Mill-right 529 User manual

f 6r

r

- 0/ , ro-r'.,.,/llr'f

\qAEl.I/

/W^VU\U,

CAUTION!

Readall Safety

Instructions

Careful

ly

IKONWOODDKAND

MILL.RIGHT

ROUTER

MILLING CENTER

Designed,ManufacturedandSold

by: POSITIVE POSITION,INC.

SCHENECTADY.NY I2309

OWNER'S

MANTJAL

(Part

No :1t,B3052)

ModelNo.529

and

Accessories

Verli.Mill

B5018

Side.Mill

85041

Y-Posi.Mill85032

Extend.A.Mill

B5057

Spindle.N1ill

85071

Clamping

Kit85028

DovetailIndex85055

Dust

Collcctor

B5045

Convenience

Switch

85063

OWNER'SMANUAL

SAFETY

PRACTICESANDINSTRUCTIONS

I. GETTO

KNOWYOURMILL.RIGHT

Read

andunderstandyour owner's manualandthe

CAUTION! and WARNING! labels

in themanualand

affixed to thetool . Learnthe operationsandthe limitations

of theMILL.zuGHT as

well as

anypotential

hazardsthat

may

resultfrom itsoperation.

2. ROUTERSAFETY

Followthe

safety

practices

andinstructions

recommendedby

yourroutermanufacturer.

Ifyour routerrequires

grounding,

be

sure

to use

the

propergrounded

typereceptacle.

3. KEEPWORKAREACLEAN

Avoid accidentsby keeping

yourwork areaclutterfree.Do

notworkonwaxedfloorsor floorscovered

with sawdust.

4. AVOIDDANGEROUSCONDITIONS

Don'tuse

your

Mill.Rightindamporwetlocations.Use

adequate

lighting.

5. KEEP

CHILDRENSAFE

Donotoperate

with children

present.

Remove

starter

keys

whennot

inuse.

Lockworkshop

when

notinuse.

6. DON'TFORCETHETOOL

Do thejob better

and

safer

by operatingtherouterattherate

andspeedforwhichitwasdesigned.

Don'tforce

the

machinetodo

a

job itwasnot

designedfor.

7. CLOTHING

Donotwear

looseclothing,

gloves,

neckwearor

jewelry

which

can

get

caughtinmoving

machinery.Usenon-slip

shoes.

Containlong

hair.

Rolllongsleevesabovetheelbow.

8. USESAFETYGLASSES

Asaminimum,wear

safety

glasses

with

side

shieldsatall

times

(comply

with

ANSIZ'18.1).Usefaceordustmaskif

operation

warrants

and

ear

protection

during

extended

periods

ofoperation.

9. LNATTENDED

MACHINE

Neverleave

arunningmachineunattended.Be

sure

the

router

hascompletely

stoppedbefore

leaving.

IO.SECURE

WORK

Useclampsto secure

work towork surfaces.

When .. -.

movedfor operation,use

hold-downsor featherboa::r

againsttableand

guide

fence.When

possible.

freer:'-:

operatethemachine.

1I. DON'TOVERREACH

Maintain

footingand

balance

atall times.

12.

CAREANDMAINTENANCE

Use

only

sharpandcleantools.Follourouter

r:- -':,. -

maintenance

gu

idelines.

I3. DISCONNECTTOOLS

Turn

off router

andunplug

it when

chaneineb :.

operations.Turnoff

yourin-linecon\.::en.e

:

-

When

plugging

inrouter,

be

surert

rs :.

::.. Oi : :.

14.

USEACCESSORIES

DESI(

i\F.D

i

THEMILL.RIGHT.

Seeowner'smanualforrecommende:

:- --,i:.--i

accessoriesmay

resultinhazardous

.-','

15.DAMAGEDPARTS

Damaged

parts

shouldbe

properly

..i... j -<: .: --:-r'-

Check

foralignment,movemen!.

t're:r:.: ' :',- r -

mayhavebeenaffected.

Repairor:i: 3-.

beforecontinuingoperation.

16.

WORK

FEEDDIRECTIT

tr.

Alwaysfeed

workagainstthedirec:..: ' '

fixed.

feedtherouterintothe

uork ::r -i.' ,': . --

I7.

STABILITY

TheMILL.RIGHT

is

construcled.:

-:i, -! r ';-

any

tendency

fortheunittotipdur::.;-- ,:.:-

beboltedtothefloor or asuppon

:ia- : '- .' . .:-

securingthemtothelegs

andexten:

-r '' :-

potential

tipping.

I8.CUTTING

LINE

Neitherthe

operator

orobserver{

s r: - : .L'

- .'-

when

the

workisbeingmoved

int.-

:-: ' -':.- '

--:lt

' : ;i ct'ii

'- l: li

: -iiO0llC€

-':.3One.

. .\

ITH

'-' ?r

- ::al

'.!-- l

- rkis

-i Jn.

'::eis

.'-ruld

{l by

ll

O 1996,

PositivePosition,

Inc

..iung

l9 ROUTING

S.{FETYUSINGTHE

CONVENTIONAL(BIT UP)ROUTING

STATION

Alwaysfeed

thework

against

thedirectionof

rotation.

Proceedcounterclockwise

aroundthe

outsideofa

workpiece.

Proceed

clockuisearound

the

interiorof aworkpiece

(such

asa

cutout

orarecess

inthebody

ofthe

workpiece)

Never

pass

the

rvorkpiece

betweentherouterbitand

the

guide

fence.The

workpiece

couldbecome

trapped

and

"kickback".

Notethat

this

operation

wouldalso

violatethe

"counterclockwise

aroundthe

outside

ofthe

rvorkpiece"

rule.

When plough

cuttingthrougha

workpiece

(such

as

adado

cut

with

the

routerbitpointing

up)

alwaysbe

awarethat

therouterbitwill behidden

until

it

emerges

fromthe

workpiece.

DONOT PLACE

YOURHANDBEHIND

THE

WORKPIECE

AT

ANY TIME. Use

a

push

stickorsecurethe

workpieceinamiter

gauge

equippedwithaclamp.

Donotreleasethe

workpiece

untilithas

passed

completell

bevondthe

routerbit.

Useafeatherboardtoholdtheworkpieceagainstthe

main

table

rrork

surface.

The

guide

fenceis

equipped

* ith

aT-slotformountingafeatherboard.

A featherboard

designed

specifically

forthis

operation

isavailablefronr

IRONWOOD/MILL.RIGIIT.Refertothe

accessories

catalog.

Use

afeatherboardto holdtheworkpiece

against

the

guide

fence.Themiter

gauge

slot

is

alsoa

T-slot

rvhich

canbeused

tomountafeatherboard.A

featherboarddesignedspecifically

for

thisoperation

isavailable

from

IRONWOOD/MILL.RIGHT.

Refer

to

the

accessories

catalog.

Donotuse

warped, twisted

or cuppedstock.

Do not

attemptto flatten

awarped

workpiece

by theforceof

holddownsor featherboards.Thesedevicesare

meanttoholdonlyflat

stockagainstthe

work

surfaces.

Use

abit

guard

whenever

your

operation

allows

its

use.

The

bit

guard

will helpkeep

your

handsaway

lionr

therouter

bitduringoperation.

Ner

erturn

therouter"ON" beforeclearingthework

surfacesoftools,woodscrapsetc.

notintendedfor

use

with

the

planned

operation.

OWNER'SMANUAL

SAFETY

PRACTICES

ANDINSTRUCTIONS

(CONTINUED)

. Wlen usingtheVERTI.MILL accessory,besure

that

the

workpiece

issecurely

clamped.

Keepbothhands

onthe

fixturewhenrouting.

. Do notattemptto moveor adjustanypaft,fixture,

holddown,

machine

part

etc.while therouterbit is

still

turning.

r Do notuse

thisstation

for "plunge

type" operations

by pressing

thework downontotherotatingrouter

bit. Usetherouter

caniagestationwith a"plunge

rype"

router

forthisoperation.

r Closethesplitfenceascloseas

possible

tothe

router

bit to prevent

cockingof thework asit passes

the

openinginthe

fence.

20.ROUTING

SAFETY

USING

THE

ROUTERCARRTAGE

(BrT

DOWN)

ROUTING

STATION

o Alwaysfeedthework againstthedirection

of

rotation.

. Proceed

counterclockwisearoundtheoutsideof a

workpiece.

o Proceed

clockwise

aroundtheinterior

of aworkpiece

(such

as

acutoutorarecessinthebodyof the

workpiece).

o Always

checkthat

theworkissecurelyclamped

beforeturningontherouter.

. Backroutingisnotrecommended.

o Make

sure

that

nomachine

parts

are

in

the

line

of

travelofthe router

bitfor

yourproposed

operation.If

machineparts

areinthe

lineof travel,use

travel

stops

orothersuitablemeansof preventing

the

router

bit

from contactingmetal

parts.

o Do notattemptto remove

the

work or anymachine

parts

whiletherouterbitisstill

rotating.

. Keepbothhandsontherouterhandles

ortherouter

caniage

whenrouting.

. Takesmall

cutsrather

than

large.The

MILL.RIGHT

wasdesignedwithprecision

positioners

which

allow

youto proceedquicklywith smallercutsfor safer

operation

and

abetterfinish.

o Theroutercarriage

router

stationwasdesignedto

enhancesaferyby clampingthework in placeand

movingtherouter

alongacontrolled

predetermined

pathin itscarriage.

Do notletthiscontrolledsituation

lullyouintocarelessness.A SECONDOF

INATTENTION CAN RESULT IN SEVERE

INJURY.

O 1996.Positive

Position.

