MIG 400 User manual

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

SLIDING GATE OPERATORS

INSTALLATION MANUAL

CE

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

GENERAL SAFETY

If correctly installed and used, this automation device satisfies the required safety level

standards.However, it is advisable to observe some practical rules in order to avoid acci-

dental problems.

Before using the automation device, carefully read the operation instructions and keep them

for future reference.

Keep children, people and things outside the automation working area, particularly during its

operation.

Keep radio control or other control devices out of children’s reach, in order to avoid any

unintentional automation activation.

Do not intentionally oppose the leaf movement.

Do not modify the automation components.

In case of malfunction, disconnect the power supply, activate the emergency release to have

access to the automation and request the assistance of a qualified technician (installer).

Before proceeding to any outside cleaning operation, disconnect the power supply.

Keep the photocell optical components and light signal devices clean.

Check that the safety devices (photocells) are not obscured by branches or shrubs.

For any direct assistance to the automation system, request the help of a qualified technician

(installer).

Have qualified personnel check the automation system once a year.

Manual release activation could cause the door to be subject to uncontrolled movements in

the case where any mechanical faults are present or the door is not balanced.

Inspect the installation frequently if it shows any unbalance or signs of mechanical damage to

cables and supports”. Do not use the operator if it needs to be repaired. Keep the

instructions together with the technical brochure for future reference.

This product was exclusively designed and manufactured for the use specified in the present

documentation. Any other use not specified in this documentation could damage the product

and be dangerous.

The Company declines all responsibility for any consequences resulting from improper use of

the product, or use which is different from that expected and specified in the present

documentation.

Do not install the product in explosive atmosphere.

The construction components of this product must comply with the following European

Directives: 2004/108/CEE, 2006/95/EEC, 98/37/EEC and subsequent amendments. As for all

non-EEC countries, the above-mentioned standards as well as the current national standards

should be respected in order to achieve a good safety level.

The Company declines all responsibility for any consequences resulting from failure to

observe Good Technical Practice when constructing closing structures (door, gates etc.), as

well as from any deformation which might occur during use.

The installation must comply with the provisions set out by the following European

Directives: 2004/108/CEE, 2006/95/EEC, 98/37/EEC and subsequent amendments.

Disconnect the electrical power supply before carrying out any work on the installation. Also

disconnect any buffer batteries, if fitted.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

Fit an omnipolar or magneto thermal switch on the mains power supply, having a contact

opening distance equal to or greater than 3,5 mm.

Check that a differential switch with a 0.03A threshold is fitted just before the power supply

mains.

Check that earthing is carried out correctly: connect all metal parts for closure (doors, gates

etc.) and all system components provided with an earth terminal.

Fit all the safety devices (photocells, electric edges etc.) which are needed to protect the area

from any danger caused by squashing, conveying and shearing.

Position at least one luminous signal indication device (blinker) where it can be easily seen,

and fix a Warning sign to the structure.

The Company declines all responsibility with respect to the automation safety and correct

operation when other manufacturers’ components are used.

Only use original parts for any maintenance or repair operation.

Do not modify the automation components, unless explicitly authorized by the company.

Instruct the product user about the control systems provided and the manual opening

operation in case of emergency.

Do not allow persons or children to remain in the automation operation area.

Keep radio control or other control devices out of children’s reach, in order to avoid

unintentional automation activation.

The user must avoid any attempt to carry out work or repair on the automation system, and

always request the assistance of qualified personnel.

Check that the stated temperature range is compatible with the place where the operator is

to be installed.

If present, the hold button (hold-to-run control) must be fitted within sight of the door but

away from the moving parts, at a height of 1.5 m, and must not be accessible to the public.

If the operator is fitted at a height lower than 2.5 m, you must guarantee an adequate degree

of protection for the electrical and mechanical parts.

Make sure that squashing is avoided between the moving parts and surrounding fixed parts.

Fit all the safety devices (photocells, safety edges etc.) required to protect the area from any

danger of squashing, drawing in and shearing.

After completing the installation, ensure that the motor is set correctly and that the

protection and release systems operate correctly.

Anything which is not expressly provided for in the present instructions is not allowed.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

1. GENERAL OUTLINE

Electromechanical operator designed to automate residential-type gates. The

operator keeps the gate blocked on closing and on opening, without needing an

electric lock. The operator has no mechanical clutch. It must be controlled by an

electronic control panel provided with torque setting. The end-of-stroke operation

is managed by the control panel.

