Mikuni MY Series Manual

Installation of the heater

.

The Mikuni MY series heaters are blown air diesel fired heaters running off either a

12

or

24

volt DC supply

.

To ensure good service from your heater it is important to install it correctly

paying attention to all the details laid out

within this instruction leaflet

.

Planning the Installation

Take time to plan your installation

!

The heater should be sited in an area where

:

(i

)

It will not have items stored against it.

(

ii

)

It will not be exposed to weather

.

(

iii

)

It is within the parameters set out in this manual regarding fuel and power supply.

(

iv

)

It is within the parameters set out in this manual regarding heater mounting

.

(v

)

The exhaust outlet skin fitting is well clear of the water line.

(

vi

)

The exhaust pipe is not touching anything inside the boat which could be damaged by

heat

-The exhaust pipe does get hot even though it is insulated!

Tools for your installation

:

Here is a list of some of the tools required to help with your installation

:

1.

Electric drill with slow speed

.

2.

Crimping pliers

.

3.

Wire cutters

.

4.

Metric spanners

8

mm to

13

mm

.

5.

Flat blade

& posidrive screwdrivers.

6

.

Sharp knife

.

Application

Hot air outlets

Ducting

Skin fitting

Fuel standpipe

MY

16

95

mm

60

mm

42

mm

22

mm

MY

30

95

mm

90

mm

42

mm

22

mm

Hole saws

-

1

-

The heater is supplied with a stainless

steel

'L

'

shaped mounting bracket which is

designed to be fitted on a vertical

bulkhead with the heater sat in it

(

see dia

1

.)

The heater has to be mounted in this

way for correct operation

.

22

0

22

o

Examine the chosen mounting place

carefully to make sure that it has enough

strength to support the heater and that it is

free from excessive vibration while the

boat is in use

.

MY

16

:

Fix the mounting bracket to the bulkhead

using the

4

x

3/4

"

No

10

self tapping

screws provided

.

The heater can now be

fitted in place either way round

(

whichever

is the most convenient for the ducting run

)

with the

4

x s

/

s M

6

x

20

set screws

provided

.

MY

30

:

Fix the mounting bracket to the bulkhead

using the

6

x

3/4

"

No

10

self tapping

screws provided and mount the heater

using the

4

x s

/

s M

8

x

20

set screws

.

Now screw the s

/

s exhaust stub into the

bottom of the heat exchanger

,

and slide

the combustion air manifold

'A

'

over the

top

.

1.

Mounting the heater

.

The heater should be mounted in a well ventilated locker which should be dry and within

2

metres of a suitable site

for the exhaust skin fitting

.

It should also give consideration to servicing and access to cleaning the glow plug

.

The

heater should be mounted in such a way that the axis through the hot air outlet and fresh air inlet is horizontal

.

Bulkhead

s/

s exhaust stub

.

s/

s mounting bracket

glow plug

Permissible inclination angles

.

Dia

1.

2

.

Exhaust and combustion air system

:

The exhaust skin fitting needs to be fitted as far above the water line as possible to prevent any ingress of water into

the

heater

.

An ideal place for the skin fitting is on the transom

.

Once you have planned the siting

,

drill a

4

mm pilot hole as guidance for the pilot drill on the hole saw arbour

.

Now

drill the correct size hole

:

MY

16/

MY

30

=

42

mm

.

When you have completed this re

-

drill the hole at an angle at a slow

speed

(

see dia

2

)

to allow the skin fitting to fit in a snug hole

.

Now drill

4

x

5

mm holes for the fixing bolts

,

apply

silicon to the rear of the face and secure in place with the

4

x M

5

x

40

button head s

/

s screws provided

.

Drill with hole saw at angle

after you have drilled the

perpendicular hole

.

BE CAREFUL

!

Transom

4

x fixing screws

Dia

2.

Fix the s

/

s exhaust to the skin fitting and secure with

the heavy duty clamp

.

Cut the exhaust at a

convenient place to insert the silencer

,

(

MY

30

Only

)

and secure with a tridon hose clip

.

IMPORTANT TIP

: (

MY

30

Only

.)

Put an exhaust clamp

on one end of the remaining exhaust

,

now take the

combustion air manifold and insert the split spigot into

the end

.

Push this assembly onto the exhaust spigot

of the heater making sure that it slides home over the

heat exchanger casting

,

and tighten the clamp

.

The MY

16

does not require an exhaust silencer

.