Inc. 512-tr-96

OWNER'S

MANUAL

CONTENTS AVAILABLEACCESSORIES

Safety

PracticesandInstructions I Verti'Mill

Main

AssemblyInstructions 5 AssemblyInstructions

Step

l, AssemblingtheLeg

Set 5 AdjustmentInstructions

Step2,

AssemblingtheBase 5 ApplicationInstructions

Step3,

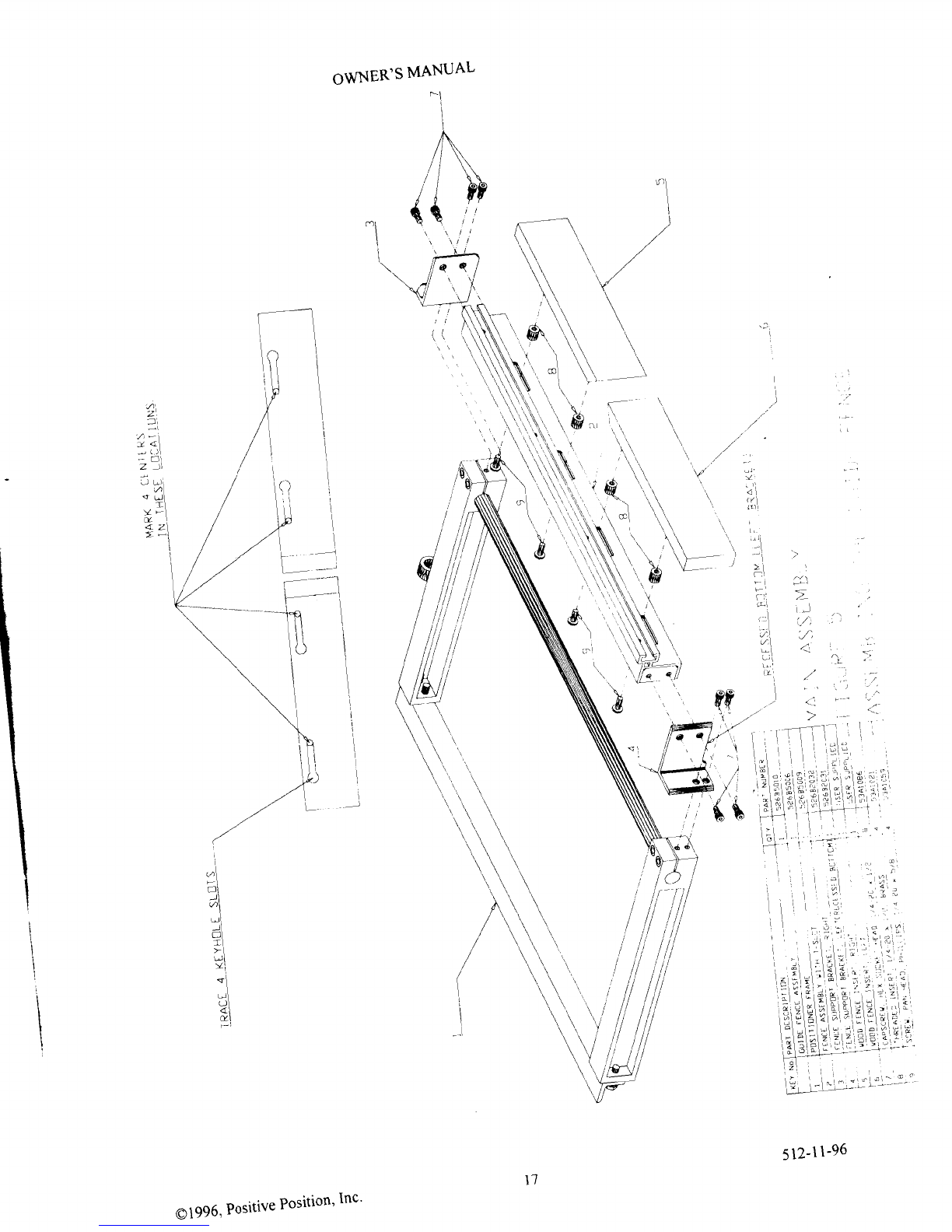

AssemblingtheMainTabletotheBase 6 AssemblyFigure

Step

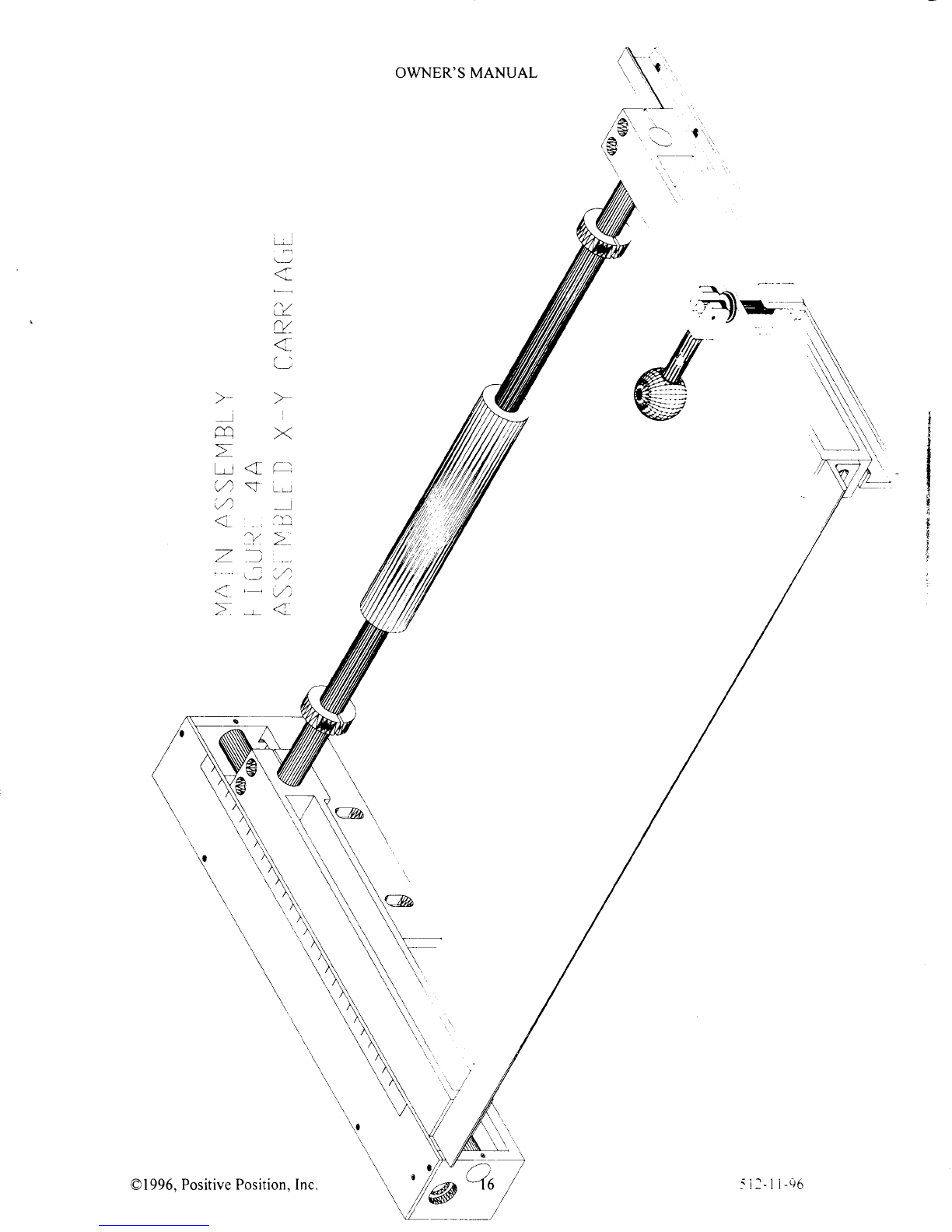

4,AssemblingtheX-Positioner 6 AssembledFigure

Step5,

assemblingtheX-Y Caniage 7 Application

Figure

Step

6,

AssemblingtheGuide

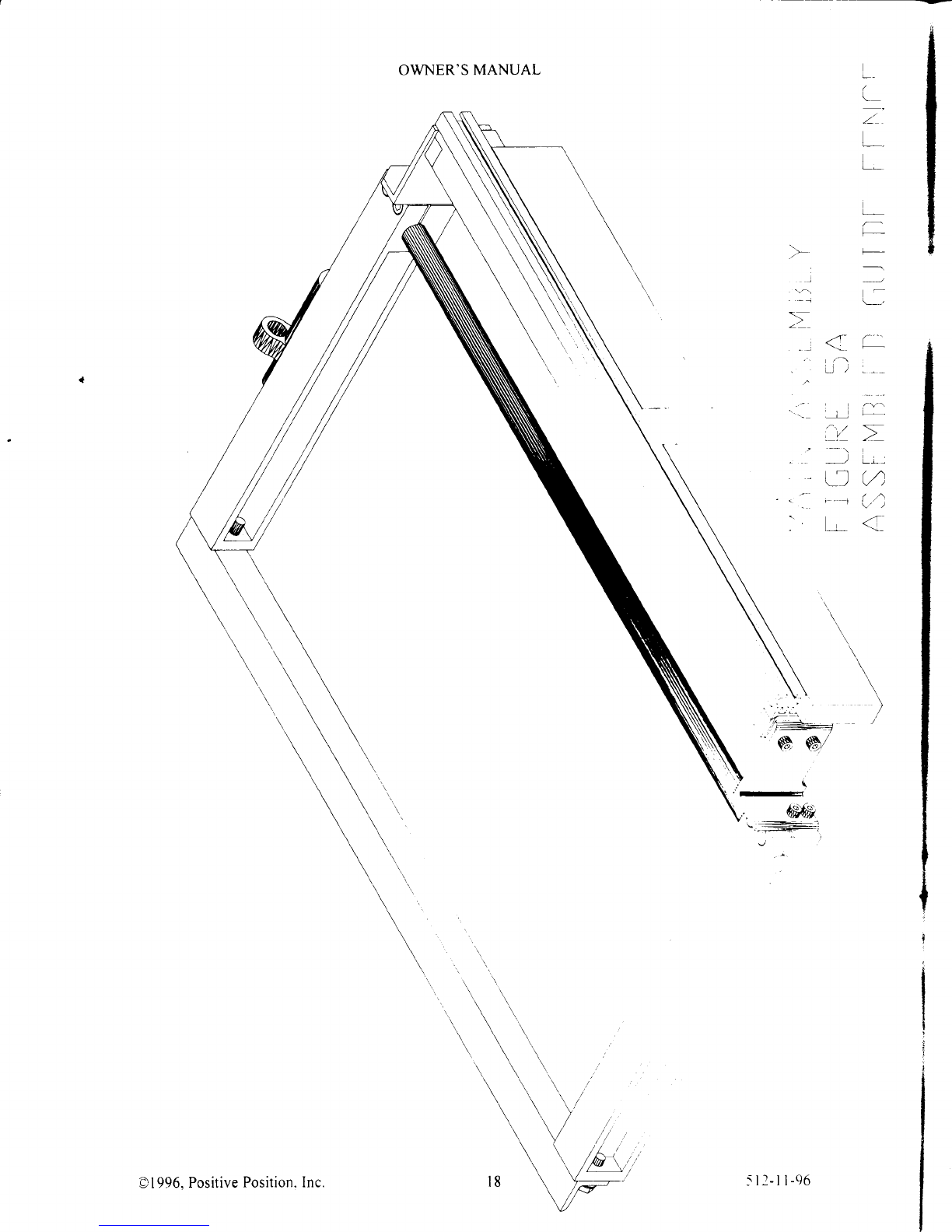

Fence 8 BasicOperation.Fig.I

Step7,

AssemblingtheAuxiliaryMillingTable

Support 8 BasicOperation,Fig.

2

Step

8,

Assemblingthe

Auxiliary

Milling

Table

(AMT) 9 BasicOperation.Fig.3

Step9,

AssemblingtheRouterCarriage 9 BasicOperation,

Fig.

4

Step

10,AssemblingtheCarriageLock l0 Y-Posi.Mill

40

40

40

40

4l

42

43

44

45

46

4',7

48

48

49

50

5l

)i

53

<t

51

55

56

5'7

58

59

60

60

6l

62

63

63

64

65

65

66

o/

68

MainAssemblyFigures

I through

9

Fig. I AssemblingtheBaseandLeg Set

Fig.2 AssemblingtheMainTable

to

theBase

Fig.3 AssemblingtheX-Positioner

Fig.

3A AssembledX-Positioner

Fig.4 AssemblingtheX-Y Caniage

Fig.44. Assembled

X-Y Carriage

Fig.

5 AssemblingtheGuideFence

Fig.

5A AssembledGuideFence

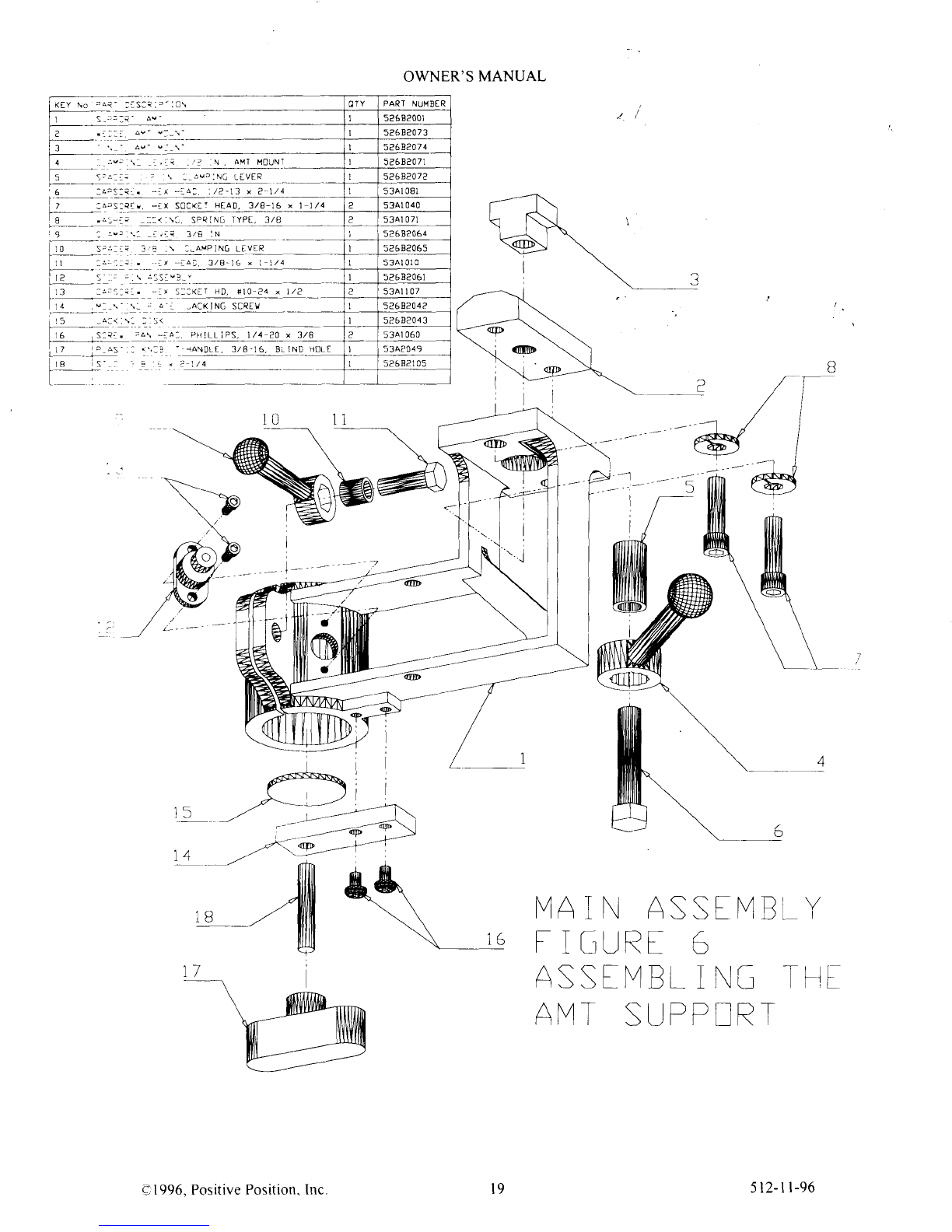

Fig.6 AssemblingtheAMT Support

Fig.6A AssembledAMT Support

Fig.7 AssemblingtheAMT

Fig.7A AssembledAMT

Fig.8 AssemblingtheRouterCarriage

Fig. 8A AssembledRouterCarriage

Fig.9 Assemblingthe

CarriageLock

Adjustments

Adjusting

theX-Y Carriage

Adjusting

theX-PositionerAcmeNut Pre-Load

AdjustingtheAuxiliaryMilling Table

(AMT)

AdjustingtheGuide