GROUND is a series of powerful and silent gearboxes made for the automatic

movement of the winged gates and doors up to 3 meters for the leaf. GROUND OIL

and GROUND 24 V version, prepared for intensive use, are an ideal choice for

condo applications.

2. INSTALATION

Preliminary checks

Check that:

• The gate structure is sufficiently sturdy.

• Also make sure that the actuator pushes against the leaf reinforced section.

• The leaves move manually and without effort all along their stroke.

• The door stop plates are fitted at the end of both closing and opening strokes.

• If the gate has not been recently installed, check the wear condition of all

components.

• Repair or replace faulty or worn parts.

-moto-riduttore una piazzola in cemento.

Power supply cable

The board power supply cable must be of the H 05 RN-F type or equivalent. The

equivalent cable must guarantee:

- permanent outside use

- rated voltage of 300/500 V

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

- maximum temperature on the cable surface of +50° C

- minimum temperature of -25° C

Moreover, it must have a minimum section of 3 x 1.5 mm2 and, for the cable to

hold correctly, it must be provided with an external sheath of Ø = 7.1 to 9.6 mm.

The wiring of the terminal board must be carried out as shown in Fig. 3

M1= operation 1

M2= operation 2

T= earthing

N = common

WARNING! When the power supply cable is damaged, it must be replaced by the

manufacturer or its technical assistance service, or else by a person having similar

qualification, in order to prevent any risk.

External meausures

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

3. POSITIONING FOR BASE PLATE

prepare the sub structure in

order to fix base plate,

respecting approximately

measures like Fig. 2

4. POSITIONING OF GEAR MOTOR

Position the gear motors (Fig. 3) on

the great plate (A), using the

appropriate

screws supplied. The right coupling

between rack and pinion may be

carried out by registering of fixing

the small

plates (B) to the great, through the

eyelets associated. unlock the gear

motors, through appropriate

release lever

(Fig. 4). For the following

positioning and attaching the rack.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

5. FIXING RACK AND END-RUN DEVICE

Position the first element of

rack on the cogwheel,

previously unlocked, as in Fig.

5. Following fix the element to

the gate, in the way you wish,

by applying to it the other

elements of rack necessary,

ensure that all be united and

aligned.

Locate the desired position

and fix end-run device (F) on

Rack as indicated in the previous Fig. 2, those with grains included. Close the

release lever and perform the necessary electrical connections.