NOTE

:

THE EXHAUST DOES GET HOT

-

DO NOT

CLAMP IT TO ANY COMBUSTIBLE MATERIALS

.

The exhaust lagging should now be wrapped around

the full length of the exhaust pipe and secured at each

end with the hose clips supplied

.

Silicon sealant

-

2

-

'A'

2.

Continued

:

MY

30

Only

:

Take the combustion air inlet silencer and fix to the front of the heater s

/

s mounting bracket with the

cable ties provided

.

Cut the black combustion air tube to length and fix to the silencer and the heater with the two

32

mm hose clips

.

3

.

Fuel system:

The heater is supplied with a fuel standpipe to be fitted into the top of the fuel tank

.

Use this wherever possible

-

it is

the preferred method because it does not interfere with the engine fuel supply

.

Find a suitable location in the fuel tank that has no obstructions inside

,

put some grease around the chosen location

and drill a

22

mm hole

-

the grease should help prevent any debris falling into the fuel tank

.

Now cut the standpipe so

that it is about

30

mm off the bottom of the fuel tank

,

slide into place and tighten the fixing nut

. (

see dia

3

.)

NOTE

:

The fuel pump is a solenoid which is pulsed by the control box

-

be careful not to mount it on a board that may

resonate

.

If after installation the pump is noisy re

-

locate it

!

Installation of copper fuel line

.

1

.

Fit the

1/4

"

to

3/

16

"

reducer onto the standpipe

.

2

.

Cut the required length of copper pipe from the

amount supplied and fit to the fuel cock

.

3

.

Fit the straight connectors to the fuel pump

.

NOTE

:

3

connectors are fitted with 1

rubber olive and

1

copper

olive and

1

straight connector is fitted with 2 rubber

olives

.

The connector with

2

rubber olives is to be mounted

between the fuel pump outlet and the fuel damper

.

Item

'A'.

4

.

Mount the fuel pump near the fuel cock at a

45

o

angle as shown

.

5

.

Fix the remaining connector to the fuel inlet on the

heater with the rubber olive on the heater stub

.

6

.

Cut the copper pipe to length

,

fit to the pump and the

heater

.

30mm

Diesel

tank

Heater

.

Fuel standpipe

1/4

"

x

3/

16

"

Reducer

3/

16

"

Fuel cock

Fuel pump

.

These olives are

neoprene rubber

.

The fitting on the heater uses a

neoprene rubber olive

'A'.

Length of pipe

(

max

)

Standpipe to fuel pump

:

Fuel pump to heater

:

Head

(

max

)

Bottom of fuel tank to pump

centre

:

Pump centre to heater centre

:

(

mm

)

2000

5000

1000

<

2000

-

3

-

Dia

3.

4

.

Electrical

:

The Mikuni heaters come complete with simple plug together wiring looms

(a

)

MY

16

:

The MY

16

wiring loom comes in

2

parts

,

the main harness and the power loom

.

Plug all the parts together

,

mount the

motor fuse next to the control box using the plate provided

.

Now run the thin

2

core cable to the fuel pump and connect up

-

polarity is not important on the fuel pump

.

Run the 6

core loom to the thermostat

,

trim to length and connect up as shown in dia

4.

Connect the main power loom directly to the battery via a

30

amp fuse

.

NOTE

:

Do not connect the live feed to the main power switch

.

If the power is turned off at the supply whilst the

heater is running

,

it will not be able to perform its cool down purge cycle

,

which could cause internal damage to the

heat exchanger

.

Mounting the thermostat

:

Try and mount the thermostat in an area where it

will get reasonable air flow

,

but is not in a

doorway or direct sunlight

.

This would cause the

heater to cycle incorrectly

.

Prise the knob off with a screwdriver and then

remove

2

x self tapping screws A in dia

4

.

The

lid will now come off to expose the pcb inside

.

Remove the pcb by undoing

2

x self tapping

screws B

.

Now fix the base plate onto a flat

vertical surface with the

2

x screws provided

.

Fix the pcb back onto the base plate and wire as

per diagram below

.

The lid can now be screwed into place and the

knob pushed back onto the spindle

.

There are

2

x blanking plugs provided to cover screws A in

the lid

.

Mount the control box on a flat vertical surface with the

17

way housing at the bottom

.

Secure in place using the

4

x

3/4

"

No

10

self tappers provided

.

Now plug the main harness into the control box and then the heater and glow plug

terminals ensuring that they are a tight fit

.