Fence

Adjustment

Figures,

MainAssemblyl0 throughl4

Fig. I0 AdjustingtheRouterCarriage

Fig.1l AdjustingtheAMT Support

Fig.12 AdjustingtheAMT

Fig.l3 Adjusting

theAMT

Fig.l4 Adjustingthe

Guide

Fence

Basic

Operations

UsingtheX-PositionerScales

UsingtheRouterTableStation

UsingtheRouterCarriage

Station

Planingwith theRouterCarriageStation

BasicOperation

Figures

Figs.l -4 BasicOperation

Figs.5-8

Figs.9-10 Basic

Operation

Basic

Operation

Usingthe

X-PositionerScales

II AssemblyInstructions

II Application

& Adjustments

12 AssemblyFigure

l3 AssembledFigure

14 ApplicationFigure

l5 ApplicationFigure

(Rear

r

ie*

)

l6

17 Side.Mill

l8 Assemblylnstructions

19 Application& Adjustments

20 AssemblyFigure

2l AssembledFigure

22 ApplicationFigure

23 Operation

Figure

24

25 Extend.A.Mill

AssemblyInstructrons

Assembly

Figure

Assembled

Figure

DustCollector

Assemblylnstruction.

Assembly

Figure

26

26

26

27

27

28

28 DovetailingIndexPlates

29 AssemblyInstructrons

30 AssemblyFigure

3l AssembledFigure

32 OptionalSet-upsFrgurc

33 Spindle.Mill

33 Assembly

Instructions

34 Application& Adjustments

35 Basic

Operation

Instrucrrons

36 AssemblyFigure

37 Assembled

Figure

37 Application

Figure

38

39 ConvenienceSrvitch

39 ClampingKit

59

69

-0

-l

-l

J

-{

'76

@

1996,PositivePosition,

Inc. 5

l2-rr-96

OWNER'S

MANUAL

ASSEMBLING

THEMILL.RIGHT

MODEL529

PLEASEREADTHESEINSTRUCTIONS

THOROUGHLYBEFORE

ASSEMBLY

TOINSUREA

TROUBLEFREEEXPERIENCE.THESEINSTRUCTIONS

HAVEBEEN

TESTEDONNOVICES

ANDWE

HAVEDONEOURBESTTOWEED

OUT

PROBLEMS

FOUND

DURING

THIS

TESTING.IFYOU

SHOULD

EXPERIENCEANYPROBLEMS,PLEASE

CALL

TOLL

FREE

888-478-2453ANDREQUESTA SERVTCE

CALL.

