Serai KIT/A9 User manual

E R A IS

GATE OPENER DIVISION

DAL 1965

KIT/A9 - 03.A9 KIT WITH 2 ARTICULATED ARM MOTORS WITHOUT CARTER FOR

WING GATES UP TO 3.50 + 3.50m AND 350 kg PER LEAF - 230 Vac

Page 1/18

INSTRUCTIONS MANUAL

Thank you for having chosen SERAI ELETTRONICA, certain that you will obtain the performance necessary for use from this pro-

duct.

Remember that you are about to install a system classified as "motorised activation destined to move gates and automatic

doors in commercial and residential buildings, with access of vehicles and persons", which is considered as potentially dan-

gerous. Normally, it is your task and responsibility to make this system "safe" for how mush this is reasonably possible.

Installation and maintenance of such a system must therefore by carried out exclusively by trained,qualified and

expert staff, with "state-of-the-art" executions, as prescribed by law 37/08 and successive amendments and

integrations. The law prohibits the realisation of these types of plants by unqualified staff.

On realisation of its own products, SERAI has respected the following:

Reference Directives for CE marking:

Machinery:

Low Voltage:

Electromagnetic Compatibility:

General reference Standards:

Electrical Safety:

Electromagnetic Compatibility - Emissions:

Electromagnetic Compatibility - Immunity:

When installing the system, as well as that mentioned previously, please also respect.

General reference Standards:

Safety of electrical plants in general environments:

Reference Standards specific of the product:

Safety regarding use of motorised doors - requisites:

Safety regarding use of motorised doors - test methods:

The SERAI products allow to realise systems that respond to these Standards. The following is very

important THE INSTALLER IS RESPONSIBLE FOR THE SYSTEM AND ITS FUNCTIONING IN

COMPLIANCE WITH STANDARDS.

This manual must be read completely before proceeding with installation of the various parts of the plant.

The installation of the mechanical stops with gate opening and closing is necessary for safety of the system

and must therefore be performed before proceeding with installation of the control unit.

2006/42/CE

73/23/CEE + 93/68/CEE

2004/108/CEE

CEI EN60335-1 + CEI EN60335-2-103

CEI EN61000-6-3

CEI EN61000-6-1

CEI 64-8 V2

UNI EN12453

UNI En12445

!

KIT/A9 I E

DAL 1965

Page 2/18

MOTOR REDUCER CLEARANCE MEASUREMENTS -with carter-

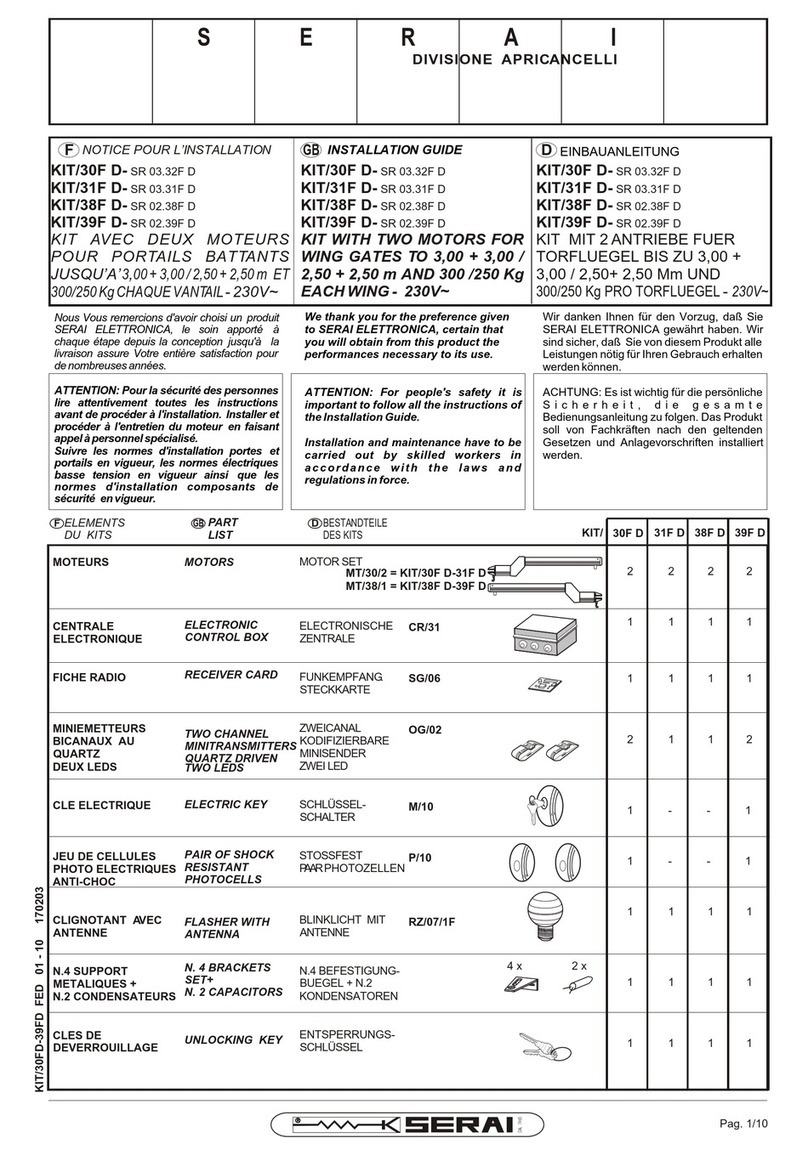

KIT COMPONENTS

QUANTITY

DESCRIPTION

248,5

88

168,5

367

!

