal parts and cable routings are

assembled properly in order for the winch tube assembly to

function properly. It also requires special tools during the as-

sembly process. It is therefore recommended that you con-

tact your local dealer should you ever have issues with the

winch tube assembly.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 11 09/06/07

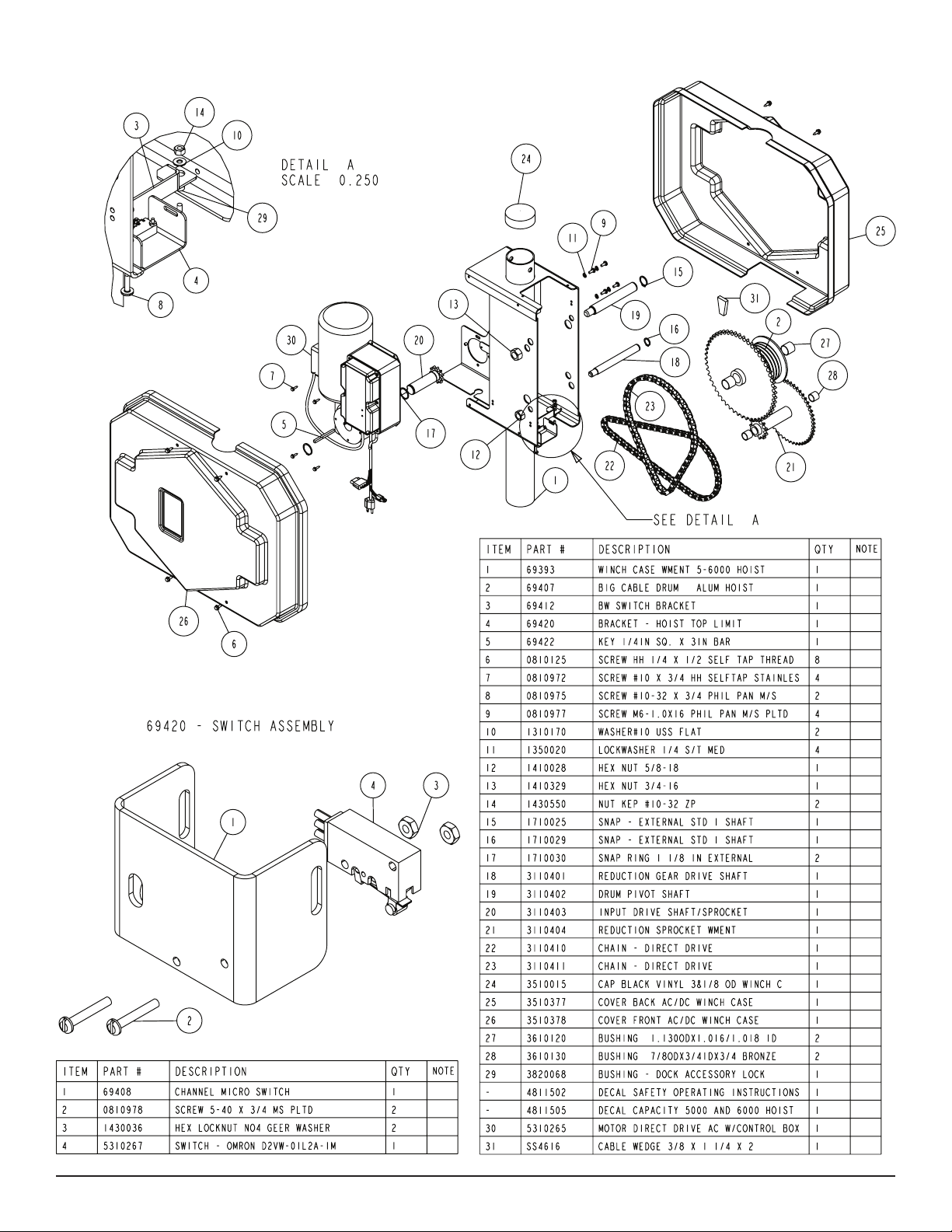

AC Drive Winch Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 12 09/06/07