Plug the

2

core fuel pump loom into the main harness

,

trim to length

,

attach the

2

bullet receptacles and plug into the fuel pump

-

polarity is not important

.

Now run the

6

core loom to the thermostat

,

trim to length and connect up as shown in dia

6.

Plug the main power loom into the harness and run directly to the battery via the

30

amp fuse supplied

.

NOTE

:

Do not connect the live feed to the main power switch

.

If the power is turned off at the supply whilst the

heater is running

,

it will not be able to perform its cool down purge cycle

,

which could cause internal damage to the

heat exchanger

.

MY

16

Wiring Instructions

+ =

Blue

/

Yellow

-

=

Black

1

=

White

2

=

Green

3

=

Red

4

=

Red

/

Yellow

-

4

-

(b)

MY

30

:

The MY

30

wiring loom is pre

-

assembled as shown in Dia

5.

6

core loom to Thermostat unit

2

core cable to fuel pump

black

red

main power feed

MY

30

main

harness

.

Yellow

/

red

black

/

white

heater plug

glow plug terminals

17

way housing

to control box

.

Dia

5.

MY

16

Thermostat unit

:

Dia

4.

1

234

+

_

25

A Glow plug fuse

A

B

Dia

6.

MY

30

Thermostat unit

:

5.Air distribution:

The hot air ducting should be run through the boat in the most direct route possible

-

the less bends the better the air

flow

!

The MY

16

uses

55

mm ID ducting so use a

60

mm hole saw to allow clearance when running the ducting through

bulkheads and partitions

,

the MY

30

uses

80

mm ID ducting so use a

90

mm hole saw

.

The hot air outlets require a

95

mm hole saw for mounting

.

There are

2

types

,

the directional vent and the open

/

close

vent

.

There must always be at least one permanently open vent on the installation to prevent overheating of the unit

.

The MY

16

vents have an extra plug in reducer on the back of the outlet to accept the

55

mm hot air ducting

. (

see

dia

7

).

PLASTIC DIRECTIONAL VENT

55.00

38

.

00

42

.

00

80.00

104

80

.

00

55

mm Reducer

-

MY

16

only

.

Dia

7.

80.00

95.00

80.00

104.00

When the holes have been drilled for mounting the hot air outlets they should be secured using the 4

x

1/2

"

No

8

black c

/

s self tapping screws provided

.

It is advisable to secure the

55

mm reducers with a self tapping screw to

prevent them working

loose

-

especially on motor boats

.

Air inlet

:

This is usually taken from within a well ventilated locker

,

but if for instance the heater was mounted in an engine

room then it would be necessary to duct the inlet air to the heater to prevent any fumes being drawn into the cabin

area

.

The inlet ducting should always be kept to a minimum length to prevent any restriction in air flow

.

MY

30

Wiring Instructions

+ =

Red

-

=

Black

1

= Green

2

=

Red

/

Yellow

3

=

Blue

/

Yellow

4

= White

-

5

-

1

234

+

_

A

B

NOTE

:

The mounting instructions are the same as

MYH

16

but note that the cable colours are different

!

TRIAL OPERATION

:

Trial operation procedure

:

(a

)

Fuel priming

:

The fuel should be primed to the inlet of the pump by either syphoning or with a syringe

.

Note

:

A priming pump is

available to distributors part no

:

SP

21

.

MY

16

:

Switch the heater on at the thermostat and turn the dial clockwise until the green light comes on

.

The red LED

will be flashing slowly and the heater motor will start

.

After approximately

40

seconds the fuel pump will start to pulse

and fuel will start pumping up to the heater

.

This may take several attempts depending on the length of the fuel line

between the pump and the heater

.

Note that the heater will go through

2

cylces and stop

,

you should then wait

5

minutes switch the thermostat off and then on again to reset the electronics

.

The cycle will now be repeated

.

When the

fuel reaches the heater it will ignite and after approimately

80

seconds the glow plug will switch off and the red LED on

the thermostat will be on constant

.

Final check

:

Confirm that all the wires are connected according to the wiring diagram and that all the connectors are

firmly in place

.

Check that the wiring loom is secured neatly in place and will not be subjected to any chafing or

excessive heat

.

ie

:

Keep away from the heater exhaust pipe

.

Check that the exhaust clamps are tight and that the pipe is secured away from any combustible

materials

.

ie

:

Bilge pipes

-

recommended min air gap

=

10

mm

.

Check that all hose clips on the hot air ducting are in place and are correctly tightened

.