6. THE ELECTRICAL PLANT SET-UP

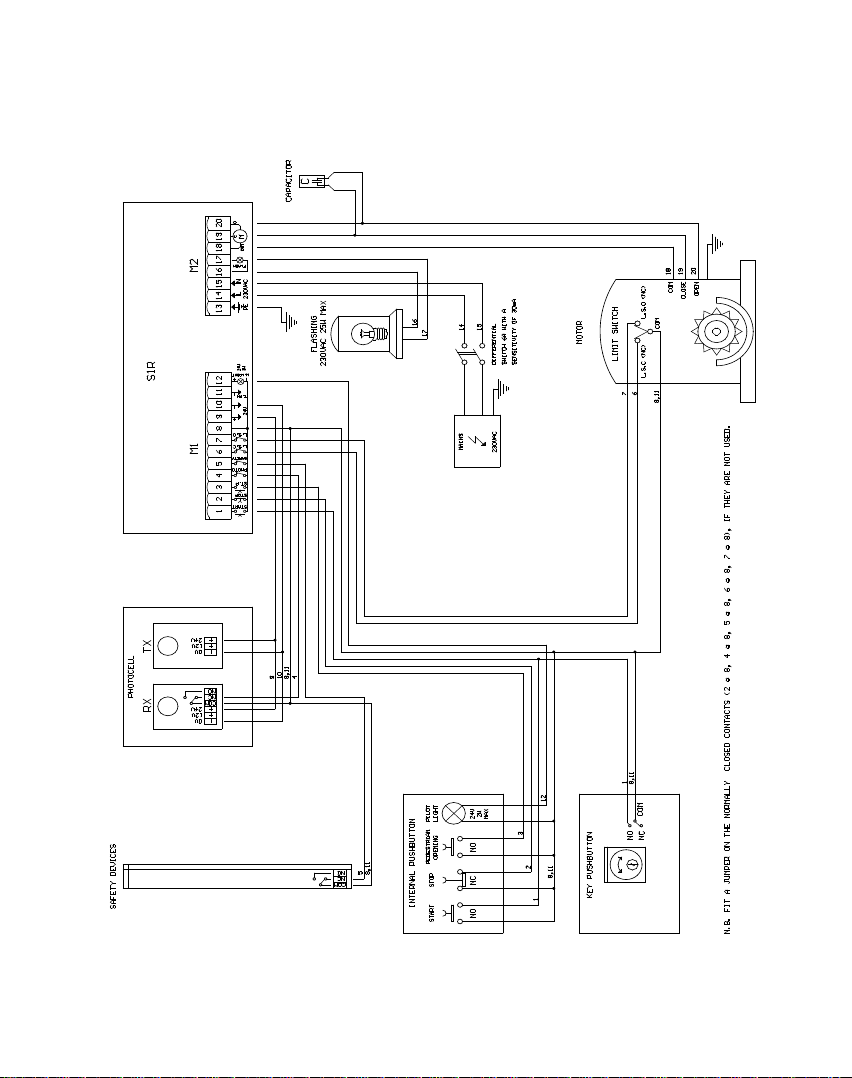

Fig.6

Lay out the electrical installation fig. 6 with reference in force for electrical

installation. The mains power supply connections must be kept totally separate

from the service connections (photocells, electric edges, control devices etc.).

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

Connect the control and safety devices in compliance with the previously

mentioned electrical installation standards.

The main automation components are:

Control panel and incorporated receiver Pair of outside photocells

Key selector Pair of inside photocells

Blinker tuned in with antenna

1-2-4 channel transmitter

Operator Antenna cable

Warning! For actuator wiring and accessory connection, refer to the relevant

instruction manuals. The control panels and accessories must be suitable for use

and conform to current standards.

Should the opening or closing direction be incorrect, it is possible to invert the

connections of operation 1 and operation 2 on the control board.

The first command after an interruption of the power supply should be an

opening maneuver.

7. CHECKING THE AUTOMATION

Before considering the automation completely operational, the following checks

must be made with great care:

• Check that all the components are firmly anchored.

• Control all the safeties work properly (i.e. photocells, pneumatic skirt, etc.).

• Check the emergency maneuvers control.

• Check the opening and closing maneuvers using the controls.

• Check the control unit’s electronic logic in normal (or customized) operation.

8. USE OF THE AUTOMATION

Since the automation may be remote controlled either by radio or a Start button, it

is essential that all safeties are checked frequently.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

Any malfunction should be corrected immediately by a qualified specialist.

Keep children at a safe distance from the field of action of the automation.

9. THE CONTROLS

With the automation the gate has a power driven opening and closing. The controls

can come in various forms (i.e. manual, remote controlled, limited access by

magnetic badge, etc.) depending on needs and installation characteristics. For

details on the various command systems, consult the specific instruction booklets.

Anyone using the automation must be instructed in its operation and controls.

10. MAINTENANCE

When carrying out maintenance operation on the controller, disconnect it from the

mains power supply. The actuator does not require periodical maintenance

operations.

• Check the safety devices of the gate and automation.

• Periodically check the pushing force and correct the value of the electric torque in

the control board if necessary.

• In case of unsolved operation failures, disconnect the unit from the mains power

supply and ask for the intervention of qualified personnel (installer).

When the unit is out of order, activate the manual release to perform manual

opening and closing maneuvers.

11. NOISE

The aerial noise produced by the gear motor under normal operating conditions is

constant and does not exceed 70dB (A).

12. TROUBLES AND SOLUTIONS

Incorrect operation of gear-motor

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

Check for the presence of power supply to the gear motor using a suitable

instrument after opening or closing commands have been given.

If the motor vibrates but does not turn, the causes could be the following:

a) incorrect connection of the C common wire.

b) operation capacitor not connected to the terminals on the control board.

c) if the moving direction of the leaf is opposite to the right one, invert the motor

running connections.

Incorrect operation of the electrical accessories

All control and safety devices can cause, in case of failure, malfunctioning or

stoppage of the automation.

To identify the failure, it is advised to disconnect all the devices of the automation

one by one until the one causing the problem is found.

After fixing or replacing the defective device, reset all the devices previously

disconnected. Refer to the relevant instruction manual for all the devices installed

on the automation.