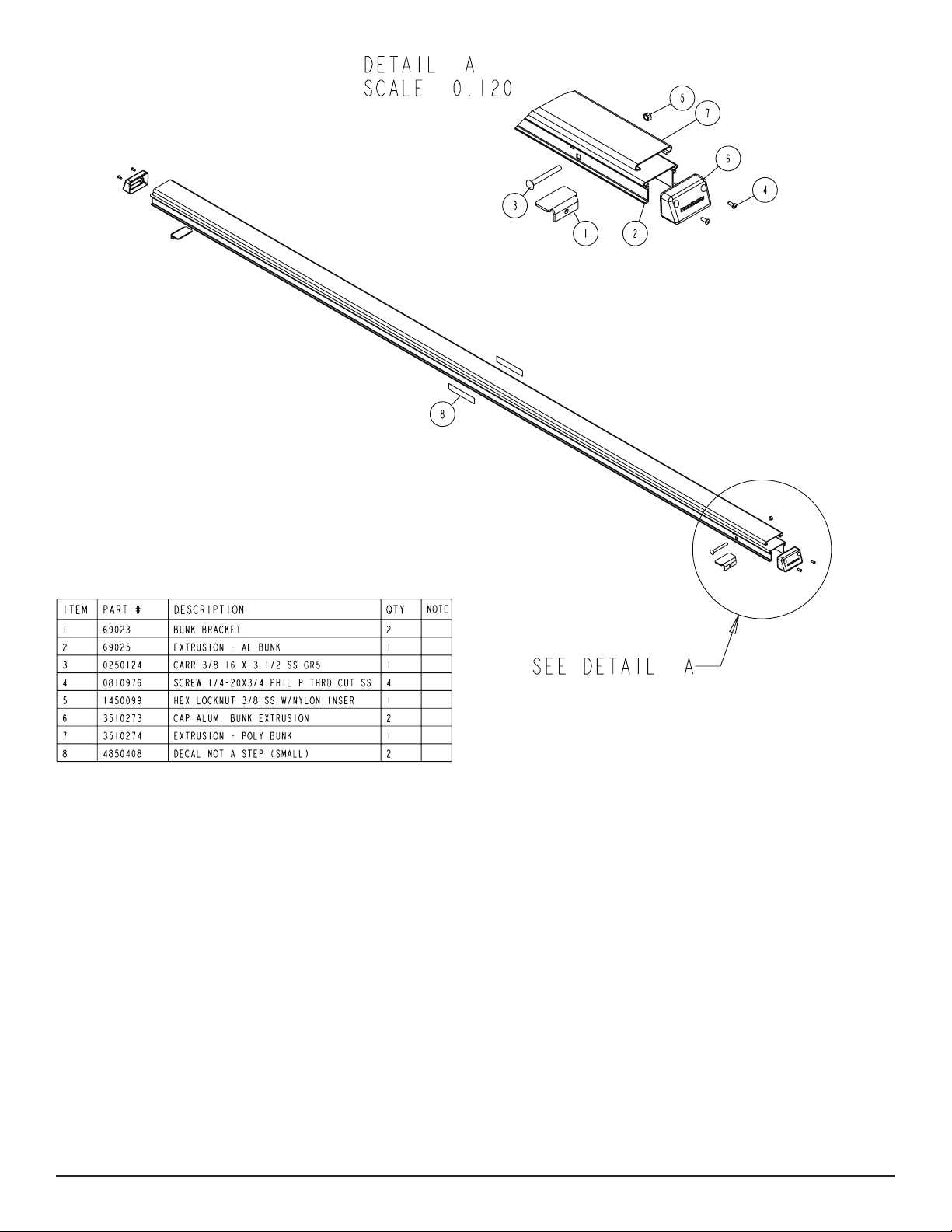

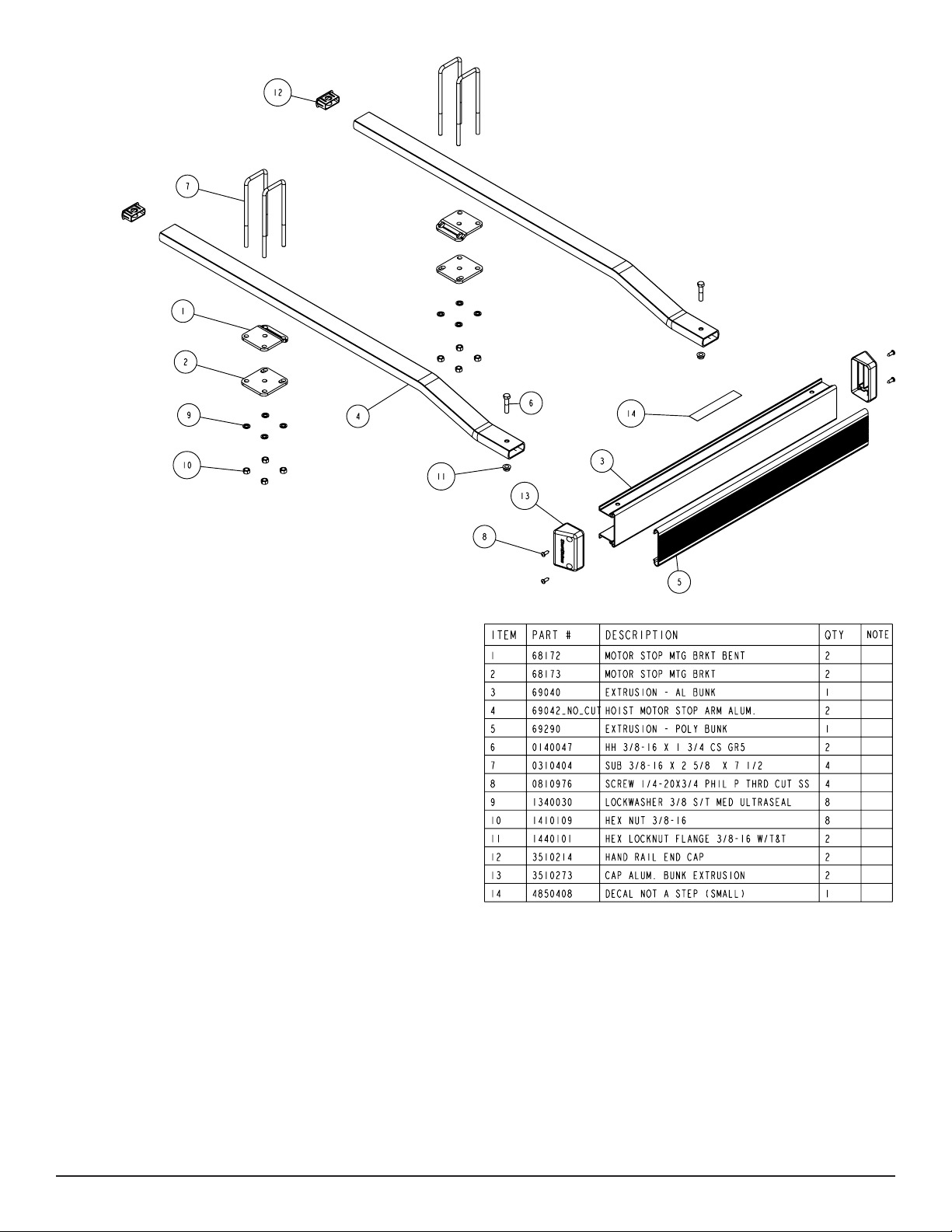

Bunk Assembly

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 13 09/06/07

HA0024 - Motor Stop

Assembly Instructions

Locate the two motor stop mounting arms (Item #4) and the motor

stop assembly that is pre-assembled at the factory.

Note that the aluminum extrusion in the motor stop assembly has

two holes pre-drilled in one leg of the extrusion. Position the motor

stop assembly so that the drilled leg is to the top as shown. Locate

a 3/8” x 1 ¾” hex bolt and drop it into the hole in the top leg of

the aluminum extrusion. Position the motor stop mounting arm as

shown so that it is on the bottom side of the top leg of the alumi-

num extrusion. Align the hole in the end of the motor stop mounting

arm with the bolt just installed. Insert the bolt through the hole in

the motor stop mounting arm. Secure with a 3/8” ange lock nut.