A SETOFHEX

[ALLEN]

WRENCHES

ANDA

COUNTERSINK

HAVEBEEN

PROVIDEDFOR

YOU

CONVENIENCE.YOUWILLALSONEED

FLAT

TIPPEDANDPHILLIPSSCREWDRIVERS

AND

A SET

OF

BOXOR

SOCKETWRENCHES.THEONLY

DRILLINGYOU

WILL

HAVETODOISFOR

YOUR

ROUTER

MOUNTINGHOLES

INTHEROUTER

SUPPORT

PLATES

AND

FOR

THEBRASSINSERTSINTOYOUR

WOODFENCEINSERTS.

STEP

I

ASSEMBLINGTHELEG

SET

(OptionalAccessory)

(Assembly

52685017)

RefertoFigure

I Find

the

parts

describedbyFigurel key

numbers7 throughl4 inthe

quantities

indicated.Check

that

allhardware

items

matchthe

description

given

inthekeylist.

Match

thethree

bolt

holes

inthe

upper

endofeach

Leg

[7]tothe

matching

bolt

holepatternin

the

endsoftheStiffeners

[0] & [l l]. The

two Long

Stiffeners

[0] shouldbeopposite

eachotherandthetwo Short

Stiffeners

I

II] should

be

oppositeeach

other.

The

Legsshouldbe

positioned

outsidetheStiffeners.Use

one

eachof

Bolt

[2], Nut|31 and

LockWasher

[3] fbreach

ofthe24holes.

Notethehardware

sequence

shown

inFigure

l.

Donot

tighten

Bolts

until

allBolts

have

beeninserted.Thenbe

suretosecurelvtightenallBolts.

Thread

oneNut [9]onto

eachFoot

[8].

AboutI inchofthreadshouldextendpast

theNut.

Insert

oneoftheseassembliesintothe

bottom

hole

ofeach

Leg.

ThreadtheremainingNuts

[9]ontothe

Feet

[8].

Note

the

harduaresequence

showninFigurel. HandtightenthetopNutandplacethe

assembled

Leg

SetonitsFeet.Once

you

halecompletedthe

MILL*RIGHT assemblyand

positioned

it inyour

shop,

level

thefeetandsecurelytighten

thetopNuts

[9].

STEP2

ASSEMBLINGTHE

BASE

(Assembly

52685022)

Refer

toMainAssembly

FigureI. Find

the

parts

describedby Figurel

keynumbersI through6 inthe

quantities

indicated.Checkthat

allhardwareitems

matchthe

descriptiongivenin

thekeylist.

If you

have

purchased

LeeSet

52685017,

position

the

unit

Base

[ ] on

the

LegSetand

alignthe

three7 I6bolt

holes

withthe

matchingboltholes

on

topofthe

StiffenersintheLeg

Set.

Q.lote:

the

Base

is

.rnrmetrical

toptobottomsoitcan'tbe

positioned

wrong.)

Looselyfastenthe

Base

totheLegSet

withone

eachof

Bolt

[3].

Washer

[4],Washer

[5]and

Nut [6] ineachof theseholes.Notethehardware

sequence

showninFigurel.

BoltoneAngle[2]tothetoprearoftheBaseasshowninFigure

l usingthefwo5/l6holesandBolt[3],Washer

[-l].

\\ asher

[5]and

Nut [6].BolttheotherAngletothe

bottom

rear

holes.

Notethat

the

Angles

are

positioned

inside

ofthe

Baseflanges.Bolt

the

bottom

AngletotheLeg

Set

usingthecenterholeinthe

bottom

Angle

and

one

each

of Bolt

[3].Washer

[4],Washer

[5]AndNut [6].

NotethehardwaresequenceshowninFigurel.

Whenall

harduareis

inplace,

be

sureto securelytightenallbolts.

@1996,PositivePosition,

lnc 512-tt-96

OWNER'SMANUAL

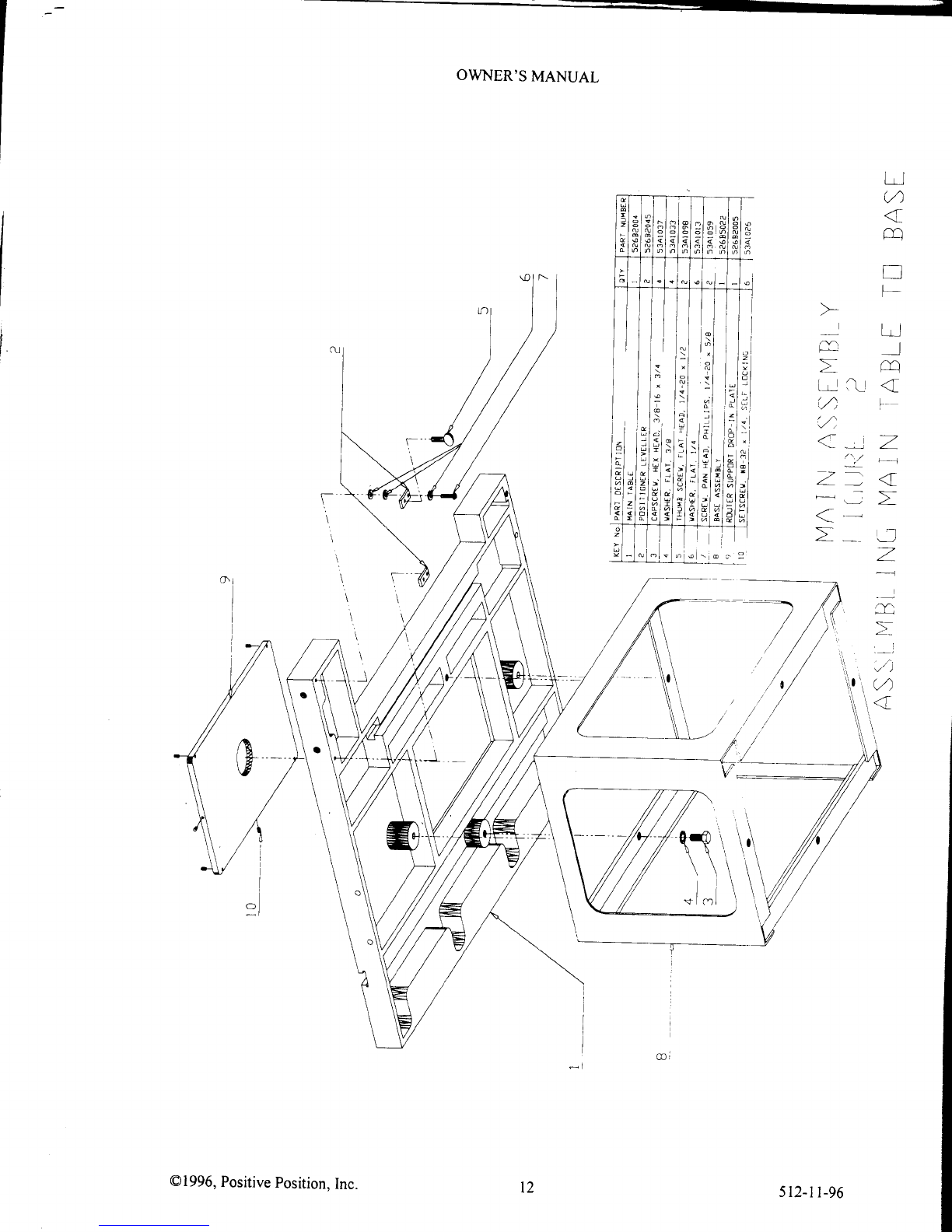

STEP3

ASSEN,IBLING

THEMAINTABLETOTHE

BASE

Refer

toMainAssemblyFigure2.

(Main

Table

Assembly52685021)

Find

theparts

describedby Figure2ke1numbersI through7 inthe

quantitiesindicated.Checkthatallhardwareitemsmatchthedescription

givenintheker lrst

Position

the Main

Table

[1]

ontheassembledBase

(step

2).

CAUTION: The

tgble

*eishs

aporoximatelv

90lbs

andthisstenmay requireassistance.

Be

sure

topositionthetable

* rththe

"U" shaped

end

andundersideT-slotoverthe

large

cutouthole

inthe

longsideof the

Base.

Looselysecure

theTable

totheBase

using

the

holesinthetopflangeof

theBase

and

Bolt

[3]

and

Washer

[J].

Whenallhardrrarersin

place.

besureIo

securelv

tightenallbolts.

AttachtwoPositionerLevelers

[2]

totheundersideofthe

Table

as

5ho\\ninFrcurcl. usrng

Screw

[7]

andWasher

[6].

Thread

the

Thumbscrews

[5]

intothethreaded

holes

oiPosrtrtne:

l.erelers

[2].

lnsertthesixLockingSetscrews

[0] into

theRouterSupptrn

I)rt,n-ln

p1311'

lal P.:;e

theRouter

Suppon

Drop-ln

Plate

in

the

rabbetcd

recessin

the

Main

'l'able

and

Ir'relttu:rir{

thclour.,.n:.':

I L

ir:rS Selscre$s.

Ad.lust

theside-to-side

fit

byad.justing

thetu'ol.ockingSr'tSCft'rrs

ltrt:itedrr::hertle:

Place

your

routerontheRouterSupporf

Drop-lnPlat.'an,l

ptr:ii.trr.

.i

lrr

i:itrrri!,:\ 3nienl

accesstothe

controls.

Note

this

routerposition.Rernove

)our

router5

phcn..lrc

b,ase

rr.: --:rSlt

J)

J:ern9:Jle.

scribevour

router

basebolt

holepattern

onto

theRouter

Support

Drop-lnPi,:icl)rrl,

hrlr- ;.:-3-ronc::i :. :..