Ensure that the

ducting has not been deformed to cause any restriction in air flow

.

Check that the fuel line is all clipped in place O

.

K and that the clips are all tight

-

ensure there is fuel in the

tank

.

Check that the battery has sufficient charge to operate the heater

.

-

6

-

H

L1

Specifications

Ducting Dia

(

mm

)

Max length L

1

(

mm

)

Max starting head H

.

Max No of

90

o

bends

MY

16

55

5000

1200

4

MY

30

80

8000

1500

7

H-

Dia

8.

NOTE

:The max length of ducting shown

is to the first permanently open outlet

.

Ducting parameters

:

90o

90o

MY

16

/

MY

30

HEATER

.

Hot Air

Outlet

MY

30

:

The thermostat on the MY

30

has a 3

position switch to allow the heater to blow cold air as well

.

First

disconnect the fuel line at the heater end and put into a suitable receptacle

.

Now disconnect one of the cables going to

the glow plug

.

Push the switch on the left side for heat

;

the red LED will illuminate and the heater motor will start

slowly

,

after approximately

40

seconds the fuel pump will start to pulse

.

The heater will go through a cycle and stop

;

switch the thermostat off and then on again to repeat the cycle until fuel is starting to pulse into the receptacle

.

Now

reconnect the fuel line and glow plug terminal and switch the heater back on

.

It should ignite and after approximately

80

seconds the glow plug will switch off and the right hand light will come on on the thermostat

.

The thermostat on the

MY

30

operates the heater between high and low heat

.

Final checks

(

both models

).

Any heater when it is new requires running in to clear any odours from ducting

,

exhaust lagging etc

.

After the heater

has ignited any smoke from the exhaust should clear within

5

minutes

(

unless the heater has been flooded during

priming

).

Continue running the heater and recheck all the items in the final check list

.

Run the heater for two hours at full heat to clear any odours from the ducting etc

.

WARNING

:

1

.

Ensure that no flammable substances are near the heater exhaust pipe

.

2

.

Ensure that there are no obstructions near the exhaust outlet ie

:

Fender or pontoon

.

Note that

exhaust gases are hot

!

3

.

If the heater overheats whilst operating

,

first turn off the operation switch

,

investigate the cause

and rectify before operating the heater again

.

4

.

Always switch the heater off when filling fuel tanks

.

5

.

If ignition fails do not attempt to start the heater more than

3

times

,

you will flood it with diesel

!

-

Investigate the cause and rectify

.

-

7

-

Specifications

Heat output

Air Flow

Rated voltage

Operating voltage

Current consumption

Fuel

Fuel consumption

Operating temperature

CO

2

value in exhaust gas

Smoke value in exhaust

gas

Safety device

Heater dimensions

Weight

Model

:

(

kw

/h)

m3/h

D.C.V

D.C.V

A

L/h

Gallon

/h

oC

oF

Vol

%

No

.

mm

kg

MY

16

1.9

50

12

/

24

12

v=

10

.5-

14 24

v=

21

-

28

12

v=3.4

A

24

v=1.7

Diesel fuel

0.

22

0.

06

-

40

-

plus

40

-

40

-

plus 104

10

-

11

.5

Max

:3

See operation manual

364

x

146

x

141

3.6

MY

30

Hi

=3.

5

Lo

=1.

75

Hi

=

136

Lo

=

92

12

/

24

12

v=

11

-

14 24

v

=

22

-

28

12

v=3.8/1.

9 24

v=2.0/1

Diesel fuel

Hi

=0.

42

Lo

=0.

21

Hi

=0.

11

Lo

=0.

058

-

40

-

plus

80

(

control box

:

-

40

-

plus

40

)

-

40

-

plus

176

(

control box

-

40

-

plus

104

)

Hi

=

10

-

11.

Lo

=

7- 8

Max

:2

See operation manual

426

x

182

x

179

5.

65

Specifications.

02 October 2006

Mikuni Heating (UK) Ltd. MY16 Wiring diagram

HeaterControl Box

2R

Q6

Q3

Q4

Q5

SELF DIAGNOSTIC

LAMP

Solenoid Fuel

Pump

FUSE

5A 24VOLT.

7.5A 12 VOLT.

L L

B B

12 or 24V

DC.