13. MANUAL MODE

In case of interruption of the power supply, failure, or need activities on the plant,

is possible to operate the gate in manual mode, as shown in Fig. 4. Insert the key in

lock release lever and rotate in order to open it. Pull off the lever up to a corner

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

over 90° and make the manoeuvres you like. At the end of the operations, restore

the lever in the starting position.

14. CARATTERISTICHE

MIG 400 MIG 600 MIG 1000

Supply (Vac 50Hz) 230 230 230

Engine supply

(Vac/Vdc)

24/220

220

220

Engine power

(W)

70/300

400

500

Max weight (kg) 400 600 1000

Max thrust (Nm) 300 690 870

Thermal protection

-/integrated

integrated

integrated

Temperature range

(°C)

-25 / +70

-25 / +70

-25 / +70

Cycle (%) 90/40 50 50

Weight (Kg) 9 9,5 10

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

11. ELECTRONIC EQUIPMENT L1 (220V)

INTRODUCTION

The electronic equipment Type S1R can be used to control one actuator for a sliding

gate. The max. absorption of the device is 600W per 230V 50Hz. The set-up of the

parameters must be carried out after the installation of all the equipment.

DESCRIPTION

TR1 – TR4 = Trimmers

DSW1 = Dip switches

DL1-DL8 = LED

F1 = Line 230V fuse

F2 = Low voltage fuse

M1 = Signal terminal board

M2 = Power terminal board

CN2 = Antenna terminal board

K1-K3 = Relais

TF1 = Transformer

U1 = Microprocessor

JR1 = Reset jumper

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

INSTALLATION

Before making the electrical connections it is necessary to turn off the mains of 230V

50Hz and regulate the motor torque to a minimum.

Use 0.5mm2 wires to make connections to the pushbuttons, photocells and 24V power

supply. For connections to the electric lock, flasher and motors it is necessary to use at

least 1.5mm2 wires. Use wires of at least 2,5mm2 to make connections to supply

mains of 230V 50Hz.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

M1 terminal board

START = Normally open pushbutton (opening / closing)

STOP = Normally closed pushbutton (stop)

ST.P = Normally open pushbutton (pedestrian opening)

PHOTO = Normally closed input external photocell

SAFETY = Normally closed safety contact

L.S.C. = Normally closed contact limit switch closing

L.S.O. = Normally closed contact limit switch opening

COM = Common for inputs and warning light

+ 24V = Positive supply accessories 24V CC

- 24V = Negative supply accessories 24V CC

W.LIGHT = Warning light 24V 3W max

M2 terminal board

L = Input 230V 50Hz Line

N = Input 230V 50Hz Neutral (Flash light common contact)

FLASH = Flash light 230V 50Hz 15W max

COM = Motor common coils

C = Motor closing windings

O = Motor opening windings

It is necessary to connect a capacitor between C and O terminals.

It is necessary to clamp the cables of the M1-signals terminal board to M2-power

terminal separately. Fit a jumper cable on the normally-closed contacts when they are

not in use.

If one of the normally-open inputs (START and STOP) is closed, or one of the normally-

closed inputs is open, the TEST LED flashes at high frequency.

In this case it is not possible to carry out the learning strokes procedure.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

OPERATING MODES

CONDOMINIUM AUTOMATIC:

The gate is opened when the START button is pressed whether the gate is

closed or being closed. The START command is ignored while the gate is being

opened, whereas during the pause phase it makes the timing of this phase

restart. After pressing STOP, pressing START closes the gate.

SUPERAUTOMATIC:

The gate is opened when the START button is pressed whether the gate is

closed or being closed. While the gate is being opened however it produces a

STOP, after which a subsequent START closes the gate. During the pause phase,

pressing the START button closes the gate. After pressing STOP, pressing START

closes the gate.

AUTOMATIC:

The gate is opened when the START button is pressed whether the gate is

closed or being closed. The START command is ignored while the gate is being

opened, whereas during the pause phase it makes the gate close again. After

pressing STOP, pressing START closes the gate.

SEMIAUTOMATIC:

The START button controls the opening, closing and halting of the gate. After it

is opened, it is necessary to press the START button to close it again. While the

gate is being opened, pressing START halts the gate and another pulse makes

the gate close. If START is pressed during the closing phase the direction is

inverted. After pressing STOP, pressing START closes the gate.

STEP BY STEP:

The gate is opened when START pulse is pressed while the gate is closed.