-: :!ruter

basescrens

andcountersinkthetopoftheRouterl\,lountingPlatcusrnS:hccct.rnis:.r\::.r\:ie;

'--\';i()\'Useflatheaded

scrcwsof thefight threudundlengthlo fully engapethetuppedhttles

.:.

'.i-r rt]urir 'r: - :'.:' hare

to buylonger

screws

than

the

onesthatcome

with

)-our

router.

AnachthcfrrLlirii ::..R-

-:.: \tou:.:.:i ? j:3

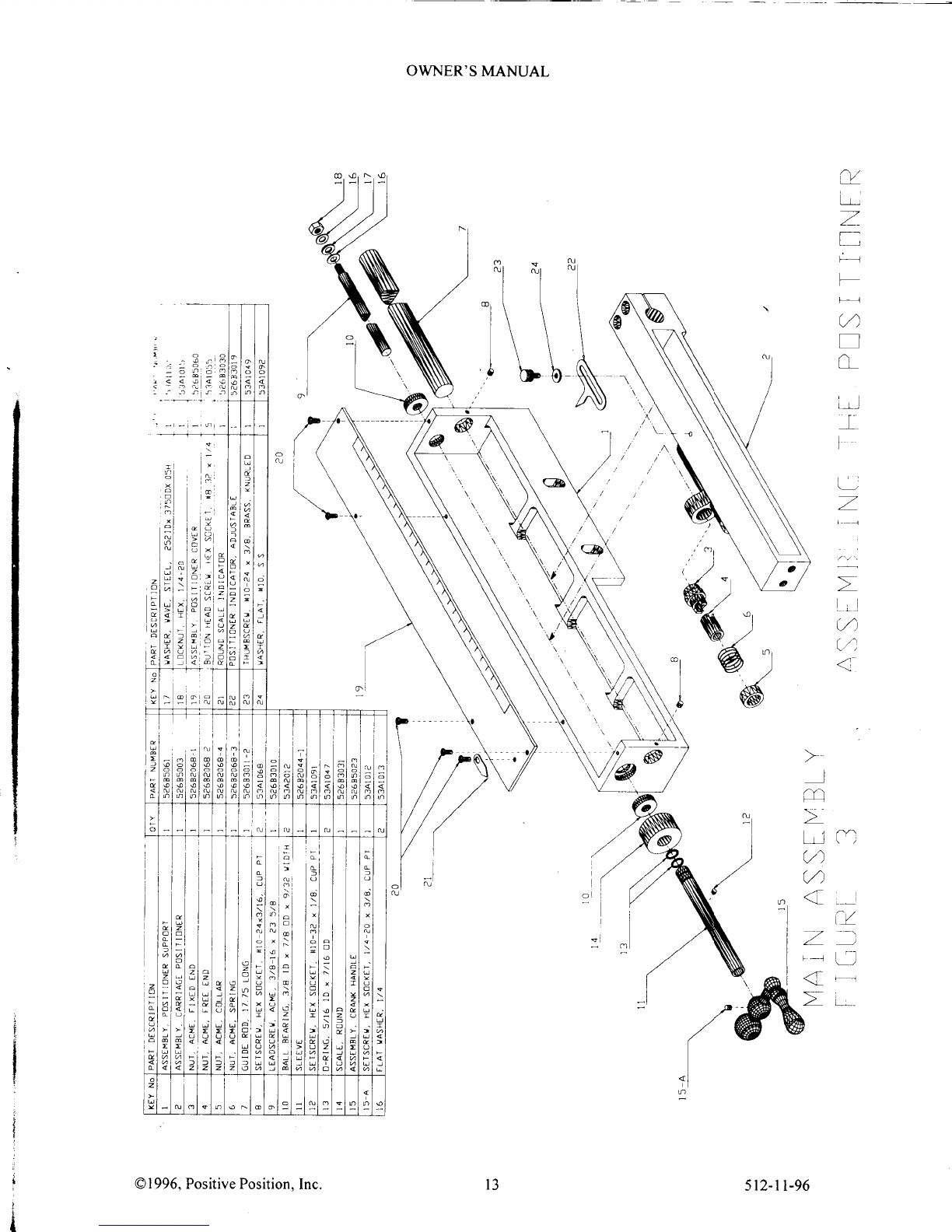

S'l

l:P

l

ASSENIBLI\C tllf: Pr

ts;' r \i {

(Positioner

.-\::enrb.":l: 3

j

Ret-ertoMainAssemblyFigure

j. Firrdthe

panr

Jes.:.:;::, i :-:r I xcr1-"':.-':.

. ::.:ough

24inthe

quantities

indicated.Check

that

allhardrvareitenrsnratchthc;e:;::::..

- i .i: iirri3ri. .:

Placethe

PositionerSupport

u]on a

rrork

surt'ace

rllhe::: : ::: es-:::ce;t :::: ,.

::::ranple.)

Insert

thetwoBall

Bearings[0]intothetwocounterbored]E'holes::i..::.e::s.-:'.i.Po::,-3-:-::.:r[].TheBall

Bearingouterdiameterisdesigned

as

a

slip

fitintothesebrrrc:a..J,

l:i B:..Bea:lngs

s:..- : :3 \e:: jquare

to

the

bores

uhile

insertingto

prevent

binding.

Screu,theFixed

End

Acrne

Nut

[3]

intothe5 l6-l8lrr:i:r.l rl:: ,:,:

Cr:-:lase

?--:

i .-r3:{ssembly

[2]

as

shown

inFigure

3.IMPORTANT! Tishtenbr handonlr

Position

Carriage

Positioner

Assembl;

[2]

urth

the

r. .e::::.: :r:: .-:'

'i' a.:g:.e:

bothends

of PositionerSupport

[1. InsertGuideRod

[-] lh:..ugr.::,e:.:. ": ,::eeni l: '

bearingboreof[2]andthenthroughtheboreattheothcrcnir,i'i.'\..;-::3.:Jitii-l :l

surfacesof[]then secure

[7]

in

[]with two

setscre\\s

[81

as

sii\\;i :nF::-:e -:

With

theopeningof Il] facing

y'ou.

insenAcnrc'Lerd:cre*

'91

:ni..i:.e:!,reoi:r'.e:lshl

nanlBall

Bearing

[10].

The

l/4-20

threadedendof [9]

mustbeon

therrghrl'hen:r'.rerJ'q

l.rn\ra\ ::io i-. ,,rhrch

has

alreadybeenscrewedinto[2].Makesure[9]doesnotprojectrntothc.r3''\St)i-:'lirtdols.

Ih.n:.ici[9]

offuntil

thejawareaof

[3]

isclear.Alignthematingja*sofFrceEnd.{:;lerut

l; ',rr:n:retd*Sraii:i:n.trullr

engage

thc

jaws.

Holding

[4]in

this

position,

continuescrolins

[9]

rnto

[-r]

rnj i-l]

I'eepr:i

IJ]

as;..,:ell [-l]as

possible.

Whenthethreadsof[9]har,eengagedboth[3]and[1].both[-r]

andlll

'.rrll

r;:3)runir \er:.s,rpAcmeNut

Spring

[6]

andthenAcmeNut

Collar

[5]

overthe

por-tionof [9]

trhrch

ha:arreiJ\

rr>:ei li.:'rr.gh

[-rl

and

[4].

Thread

[5]

onto

[1]

slightll'

compressing

[61.

''\

.:: ::.3

;

.' boresat

::.::.::.:,-;gh

the

-:i. '\.ll ::e

outside

O 1996.