Fuse 30A

B R

M

Overheat Thermostat

Bl

B

G

Br

R

WR

Heater connector

Pin Layout

w

w

Br

L

R

B

WR

G

R B Br L WR G

Flame sensor

Motor

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

W B RR BWBr L YRG LY 123456789

L L W W B B WR R R

WR

W W

R R

Glow Plug

W B R R

BW Br L YR LY

1 8

169

Wiring Instructions for

"Solid State" Thermostat.

+ = Blue/Yellow

- = Black

1 = White

2 = Green

3 = Red

4 = Red/Yellow

1

2

3

4

+

-

G RY

RY

"Solid State" Thermostat

1

234

+

_

-8-

02 October 2006

Mikuni Heating (UK) Ltd. MY30 Wiring Diagram using solid state thermostat

GlowResistor

24VModels

Only

Notes:

1.Theglowresistorisfittedon24Vheatersonly. Thisisa

'dropper'resistortoreducethevoltageontheglowplugto

12V.

2.*Fuse:Thisisa20mmglassfusetoprotecttheairmotor.

12V=10A. 24V=8A

3.OverheatTrips:Resetbuttonstoprotect theheaterifthe

ductinggetsblockedetc

M

MotorResistor

7 10 13

14 15 16 2

Glowplug

OverheatTrip

8

8

OverheatTrip

FlameSensor 14

13

3

3 4

4

ElectronicThermostat

1

234

+

_

2

2

13

7

15

10

14

13

10

14

7

15

Motor *Fuse

10

7

ControlBox

1

1

1

1

2

2

3

3

3

3

6

6

7

7

10

10

11

11

13

13

14

14

15

15

16

16

17

17

20

20

21

21

14

15 16

21

2

13 1

1

3

10

3

17

20

6

11

7

Fuel SolenoidPump

10

11

Fuse 25A

Fuse30A

12Or24VDC.

1 2

21

Heater Body

Heater

Plug layout

152

13 15

+

-

1

2

3

4

1

2

21

6

14

20

Thermostat terminal blocks

Mikuni cable numbers

Cable Ref

1

2

3

6

7

10

11

13

14

15

20

21

Cable Colour

Red

Black

White

Red/Yellow

Green

Yellow/Red

Black/White

Brown

Blue/Yellow

Red

White

Green

FUEL SOLENOID

VALVE.

RELAY

FUSE 3 A.

OPTIONAL ELECTRIC FUEL

VALVE KIT.