CANCELLO

AUTOMATICO

1

1

1

1

1

1

1

2

MT/A39

CR/41

OG/64

M/10

P/10

RZ/20

RZ/99

M/12 SERAI board

Motor reducer without

carter

Electronic control unit with

receiver incorporated

Dual channel superminitele

with pouch

Electric key

Pair of shock-proof

photocells

Flashing light with antenna

incorporated without

internal electronicsfor

flashing

Elbow support

CARTERS SOLD SEPARATELY

A/69 Carter of ICE colour

A/79 Carter of EMERALD colour

A/89 Carter of DARK GREY colour

A/99 Carter of DARK BROWN colour

2

KIT/A9 I E

DAL 1965

Page 3/18

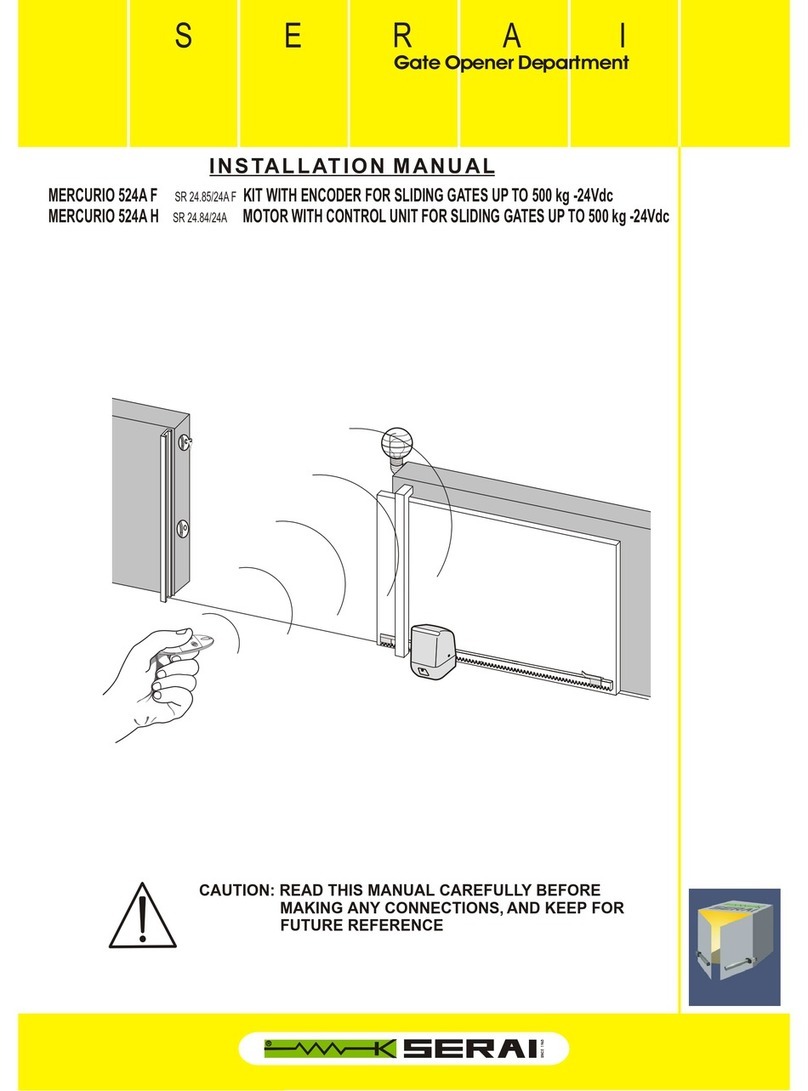

4

5

6

M/10 electric key

Pair of P/10 photocells

Flashing light with antenna RZ/20

PLANT TYPE

1

2

3

Motor reducer

CR/41 electronic control unit with

receiver incorporated

OG/64 4-channel remote control

Recommendations for connections in general rooms

1. Upstream from the system, prepare an omnipolar isolating switch with distance of 3 mm or more between the

contacts. As an alternative, use a 10Amagnet circuit breaker switch.

2. Make any type of connections always with the system not powered, i.e. with the isolating switch in the "open"

position ("0" symbol). In particular, the control unit must never be powered during wiring or while any expansion

cards are being inserted.

3. When installing the plant, use the following cables:

- for the power supplies of the control unit, motors and the electric locks: section 1.5mm2 for maximum length of

19m, section 2.5mm2 for lengths up to 31m,

- for the flashing light section 0.75mm2 for maximum lengths of 3m, section 1.5mm2 for lengths up to 19m.

- for low voltage and current lines, such as photocells, control buttons, electro-mechanical key, sensitive edges

and other safety devices: section 0.5mm2 for maximum length of 50m, section 0.75mm2 for lengths up to 100m.