Tighten. Tap the black plastic caps into the other end of the motor

stop mounting arms.

Repeat step three on the remaining motor stop mounting

arm.

Installation

Locate the two hoist motor stop U-bolt brackets with the

offset (Item #1) and position them as shown in the diagram on the

top side of the hoist platform so they are spaced correctly to t the

motor stop assembly. The offset must be placed as shown to com-

pensate for the V-shape in the platform.

Place the motor stop assembly on the two hoist motor

stop U-bolt brackets with offset just positioned. Drop the

3/8” x 2 5/8” x 7 ½” U-bolts over the motor stop mounting

arms, then down through the holes provided in the motor

stop U-bolt brackets with the offset.

Push the U-bolts all the way down until the tops of the

U-bolts are resting on the motor stop mounting arms.

Place a straight motor stop U-bolt bracket on the U-bolt

legs on the bottom side of the platform. Secure in place

with 3/8” lock washers and hex nuts. Hand tighten only at

this point.

Repeat steps 5, 6 and 7 on the other motor stop mounting

arm.

Adjustment

Position the hoist motor stop assembly on the hoist so it

is centered side to side on the hoist platform. Changing

the motor stop location front to rear is accomplished by

sliding the straight portion of the motor stop arm through

the U-bolts. This allows you to change the motor stop

location to best position your boat on the hoist. Once the

assembly is in the proper position, tighten the nuts on the

U-bolts.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 14 09/06/07

DW (Deep Water) SECTION:

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 15 09/06/07

The deep water version of this boat hoist is assembled using

the same assembly instructions as the standard hoist. The

only items that are different between the two hoists are the

length of the upright corner posts and the adjustable legs in-

side them as identied in the drawings for deep water legs.

The water depth where your hoist is going to be installed will

determine whether you should use the deep water version

of this hoist.

The deep water version of this hoist can be used in deeper

water depths because of the additional length of the exten-

sion legs. Listed below is the amount of adjustment the vari-

ous legs have.

• A standard leg shipped with the hoist has 20” of

adjustment.

• The deep water legs have 55” of adjustment.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 16 09/06/07