The START command produces a STOP during the opening phase, subsequently

pressing START causes the gate to close, and pressing START again produces a

STOP. After pressing STOP, pressing START closes the gate.

MAINTENANCE

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

There are two 5x20-size fuses on the board that protect the 230V line and the

secondary of the transformer.

The fuses have the following values:

230V line F1 = 5 A fast

Secondary F2 = 630 mA fast

Before replacing the fuses it is necessary to turn off the 230V mains power supply. The

power of these fuses must not be modified.

There is no other component on the board that can be repaired or replaced by the

installation personnel.

For any other intervention it is necessary to contact technical support.

SETTINGS

DIP 1 DIP 2 DIP 3 Operating mode

OFF

OFF

OFF

Condominium automatic

OFF OFF ON Condominium automatic + Comfort (*)

OFF ON OFF Superautomatic

OFF

ON

ON

Superautomatic + Comfort (*)

ON ON OFF Automatic

ON ON ON Automatic + Comfort (*)

ON

OFF

OFF

Semiautomatic

ON OFF ON Step by step

DIP Function ON OFF

4

Preflashing

Enabled

Disabled

5

Flash light type

With board

Lamp only

6 Photocell retrigger(***) Enabled (**) Disabled (**)

DIP 7

DIP 8

Installation type

OFF

OFF

SLIDING GATES

(*) The function comfort enables the gate to be closed 5 seconds after the

photocells have received a pulse, regardless of the timing of the pause setting.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

(**) If comfort is enabled dip 6 don't cares

(***) The function photocell retrigger makes the timing of the pause restart if the

photocells are in use during the pause itself.

After each mode change it is necessary to short circuit JR1 reset contacts for a few

seconds so that the change can take effect)

REGULATIONS

Trimmer

Function

Range

(TR1) DELAY Pause time From 0 to 140 secondi

(TR2)TORQUE

Motor torque

From 20 to 100%

(TR3) SK - CU Slowing speed From 0 to 100%

(TR4) BRAKE

Brake intensity

From 0 to100%

The TR1 DELAY trimmer regulates the timing of the pause (the time the gate

remains still before being closed automatically), which varies from 1 to 120

seconds.

The TR2 TORQUE trimmer regulates the torque of the motor. For motors equipped

with a clutch or for oil-pressure motors it is necessary to rotate the TR2 TORQUE

trimmer to the maximum extent possible (i.e., a complete clockwise rotation).

The TR3 SK-CU trimmer regulates the speed at which the timing is slowed, which

can be regulated within the safety parameters. By regulating the TR3 SLACK

trimmer to the maximum extent possible (i.e., a complete clockwise rotation),

the slowing does not take place (see learning procedure without slowing).

The TR4 BRAKE trimmer regulates the brake intensity. To disable the brake it is

necessary to regulate the trimmer to a minimum.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

REMOTE CONTROLS LEARNING

The SR equipment is equipped with a built-in decoder able to memorize up to 128

rolling-code remote controls or one fixed-code remote controls.

Start function

In closed-gate mode, press the PROG.B button and hold it down until the TEST LED

starts to flash. Release the PROG.B button.

Within 10 seconds, set the remote control button that you want to connect to the

START command. The completion of the process will be indicated by the

simultaneous flash of the TEST LED, of the flasher and of the pilot lamp, followed

by the termination of the flashing of the TEST led.

With rolling code remote controls, repeat the process for each remote control to

be set. With fixed-code remote controls it is sufficient to carry out the process for

only one model.

Pedestrian start function

In closed-gate mode, press the PROG.B button and hold it pressed until the TEST

led starts to flash; don’t release the button and wait until the flashing speeds up.

Release the PROG.B button.

Within 10 seconds set the button of the remote control to learn and to be

connected with the PEDESTRIAN START control. When the learning has been

carried out it will be indicated by the simultaneous flash of the TEST led, flasher

and of the pilot lamp, followed by the termination of the flashing of the TEST led.

In case of rolling code-type remote controls repeat the operation for each remote

control to learn. In case of fixed-type remote controls it is sufficient to carry out the

learning of one single model.

Complete erasing of the learnt remote controls

In closed-gate mode, press the PROG.B button and hold it pressed till when the

TEST led starts to flash; don’t release the button and wait until the flash gets

quicker; don’t release the button and wait until the flash gets very quick; don’t

release the button. When the blanking /blackout of ALL the learned remote

controls has been carried out it will be indicated by the simultaneous flash of the

TEST led, flasher and of the pilot lamp, followed by the termination of the flashing

of the TEST led.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

INSTALLATION SLIDING GATE TYPE

TRIMMER

•Trimmer TR1 DELAY as you need.