+12/24v

No 6

Neg

+

-

1

2

3

4

Red

Black

Green

Red/Yellow

Blue/Yellow

White

+12/24 Volts

Negative

Cold Air

Switch return Heat

Hi Lo Heat

Hi Lo Heat

Cable Colour Function

Thermostat wiring

-9-

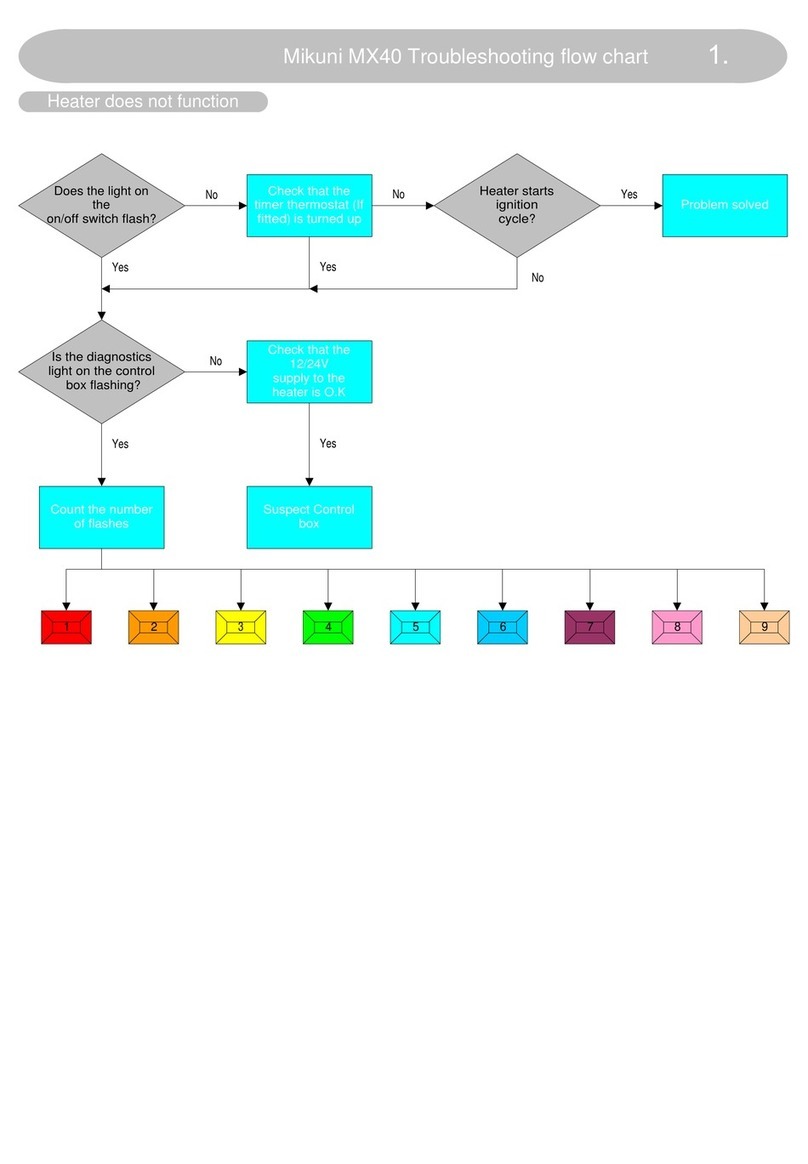

The MY16 heater is equipped with a self diagnostic fault finding system to aid repair should a fault occur. NOTE: Should any

part fail or if there is a loose connection then the control box will not allow the heater to start at all and a fault code should flash

in the control box window. The following table should assist you in repairing the heater if you follow the instructions step by

step. This list has been compiled from experience of the MY16 on the UK market. If you discover any new anomalies please

inform us so that we may add them to our list.

ON/OFF FREQUENCY

1.

2.

5.

6.

7.

8.

CAUSE

IGNITION FAILURE

NO FLAME SENSING.

MOTOR FAILURE

FUEL PUMP FAILURE

GLOW PLUG FAILURE

BATTERY VOLTAGE ABNORMAL

REMEDY-MOVE FROM POINT TO POINT IN ORDER UNTIL FAULT IS LOCATED

CHECK FUEL SUPPLY > FROZEN FUEL LINE? > CHECK AND CLEAN FILTER IN FUEL PUMP > CHECK FOR BLOCKED STANDPIPE > COMBUSTION AIR OR

EXHAUST PIPE BLOCKED OR DAMAGED? > IF HEATER RUNS OK FOR APPROX 3 MINS AND STOPS-SUSPECT FLAME SENSOR > IF HEATER SMOKES

BADLY AND STOPS AFTER 3 MINS STRIP DOWN AND DECOKE.

CHECK ALL PLUGS AND SOCKETS IN WIRING LOOM > LOOK AT FLAME SENSOR;IF THE SEALANT IS PUSHING OUT OF THE RETAINING NUT REPLACE

WITH A NEW FLAME SENSOR.IF NOT CHECK FOR BAD CONNECTIONS ON PCB INSIDE GLOW PLUG COVER > CHECK CONTROL BOX.

CHECK MOTOR FUSE 12V=7.5A 24V=5A > IF FAILED ENSURE THAT MOTOR SPINS FREELY > CHECK WIRING LOOM CONTINUITY > CHECK MOTOR >

CHECK CONTROL BOX > CHECK FOR BAD CONNECTION ON PCB INSIDE GLOW PLUG COVER.

CHECK CONTROL BOX > CHECK CONTINUITY OF WIRING LOOM AND INSPECT FUEL PUMP TERMINALS FOR CORROSION > CHECK CONTINUITY OF

FUEL PUMP.

CHECK GLOW PLUG FUSE=25A (IF APPLICABLE) > CHECK GLOW PLUG AND GLOW PLUG RESISTOR ON 24V MODELS. > CHECK CONTROL BOX > CHECK

WIRING LOOM. NOTE:THE GLOW PLUG RESISTOR IS A DIFFERENT PART TO THE GLOW PLUG -DO NOT INTERCHANGE! [24 VOLT ONLY].

THE HEATER WILL CUT OFF IF THE BATTERY VOLTAGE IS TO HIGH OR TO LOW.OPERATING RANGE FOR THE 12V MODEL IS 10.5 > 14VOLTS AND THE

24V MODEL IS 21 > 28 VOLTS.CHECK THE VOLTAGE AT THE HEATER WHILE IT IS RUNNING (SO THAT THE BATTERY IS UNDER LOAD) WITH THE BOAT

ENGINE OFF AND AGAIN WITH THE ENGINE RUNNING TO ENSURE THAT THE VOLTAGE IS WITHIN THE OPERATING RANGE OF THE HEATER.