Positive

Positiorr 5ll-rl-96

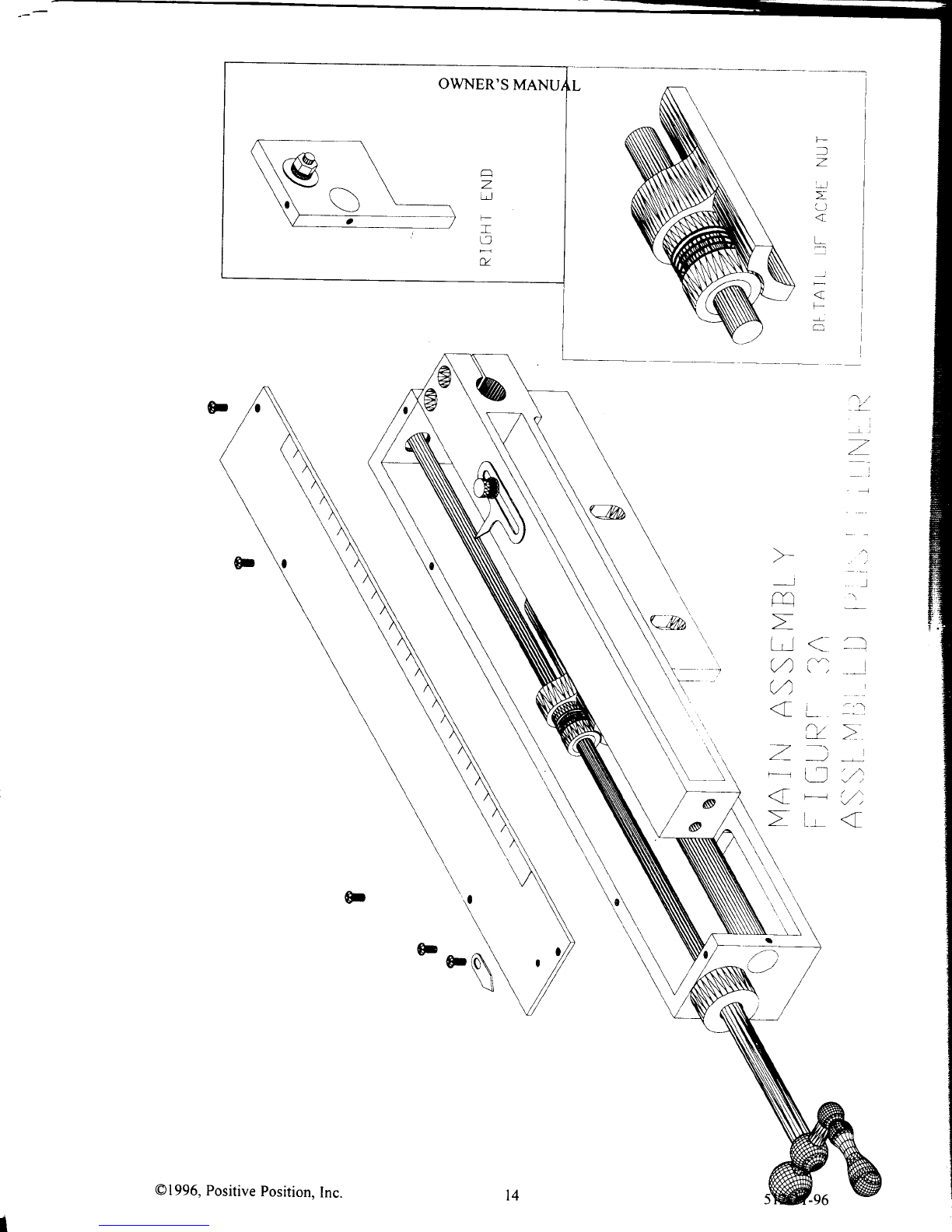

OWNER'SMANUAL

STEP

4

ASSEMBLINGTHE POSITIONER

(CONTINUED)

Continuetuming

[9] untilitpasses

through

the

ID ofthe

BallBearing

[0] on

the

left

and

projects

beyond

- . :frrut

5.5inches.

Apply'

afew

dropsof light

machineoil tothetwoO-Rings

fl 31andslide

them

overthe

endof Sleeve

Il I

]

"

- ;n isnearest

the

fwoO-ring

grooves.

Position

one

O-Ring

ineach

groove.

Next,slideRound

Scale

[4] over

the

' t-)-

Rings

[ 3

].The

scalemarkingsof [ 4] mustbe

at

theend

ofthe

assembly

andtheknurled

part

of fl 4l must

-',:..u

ardthecenter.If not,turn

il 4] aroundnow.

Slidethisassemblyover

the

left

endof [9].

Slide

the

bore

of CrankHandleAssembly

[15]

overtheendof [9]until

[9] bonomsoutinthebore.Secure

' to[9]withSetscrew

[15-A].

Tighten

securely.Push

the

CrankHandle

andLeadscrew

Assemblyallthe

wayto

-

i :rsht.Thet/u20

threaded

endshould

beoutsidethePositioner

SupportAssembly

Il]. Applytwo %FlatWashers

^ theWaveWasher

Il7] andthe

t/*20

Locknut

[ 8].TightentheLocknuttoremove

axial

play

ofthe

::iscrew.Donotovertightenasthiswill make

the

Leadscrewdifficult

toturn.

InsertSetscrew

fl2] into

Sleeve

andtighten.

Applyafewdropsof lightrnachineoil toGuideRod

[7]

just

outside

ofthetwo linear

bearinssatbothends

' ,-

.rrriagePositioner

Assembly

[2].Slide

the

CarriagePositionerAssemblv

[2]backandforth

repeatedly

towork

-: orlinto

the

linearbearings.WipetheGuideRod

[7]

clean.

Place

Cover

[9] onPositionerSupport

[]and securewithfour

screws

[20].

Attach

RoundScaleIndicator

- ' tocover

with

screw

[20].

Attach

AdjustablePositionerIndicatortoCarriagePositioner

[2]withThumbscrew

-:; andWasher

[2a]

in

thesequenceshown.

STEP

5

ASSEMBLING'THEX-YCARRIAGE

i.cter

toMainAssemblyFigure

4. Find

the

parts

described

by Figure

4 keynumbersI throughl5 inthe

:uantitiesindicated.Checkthatallhardware

itemsmatchthedescription

given

inthekeylist.

Placethe

bottomedgeofthePositionerAssembly

[5268500

I

] ontopof theLevelers.

[See

..*e lersinMainAssembly

Figure2.1

Secure

thePositionerAssemblytothe

Main

Table

[2]withtwoCapscrews

1,11.

Finger

tightenonlyatthistime.Attach

CarriageTrack

[6]tothe

MainTableusingtwoCapscrews

[4], three

\\ ashers

I l

] andthreeDisk

Springs

[ 2].

Notethat

theDiskSpringsareneartheedge

of the

MainTable

and

the

\\'ashers

areinboard.

Placetwoeach

Washers

and

Disk

Springsbelowthetableand

oneeachabove.

[This

stackup

na1changelaterwhen

levelingtheX-Y CaniageAssembly.]

SlidetheLinearBearingAssembly

[7] onto

theGuide

Rod

[3].[Note:

if youhave

purchased

theClamp

Kit 85028,

slidethe

twoShaft

Collars

[5]onto theGuideRodas

.rell

placing

on

ateach

endof theLinearBearingAssembly.]Slide

oneendoftheGuide

Rod

intothe%" boreof

:reCarriagePositioner

IKeyNo.2, MainAssemblyFigure3.]Slidethe'io"boreofthe

BallBearing

Caniage

\ssembly

[5] ontotheotherend

ofthe

GuideRod.ScrewtwoCapscrews

[8]eachinto

bothends.Snug

tighten

only

:: this

time

withtheAllenwrenchprovided.

Screw

the

SupportAngle

[4]ontotheendsof the

Caniage

Positioner

:ndBallBearingCaniageAssembly

usingfourCapscrews

[9].Use

the

twoWashers

[10]

ontheBallBearing

.arriase

Assembly

endonly.At thistime,

goback

andsecurelytighten

thetwoCapscrews

[ 3].Check

toseethat

:.:e

ballbearingsof theBallBearingCaniageAssemblyaresittingontopofthe

Caniage

Track.If necessaryadjust

:r.e

position

oftheBallBearing

CaniageAssembly.

Once

thisisdone,securelytightentheeight

Capscrews

[8]&

.l TurnthePositioner

CrankHandletocheckthattheX-Y Carriage

Assembly

movesfreely.

Wewill level

the

X-

': CarriageAssemblylater.

Apply

a

fewdropsof lightmachineoil toGuideRod

[3]

just

outsideofthe

two linear

bearinssatbothends

: ::e LrnearBearingAssembly

[7].

Slide

the

LinearBearingAssembly

[7] backandforthrepeatedlytoworkthe

:nto

thelinear

bearinss.Wipethe

Guide

Rod

[3] clean.

rqq6 PosirivePosition,Inc 512-tt-96

OWNER'S

MANUAL

STEP6

ASSEMBLINGTHEGUIDE

FENCE

[526B5o

lo]

Referto Main AssemblyFigure5. Findthe

parts

describedby Figure5 key numbersI through9 inthe

quantities

indicated.Check

thatall hardware

itemsmatchthedescription

givenin thekey list.

AttachtheRightFence

Support

Bracket

[3] andtheLeft Fence

Support

Bracket

[4] totheFence

Assembly

[2] with four Capscrews

[7].Notethat

theLeft FenceSupport

Bracket

[4] hasarecessonthebottomto

provide

clearance

fortheoptional

DustCollectorattachment

85045.

Attach

the

resultingassemblytotheX-Y

Caniage

Assemblyof MainAssembly

Figure4 usingfourCapscrews

[7].

Make

twoWoodenFenceInserthalves

t4]

& t5] fromscraphardwood.

WoodFenceInserts

shouldbe%"thick

and90"beveledononeend.Measure

the

distance

fromtheundersideof theAluminumFence

T-Slottothe

MainTablesurface.Makethe

width

oftheWood

FenceInsertsequal

tothisdistanceless

l/8". Makethe

rightWoodFenceInsert

12.5"longandtheleftWood

Fence

InsertIl" long.Positionthe

WoodFenceInsert

halveswiththebevel

inthecenterasshownandlineup

the

bevelededge

withthecenterofthe

RouterDrop-lnSupport

Plate

[Main

AssemblyFigure2 Key

No.9]. Holdingthe

WoodFence

InsertagainsttheAluminum

Fence

[2]andup

aqainsttheAluminum

FenceT-Slot,tracetheoutlineof

thefour

(4)Keyholesinthe

AluminumFenceonto

thebacksof the

WoodFencelnserts.Mark

the

centerofthe

narrow

endofeach

Keyholeasshown.Drill aflatbottomA318"

x 5i8"deephole

inthecenterofeachof thefour

locations

marked.Threadthe

fourBrassThreaded

Insertsintothese

holes.InsertthefourPanHeadPhillipsScrews

[9] intotheBrassThreaded

Inserts.

Slide

theheadsof thePanHead

Philips

Screws

intotheke1'holeslotsand

tighten

theWoodFence

Insertsagainstthe

AluminumFenceinthe

desired

position.

STEP

7

ASSEMBLINGTHE

AUXILIARY MILLING TABLE

(AMT)SUPPORT

Ref'ertoMainAssemblyFigure6. Findthe

parts

described

by Figure6 keynumbers

I throughl8 inthe

quantities

indicated.Checkthatallhardware

itemsmatchthedescription

given

inthekeylist.

Bolt

theAMT MountingWedge

[2]tothe

AMT Support

[ ] usingtwoCapscreu

s[7]and

LockingWashers

[8].

AttachtheStopPinAssembly

[12]

totheAMT SupportusingtwoCapscreus[13].