4. Make the "earth" connection as envisioned by the Standards.

4 x 0,5 mm²

4 x 1,5 mm²

2 x 0,5 mm²

3 x 0,5 mm²

1

5

5

4 x 0,5 mm²

2 x 0,5 mm²

230V~

3x1,5 mm²

4 x 1,5 mm²

1

4

3

Power supply ........................230 Vca ±10% 50/60 Hz

Leaf max. length ...................3,5 m

Leaf max. weight...................350 Kg

Max. opening angle...............120°

Max. absorption ....................1,6 A

Power .................................190 W

Max motor torque..................245 Nm

Angular speed.......................0,12 rad/sec

Opening time.........................13 s per 90°

Motor thrust regulation..........via power supply voltage

regulation

Condenser ............................12,5µF

Motor circuit breaker protection...150 °C

Protection rating....................IP54

Temperature..........................-20° ÷ +60°C

Dimensions -with carter- .......168,5x367x248,5mm

Weight (motor + levers) ........14 Kg

MT/A39 MOTOR REDUCER TECHNICAL DATA

RG58 + 2 X 0,75 mm²

6

2

5

KIT/A9 I E

HINGE

GATE STOP BASE

IN OPENING

AND CLOSING

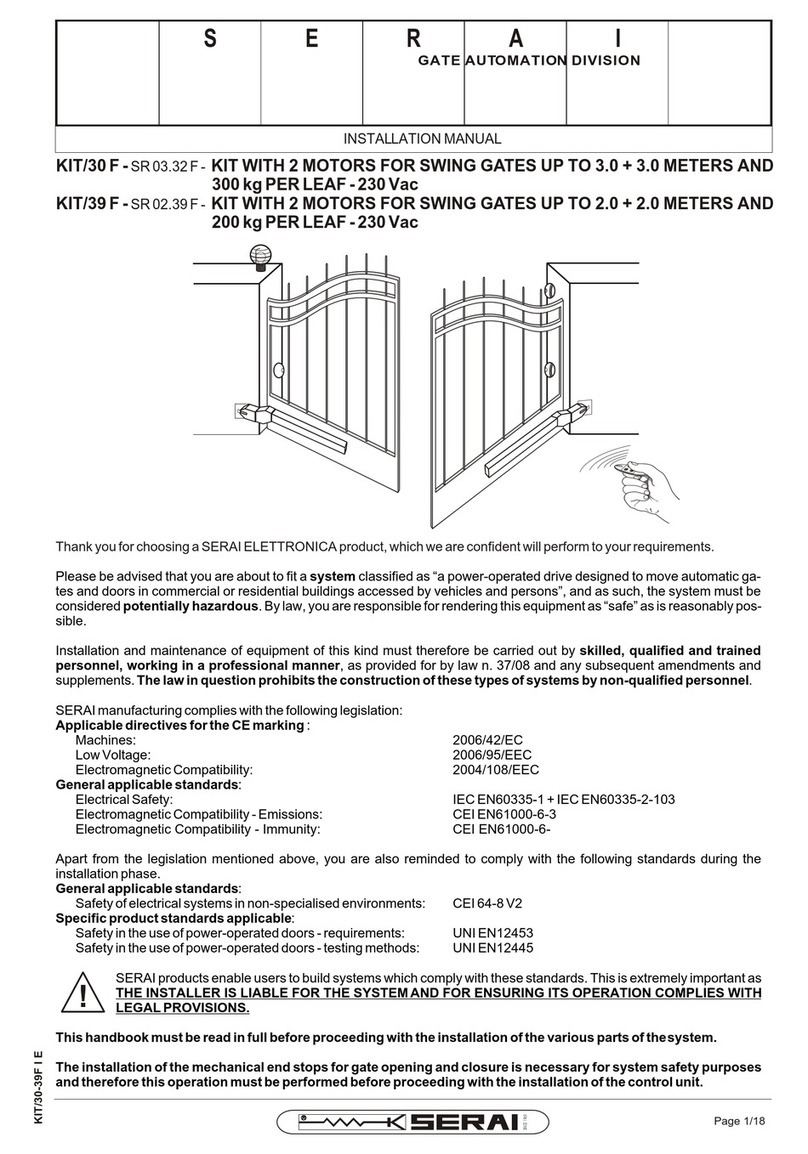

1- Control the perfect perpendicularity of the gate hinges to allow rotation of the wing in absolute level conditions

and most of all not unbalanced. The articulated arm of the motor must operate horizontally only without any ver-

tical movement.

The installation of the mechanical stops in opening and closure mode of the gate is necessary for the

safety of the plant.

!

2- Define the motor installation position, which varies according to the angle of opening of the gate position with re-

spect to the pillar, respecting the measurements and drawings given below.

EXAMPLE FOR OPENING UP TO 120°

B=200

A=300

400

MAX 120°

BEFORE INSTALLING THE MOTORS

DAL 1965

Page 4/18

Fig. 1 Fig. 2

Fig. 4

KIT/A9 I E

INSTALLATION MEASUREMENTS

315 for 90°

375 for 100°

162

B

A

C³100

CORNER

ATTENTION:

RESPECT THE MEASUREMENT

C 100mm FOR CORRECT

MOVEMENT OF THE LEAF

³

!

Fig. 3

160 200

220

240

260

280

300

320

----

512

100

100

100

100

100

100

95

----

90

A B CORNER

³100

C

200160

180

200

220

240

260

300

100

105

110

113

116

120

120

A B CORNER

³100

C

IMPORTANT:

MEASUREMENTS

TO RESPECT IN THE

CASE OF A LATERAL WALL

IF NECESSARY USE ARM K/75

DAL 1965

Page 5/18

4 MOTOR FIXING POINTS

EXAMPLE FOR GATE INSTALLED TOWARDS THE EXTERNAL PART OF THE PILLAR

B=512

A=160

MAX 350

INSTALLATION

Fig. 5

MOTOR FIXING

POINTS INTERAXIS

3 - After having defined the position of installation, fix

the motor to the pillar using N°4 M8 screws (hex

head or cylindrical head with recessed hexagon)

complete with large washer (external diameter

24mm) with fixing system suitable for the type of

pillar.

4 -

fig.7-8.

5 -

Assemble the levers, in left and right assembly, only

the position of the curved arm differs while the

straight arm must always be mounted with the pin

downwards, see

Insert the straight lever bush into the toothed outlet

of the shaft and fix it using the nut and washer. Fig. 7

Fig. 6

Fig. 8

110mm

100mm

6 -

fig.9.

7 -

8 -

9 -

Position the articulated arm bracket on the gate as far away from the column as possible, extending the arms

to maximum and always respecting the measurement of as indicated in

Fix the articulated arm bracket to the leaf suitably using screws or by welding.

Keeping the motor reducer released, check the correct movement of the articulated arm and of the leaf.

Repeat the same operation for the other leaf.

C³100

C³100

Fig. 9

KIT/A9 I E

!ATTENTION:

- Should pillar be too narrow, e.g. 100mm,

use the plate K/88

- Should pillar be made of light material,

e.g. stones or tuff, the strength of the

motor against the mechanical stops

could be too high for a normal fixing

system and the motor could come off the

pillar. Use in this case a proper fixing

plate

DAL 1965

Page 6/18

FIX THE GUARD USING

THE 2 SCREW

FASTENERS

TURN THE KEY TO

RELEASE THE HANDLE

10 - Close the motor by inserting the guard and release handle. Fix the guard using the two screws 2 and lock the

release handle using the key in the lock.

Fig. 10 Fig. 12Fig. 11

CARTER OPENING

-

-

Insert the release key into the lock positioned on the

handle; turn it to release the handle. Release the

motor by turning the handle clockwise 180°. Remove

the handle by lifting it.

Lift the guard after having removed the two screw

fasteners.

If it is necessary to act on the leaf manually, e.g. if there is a power cut, the following operations must be

performed:

remove the electric power supply;

insert the key into the lock on the release lock and rotate it;

turn the release handle clockwise by 180°;

now the leaf can be moved manually.

-

-

-

-

MANUAL RELEASE FOR EMERGENCIES

INSERT AND ROTATE THE

KEY TO UNLOCK THE

RELEASE HANDLE

TURN THE RELEASE

HANDLE CLOCKWISE BY

180°

RELEASE THE HANDLE USING THE

KEY AND ROTATE 180°

CLOCKWISE

2 GUARD SCREW

FASTENERS

KIT/A9 I E

INSTALLATION OF THE CR/41 CONTROL UNIT

Position the appliance in proximity of the gate in a way to reduce the length of the connection cable, to the rest of

the system, to a minimum.

For greater protection from atmospheric agents it is recommended to position the control unit under a roof or, even

better, in a room that has two lateral walls. It is also good practice to install the appliance at a height above 1.5 m

where possible in order to prevent it being tampered with by children.