9. OVERHEATING MAKE SURE THAT THE HEATER HAS COOLED DOWN AND CHECK THE MOTOR FUSE > CHECK THE AIR INLET AND THE HOT AIR OUTLET FOR

BLOCKAGETHE HOT AIR OUTLET FOR BLOCKAGE OR RESTRICTION. NOTE: OVERHEAT CUT-OUT WILL AUTOMATICALLY RE-SET WHEN THE HEATER

COOLS DOWN.

NOTES: (a)

(b)

(C)

IF THE HEATER FAILS TO START BUT THE DIAGNOSTIC IS NOT FLASHING-CHECK THE THERMOSTAT BY LINKING THE TWO RED WIRES TOGETHER.

ON INTIAL OPERATION OR IF THE VEHICLE HAS RUN OUT OF FUELTHE SYSTEM WILL NEED TO BE RE-PRIMED.THIS SHOULD BE DONE BY PUSHING

FUEL THROUGH THE PUMP WITH A SYRINGE OR BY USING THE MIKUNI SP21 PRIMING PUMP.

IF THE GLOW PLUG FAILS, INSPECT THE BOSS FOR CARBON DEPOSIT OR STRAY STRANDS OF S/S GAUZE.CLEAN AS NECESSARY AND ENSURE THAT

THE GAUZE IS NOT BURNT OR DAMAGED.IF IT IS REPLACE THE GLOW PLUG BOSS ASSY.

MY16 Self Diagnostic Fault Finding System.

-

10

-

MY16 FAULT FINDING SEQUENCE

RED LIGHT ON

THE THERMOSTAT

FLASHES SLOWLY.

IS THE 12/24V

SUPPLY CORRECT? SUSPECT ELECTRONIC

CONTROL BOX.

DO YOU HAVE A

12/24V SUPPLY? IS THE MAIN

30A FUSE O.K?

CHECK FOR LOOSE CONNECTION

OR CORROSION OF TERMINALS

ON THE MAIN POWER FEED.

REPLACE!

HEATER MOTOR

STARTS

CHECK THE SELF DIAGNOSTIC

LAMP IN THE CONTROL BOX AND READ

NUMBER OF FLASHES.

IS THE LIGHT

FLASHING 5 TIMES?

REFER TO SEPERATE SHEET

DESCRIBING SELF DIAGNOSTICS.

IS THE MOTOR

FUSE BLOWN? CHECK MOTOR BY APPLYING

SUPPLY VOLTS DIRECTLY TO IT.REPLACE

MOTOR.

SUSPECT CONTROL BOX

AND CHECK CONTINUITY

OF WIRING LOOM.

REPLACE!

12V = 7.5A

24V = 5A .

IF THE MOTOR FUSE FAILS AGAIN

SUSPECT MOTOR. IF THE MOTOR RUNS

CONTINUOUSLY AT FULL SPEED FROM SWITCH

ON, CHANGE THE CONTROL BOX.

IF THE VOLTAGE IS LOW CHECK THE

VEHICLE BATTERIES OR CORROSION

OF TERMINALS ON THE MAIN BATTERY FEED.

IF THE FUSE BLOWS AGAIN CHECK THE

GLOW PLUG.IF IT IS COVERED WITH CARBON

CLEAN THOROUGHLY OR REPLACE.

IS THE GREEN LIGHT

ON THE THERMOSTAT

ILLUMINATED?

TURN UP

THE DIAL

ON STAT.

SWITCH

ON

FUEL PUMP STARTS

15 SECS AFTER SWITCH ON. SUSPECT FUEL PUMP OR

BLOCKAGE IN FUEL LINE.

HEATER IGNITES AND

CONTINUES TO RUN

DOES THE HEATER EMIT

WHITE SMOKE FROM

THE EXHAUST

CHECK THE FUEL SUPPLY

AND ALSO FOR FOULING OF

THE GLOW PLUG.

DOES THE HEATER RUN FOR

ABOUT 3 MINS AND STOP? IF THE HEATER EMITS WHITE SMOKE AND POPS

THEN IT WILL REQUIRE DISMANTLING AND CLEANING

SUSPECT FLAME SENSOR-

REPLACE!