•Trimmer TR2 TORQUE to the minimum.

•Trimmer TR3 SK-CU as you need.

•Trimmer TR4 BRAKE as you need.

DIP SWITCH

•From 1 to 6 as you need.

dip switch 7 = OFF and dip switch 8= OFF

Press the PROG.A learning button for at least 3 seconds, until the TEST

LED starts to flash, then do as follows. Learning ends when the TEST LED turns

off.

USER’S MANUAL MIG

____________________________________________________________________

____________________________________________________________________________________

MATT di LIEVORE SRL Via Bianche 7 36010 Carre’ ( VI ) Tel. 0445 / 892223 Fax 0445 / 390346

CONNECTIONS

This manual suits for next models

2

Table of contents

Popular Gate Opener manuals by other brands

Bandini Industrie

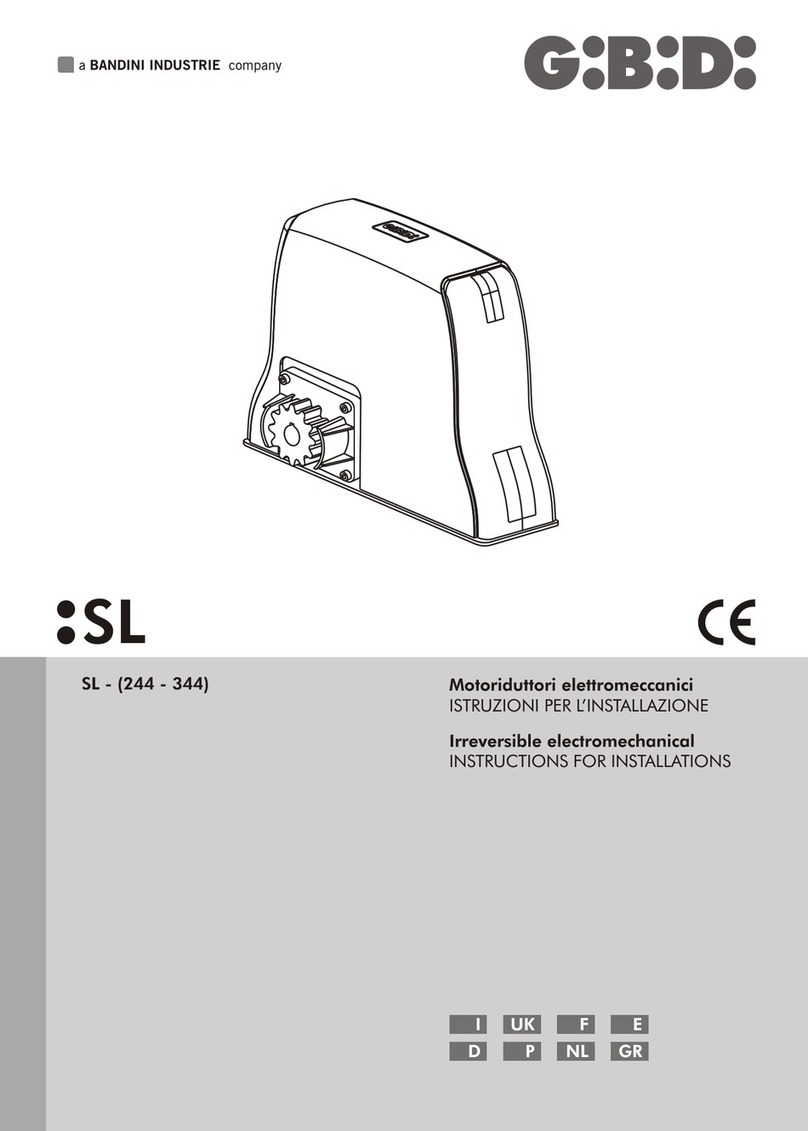

Bandini Industrie GiBiDi SL Series Instructions for installations

CAME

CAME FA4024CB installation manual

Merlin

Merlin G815D Instructions for installation & use

Platinum Access Systems

Platinum Access Systems BLSL2250 Installation instructions & owner's manual

Allmatic

Allmatic IND4000V/T manual

SOMFY

SOMFY Axovia 400C NS quick start guide