WHERE TO POSITION THE CONTROL UNIT

The control unit leaves the factory with the lid positioned to open from the left side.

If you wish to open the lid from the opposite side, proceed as follows:

ATTENTION: This operation must be carried out

before fixing the container to the wall.

Insert a flat tip screwdriver into the fixing recess of the hinges

positioned on the rear of the base and lever on the attachment

notch of the hinge itself; pull the lid at the same time.

(see Fig.1)

Fig.1

Insert a flat tip screwdriver into the fixing recess of the hinge

positioned on the front part of the lid and lever on the notched

attachment of the hinge itself; pull the hinge at the same time.

(see Fig.2)

Fig.2

DAL 1965

Re-mount the hinges on the right side of the base by

inserting them in the relevant seats with the attachment

notch facing towards the inside of the container until the

attachment clicks (see Fig.3)

Fig.3

LID SET-UP FOR LID OPENING TO THE RIGHT

!

Page 7/18

KIT/A9 I E

DAL 1965

CABLES INPUT

Seats for fairleads PG11 and PG 13,5 which are easy to break through, are envisioned in the lower part of the

container for the passage of input cables

!

Cables passage

ATTENTION: Close all inputs well to prevent the entry of insects,

which may damage the control unit.

FIXING THE CONTROL UNIT TO THE WALL

Ø 6 ÷ 8 mm

It is recommended to position the appliance in

proximity of the gate in a way to reduce the length of

the connection cable, to the rest of the system, to a

minimum.

The control unit must be fixed via the cable passage

holes facing downwards.

Page 8/18

NO NO YES

OPENING AND CLOSING THE BOX

When opening the box, make sure that most of the hinges

escape from the guide on the bottom of the control unit in order

to guarantee that the lid remains open without obstructing the

control unit wiring operations.

In the closing phase, accompany the lid until complete return of

the hinges. Pay attention that the gasket is inserted correctly

Close the lid using the appropriate screws.

Recommendations for connections in general rooms according to the Italian

Standards (IEC 64-8).

1. Upstream from the system, prepare an omnipolar isolating switch with distance of 3 mm

or more between the contacts. As an alternative, use a 10A magnet circuit breaker

switch.

2. Make any type of connections always with the system not powered, i.e. with the

isolating switch in the "open" position ("0" symbol). In particular, the control unit must

never be powered during wiring or while any expansion cards are being inserted.

3. When installing the plant, use the following cables:

- for the power supplies of the control unit, motors and the electric locks: section 1.5mm2

for maximum length of 19m, section 2.5mm2 for lengths up to 31m,

- for the flashing light section 0.75mm2 for maximum lengths of 3m, section 1.5mm2 for

lengths up to 19m.

- for low voltage and current lines, such as photocells, control buttons, electro-

mechanical key, sensitive edges and other safety devices: section 0.5mm2 for

maximum length of 50m, section 0.75mm2 for lengths up to 100m,

4. Make the "earth" connection as envisioned by the Standards.

KIT/A9 I E

DAL 1965

DAL 1965

Page 9/18

CLAMPS CONNECTIONS DESCRIPTION

21 - 22

POWER SUPPLY

230VAC ±10% 50/60 Hz board power supply input.

11 - 12

FLASHING

12 - 13

COURTESY LIGHT

14 - 15 - 16

MOTOR M1

Motor power supply output M1 (14=Common, 15=Opening, 16=Closure)

for single or pedestrian leaf (to which the electric lock is connected)

26 - 27

PHOTOCELLS

POWER SUPPLY

24Vac power supply output (max 500mA) for photocell type accessories.

6

OPENING

PHOTOCELL/

SENSITIVE EDGE

DO NOT USE

5

CLOSURE

PHOTOCELL

2

4

PEDESTRIAN

CONTROL

input (NO contact). With DIP1 SW1 OFF open only the leaf is connected to M1.

With DIP1 SW1 ON the single leaf opens for 7s.

STOP KEY

Stop control input (NC contact). When pressed it blocks

functioning of the motors, if pressed during the open gate

pause time it annuls automatic closure.

3

START

CONTROL

Start control input (NO contact),

controls the opening and closure in step-by-step mode.

With DIP4 SW2 OFF: Photocell input active in opening and closing (NC contact). If

blacked-out in the opening phase, the gate stops, re-starts opening as soon as the

photocell is no longer engaged. If blacked-out in the closure phase, the gate stops,

re-opens as soon as the photocell is no longer engaged.

With DIP4 SW2 ON: Sensitive edge input (NC contact), inverts movement by 10cm.

Photocell input active only in closing (NC contact). If blacked-out in the

closure phase, the gate stops and then re-opens.

COMMON

INPUTS

Inputs common clamps.

17 - 18 - 19

MOTOR M2

Motor power supply output M2 (17=Common, 18=Opening, 19=Closure) for

delayed motor in opening mode (gates with 2 leaves)

25 - 26

ELECTRIC LOCK

CONTROL

23 - 24

INCORPORATED

RECEIVER

ANTENNA

28 - 29

GATE OPEN

INDICATOR LIGHT

Output 24Vdc (28=+, 29=-) max 50mA for gate open indicator light open.

ATTENTION: to connect warning lights with consumption

exceeding 50mA, use an appropriate additional external relay

Sw1= Micro switches for setting the

control unit -see micro

switches setting-

A= Button used to enter

programming (SET)

B= Button used to program times

(BREAK)

C= Button used to program times

(WORK)

POWER= Trimmer motor thrust

regulation

Sw2= Micro switches for setting the

control unit -see micro

switches setting-

20

DO NOT USE

ADDITIONAL

RELAY

24Vcc - max 50mA

2928

INDICATOR

LIGHT

INDICATOR LIGHT

POWER SUPPLY

FUSES:

F1 = T1,6A 250Vac -delayed-

-ACCESSORIES 24V-

F2 = 5A 250Vac -instantaneous-

-230V POWER SUPPLY-

Flashing light power supply output (230Vac-max50W) to be used with

flashing light without -SERAI RZ/20-internal electronics.

Courtesy light output (230Vac-max 100W): active for 90s from the STOP

8 - 9 Short circuit on the common with jumpers.

1 - 7 - 10

Output 12 Vac 15 VA max for direct control of electric lock -SERAI M/83/1-.

To reduce the noise a rectifier bridge can be used as per layout

Input for the connection of the antenna for the built-in receiver.