OVERHEAT THERMOSTAT

IS ACTIVATED

1.CHECK AIR INLET FILTER

2.CHECK FOR DAMAGED DUCTING

3.CHECK FOR BLOCKAGE OF AIR OUTLET GRILL

4.SUSPECT OVERHEAT THERMOSTAT.

AFTER 2 MINS COOL DOWN

CYCLE THE HEATER STOPS

TEST COMPLETE!

SUSPECT CONTROL BOX

OR ON/OFF SWITCH FAILURE

SWITCH OFF

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO GO.

O.K.

-

11

-

SWITCH ON

MOTOR STARTS CHECK 12V SUPPLY DOES FUEL PUMP START

AFTER 40 SECONDS? CHECK MOTOR

FUSE SUSPECT MOTOR

30 AMP FUSE

BLOWN? CHECK OVERHEAT

CUT-OUTS REPLACE WITH 10 AMP

SLOW BLOW TYPE.

IF THE TOP TRIP HAS FAILED

THE SUPPLY HAS PROBABLY

BEEN CUT WHILST THE HEATER

IS RUNNING-RESET!

IF THE NOSE CONE TRIP HAS

FAILED CHECK FOR RESTRICTION

IN AIR FLOW i.e:BLOCKED INLET

FILTER OR OBSTACLE IN FRONT

OF HOT AIR OUTLET.

SUSPECT CONTROL

BOX REPLACE

CHECK FOR SHORT

OR FOULING OF

GLOW PLUG

CLEAN OR IF COILS

ARE DAMAGED-REPLACE!

HEATER RUNS COLD

FOR APPROX 3 MINS

AND THEN STOPS

NO

YES

NO

O.K.

YES YES O.K.

FAILED

NO

O.K.

FAILED

YES

NO

MIKUNI MY30 FAULT FINDING SEQUENCE.

HEATER RUNS HOT

FOR APPROX 3 MINS

AND THEN STOPS

CHECK FIRING CONTROL

(FLAME SENSOR) INSUFFICIENT FUEL

SUPPLY AIR LEAKS

IN FUEL PIPE REPAIR!

REPLACE!

CHECK COMBUSTION AIR

INLET & EXHAUST FOR

BLOCKAGE OR DAMAGE

FUEL RESTRICTION.

CHECK:

1.FUEL FILTER

2.TANK STANDPIPE

3.FUEL PUMP.

OVERHEAT CUT-OUTS

TRIP AFTER A FEW

MINUTES.

CHECK FOR RESTRICTED

AIR FLOW. REMOVE OBSTACLE OR

CLEAN AIR INLET FILTER.

HEATER WILL REQUIRE

SERVICING

SWITCH OFF

DOES HEATER CONTINUE

WITH A 2 MINUTE COOL

DOWN CYCLE?

SUSPECT FIRING CONTROL

(FLAME SENSOR) REPLACE!

TEST COMPLETE

O.K.

YES

YES YES

YES

YES

YES

YES YES

O.K.

FAILED

NO

NO NO

NO

NO

CHECK GLOW PLUG REPLACE AND CHECK

FOR CARBON IN G.P. BOSS

CHECK VOLTAGE ON

GLOW PLUG. SUSPECT WIRING OR

CONTROL BOX

SUSPECT FUEL SUPPLY

CHECK:

1.DAMAGED FUEL LINES

2.AIR LOCK IN FUEL PUMP

3.FUEL PUMP OPERATION

FAILED

O.K.

ZERO

O.K.

NO

-

12

-

-

13

-

Mikuni MY Series Marine Installation Manual

.

Part No

:

MY

30

Marine ins

-

NT

.

9

th Edition

:

Sep

2006

Mikuni Heating

(

UK

)

Ltd

Unit

6

& 7

,

Second Avenue Business Park

,

Millbrook

,

Southampton

,

SO

15 0

LP

.

Tel

:

023 8052 8777

.

Fax

:

023 8052 8808

.

Specifications

,

designs

,

etc in this manual are subject to change without prior notice

.

All rights reserved

.

No reproduction or reprinting are allowed

without our consent

.

This manual suits for next models

2

Table of contents

Other Mikuni Heater manuals

Popular Heater manuals by other brands

Trotec

Trotec TIH 300 S operating manual

Ozeanos

Ozeanos OT-FH-2000T instruction manual

STIEBEL ELTRON

STIEBEL ELTRON Eltronom SHU 5 S Operating and installation instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-6 Installation instructions and owner's manual

Broan

Broan 114 owner's manual

HJM

HJM 624 Using instructions