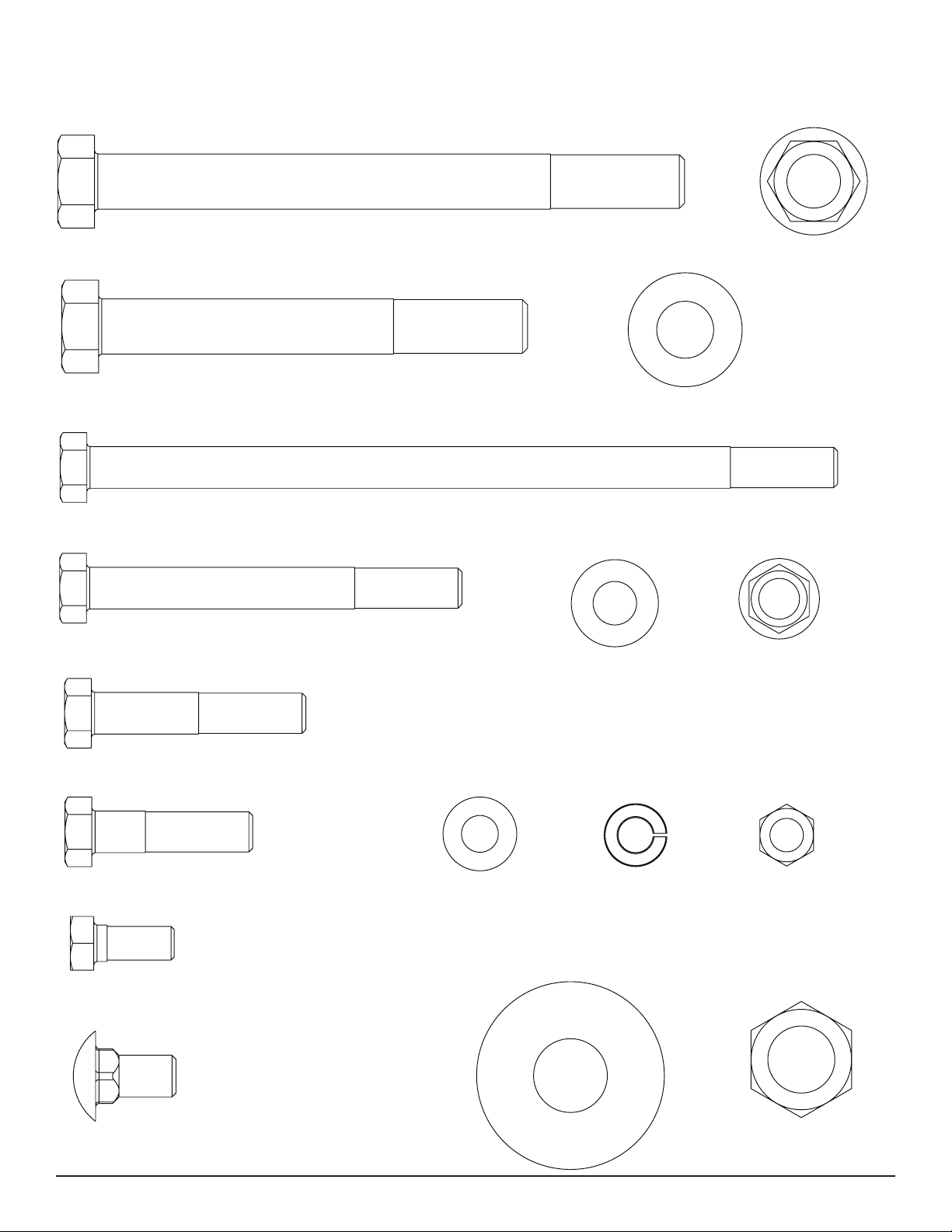

1/2”X 5-1/2”Hex Bolt - Qty: 4 (0110125)

1/2”X 4”Hex Bolt - Qty: 1 (0110114)

3/8”X 7”Hex Bolt - Qty: 16 (0110070)

3/8”X 3-1/2”Hex Bolt - Qty: 4 (0110058)

3/8”X 2”Hex Bolt - Qty: 6 (0110048)

3/8”X 1-1/2”Hex Bolt - Qty: 13 (0110045)

5/16”X 3/4”Hex Bolt - Qty: 16 (0140022)

3/8”X 3/4”Carriage Bolt - Qty: 8 (0210100)

1/2”Flange Lock Nut

Qty: 5 (1440102)

1/2”Flat Washer

Qty: 8 (1340100)

3/8”Flat Washer

Qty: 60 (1340095)

3/8”Flange Lock Nut

Qty: 48 (1440101)

5/16”Lock Washer

Qty: 16 (1310025)

5/16”Flat Washer

Qty: 16 (1310085)

5/16”Hex Lock Nut

Qty: 16 (1410079)

5/8”Flat Washer

Qty: 6 (1340105) 5/8”Brass Hex Nut

Qty: 10 (1410362)

0160042 Pre-Packaged Hardware Bag

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorestation.com 0003853

PAGE 32 09/06/07

4850408

Not A Step Decal

4811312

Clamp Arrow Decal

4811319

Adj. Guage Decal

4811505

Max Load

Decal

4850363

Safety Decal

4811312

Clamp Arrow Decal

4811319

Adj. Gauge Decal

4811502

Safety Operating Decal

4850394

Max Load Decal

4850408

Not A Step Decal

SSV60120EAC Decal Placement

4811505 Maximum Load Decal - Winch Assy

4811502 Safety Operating Decal

4811312 Clamp Arrow Decal

4811319 Adj. Gauge Decal

4850363 Safety Decal

4850408 Not A Step Decal

4850394 Maximum Load Decal - Winch Tube

This manual suits for next models

1