(23=BRAIDING, 24=ANTENNA)

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9

DL8

DL10

1 2 910 11 121314 1516171819 20 21 22

272526

2324

OPEN

CLOSE

COMUNE

230Vca ±10%

50/60Hz

FN

FLASHING LIGHT

230Vca

COURTESY LIGHT

230Vca

OPEN

CLOSE

COMMON

M2M1

PED

NC

NC

PHOTOCELL

FOR CLOSURE

RECEIVERTRANSMITTER

PHOTOCELL

FOR OPENING

(or SENSITIVE EDGE) RECEIVERTRANSMITTER

NC

NC

NO

NC

NO

PEDESTRIAN

START

STOP

ELECTRIC LOCK

-SERAI M/83/1-

24 Vca

CONNECTIONS LAYOUT

DISCONNECT THE POWER

SUPPLY BEFORE INTERVENING

ON THE CONNECTIONS

OP.DEL.

SET BREAK WORK

A B C

Com

+24

spia

12Vca

RX

2829

+ -

230Vca

ELECTRIC LOCK

-SERAI M/83/1-

RECTIFIER

BRIDGE

ADDITIONAL

RELAY

12Vca

TRANSFORMER

230/12Vca

-SERAI TR/01-

F

N

REDUCTION OF ELECTRIC LOCK NOISE

To reduce the electric lock noise it is possible to use a 50V

4A rectifier bridge found on the market, connected as per

layout shown below.

230Vca

12Vcc

12Vca

12Vca

*

*

~

KIT/A9 I E

DAL 1965

Page 10/18

CONDENSER ALREADY

WIRED INTERNALLY

!

EARTH CONNECTION BETWEEN MOTOR AND HOUSE PLANT

MOTORS OF THE

YELLOW-GREEN

CABLESI

CONNECTION CLAMP

230 V~POWER

SUPPLY CABLE

MOTOR 2

CABLE

MOTOR 1

CABLE

HOUSE PLANT

YELLOW-GREEN CABLE

MOTOR ELECTRIC CONNECTIONS

Connect the motors to the electronic control unit using cables with

section of 1.5 mm². Respect the clamps as follows:

COM : Common

A/C : Open/Close - Condenser

A/C: : Open/Close - Condenser

: Earth

The following prescription must be respected (IEC 64-8):

- Connect the motors earth (yellow-green cable) to an efficient

earth plant.

- Install an omnipolar switch upstream from the plant with an ope-

ning distance of 3 mm or more between the contacts.

|

__

_

_

|

__

_

_COM A/C A/C 1 2 3

HOLE FOR CABLE

INPUT

CABLE FIXING

CLAMP

!

Also remember that the large

temperature differences between the

summer and winter cause different

dilation of materials, including those with

which the motors are built. For this

reason it is recommended to control the

regulation of the motor thrust at the start

of the winter and the summer.

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9 DL8

DL10

1 2 910 11 121314 1516171819 20 21 22

272526

2324

28 29

SET BREAK WORK

A B C

Com

+24

spia

RX

ADJUSTMENT OF THE MOTORS STRENGTH

The SERAI CR/41 control unit allows:

A- adjustment of the motors strength by acting on the "Power" potentiometer in the control unit

B- programming of the slowing which prolongs the life of the motor avoiding the gate banging against the

mechanical stops

If slowing has been inserted, the motor has less strength and therefore the gate, if not well-done,

may stop before having completed the manoeuvre.

By excluding the slowing the gate bangs against the mechanical stops causing a, more or less, loud

noise, according to installation. Also, the internal gears are subject to greater stresses.

"POWER" POTENTIOMETER

KIT/A9 I E

DAL 1965

Page 11/18

SETTING OF EACH INDIVIDUAL MICRO SWITCH

SETTING

THE MICRO SWITCHES DESCRIPTION OF THE FUNCTIONING

FUNCTIONING

- Single wing logic: just the output indicated with M1 is controlled

- Double wing logic: both outputs M1 and M2 are controlled

-M2 leaf delayed on opening-

CONFIGURATION

GATE

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

REGULATION

SLOWING

SPEED

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

- High slowing speed.

- Low slowing speed.

- Final blow activated: full power is given to the motors for 2 s at the

end of the closure cycle for better attachment of the electric lock.

- Final blow deactivated.

FINAL BLOW

IN CLOSURE

- Hammering activated: the electric lock is activated during a brief

closure phase against the stops and is deactivated after the start-

up of M1.

- Hammering deactivated: The electric lock is activated just after the

start-up of M1 and is deactivated a little after the start-up of M1.

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

ELECTRIC LOCK

HAMMERING

!ATTENTION:

In case of varying the setting of the micro switches to make the new settings active, it is necessary

to switch the control unit off and on.

We recommend, after having adjusted the micro switches, to program the work times -see control unit

programming-.

SW1 SW2

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

PEAK ON

START-UP

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

SLOWING

SETTING

- Slowing deactivated.

- Sowing activated.

-Peak on start-up activated: on start-up, the motors are

powered at maximum voltage for 2s.

RECOMMENDED ESPECIALLY IN THE WINTER

- Peak on start-up deactivated: on start-up, the motors are powered

at the voltage set with the potentiometer.

ATTENTION: in this case, there may be difficulties on

start-up if the force is regulated low

!

!

ATTENTION: If slowing has been inserted, the motor has less strength and therefore the gate, if

not well-done, may stop before having completed the manoeuvre.

By excluding the slowing the gate bangs against the mechanical stops causing a, more or less,

loud noise, according to installation. Also, the internal gears are subject to greater stresses.

KIT/A9 I E

DAL 1965

Page 12/18

- Sending a start control during the opening of the gate, causes

the same to stop.

- A successive start control makes the gate close.

STEP-BY-STEP

FUNCTION DEACTIVATED

DURING

OPENING

- Sending a start control during gate closing cause it to stop for 2"

and the successive automatic re-opening.

- Sending a start control during opening is ignored, while during

the gate opening pause, it makes the gate close.

DURING

CLOSURE

2 s

start start

start

start

DURING

OPENING

DURING

CLOSURE

SENDING

A COMMAND

DURING GATE

MOVEMENT

SETTING

THE MICRO SWITCHES DESCRIPTION OF THE FUNCTIONING

FUNCTIONING

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

- Sending a start control during gate closing cause it to stop for 2"

and the successive automatic re-opening.