Pass

Capscrew

I l]through Spacer

[0] and

throughClampingLever

[9]making

surethehex

pan

ofthe

Clamping

Leverholeisfacingthe

headof Capscrew

[11].

ThreadCapscrew

[11]

intotheAMT Supportclamping

flangeas

shown.

AttachtheJackingScrew

MountingPlate

[4]to the

AMT Support

undersideusingnvoPanHeadPhillips

Screws

[ 6].Insert

Stud

[ 8] intothePlasticT-Handle

Knob

[ 7]andtightenusingdouble

3

'8-

16nuts Threadthe

assembled

T-Handle/StudintotheJackingScrew

MountingPlate.

Drop

the

JackingDisk

[ 5] intothe

top

ofthe2"

boreoftheAMT Support.

PassCapscrew

[6]through

Spacer

[5]andthroughClamping

Lever

[4] PassCapscreu'

[6]through

thel" bore

oftheAMT Supporttop

flange.throughthe

AMT MountingWedgeand

loosely

screu

Capscrew

[6] intothe

AMT MountT-Nut

[3].Lift theentireassembly

andmaneuverthe

AMT llount T-Nut

[3]

into

either

end

oftheAMT MountingT-Slotlocated

undertheMainTable.

[See

MainAssembllFigure2 for

location

oftheAMT Mounting

T-Slotl.SlidetheAMT Support

Assemblytoa

position

atabout

themiddleofthe

AMT MountingT-Slotandlocksecurelyinto

place

using

theClampingLever

[5].

O 1996,

PositivePosition.Inc 512-n-96

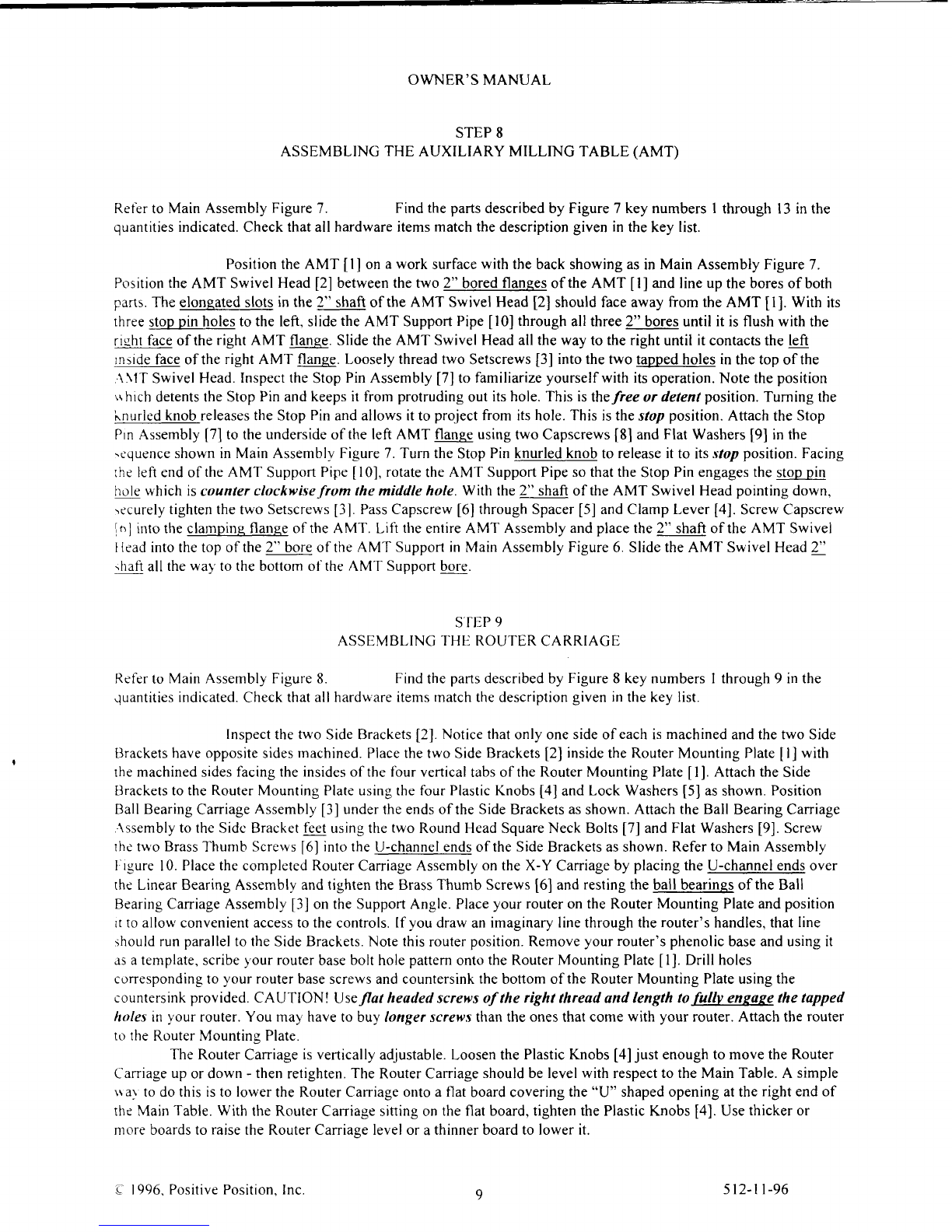

OWNER'SMANUAL

STEP8

ASSEMBLING

THE AUXILIARY MILLING TABLE (AMT)

Ret-er

toMainAssembly

Figure

7. Find

theparts

describedby Figure7 keynumbersI throughl3 inthe

quantities

indicated.

Check

thatallhardwareitemsmatchthedescription

given

inthe

keylist.

PositiontheAMT [ ] on

aworksurface

with

thebackshowingas

inMainAssemblyFigure7.

Position

the

AMT SwivelHead

[2]betweenthetwo2" bored

flanees

ofthe

AMT []and lineuptheboresofboth

parts.

Theelons,atedslots

inthe

2" shaftof theAMT Swivel

Head

[2]shouldfaceaway

from

theAMT Il]. With its

rhree

stop

pin

holes

totheleft,slide

the

AMT Support

Pipe

[0]through allthree2" boresuntil

it isflush

withthe

rieht

faceof the

rightAMT flanee.Slidethe

AMT SwivelHeadalltheway

totherightuntilit contacts

the

left

rnsidefaceofthe

rightAMT flanse.LooselythreadfwoSetscrews

[3] intothefwotappedholesinthetop

ofthe

\\1T SwivelHead.

Inspectthe

Stop

PinAssembly

[7]tofamiliarize

yourself

with itsoperation.

Notethe

position

irhich

detentstheStop

Pin

and

keepsit from

protruding

out

itshole.Thisis

thefreeor detent

position.

Turningthe

inurled

knobreleasestheStop

Pin

andallowsittoproject

fromitshole.Thisisthe

slop

position.

Attachthe

Stop

PrnAssembly

[7]to theundersideof the

left

AMT flanseusing

fwoCapscrews

[8] and

Flat

Washers

[9] inthe

.cquence

shownin MainAssemblvFigure7.Turnthe

Stop

Pin

knurled

knob

toreleaseitto its.r/op

position.

Facing

lheleftendof theAMT Support

Pipe

[ 0],rotate

the

AMT SupportPipesothatthe

Stop

Pinengagesthe

stop

pin

holewhichiscounter

clockwisefrom themiddlehole.tNilhthe2" shaftof theAMT SwivelHead

pointing

down,

)ecurelytightenthe

two Setscrews

[31.

PassCapscrew

[6]throughSpacer

[5]andClampLever

[4].ScrewClapscrew

l6l intotheclampineflangeoftheAMT. Lifi the

entireAMT Assemblyandplace

the

2" shaftofthe

AMT Swivel

tteadintothetopof the

2" boreof the

AMT SupportinMainAssembly

Figure

6.SlidetheAMT SwivelHead2"

r,haft

allthewa1'tothebottomof theAM-f Supportbore.

s fllP 9

ASSEMBLINGT'HEROUTERCARRIAGE

Refer

toMainAssemblyFigure8. Find

the

parts

describedbyFigure

8keynumbersI through9 inthe

.'1uantities

indicated.

Check

thatallhardwareitems

rnatch

thedescription

giveninthekeylist.

Inspect

the

twoSideBrackets

[2].

Noticethat

onlyonesideof each

is

machined

andthetwo Side

Bracketshaveoppositesides

rnachined.

PlacethetwoSide

Brackets

[2] inside

theRouterMountingPlate

[ ] with

rhe

machined

sides

facingtheinsidesof thefbur

verticaltabsofthe

RouterMountingPlate

[]. Attachthe

Side

BracketstotheRouterMountingPlateusingthefourPlasticKnobs

[4]and

LockWashers

[5J

as

shown.

Position

BallBearing

Carriage

Assembly

[3]under

theendsofthe

Side

Brackets

as

shown.

AttachtheBallBearingCarriage

\ssembly

totheSidcBracket

feet

usingthe

twoRoundHeadSquareNeckBolts

[7] andFlat

Washers

[9].Screw

thetwoBrass

Thumb

Scrervs

[6] into

theU-channelendsoftheSideBracketsasshown.

RefertoMainAssembly

lrrgure

10.

Placethe

completed

Router

CaniageAssembly

ontheX-Y Carriage

byplacing

theU-channelendsover

rheLinearBearingAssemblyandtightentheBrassThumbScrews

[6] and

restingthe

ballbearinssofthe

Ball

BearingCarriageAssembly

[3]ontheSupportAngle.Place

your

routeronthe

Router

MountingPlateandposition

rttoallowconvenientaccesstothe

controls.

[f you

draw

an

imaginarylinethroughthe

router's

handles,that

line

shouldrun

parallel

tothe

Side

Brackets.Notethis

router

position.