2 s

start

STEP-BY-STEP

FUNCTION ACTIVATED

SW 2SW 1

OPENING

PHOTOCELL

INPUT OR

SENSITIVE EDGE

1 2 3

ON

4 1 2 3

ON

4

1 2 3

ON

4 1 2 3

ON

4

LEDS INDICATION

LED

FINE CH

FINE AP

FOTO AP

FOTO

STOP

PED

START

ON OFF

FUNCTION

Internal photocell

External photocell

Stop button

PEDESTRIAN button

Open/Close button

Opening Photocell free

from obstacles

Closure photocell free from

obstacles

Stop button in normal state

Pedestrian button pressed

Open/Close button pressed

Regular connection between

clamps 8-10 No jumper between clamps 8-10

Opening Photocell blocked out

(presence of an obstacle)

Closure Photocell blocked out

(presence of an obstacle)

Stop button pressed

Pedestrian button in normal state

Open/close button in normal state

DL10 Programming Indicates the various phases of the programming

DL8 M2 motor command Different light intensity

depending on the voltage

control of motor M2

Motor M2 not powered

DL9 M1 motor command Different light intensity

depending on the voltage

control of motor M1

Motor M1 not powered

Regular connection between

clamps 9-10

No jumper between clamps 9-10

- Sensitive edge function activated: the input at clamp 6 both in the

opening and closing phase inverts movement by 10 cm.

- Open photocell function activated: by connecting the photocells to

clamp 6, if blacked-out in the opening phase, the gate stops, it starts

opening again as soon as the photocell is no longer engaged. If

blacked-out in the closure phase, the gate stops, re-opens as soon

as the photocell is no longer engaged.

KIT/A9 I E

DAL 1965

Page13/18

PROGRAMMING THE CONTROL UNIT

The programming must be carried out point by point. In the case of errors during this phase, it is necessary to

proceed with new programming, which will delete the first.

Switch the control unit on and off to exit incorrect programming.

Before programming, the system must be complete with all electrical devices and safety devices connected

(buttons, photocells, flashing lights etc.).

Check their correct functioning:

In the case of anomalies check and remove the cause.

:

All signal LEDs of the NC inputs (stop, photocells, etc) are on.

All signal LEDs of the NO inputs (start, pedestrian) are off.

ATTENTION The normally closed (NC) inputs that are not used must be jumpered.

PROGRAMMING WORK TIMES AND SLOWING FOR GATE WITH TWO LEAVES (DIP1 SW1 OFF)

With the control unit powered and the gate closes, press key A once (SET) to enter programming. The DL10

LED starts to flash to indicate that the control unit is in the programming state.

Wait for a period of time equal to the phasing that is to be given to motor M2 in the opening phase (max 15s),

now press the B (BREAK) key once to start the opening phase of motor M2 (after 15s it is started automatically).

While both leaves are opening, regulate the power of the motors by intervening on the POWER potentiometer.

ATTENTION: - If the POWER potentiometer is regulated too low, the gate cannot open. We

recommend that the POWER is regulated starting from MAXIMUM and gradually

dropping to minimum.

- The large temperature differences between the summer and winter cause

different dilation of materials, including those with which the motors are built.

For this reason it is recommended to control the regulation of the motor thrust

at the start of the winter and the summer.

ATTENTION: - If one or more parameters are varied, programming must be repeated from

the beginning.

- In the programming procedure, slowing has only been set in the closure

phase, but in normal functioning mode it is also introduced in the opening

phase.

Press key C (WORK) once to start the opening phase of motor M1 (M2 remains at a standstill).

When the leaf connected to M1 is against the opening stop, wait a few seconds (3-4s max) and then press key

C (WORK) once. The motor M1 is switched off.

When the leaf connected to M2 is against the opening stop, wait a few seconds (3-4s max) and then press key

B (BREAK) once. The motor M2 is switched off.

When the leaves are completely open and the motors are powered, press key B (BREAK) once to start the

closing phase of the motor M2 (M1 remains at a standstill).

Wait for a period of time equal to the phasing that is to be given to motor M1 in the closing phase (max 15s),

now press the C (WORK) key once to start the closing phase of motor M1 (after 15s it is started automatically).

When Motor M2 should start flowing (we recommend at least 50cm before the stop) press key B (BREAK). The

motor M2 slows down.

ATTENTION: jump this point id slowing has been excluded (DIP2 SW2 ON)

When Motor M1 should start slowing (we recommend at least 50cm before the stop) press key C (WORK). The

motor M1 slows down.

ATTENTION: jump this point id slowing has been excluded (DIP2 SW2 ON)

When the leaf connected to M2 is against the closing stop, wait at least 5 seconds and then press key B

(BREAK) once. The motor M2 is switched off.

When the leaf connected to M1 is against the closing stop, wait at least 5 seconds and then press key C

(WORK) once. The motor M1 is switched off and the control unit exits automatically from the programming

phase and is ready for normal functioning.

KIT/A9 I E

DAL 1965

Page 14/18

With the control unit powered and the gate closes, press key A once (SET) to enter programming. The DL10

LED starts to flash to indicate that the control unit is in the programming state.

While the leaf is opening, regulate the power of the motor by intervening on the POWER potentiometer.

: - If the POWER potentiometer is regulated too low, the gate cannot open. We

recommend that the POWER is regulated starting from MAXIMUM and gradually

dropping to minimum.

ATTENTION

- The large temperature differences between the summer and winter cause

different dilation of materials, including those with which the motors are built.

For this reason it is recommended to control the regulation of the motor thrust at

the start of the winter and the summer.

ATTENTION: - If one or more parameters are varied, programming must be repeated from

the beginning.

- In the programming procedure, slowing has only been set in the closure

phase, but in normal functioning mode it is also introduced in the opening

phase.

Press key C (WORK) once to start the opening phase of motor (M1).

When the leaf is against the opening stop, wait a few seconds (3-4s max) and then press key C (WORK) once.

The motor (M1) is switched off.

When the leaf is completely open and the motor is not powered, press the key C (WORK) once to start the

closure phase.

When motor (M1) should start slowing (we recommend at least 50cm before the stop) press key C (WORK).

The motor (M1) slows down.

ATTENTION: jump this point id slowing has been excluded (DIP2 SW2 ON)

When the leaf is against the closing stop, wait at least 5 seconds and then press key C (WORK) once. The

motor (M1) is switched off and the control unit exits automatically from the programming phase and is ready for

normal functioning.

PROGRAMMING OPEN GATE PAUSE TIME (AUTOMATIC RE-CLOSURE)

With the control unit powered and the gate closes, press key A once (SET) to enter programming. LED

DL10 starts to flash, indicating that the board has entered the programming phase.

Press key B (BREAK) once -until the flashing light switches on-, the control unit starts the gate open pause

count, highlighted with the intermittence of flashing.

When the desired time has passed, press key B (BREAK) again, the control unit automatically memorises

the time passed between the two times the key B (BREAK) was pressed and leaves programming, going

back to normal functioning.

If key B (BREAK) is not pressed a second time, after 120s the control unit escapes from the programming

memorising the max time of 120s.

ACTIVATE AUTOMATIC RE-CLOSURE (maximum time that can be set 120s)

Press and hold key B (BREAK) until LED DL10 switches off.

The control unit leaves the programming phase and sets itself for normal functioning.

Automatic re-closure is deactivated in this way.

DEACTIVATE AUTOMATIC RE-CLOSURE

With the control unit powered and the gate closes, press key A once (SET) to enter programming. LED

DL10 starts to flash, indicating that the board has entered the programming phase.

PROGRAMMING WORK TIMES AND SLOWING FOR GATE WITH SINGLE LEAF (DIP1 SW1 ON)

KIT/A9 I E

LEARNING THE RADIO CONTROL CODE

The circuit board incorporates a dual-channel radio receiver at 433.92 MHz, which allows to control the gate at a

distance via micro switch radio controls from the OG/02, OG/04 range and self-learning radio controls from the

OG/62, OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1 and OG/84 range. Both of the channels are used

exclusively to control the gate. In particular channel 1 of the radio receiver acts from start, while channel 2 acts from

the pedestrian.

DELETING CODES IN THE MEMORY

The deleting of all radio codes memorised is carried out by pressing and holding the A (SET) key until the DL10

LED switches off (about 10s) without sending any radio code.

!ATTENTION: - before using a minitransmitter, perform the programming procedure.

- a maximum of 32 codes can be memorised for start control + 32 for pedestrian

control (other combinations are not possible for example 40 start + 24 pedestrian

etc.). Below find two examples of codes that can be memorised:

- example A:

- example B:

32 self-learning minitransmitters OG/62, OG/64, OG/28, OG/48, OG/52,

OG/54, OG/82/1 and OG/84 as start control (e.g. left button) + 32 self-

learning minitransmitter OG/62, OG/64, OG/28, OG/48, OG/52, OG/54,

OG/82/1 and OG/84 as pedestrian control (e.g. right button)

31 self-learning minitransmitters OG/62, OG/64, OG/28, OG/48, OG/52,

OG/54, OG/82/1 and OG/84 as start control (e.g. left button) + 1

minitransmitter with micro switches OG/02, OG/04 as start control (the

other OG/02 and OG/04 do not have to be memorised just set the micro

switches in the same sequence as that memorised) + 31 self-learning

minitransmitters OG/62, OG/64, OG/28, OG/48, OG/52, OG/54, OG/82/1

and OG/84 as pedestrian control (e.g. right button) + 1 minitransmitter

with micro switches OG/02, OG/04 as pedestrian control (the other

OG/02 and OG/04 do not have to be memorised just set the micro

switches in the same sequence as that memorised)

!

DAL 1965

Page 15/18

LEARNING START CODE

- With the control unit powered and the gate closes, press key A once (SET) to enter programming. The DL10 LED

starts to flash to indicate that the control unit is in the programming state.

- Press the minitransmitter button (e.g. on the left), which wants to act as start control and hold it down until the

DL10 LED switches off. The control unit has memorised the radio code received and automatically leaves

programming, setting itself for normal functioning.

- Repeat the procedure if several minitransmitters must be memorised.

LEARNING PEDESTRIAN CODE

- With the control unit powered and the gate closed, press and hold key A once (SET) to enter programming. The

DL10 LED starts to flash to indicate that the control unit is in the programming state.

- Hold down key A (SET), Press the minitransmitter button (e.g. on the right), which wants to act as pedestrian

control and hold them down until the DL10 LED switches off. The control unit has memorised the radio code

received and automatically leaves programming, setting itself for normal functioning.

- Repeat the procedure if several minitransmitters must be memorised.

12 34 56 78910

123 45 67 8 910

!

MODIFY THE FACTORY

CONFIGURATION TO PREVENT

UNDESIRED CONTROLS

CONFIGURATION OF MICRO SWITCHES ONLY IN THE CASE OF OG/02 AND OG/04 MINITRANSMITTERS

Only if OG/02 and OG/04 radio controls with micro switches are used, before performing learning of the codes on

the receiver, the factory configuration of the micro switches must be modified to prevent undesired controls

ATTENTION before starting first programming or deleting the radio controls, temporarily

disconnect the antenna to prevent the receiver from acquiring other signals during this phase,

which may cause incorrect functioning of the automation. Re-connect the antenna when the

procedure has ended.

:

KIT/A9 I E

DAL 1965

Page 16/18

TECHNICAL DATA OF THE CR/41/ CONTROL UNIT

Power supply: 230Vac ±10% 50/60Hz

Motors power supply: Two 230Vac single-phase motors, 200W+200W

Accessories power supply: 24Vac 500mA

Flashing light power supply: 230Vac, max 50W

Courtesy light power supply: 230Vac, max 100W

Electric lock power supply: 12Vac 15VA

Motors working time adjustment: from 0 to 120s

Pause time adjustment: from 4 to 120s

Phasing regulation in opening and closure: from 0 to 15s

Operating temperature: -20°C ÷ +70°C

Protection rating: IP54

Dimensions (H x L x D) and weight: 270x212x118mm, 1,7Kg

EXPANSION OF THE MINITRANSMITTER NUMBER

If the 32 minitransmitters that can be memorised in the built-in receiver are not sufficient, it is possible to increase them

by inserting the SOG/4A receiver (that takes the number of minitransmitters to 40) eventually with the addition of the

SOG/2A expansion (that takes the number of minitransmitters to 834).

After having inserted the SOG/4A receiver, all codes memorised in the built-in receiver must be deleted and all

of the minitransmitters must be re-programmed on the new SOG/4A receiver, see specific instructions. The an-

tenna must be moved from the clamp on the control unit to the clamp found on the SOG/4A.