Remove

your

router'sphenolic

baseand

using

it

.lsatemplate,

scribe

),our

router

base

bolt

hole

pattern

onto

the

Router

MountingPlate

[]. Drill holes

conesponding

toyour

routerbase

screwsandcountersink

the

bottomoftheRouter

Mounting

Plate

using

the

countersink

provided.

CAUTIONI Use

flat heudedscrewsof theright threadandlengthtofullv ensssethetapped

holestnyourrouter.You mayhave

tobuylongerscrcwsthanthe

ones

that

comewith your router.Attachthe

router

tothe

RouterMountingPlate.

The

RouterCarriage

isvertically

adjustable.Loosenthe

PlasticKnobs

[4]

just

enoughtomovetheRouter

Carriage

up

ordown

- then

retighten.

The

RouterCarriage

shouldbelevelwithrespect

totheMainTable.A simple

\\a\ todothisisto lower

theRouter

Carriageontoaflat

boardcovering

the

"U" shapedopeningatthe

rightendof

theMain

Table.

With

the

Router

Caniagesittingon

theflatboard,tightenthePlasticKrobs [4].Use

thickeror

moreboardstoraise

theRouterCarriaselevelora

thinnerboardto lowerit.

e' 1996,PositivePosition,Inc 512-11-96

OWNER'SMANUAL

STEPIO

ASSEMBLING

THECARRIAGELOCK

Refer

toMainAssemblyFigure9. Findthe

parts

describedby Figure9 keynumbersI through6 inthe

quantitiesindicated.

Checkthatallhardwareitemsmatchthedescription

given

intheke1list.

PasstheStudandHandleLockAssembly

[2]throughtheBronzeFlat

S'asher

[.1]

andnro Disk

Springs

[5].

IMPORTANT! TheDiskSpringsaredished

which

is

whatgives

themtheir

springBesuretheDisk

Springsareanangedsuchthattheyaretouchingbacktobackattheircenterholes.Next.

pass

the

studthroughthe

3/8"boreatthe

rear

oftheBallBearingCaniageAssembly

[ ]. PlacetheLockClampAngle

[3] overthesrud

and

thread

theLocknut

on

the

endof thestud.TheLockClampAnglemustengagethetopflangeoi the

CarriageTrack

[Main AssemblyFigure4, Key No. 6]. TheCarriageLock Assemblyisunlockedwhen

the*nob is verticaland

lockedwhentheknob ishorizontol.AdjusttheLocknut[6] to giveadequateDrskSprineforceto lockthecarriage.

IMPORTANT! Donot

overtightentheLocknutas

excessive

lockingforce

rr

rllcausethe

b,allL'earingsto tarl

prematurely.

WiththeCaniageLockAssemblyinthe

unlocked

position.

the\-\ Carriase

.:.r:ld mor.etieelr

whenthePositioner

CrankHandleisturned.CAUTION! Donotturn

lhePc)srliofrcr

Cra:r'ii.:.:.iie

uith theCaniase

LockAssemblyinthelock

position

asthismaydamagethe

Positroner.{ssemb,r

l0

e 1996.Positive

Position.Inc.

OWNER'S

MANUAL

t/

MA

i \,1

ASSTIVBLY

t IGt,]RT I

ASSIiVEL

I i\G -tFrl

EASI & L[G SI-t

PART

DESCRIPTI

BASE ASSEMBLY

(STANDARD)

CAPSCREU.Htx HEAD. 1/4-20 \ 3/1

VASHER,

FLAT I/{

INTERNALTOOTH,

TYPE

B, I/4

NUT, HEX JAH, I/4-20

T ASSEHBLY

(OPTIONAL

ACfSSORY)

'ODI, I 5 DIAH RUBBIR,

l/?-13 x ? STUD

NUT, HEX, I,/2_I3

SIIFFENER, LON6

STIFFTNER,

SHDRI

BoLT. RoUNDAEAD, I/4-2o x 5/8

NUT, HfX, I,/4.20

VASHER,

LOCK, INTfRNAL TOOTH,

TYPt B, I/4

CAPSCREv,

HEX HEAD. 3/8-16 x 3/a

IASHER,

FLAI,3/A

R, LUCK, INTERNALTOOTH,

T"ti.iA

NUT, HfX JAX, 3/8 l6

53al033

c-

4{!

l't / \ t4

O

I996.Positive

Position. 512-l

l-96

OWNER'S

MANUAL

L-l,-l

(/)

{

an

T

l--

;*, J

rrtu {

(/) I

7)

<- r z

:',/

.a-,{

* a,-

Z

t2

ll

ll

l"i

tl

-l

\1

2

:l

;

tl

-1

v,l

a)

I

I

i

l

r-i

lel

zi

iIl

]F

l:i

+

hl

si

ll

u

\

512-l

l-96

@1996,

Positive

Position,

Inc.

iri ru.Tpaci-

orsc*,

"i*J

ASSEMBLY,

POSITIONTR

SUPPORT

ASSTMELY,

CARRIA[t POSII

IONTR

KEvr.fpaBr orscprprtol

T7 VASBIR,YAVE,

STIfL asa:0":isrnx

os"

9

r^l

o\

(D

I

NU] ACMI, FIXfD tND

NUT, ACMI, FREE IND

1

s.,o'o',,

1

i 5;1685060

53A1055

52682068 l

5268e068 2

5a6B30rl

-e

53Al068

2l I

oO:\t SCA.t I\0 1

CA 0a 52683030

a0

'o

'# ?3

-'-''

Y?4

*____-,-

(?

t-^

{

z

lTl

ctt

3

z

(-

-

l5

N)

I

\o

o\ \4A

i N ASSf IVELY

i lrJrrRi 3

NUT, ACMI, COLLAR

NUI, ACME,

SPRIN6

GUIDE

ROD,

]7 75 LON6

SETSCRty,HEX

SOCKtT.

Bl0-3a x 1/8. CUP

Pl

0-RING. 5/16 lD x 7/16 0D-

SCALE, ROUND

ASSIMBLY, CRANKHANDLE

POS]TlONER

INDICA

iHUfBSCRE!,

*10 24 x 3/8, BRASS.KNTRLED

,ASHIR, FLAT, {1

O, S S

SETSCREH,HtX SoCKET,

i/4 2D x 3/8. CUP

Pl

@.,

\44 ^SSi \/

il fl\[ -!L PISI f ll_1

i\tR

F

l

z

rl

:

-

al _l

t.. :.-

(-z \-

!--L z'

l*r

Ll './:

7,

L{

i

aY)

LLI

(/)

(a

.'

T

-

''t '21

[ \,\

t4

,€

\o

OWNER'S

MANU

a

3

I

t-.)

u

@1996,

Positive

Position,

Inc.

OWNER'S

MANUAL

lli

lllli

)

t't'

II

T

\1 -/7

/n

(,/\

-''i.".

r- j /^j

^l

{

O1996,Positive

Position,

Inc. l5 512-tt-96

\

,-\

6*"':-'

\"

OWNER'SMANUAL

ir,-l

r-

!J

4

\

-

a

\*-,

-l

m\/

;r-r { Q

(l s]-1.

t"a --l

.r't t\l

^,/ \

.l I

z )'-,

,", ,I- l.,l

<T ' . l-z^,

}.-(-

\'

qr/

O1996,

PositivePosition,Inc

r.RACt

4 -K!JH0LL

SL0ls -- -\

vaR<

^ ' u-]

l,),,,nt

, \ --[Sr u - '*

(D

9,

-+

t, v,--

1

z

rrj

a

3

,JZ c

r

!--- .-\\ \

-P=--*

'.',7

'-"#,

-J

--:

-

.-----

.._

rr\..'lN1B

.- a

.

s

t-)

I'\

i .-r.

r';

&/. -,i

,\@;

/'

I

OWNER'SMANUAL

=

4-

\

,: ,' :--

.\,\

tl--

-.

/

tl -2

*_\

) -1

I 'l (,/\

i- i (./^

,4

L1 \

l

l

i

5ll-ll-96

O1996.

Positive

Position.Inc.

:as:i.,-

:c\ PART NUMBER

la- av- I52682001

Is26820

7

3

23!!3!11

5a6Ba0

7

I

\ :-iv3tN6 ifVER I5268e07e

/?-r3 ? t/ I53Al 081

:atr. -lx SOC([T HEAD. 3/8-16 x | 1/4 253Al

040

\., SFEIN6 IYPf, 3/A 53Al

071

52682064

\ :!AYP I

N6 LfVtR I52684065

t -rai. 3/B-16 x i \/4 53A1010

5?68?05t

(ET HD fl 0-24 |

/2 53Al I07

\: J 4' : -ACKI

N6 SCRfY I526

8204a

\: : s< 5?582043

Pf1!LLIPS l/1 20 \ 3/A 53A1

060

\:: iANDLf, 3,/8.16, Bi IND HBLT 53A2049

52582105

OWNER'S

MANUAL

jxfv t"o

.at-

r.-- - --.-

t'r-"--

T^ :-

T;--- . _

tr

4 '-t'"'

l-;-... .

'6 :4:5:

|.;-'.

-_:

l-e- ..,-

i, -:.ra

l0 S-r,r?

l12

tl a:"-a

l.'-.-

14 v_,\-

irs '_-i:.:i

1

6 S:.a.

Ill ;*

rt-

ro (-

t-

11

\

I6 IVAII\ ASStNlBt

Y

I IGUR[ 5

ASST[4EL

ING T!]

t

AI'4_t

SUPF!R_t

0

1996.PositivePosition.

Inc. l9 5t2-tt-96

OWNER'SMANUAL

4'.

,^'.- (

\\-

---

.) .)

CI1996.Positive

Position.

Inc 20 512-l

l-96