F1F1

F2F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9

DL8

DL10

1 2 910 11 121314 1516 171819 20 21 22

272526

2324

SET BREAK WORK

A B C

Com

+24

spia

RX

2829

2ND CHANNEL

OUTPUT:

AUXILIARY

CONTROL

ANTENNA

NC

C

NO

Channel 2 output (relay contact)

Max Voltage applicable=

24Vac/dc

Max Current applicable= 1A

ELECTRIC LOCK

LIGHTS

OTHER AUTOMATIONS

OTHER

INSERT THE

SOG/4A

RECEIVER

1ST CHANNEL OUTPUT:

CONTROL UNIT

START CONTROL PEDESTRIAN CONTROL

ON CR/41 -CLAMPS 1-2-

DISCONNECT THE POWER

SUPPLY BEFORE INTERVENING

ON THE CONNECTIONS

NO

KIT/A9 I E

DAL 1965

Page 17/18

90 mm

70 mm

TX RX

h MIN h MIN

h = 40 cm

MIN

l = 10 m

MAX

l

MAX

RX TXTX RX

RX RXTX TX

NO OK

PHOTOCELLS TECHNICAL DATA

Radius of action

- external.................10 m

- internal..................20 m

Power supply.........24 V~ ±10%

Absorption TX....55 mA at 24 V-; 67 mA at 24 V~

Absorption RX....15 mA at 24 V-; 25 mA at 24 V~

Ø 6mm

Ø 3,5mm

P/10 PHOTOCELLS

NO OK

RECEIVER TRANSMITTER

POWER SUPPLY

RELAY

OUTPUT POWER SUPPLY

INSTALLATION

RX TX

LED

CONNECTIONS

The cables passage hole must be realised with

dimensions suitable for the passage of just one cable

Relays output...............1A 24 V~

Temperature............-10° ÷ +60°C

Dimensions...............70 x 40 x 90 mm

Weight........................120 g

RX RX

THE POSITION OF THE CONTACT

REFERS TO THE EXCITED RECEIVER

40 mm

POSITIONDIMENSIONS

INSTALLATION

RX

ROUND YELLOW BULBS WITH 433.92 MHz BUILT-IN ANTENNA - 230 V~ RZ/20

!

RZ/99 SR 10.99

SUPPORT A

OPTIONAL ELBOW

NO

2 x 0,75 mm²

POWER SUPPLY

RG58

ANTENNA

CS/07 SR12.07

OPTIONAL CABLE

CONNECTIONS

!

ATTENTION:

IT IS RECOMMENDED TO POSITION THE FLASHING LIGHT POWER SUPPLY CABLE INSIDE A TROUGH THAT IS

NOT ACCESSIBLE TO THE USER.

IF THERE ARE ACCESSIBLE PARTS, THESE MUST OFFER DOUBLE ISOLATION TOWARDS THE USER. CABLE

CLAMPS MUST ALSO BE USED IN ORDER TO PREVENT THE ABOVE-MENTIONED CABLE FROM RIPPING.

230Vca

230Vca

USE 230 V~ MIN , 25W, E14

PEAR BULBS

FOR REPLACEMENT

KIT/A9 I E

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

The motor reducer

does not work

No voltage

to the motors

Check the presence of voltage at the power supply input

clamps to the motor.

Check that the power supply cable is not interrupted.

(The power supply cable must be replaced by an

authorised technician)

Check the fuses on the control unit.

No voltage

to the control unit

Check the network fuse and the presence of network voltage.

Intervention of the motor

circuit breaker

Leave the motor at a standstill for 10 minutes

and re-attempt functioning.

The gate does

not complete

its run

Gate lock Release the motor manually and move it manually

to check that there are no obstacles.

Remove any obstacles.

The gate

has difficulty

starting

Condensers depleted Measure the capacity of the condenser

and replace it if necessary.

Incorrect motor thrus

regulation

Repeat programming by increasing the motor thrust using

the "Power" potentiometer.

Peak on start-up

deactivated

Control the relative micro switch on the board.

Incorrect work times Repeat work times programming.

Incorrect slowing

setting

The radius

of action of the

remote controls

is reduced

Antenna connection

unsuitable

Check that the antenna is connected correctly to the

clamps 23-24.

An external antenna

is required

To have the maximum reception distance, replace the

internal antenna of the flashing light with an external

SERAI OG/50 -SR 25.50-

Use of a SOG/4A

receiver

Replace the receiver incorporated with the SOG/4A

board.

KIT/A9 I E 02 18 120214 -A4Vf/r -IS KIT/A9-E

WARRANTY CONDITIONS

The company reserves the right to make any modifications without forewarning. The conventional guarantee of SERAI product is valid for 24 months from the date of issue of the fiscal document,

which proves purchase and is applied in the seat of Legnaro - PD - or at authorised After-sales Centres. The transport costs are under the Customer's responsibility.

WEEE DIRECTIVE 2002/96/CE REGARDING THE DISPOSAL OF WASTE ELECTRIC AND ELECTRONIC ELEMENTS

This appliance has been produced after 13/08/2005. To protect the environment: at the end of use, do not dispose of the appliance as common mixed waste, but deposit it

at a WEEE collection centre (Waste Electric and Electronic Equipment).

CE DECLARATION OF CONFORMITY

SERAI spa declares that the KIT/A9 product has been designed and realised with respect to the Directives and Standards stated above.

Check that the slowing speed set is sufficient to move the gate,

if necessary try and exclude slowing -dip2 SW2 in ON-

By excluding the slowing the gate bangs against the

mechanical stops causing a, more or less, loud noise,

according to installation. Also, the internal gears are

subject to greater stresses.

ELETTRONICA PADOVA

I

SINCE 1965

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

PHONE +39 049 79 08 58

FAX +39 049 88 30 529

E-MAIL [email protected]

WEB www.serai.com

Other Serai Gate Opener manuals

Popular Gate Opener manuals by other brands

Nortek Security & Control

Nortek Security & Control Mighty Mule HD272 installation manual

tousek

tousek TURN 10 Installation and operating instructions

SOMFY

SOMFY AXOVIA 220B RTS installation instructions

Nice HySecurity

Nice HySecurity CBOX1050 Installation and programming manual

CAME

CAME FROG-PM4 installation manual

Aprimatic

Aprimatic ONDA 500 installation instructions